Energy-saving non-filling cooling tower

A cooling tower without filler technology, which is applied in the field of cooling tower equipment, energy-saving and filler-free cooling towers, can solve the problems of unstable cooling effect, prolonging the start-up time, increasing production costs, etc., achieving good cooling effect, prolonging the start-up time, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

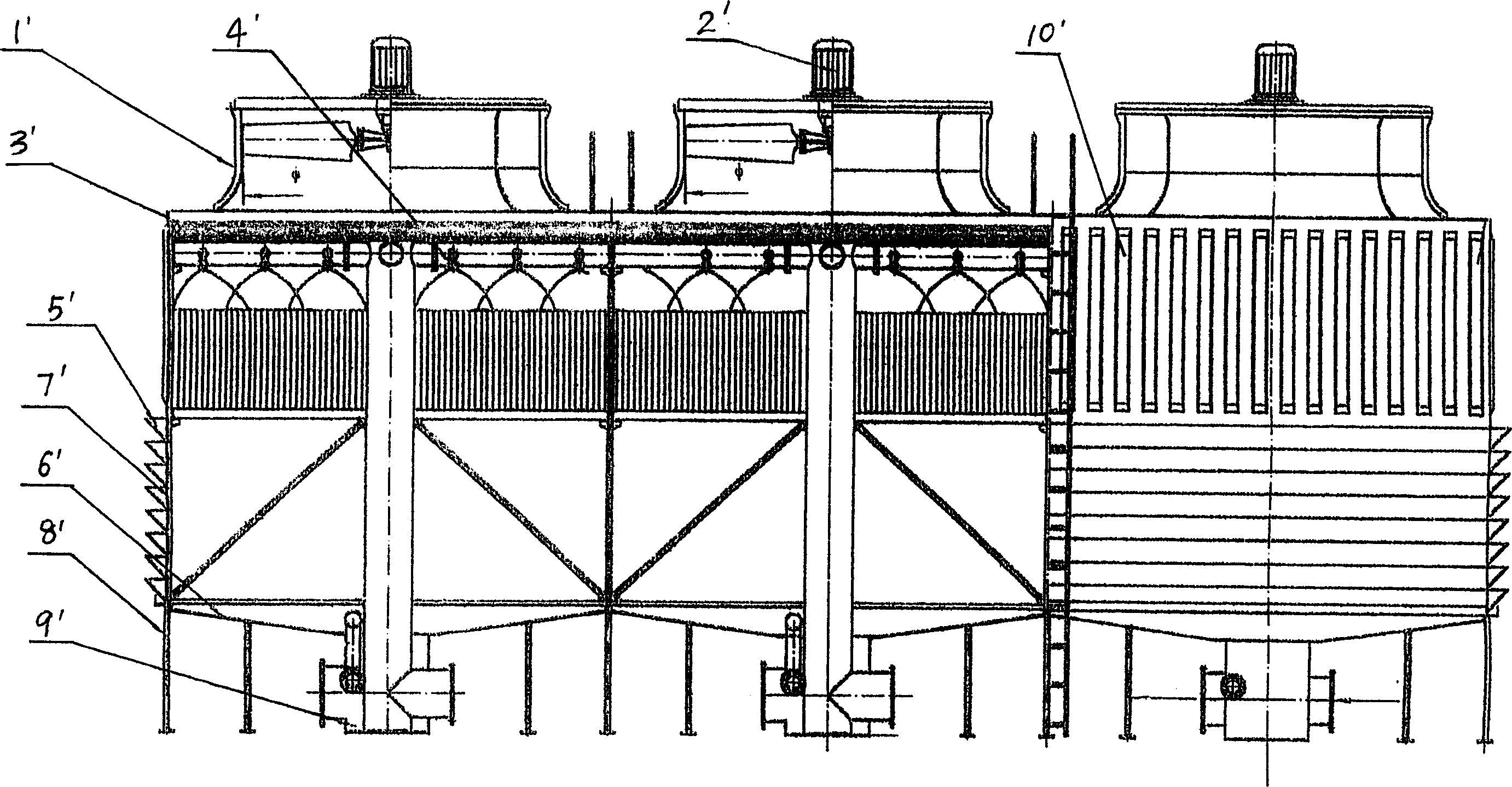

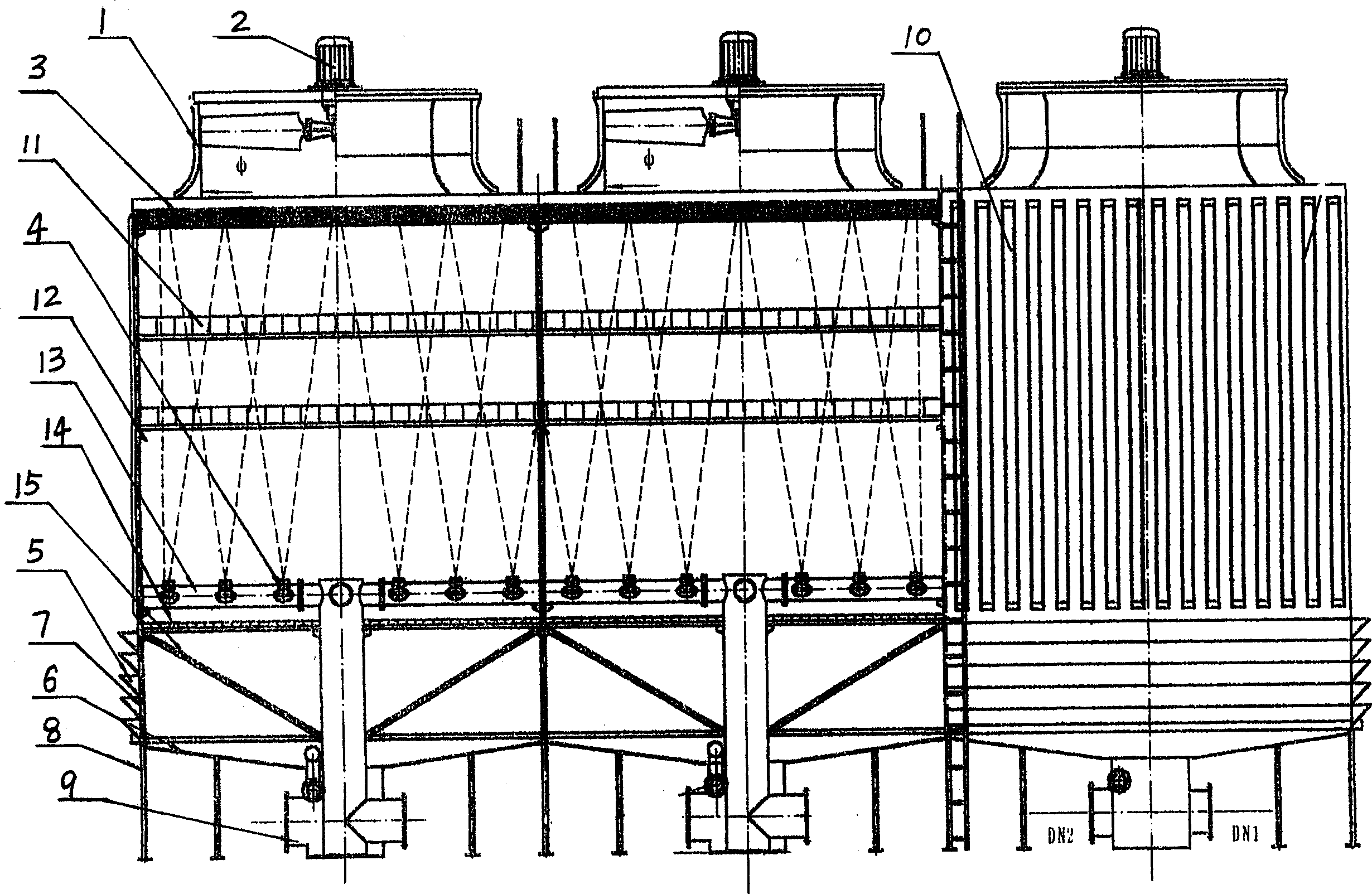

