Method for production of sandwich panels with zigzag corrugated core

A zigzag and plywood technology is applied in the field of producing plywood with a twisted and wrinkled core, which can solve the problems of reduced strength of the plywood, affecting the strength of the core-skin connection, unfavorable deformation conditions, etc., and achieves the effect of improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

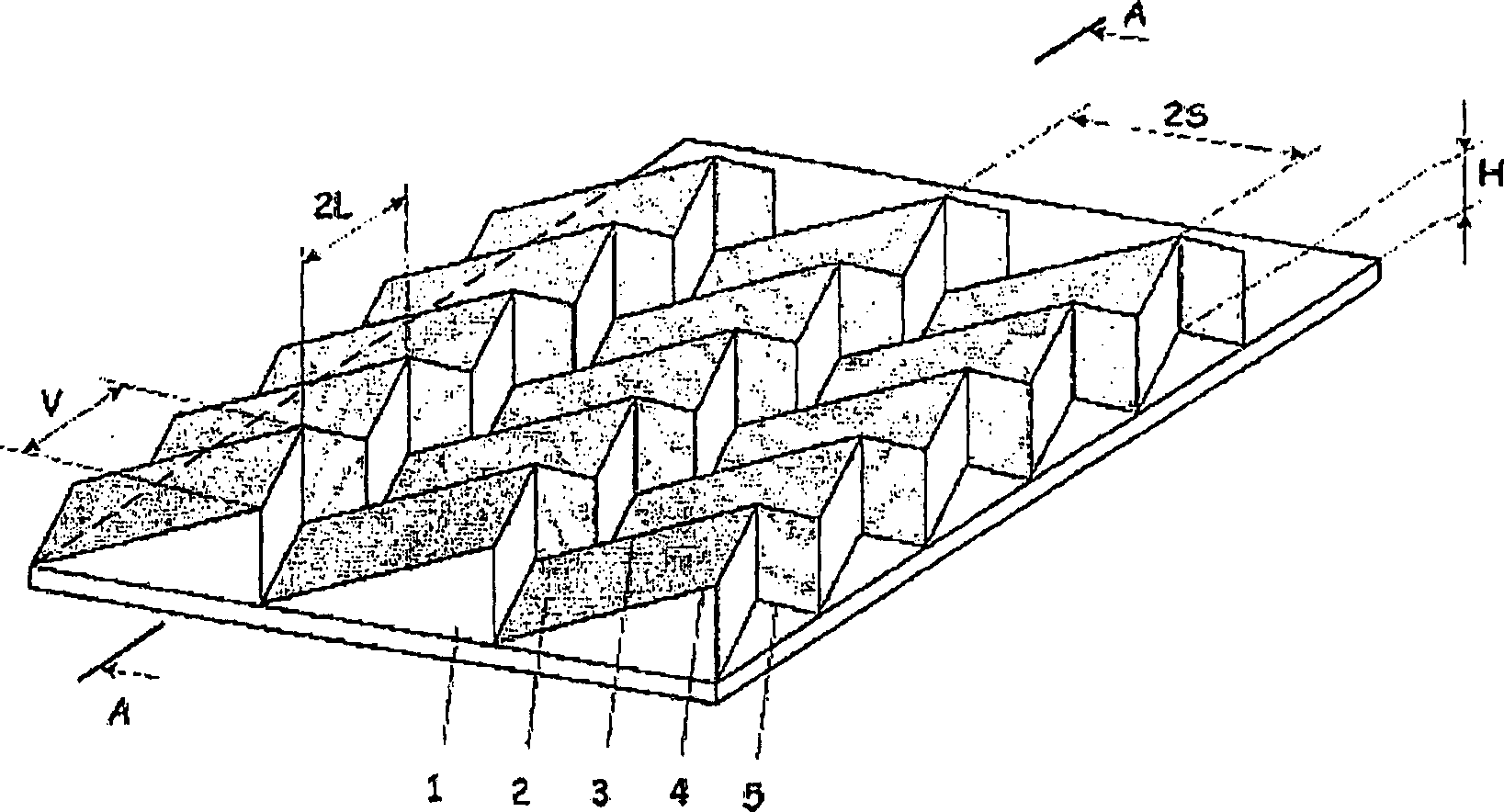

[0016] Our method can be implemented in the following way:

