Air feeding and control device for the pneumatic transporting of the weft in air-jet weaving machines

A technology of pneumatic conveying and air-jet looms, which can be used in looms, textiles, papermaking, textiles, etc., and can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

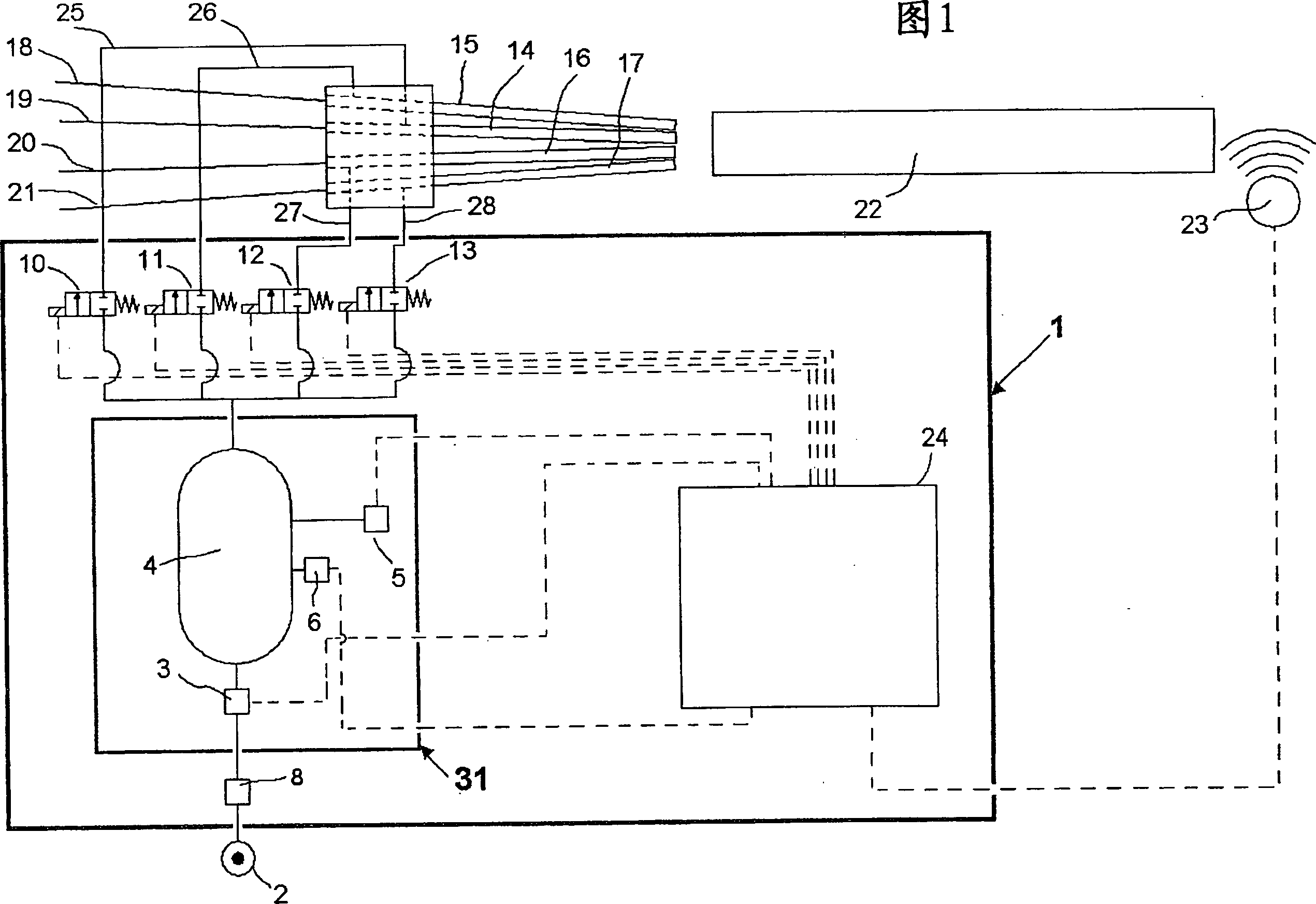

[0015] Referring now in particular to Figure 1, which relates to a particularly illustrative and preferred but non-limiting embodiment of the invention, an air feed system for pneumatically conveying weft yarns is indicated generally at 1, and which system mainly includes a control system 24. Air accumulation and feeding system 31 which requires a source of compressed air 2 stabilized by a pressure regulator 8, and a series of Electrovalves 10, 11, 12, 13 (since the system described as an example enables the insertion of four weft threads, there are four electrovalves in the pneumatic conveying device illustrated in Figure 1).