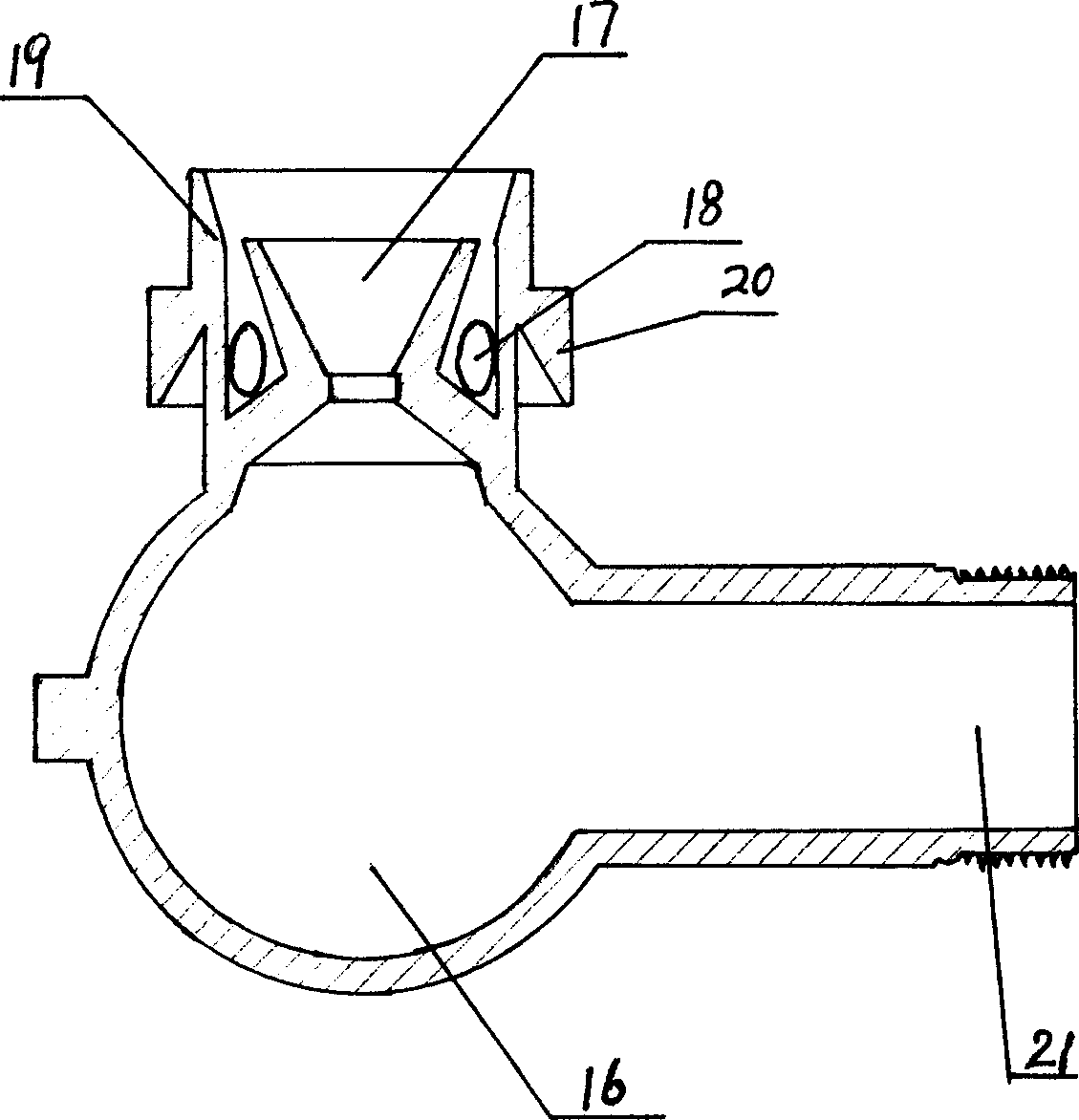

[0025] In the figure: 1-air duct, 2-transmission device, 3-water eliminator, 4-introduced air atomizing nozzle, 5-inlet louver, 6-water collection tray, 7-upper column, 8-lower column, 9 -Inlet and outlet water tank, 10-FRP enclosure, 11 Fog rectification device, 12-Wall flow elimination device, 13-Water distribution system, 14-Water and air distribution device, 15-Tie rod, 16-Eccentric shell, 17-Nozzle, 18 -Air inlet, 19-ring sleeve, 20-waterproof plate, 21-water inlet, 22-spacer, 23-insert piece, 24-tie rod, 25-upper water eliminator, 26-lower water eliminator, 26-thin short wall tube.

[0026] Such as figure 2 As shown, the energy-saving non-filler cooling tower of the present invention has a square or cylindrical tower body. The figure shows a three-tower structure, which can also be a single tower. The tower body is made of steel structure materials, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com