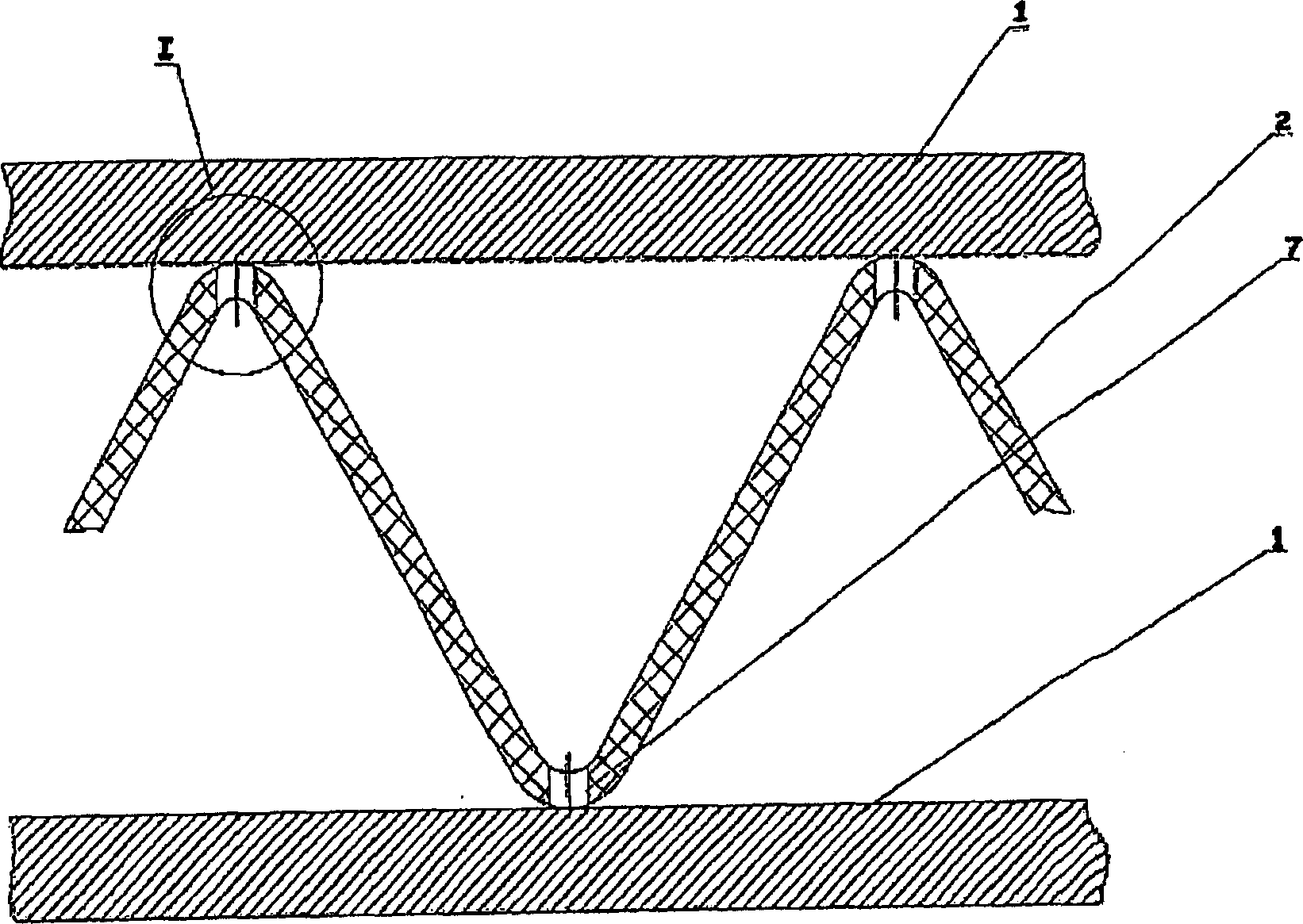

[0017] 1) manufacture the outer skin and inner skin 1 of the splint;