[0016] The air accumulation and feeding system 31 consists of a flow regulator 3 , a container 4 , an electrovalve 5 and a pressure sensor 6 in sequence.

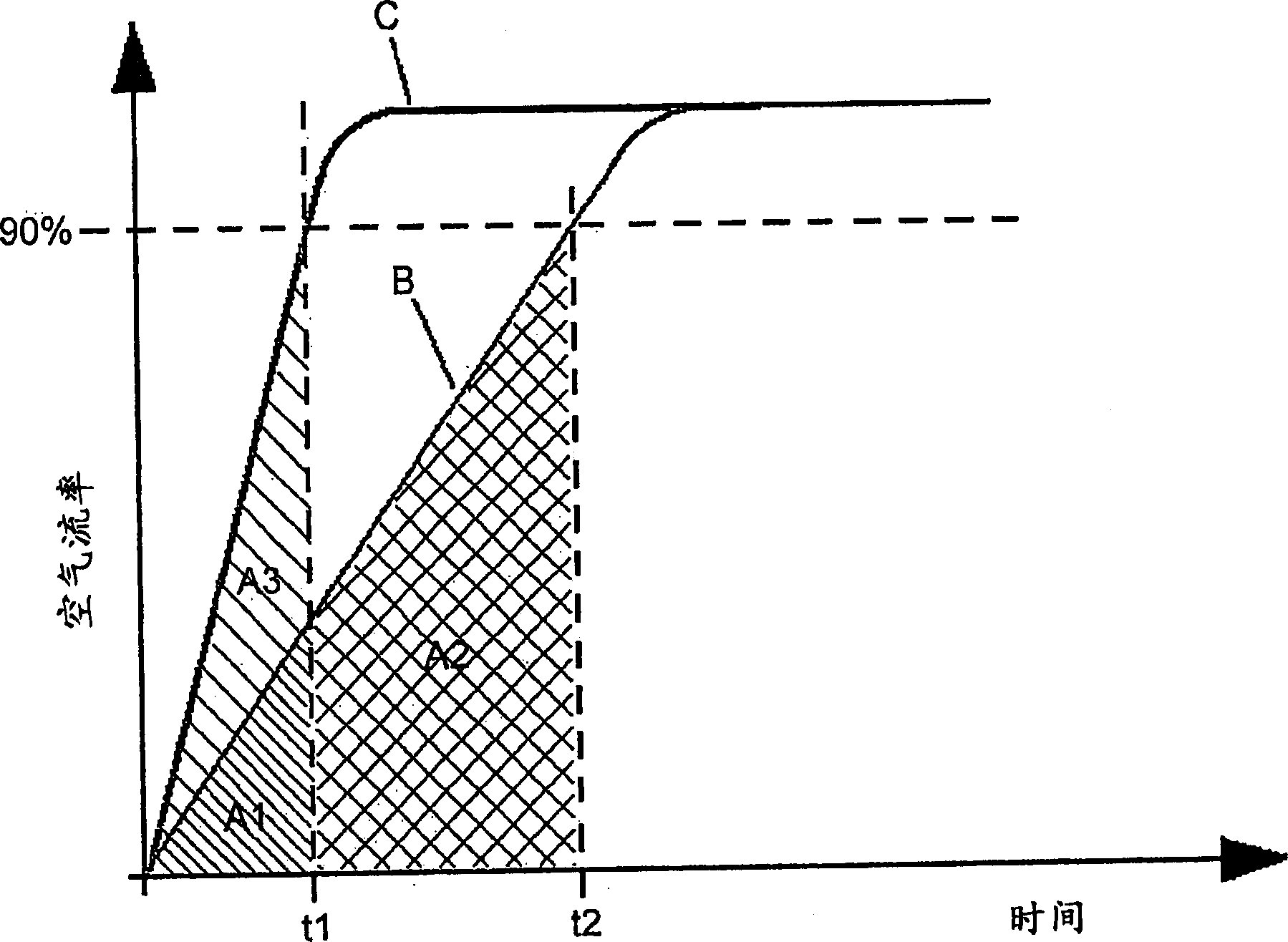

[0017] The operating cycle of the system can be divided into two basic phases: the first phase, during which the electric valves 10, 11, 12, 13 are closed and thus no air flows to the nozzles 14, 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com