Method for making water-repellent fabric with photocatalyst function

A photocatalyst and functional technology, applied in the direction of textiles and papermaking, can solve the problems of increasing the production and application fields of water-repellent fabrics, processing difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

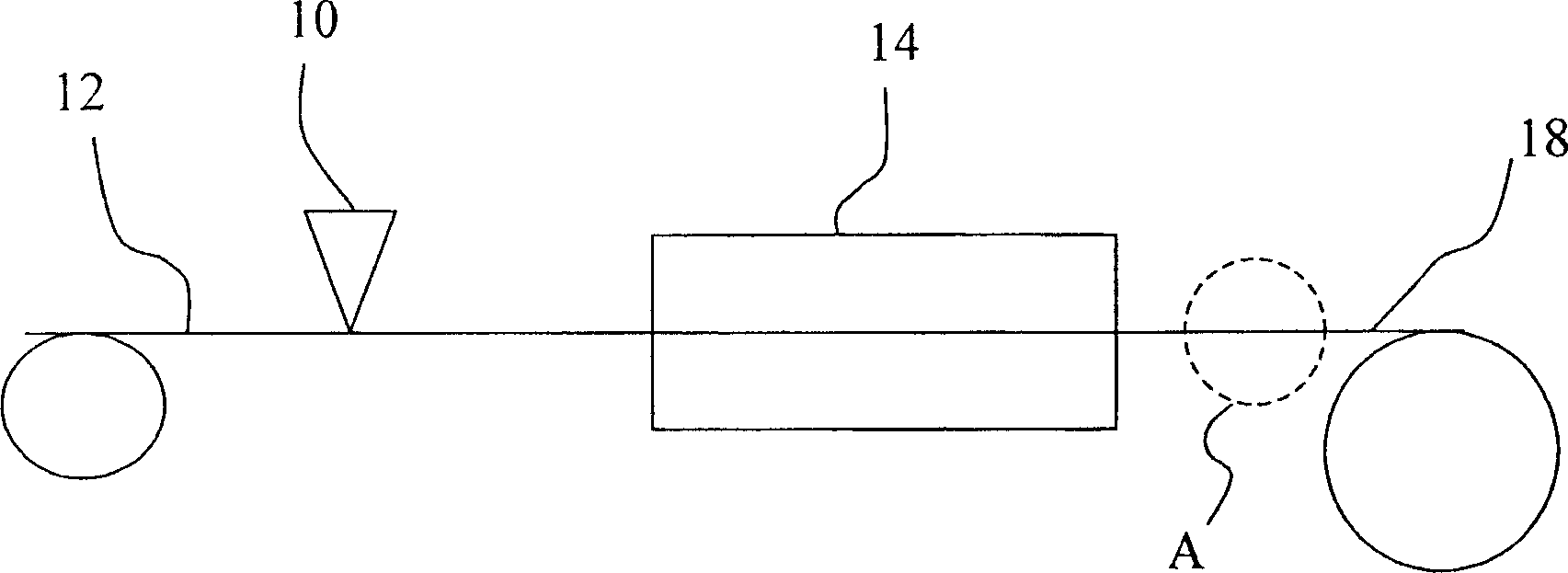

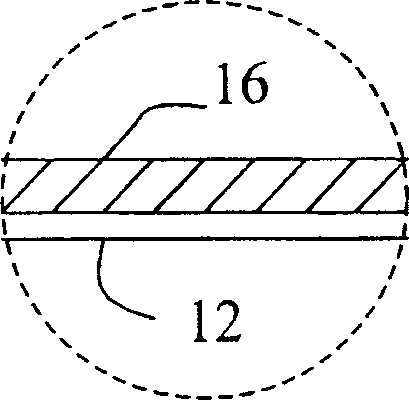

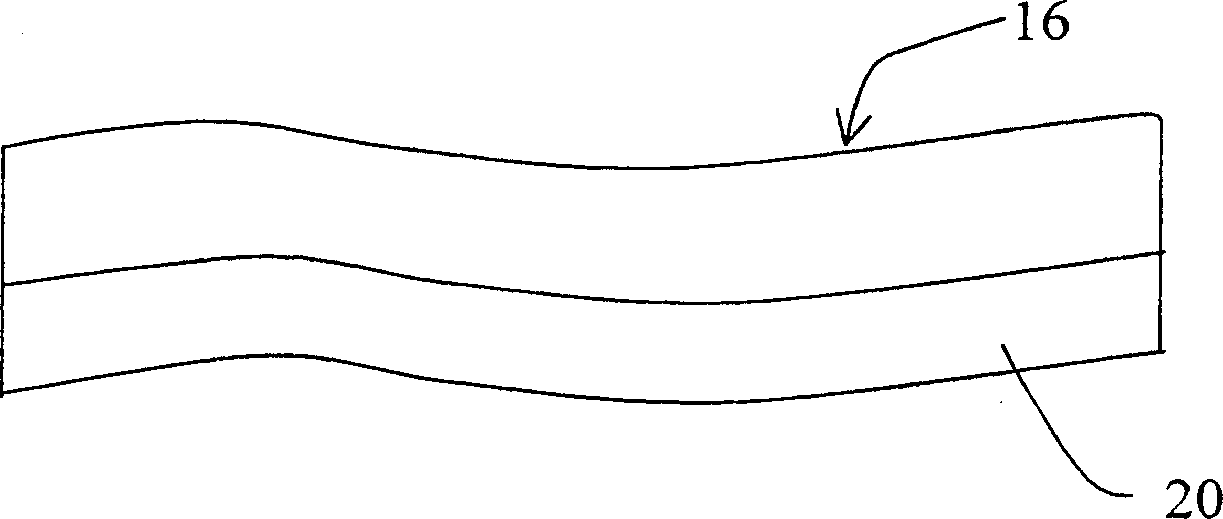

[0039] The invention relates to a method for preparing a water-repellent processed fabric with photocatalyst function.

[0040] First, raw materials such as hydrophobic resin, bridging agent, crosslinking agent and titanium dioxide photocatalyst are placed in a pressurized mixing device, and stirred to make the mixture evenly dispersed, and the temperature during the mixing process cannot exceed the bridging agent and The decomposition temperature and reaction temperature of the adhesive, wherein the preferred particle size range of the best titanium dioxide photocatalyst is 12-15 nanometers (nm), the temperature of the mixing process is controlled at 40-80 ° C, and the time of the mixing process is controlled within 30-60 minutes.

[0041] The hydrophobic resin here is generally Silicone series, Acrylic series (Acrylic), Teflon (Teflon), polyurethane (Polyurethane) or inorganic emulsified aqueous solution (TiO 2 )series.

[0042] Then, the mixture is coated, and the mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com