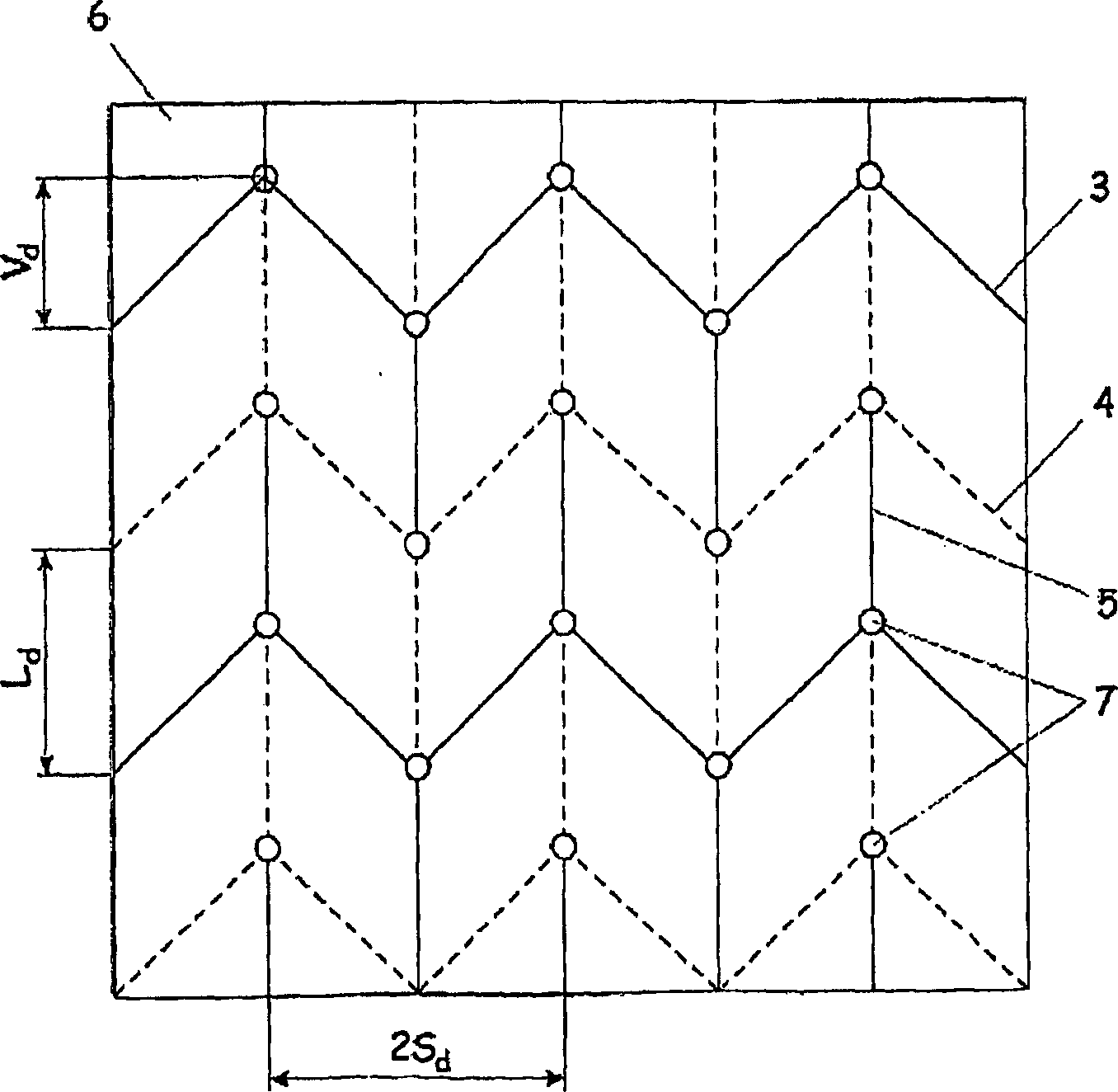

[0018] 2) Draw the bending lines 3, 4, 5 on the chip blank 6 of the core 2; the parameters and relative positions of the bending lines 3, 4, 5 are related to the design parameters of the core 2:

[0019] L d =f(H,L); V d =f(V, L d );S d =f(V,S,H,L),

[0020] where H is the height of the zigzag folds, V is the amplitude of the zigzag lines, 2S is the step between the zigzag lines, 2L is the step between the zigzag lines, with the dimensions unfolded: 2S d is the step distance between the zigzag lines, L d is the distance between the meander lines, V d is the magnitude of the meander line;

[0021] 3) Punch holes 7 in the blank at the intersection of the zigzag line 5 and the meander lines 3, 4; the diameter of these holes 7 is d h ≥R b , where R b is the bend radius of the chip blank at the intersection of the jagged line 5 and the meand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com