Method for setting and recognizing anti-counterfeit mark on printer consumable package

A technology of identification method and setting method, which is applied to record carriers, electromagnetic radiation induction, instruments, etc. used in machines, which can solve the problems of machine damage, inability to identify anti-counterfeiting, and distinction of counterfeit and inferior consumables, and avoid damage to printing and quick-printing devices. , the effect of not easy to counterfeit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

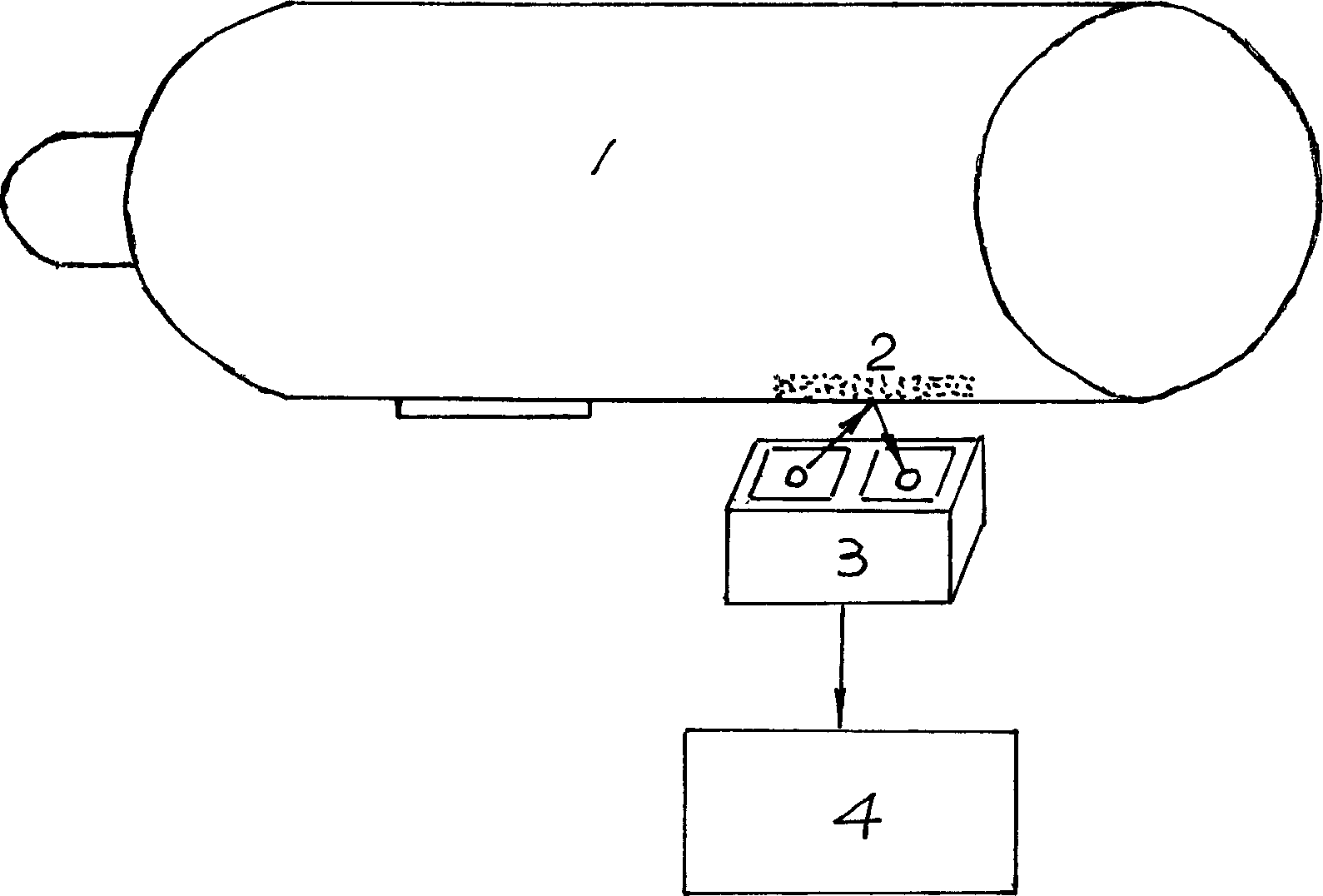

[0011] In implementing the above-mentioned process of the present invention, the position of printing the anti-counterfeiting mark block 2 on the packaging of consumables should be determined first. An optimal solution for implementing the present invention: the infrared detector 3 used is a reflective infrared sensor, the anti-counterfeiting mark block 2 is printed with colorless and transparent infrared reflective ink, the specific anti-counterfeiting mark detection level range V≤1.6V, common consumables The detection level range of components or packaging materials is V2≥2.0V. By adjusting the ink output of the coating and printing system, the printing conditions are determined by trial printing, so as to ensure that when the printed anti-counterfeiting mark block 2 is detected by the infrared detector 3, the detected signal level V' conforms to the specific paper level signal V ≤1.6V. That is, the setting of the anti-counterfeiting mark block 2 has been completed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com