Completely-loaded vehicle body

A full load bearing and body technology, applied in the load bearing body structure, vehicle parts, superstructure, etc., can solve the problems of weak vehicle strength, high center of mass, heavy structure, etc. The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

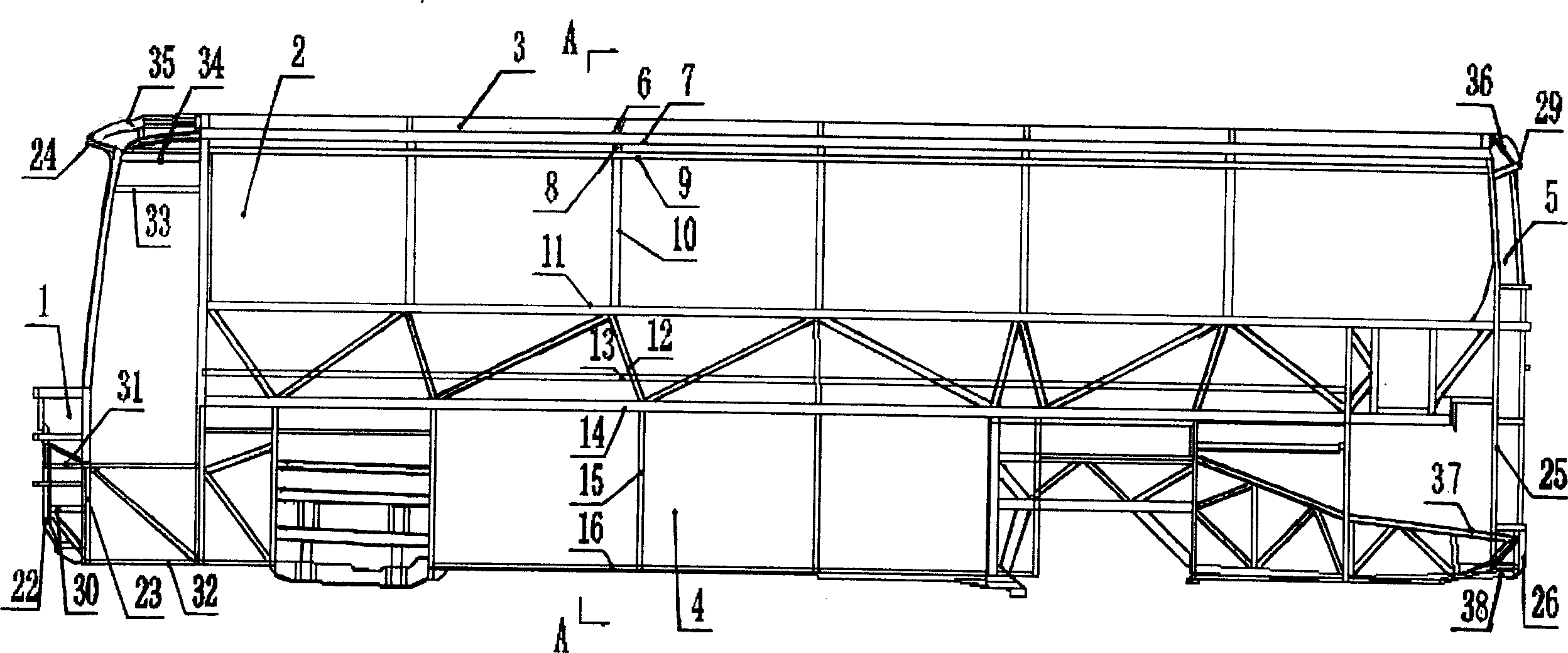

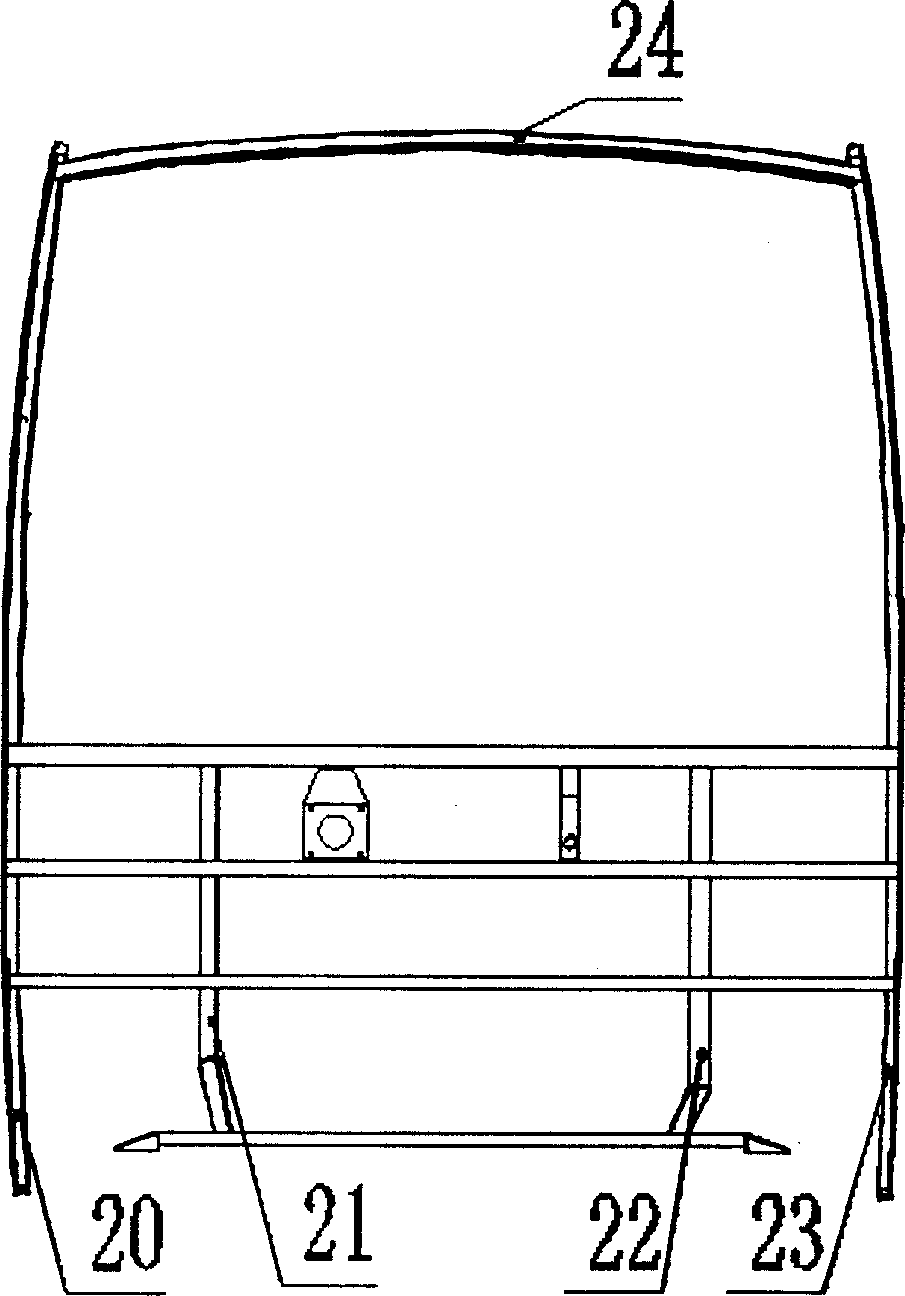

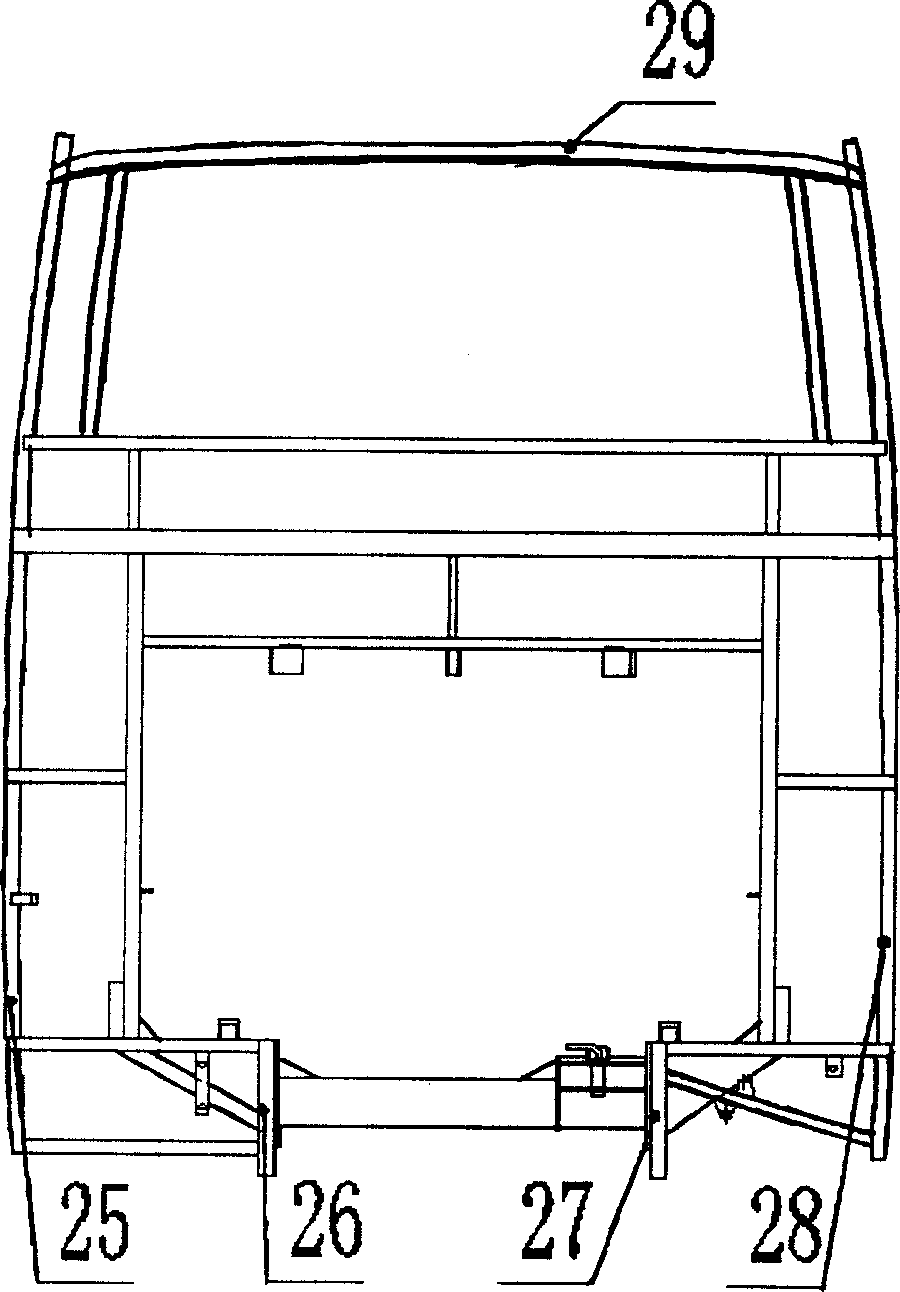

[0042] See attached figure 1 , 2 , 3, 4.

[0043] A fully load-bearing vehicle body, including longitudinal beams, cross beams, columns, and an underframe composed of longitudinal beams, beams, and columns, and also includes a front wall frame 1, a rear wall frame 5, left and right side frame frames 2, and a roof frame 3 .

[0044] Front wall frame 1 includes: front wall left column 20, front wall left two column 21, front wall right two column 22, front wall right column 23 and front wall top beam 24; rear wall frame 5 includes: rear wall left column 25. The left column of the rear wall and tail beam 26, the right column of the rear wall and tail beam 27, the right column of the rear wall 28 and the upper beam of the rear wall 29; Window column 10, side window lower longitudinal beam 11, side wall brace 12, angle iron 13, waist beam 14, warehouse door column 15, warehouse door lower beam 16, side door lower connecting beam 32, side door upper connecting beam 33, The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com