Paper pallet manufacture and forming method

A forming method and paper pallet technology, which is applied in the field of paper pallet manufacturing and forming, can solve problems such as lack of stability of the clip, difficulty in consistent positioning, waste, etc., and achieve the goals of saving glue consumption, avoiding waste, and reducing manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

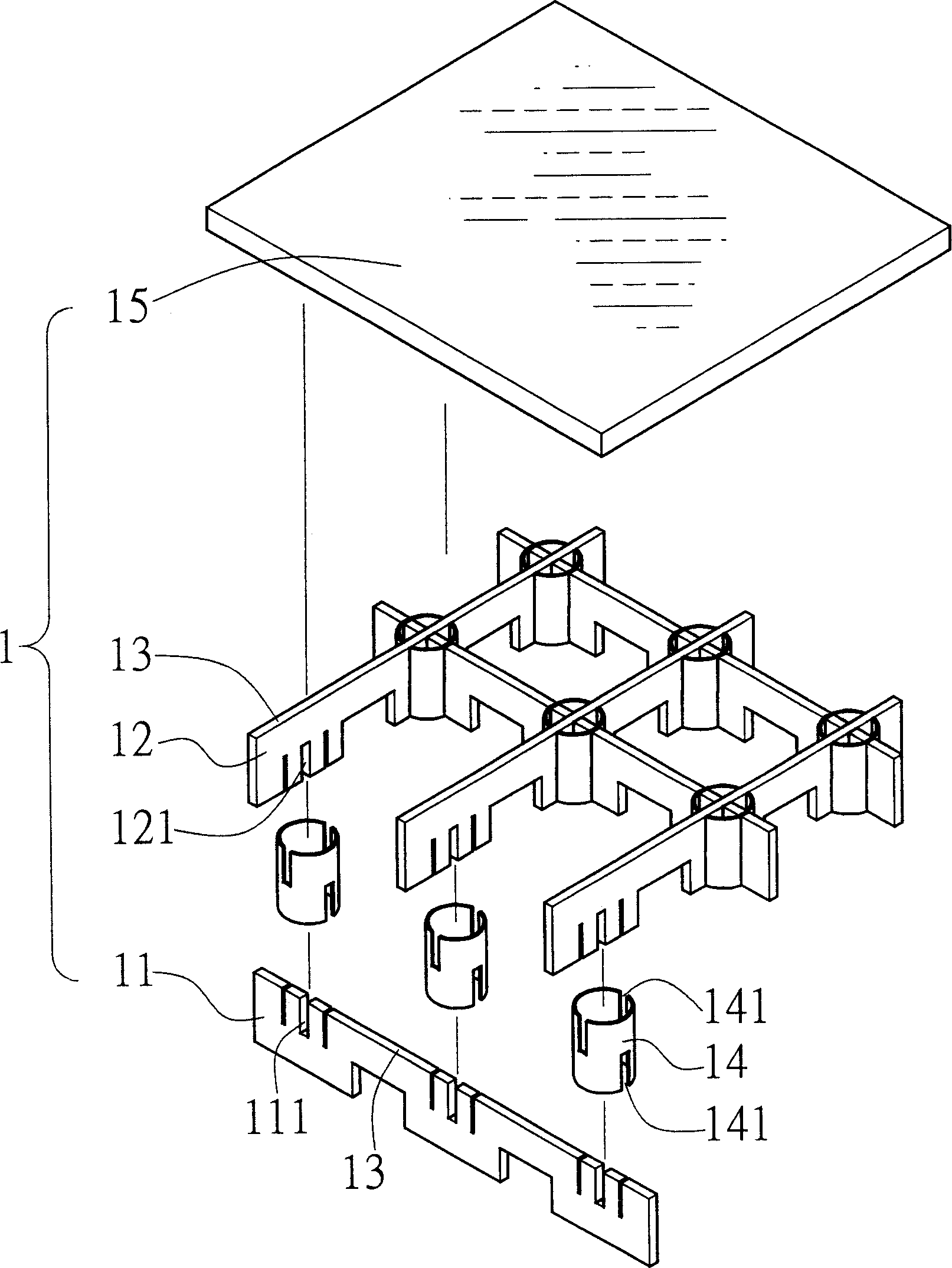

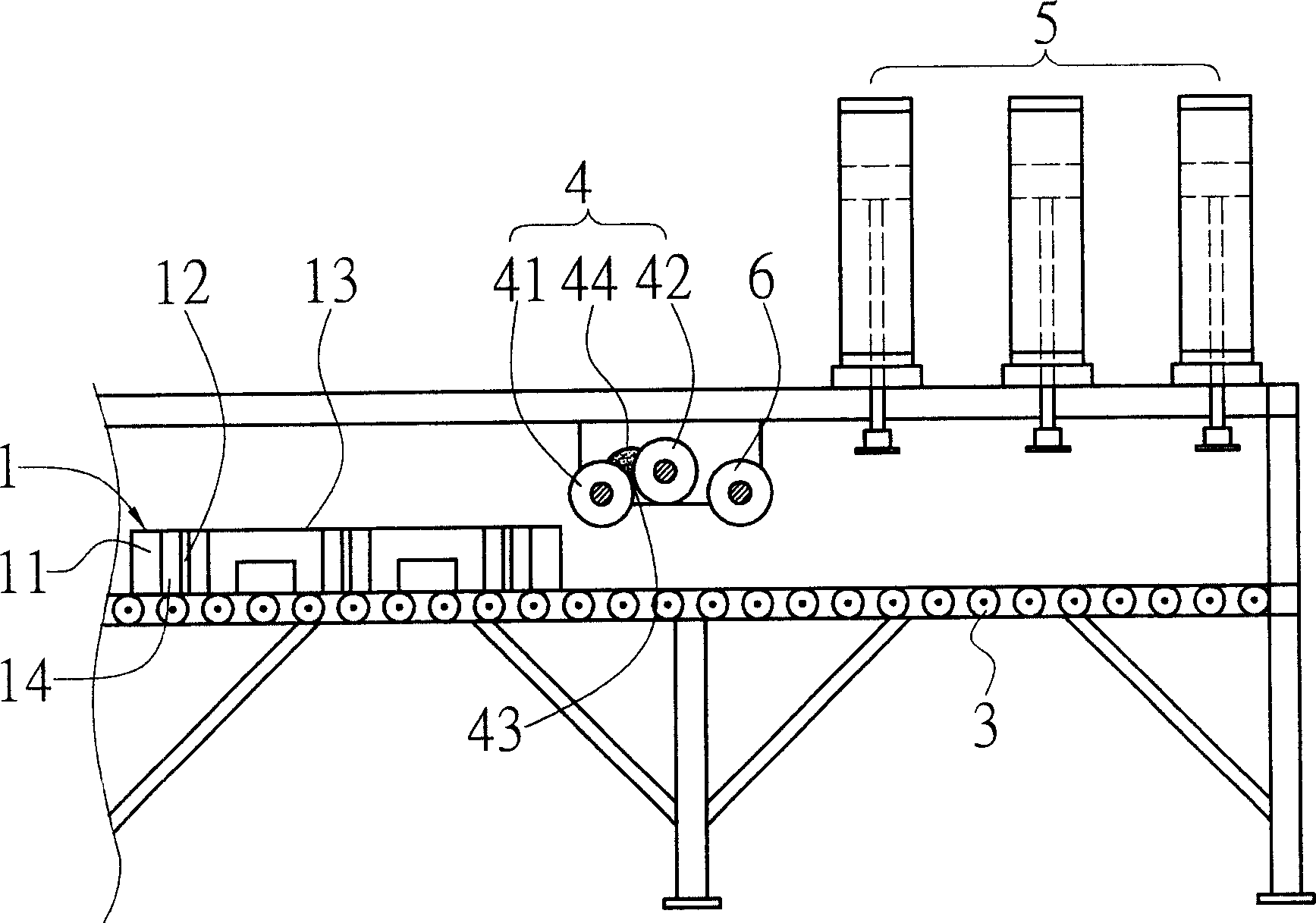

