Fiber fabric and preparation method thereof

A fabric and fiber technology, applied in the field of fiber fabric and its preparation, can solve problems such as product failure, affecting fiber strength and tensile breaking strength, and insufficient doping amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Prepare polyurethane fiber containing particle powder:

[0026] Weigh raw materials: 50 parts of polyurethane, 20 parts of hydroxymethyl cellulose, 20 parts of polydimethylsiloxane, 3 parts of polyvinyl alcohol, 4 parts of sodium tartrate dihydrate, 0.5 parts of polyvinylpyrrolidone, 3 parts of nano silicon dioxide 30 parts, 30 parts of ferric oxide particle powder, 10 parts of sodium lignosulfonate;

[0027] Add polyurethane, hydroxymethylcellulose, polydimethylsiloxane, polyvinyl alcohol, sodium tartrate dihydrate, polyvinylpyrrolidone, and nano-silica into a high-pressure homogenizer, mix well and then add ferric oxide The particle powder and sodium lignosulfonate are mixed evenly, melted at high temperature, spun and drawn to obtain polyurethane fiber for textile. The melting temperature is 340°C and the spinning speed is 1800m / min;

[0028] Composite fiber preparation: wool fiber is selected as natural fiber, and the mass ratio of polyurethane fiber and wool f...

Embodiment 2-6

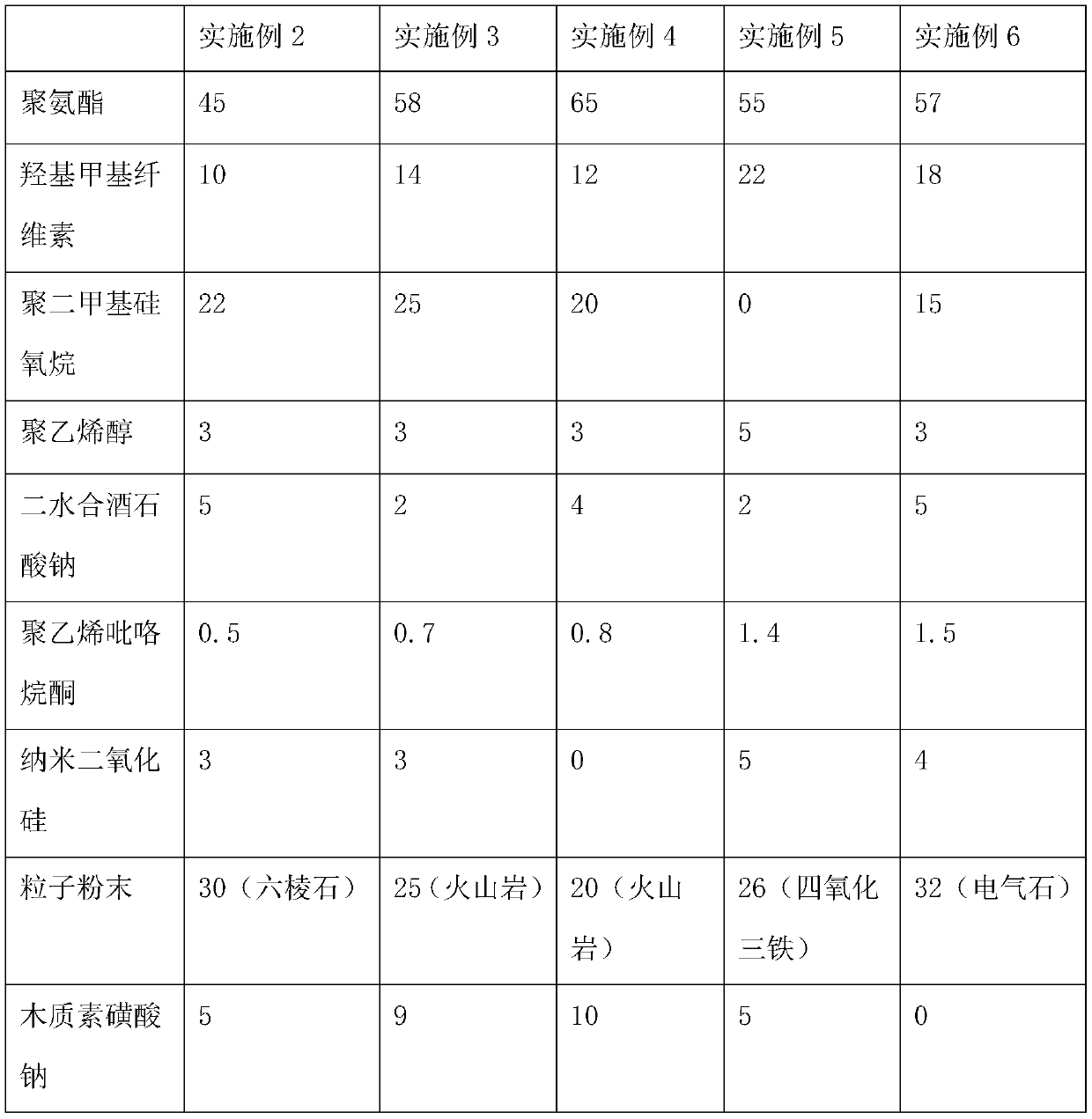

[0032] Method step is with embodiment 1, and each raw material materials are shown in Table 1:

[0033] Table 1

[0034]

[0035]

