Turning device for conveyor

A conveyor and moving direction technology, applied in conveyors, transportation and packaging, escalators, etc., can solve problems such as pallet congestion, damage, unsatisfactory track characteristics and mechanism wear, and achieve the effect of simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

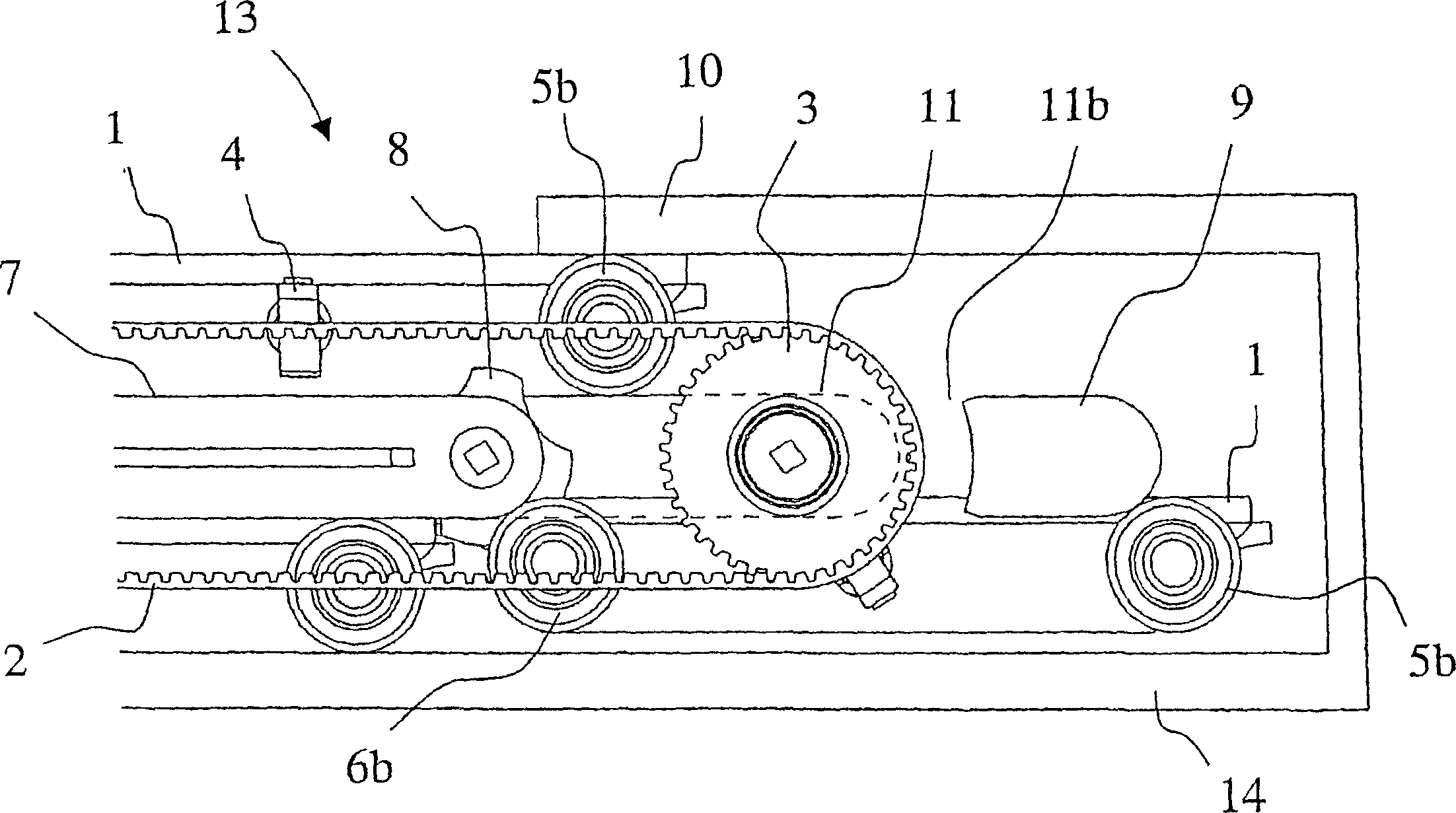

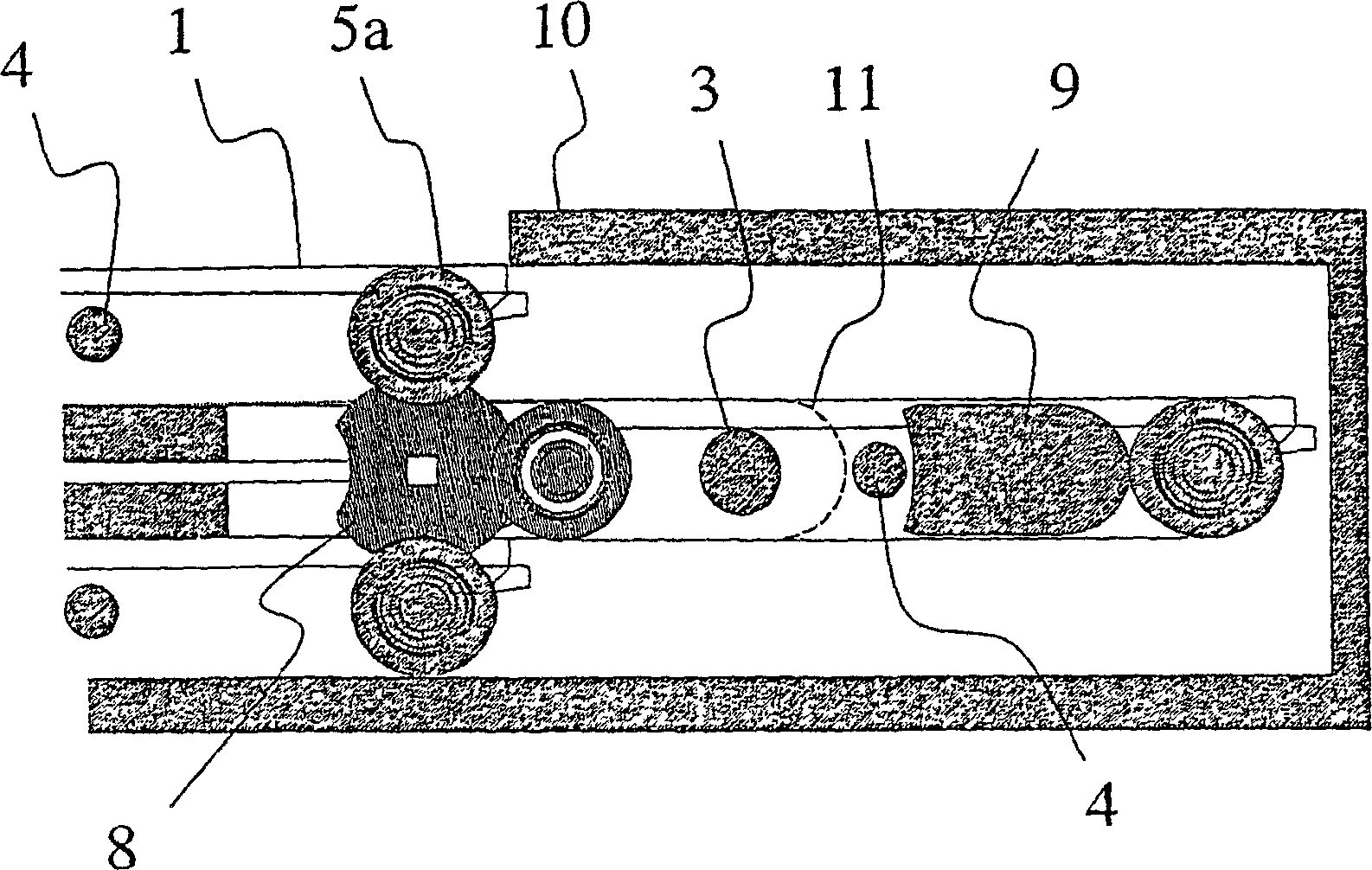

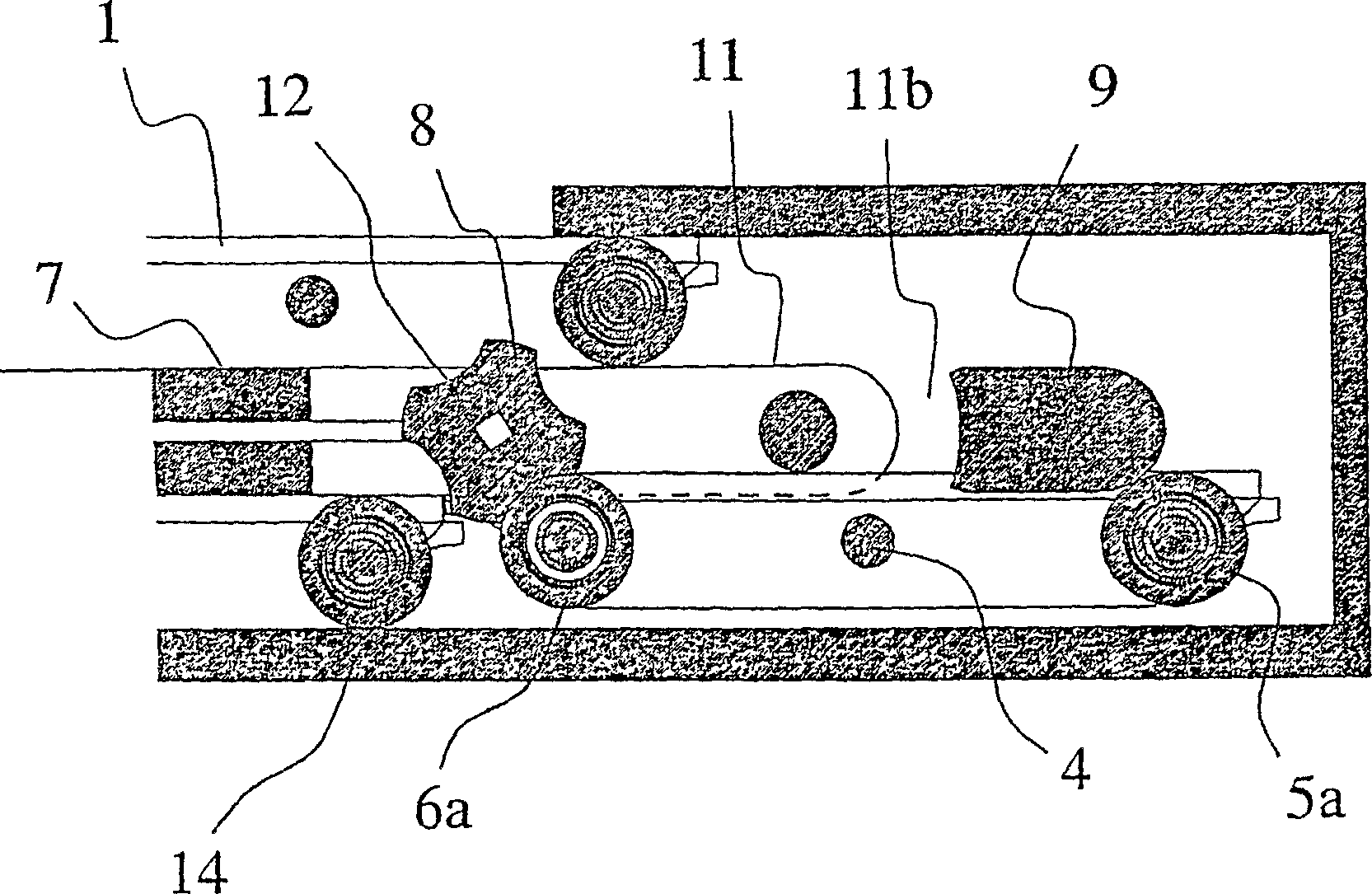

[0015] The conveyor structure 13 of the present invention includes a frame structure 14 whose function is to hold equipment together and transmit forces to the base beneath it. Inside the frame structure is the pallet track on which passengers stand on the upper surface. In addition, the conveyor structure comprises at least one pallet track drive machine and handrails and its drive machine, wherein the pallet track drive machine comprises a drive toothed pulley 3 and a toothed belt 2 .

[0016] The pallet track consists of a separate pallet 1 provided with wheels, the front wheels 5a and 5b are placed at the front corners of the pallet with respect to the normal conveying direction of the conveyor, and the rear wheels 6a and 6b are placed at the corners of the pallet. rear corner. The front wheels 5a are placed at a distance outwards at the front corners with respect to the corresponding rear wheels 6a on the same side of the pallet. Likewise, the rear wheels 6b on the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com