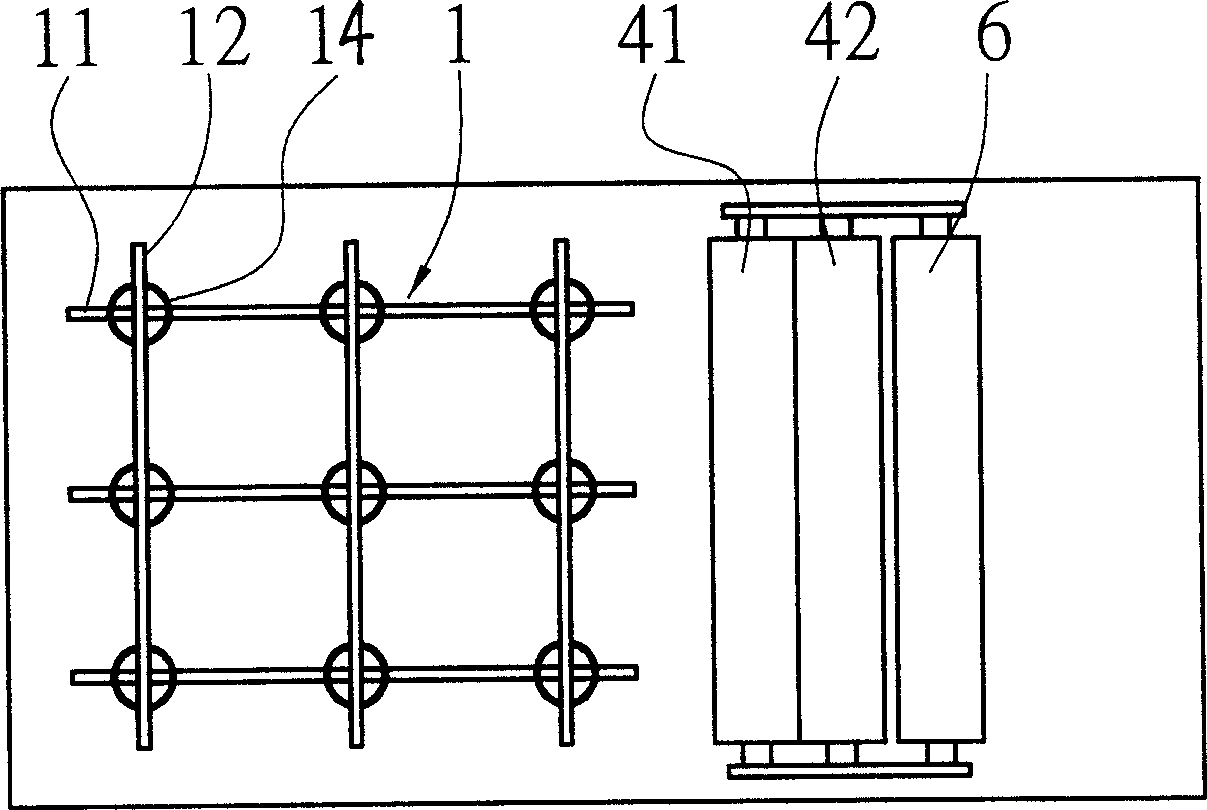

[0035] like Figure 1 to Figure 4 As shown, a method for manufacturing a paper pallet provided by the present invention mainly includes a plurality of horizontal plates 11, a plurality of longitudinal plates 12, a plurality of support surfaces 14 and a load-bearing plate 15, all of which are made of paper. The transverse plate 11 and the longitudinal plate 12 are set opposite to each other, and a first joint notch 111 and a second joint notch 121 are respectively provided on the joint surfaces thereof. The thickness of the longitudinal plate 12 itself is such that the transverse plate 11 and the longitudinal plate 12 can be interlocked with each other to form a vertical combination, and the supporting surface material 14 is designed to be cylindrical, and a third wall is provided on its cylindrical wall. Combined with the notch 141, this notch corresponds to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com