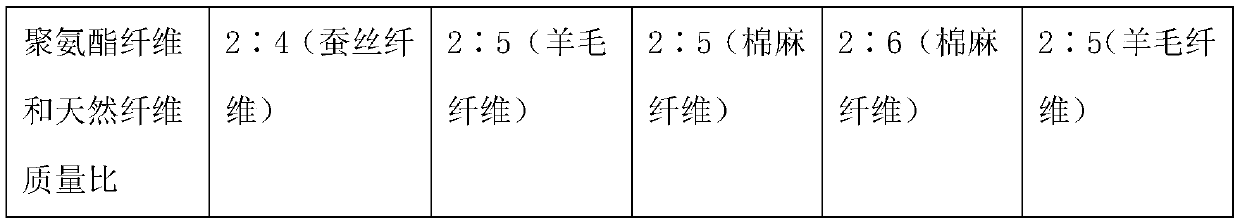

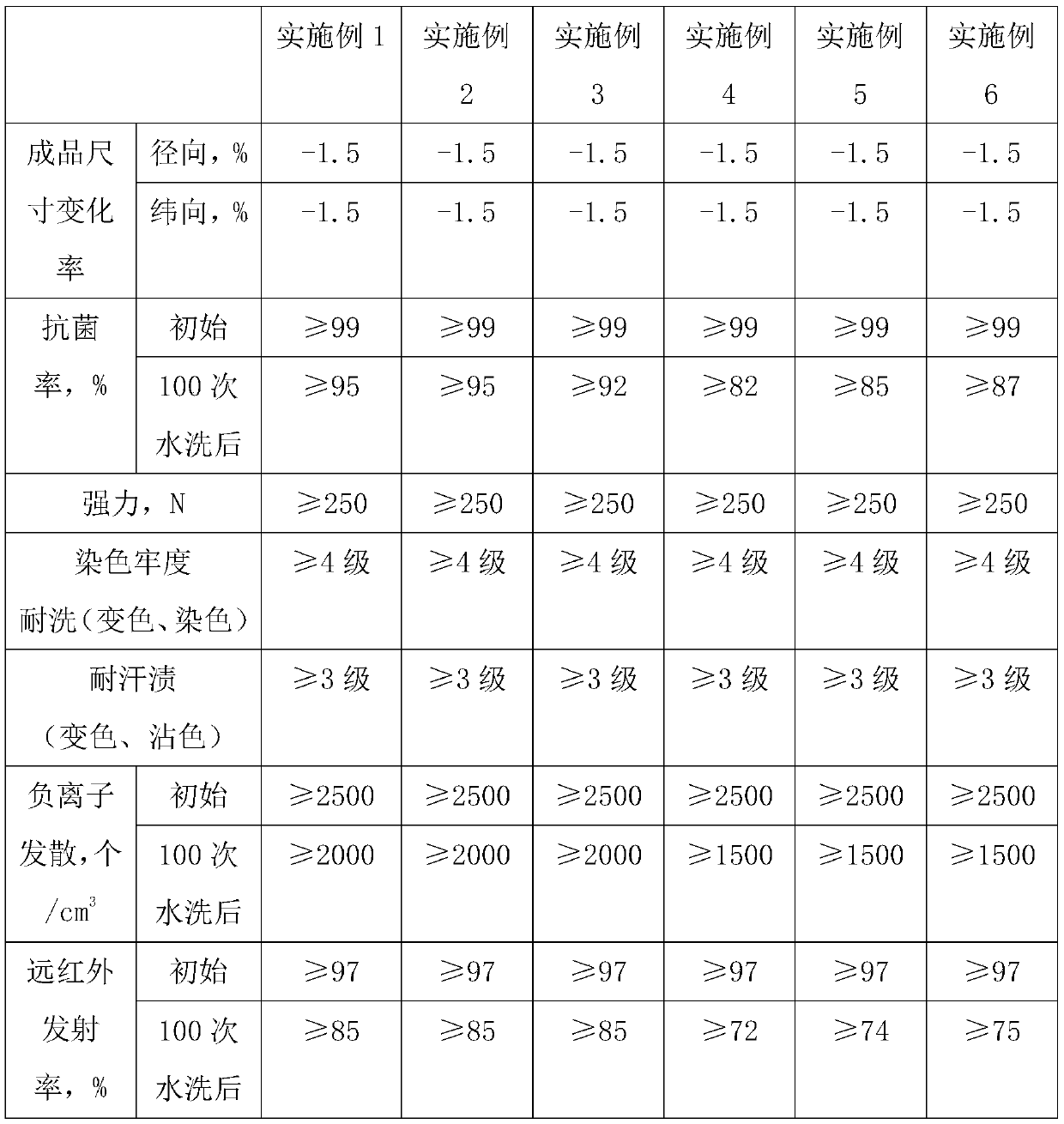

[0036] Utilize AATCC standard method to test, the main performance index of the fabric of embodiment 1-6, the result is shown in Table 2.

[0037] Table 2

[0038]

[0039] At the same time, it is found that the fabrics prepared in Examples 1-6 also have a natural temperature regulation function, and the temperature can be adjusted by itself, about 2-3.5°C. At the same time, the fabric itself can remove more than 99% of formaldehyde, ammonia and other deodorizing functions within 1 hour. However, after 100 times of washing, the fabric function prepared in Example 1-3 has no obvious change, while the fabric function prepared in Example 4-6 has a downward trend.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com