Centralised lubrication of large diesel engines

A diesel engine, centralized lubrication technology, used in engine lubrication, lubrication of engines with crankcase compressed fuel-air mixture, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

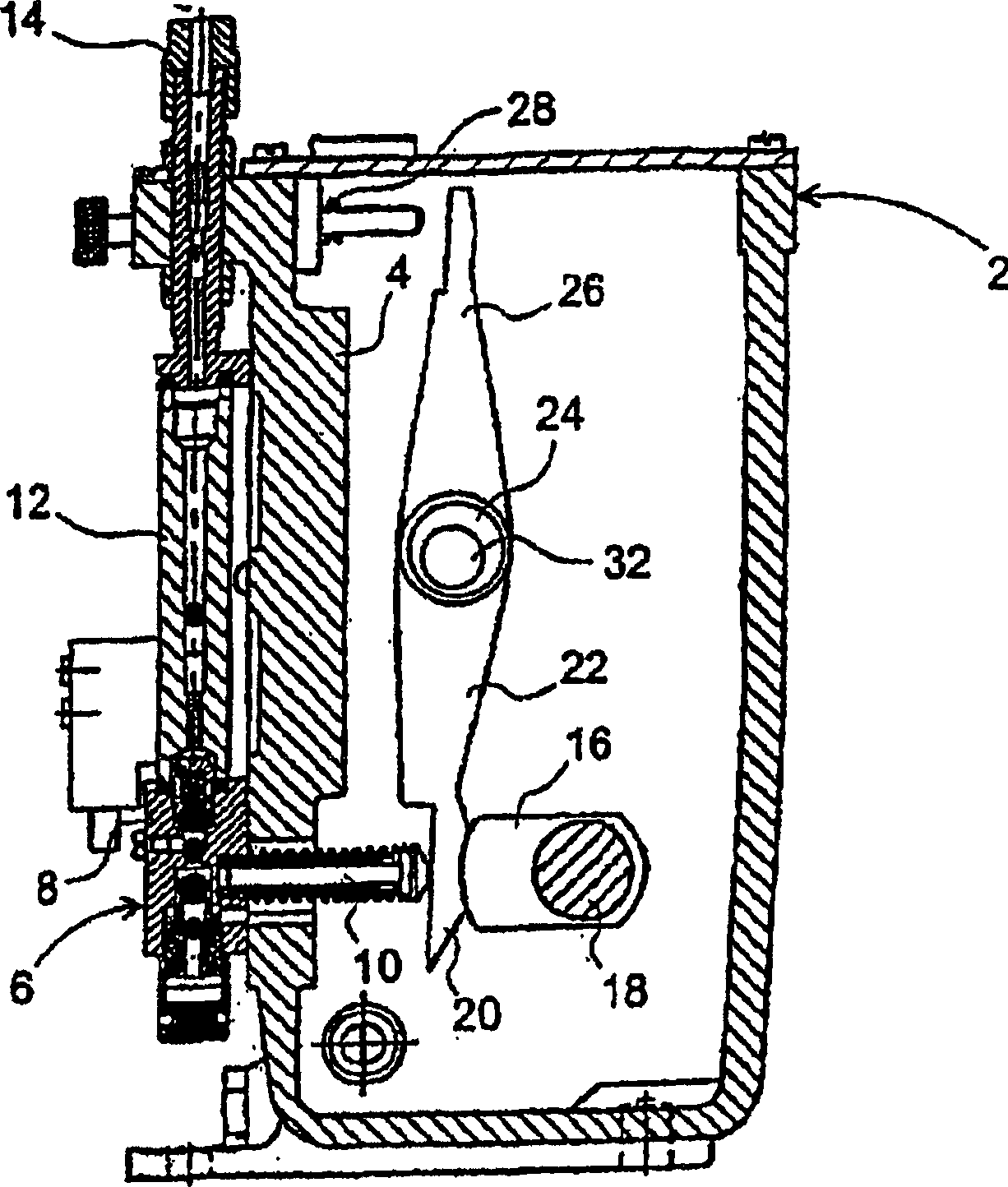

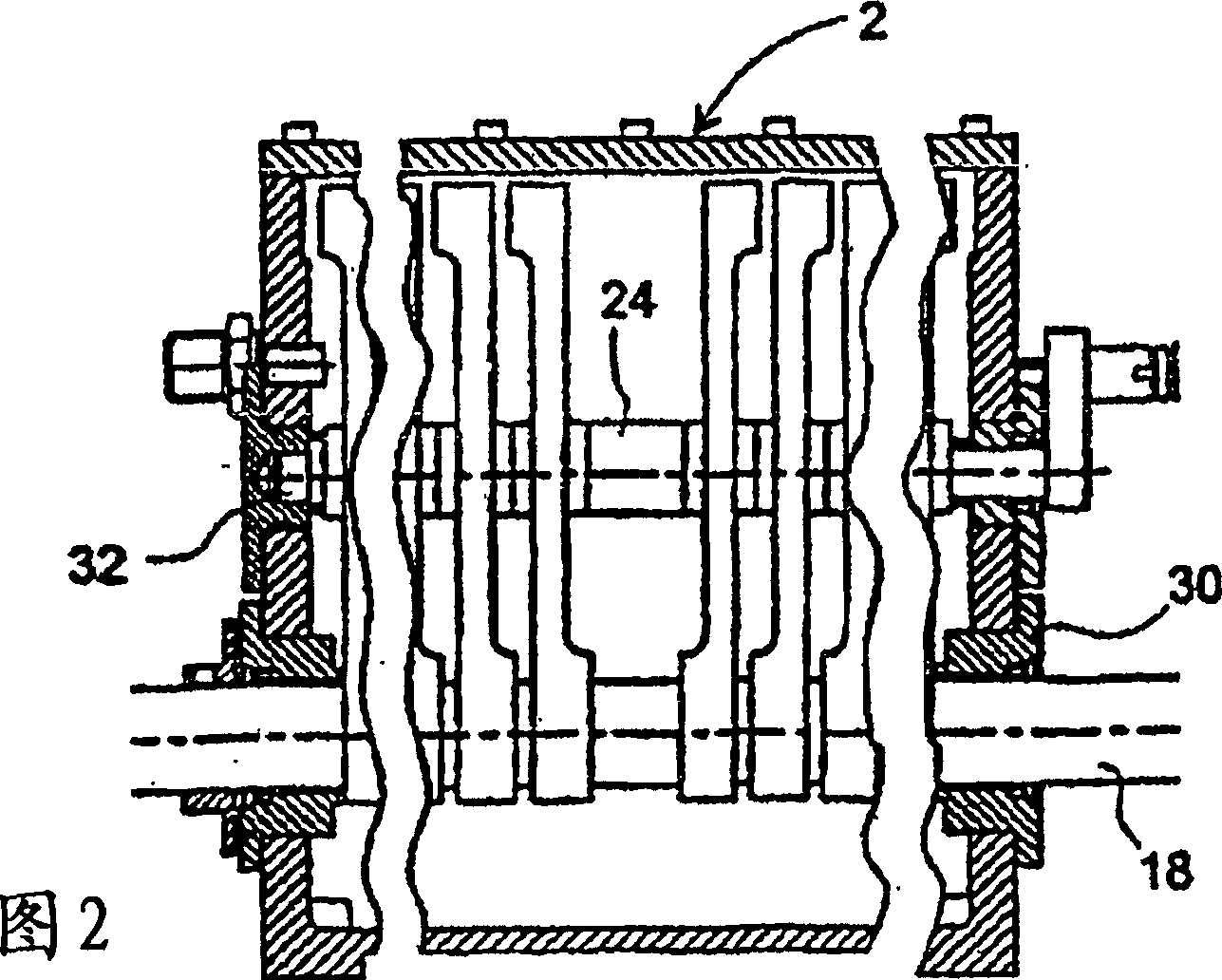

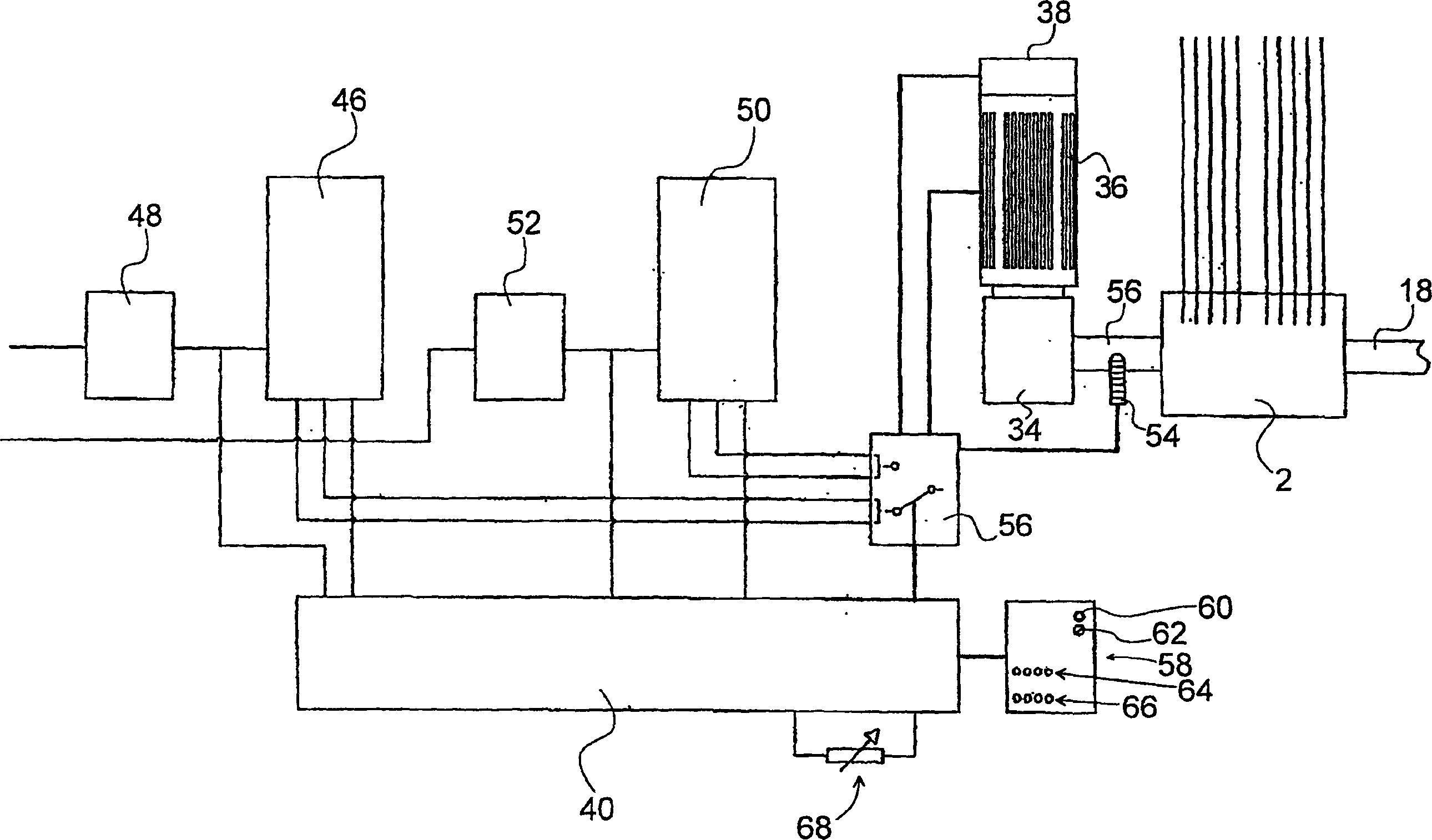

[0051] figure 1 The lubricating device shown in and 2 has a box-shaped equipment housing 2, which supports a row of reciprocating pump units 6 on the front wall 4, figure 1 Only one of them is shown. The unit has a valve housing 8 with a lower lubricating oil inlet, a middle part and an upper reciprocating pump outlet thus formed. The middle part is intended to accommodate a piston 10 which protrudes into the device housing 2 . The outlet is connected via a flow indicator 12 to an upper connector 14, from which connection pipes emanate from the entire row of these connectors to the associated lubrication points on, for example, 6 to 24 cylinders of the engine.

[0052] The piston 10 is driven to press in via a drive cam 16 on a through control shaft 18 . The control shaft 18 rotates synchronously with the crankshaft of the engine and is seated within a bearing housing 30 . The pistons are not driven directly but via thrust pads 20 on the respective rocker arms 22 . The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com