Visual inspection lighting device based on reflective light and transmission light

A visual inspection and lighting device technology, applied in the direction of measuring devices, optics, nonlinear optics, etc., can solve the problems that cannot be obtained, cannot be irradiated with converging light, and cannot distinguish the vertical position of defects, so as to achieve high degree of freedom and reduce defects Missing rate, effect of enhancing defect visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Modes for carrying out the invention will be described below with reference to the drawings.

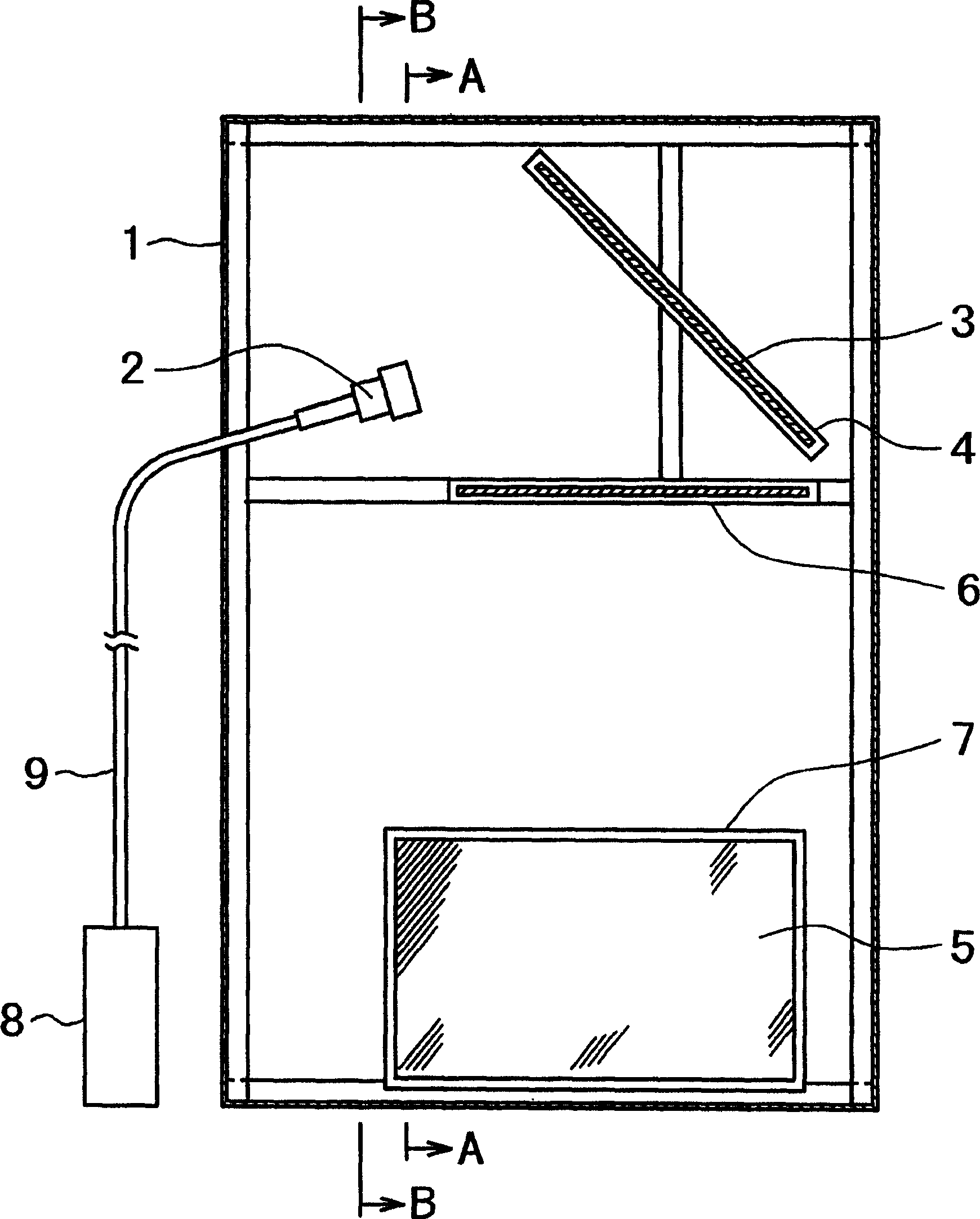

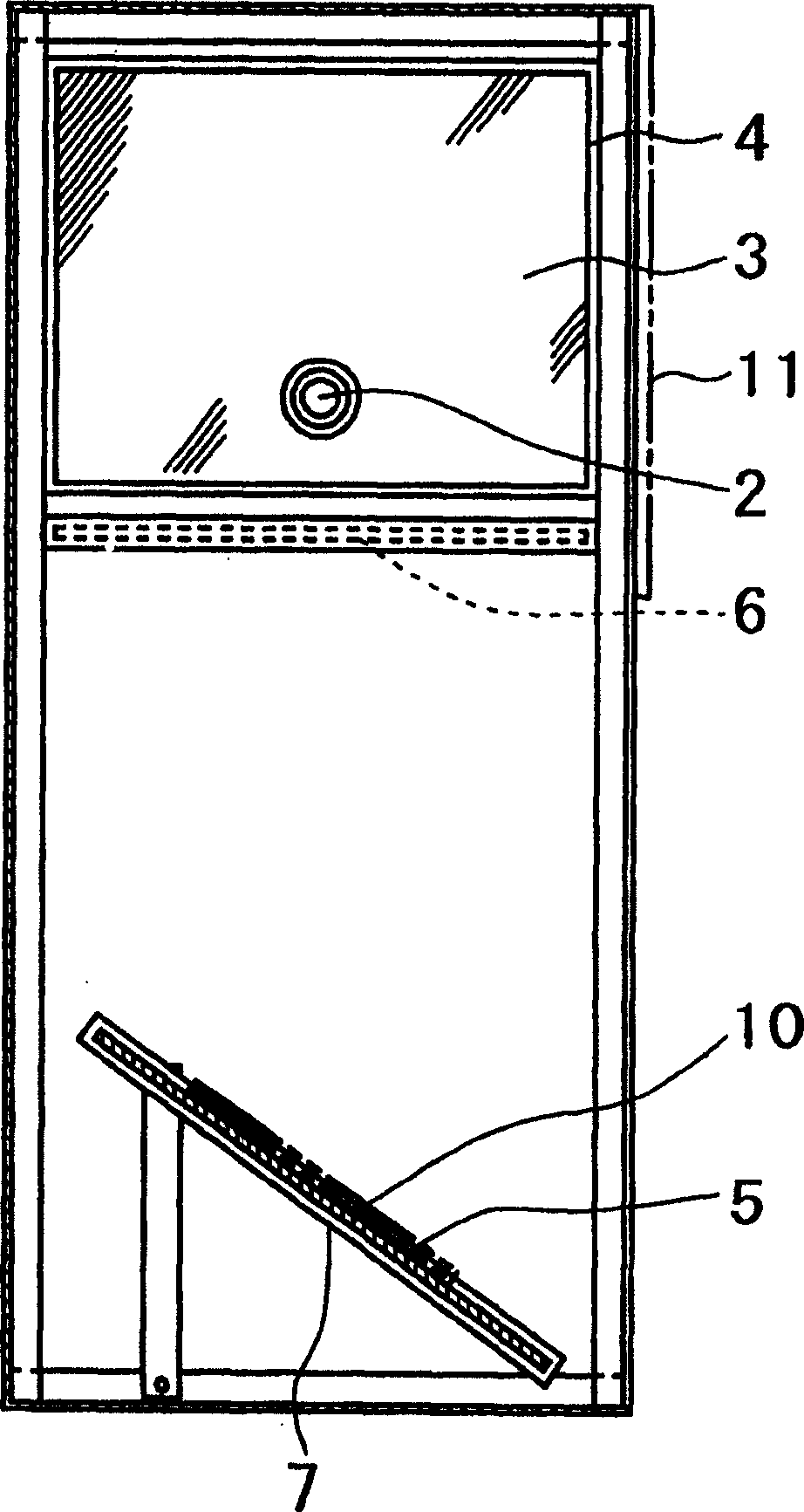

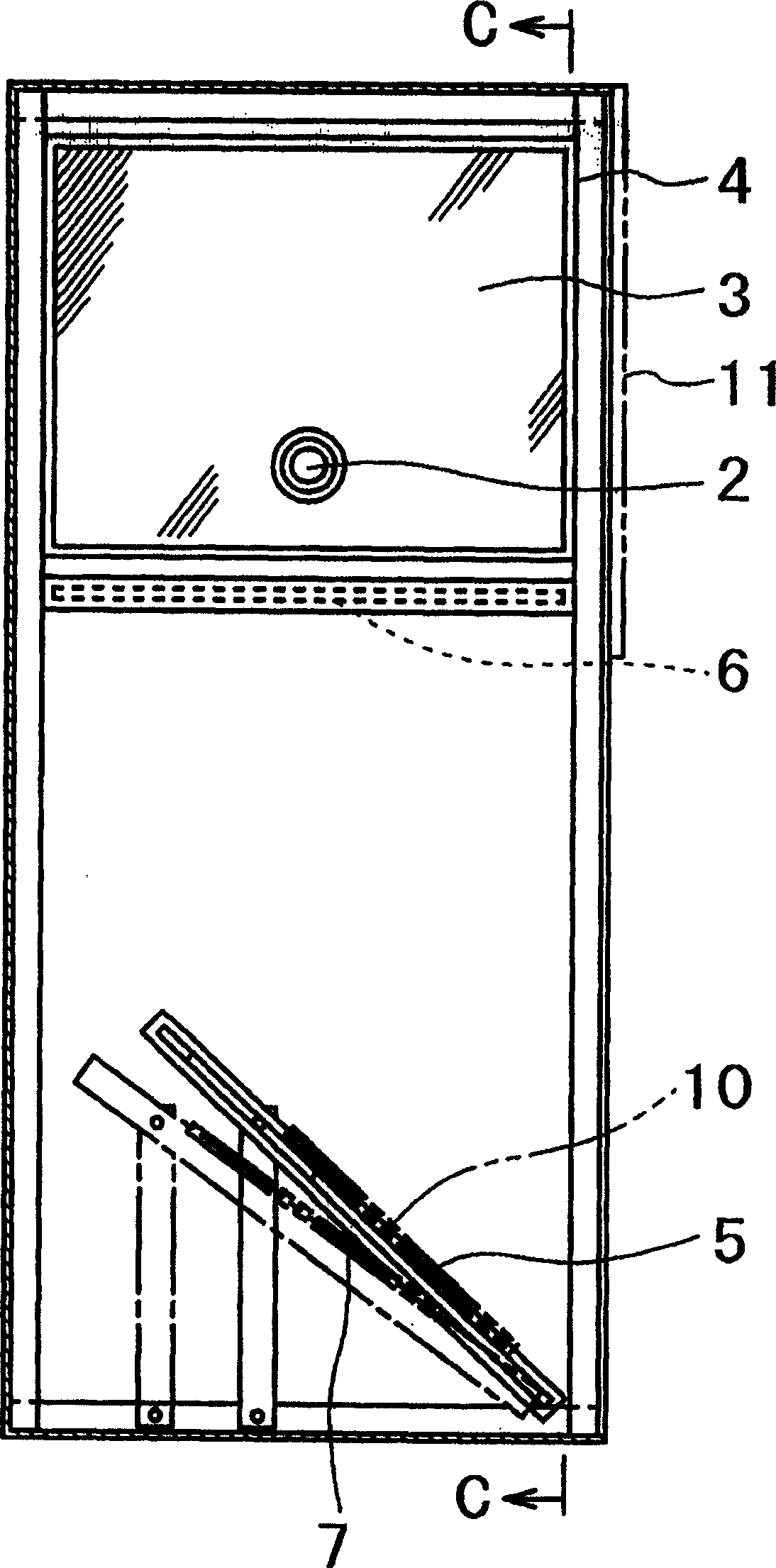

[0035] figure 1 It is a schematic cross-sectional view showing the front side of an embodiment of the lighting device for visual inspection of the present invention. figure 2 is along figure 1 Sectional view of line A-A. image 3 is used to schematically illustrate the mirror adjustment action along the figure 1 Sectional view of the B-B line. Figure 4 is used to schematically illustrate the mirror adjustment action along the image 3 Sectional view of line C-C.

[0036] In these figures, reference numeral 1 denotes a box-shaped casing formed with an open front. On the upper part of the housing 1, a light emitting part 2 for emitting illumination light is installed on the left side of the figure, and an inclined reflector 3 is installed on the right side of the figure so as to face the light emitting part 2. Such as Figure 4 As shown in , the frame portion 4 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com