Floor surface finishing device

A technology of ground and pressurizing device, which is applied in the direction of construction and building structure, can solve the problems of heavy physical burden on the legs, waist and shoulders of operators, large labor and time, and difficulty in ensuring, so as to achieve good operability and improve workability. , Improve the effect of wiping state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

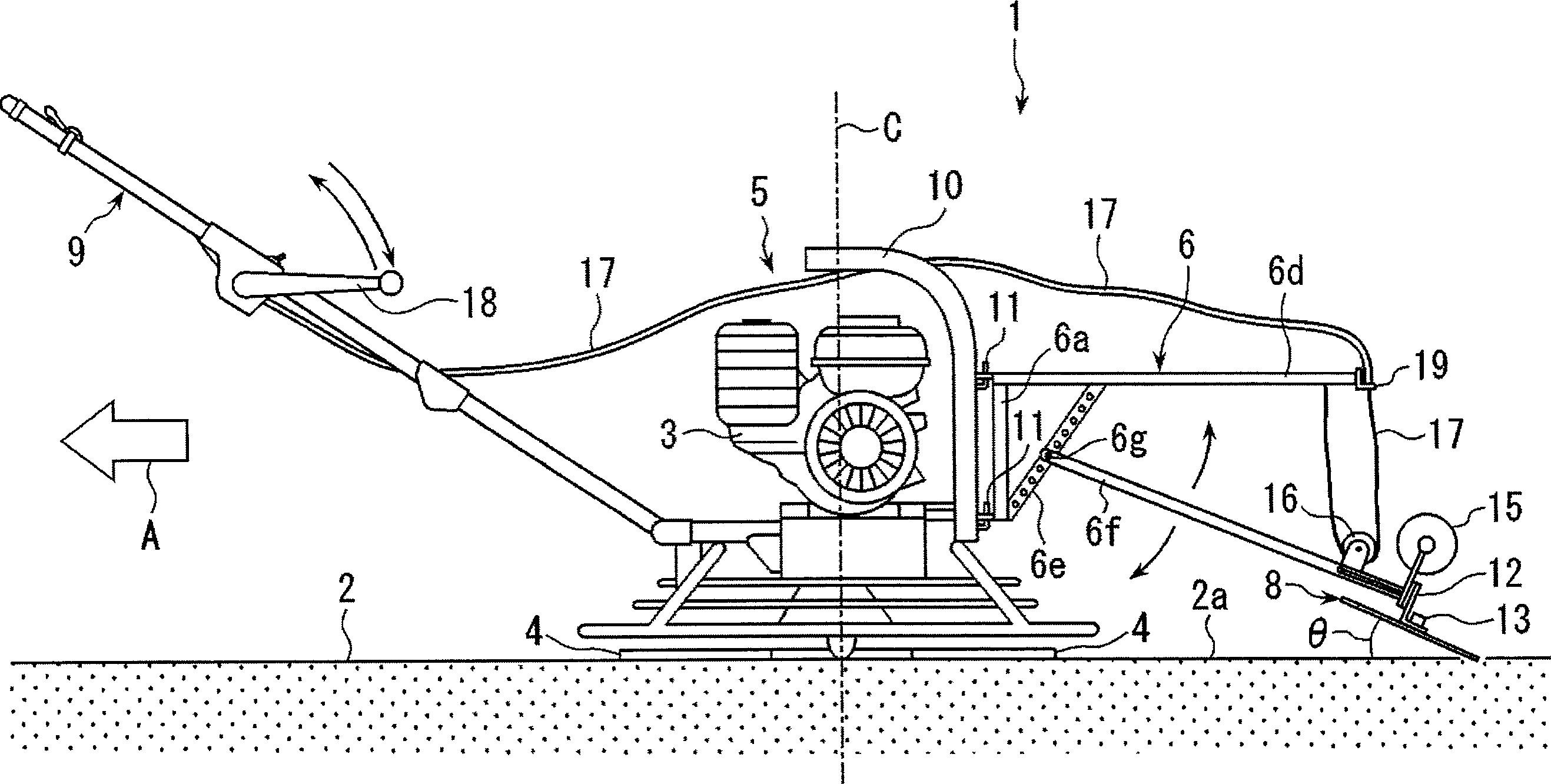

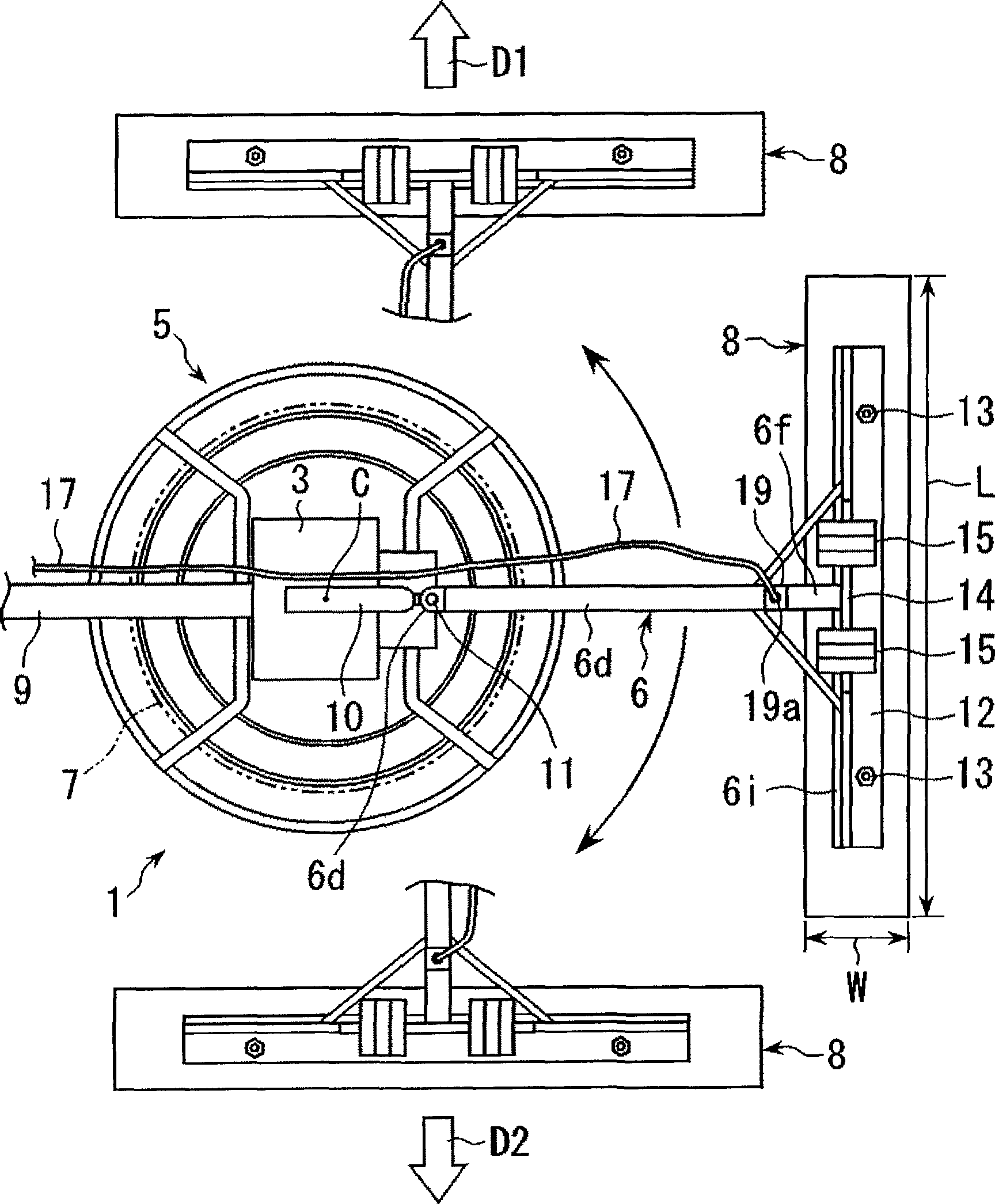

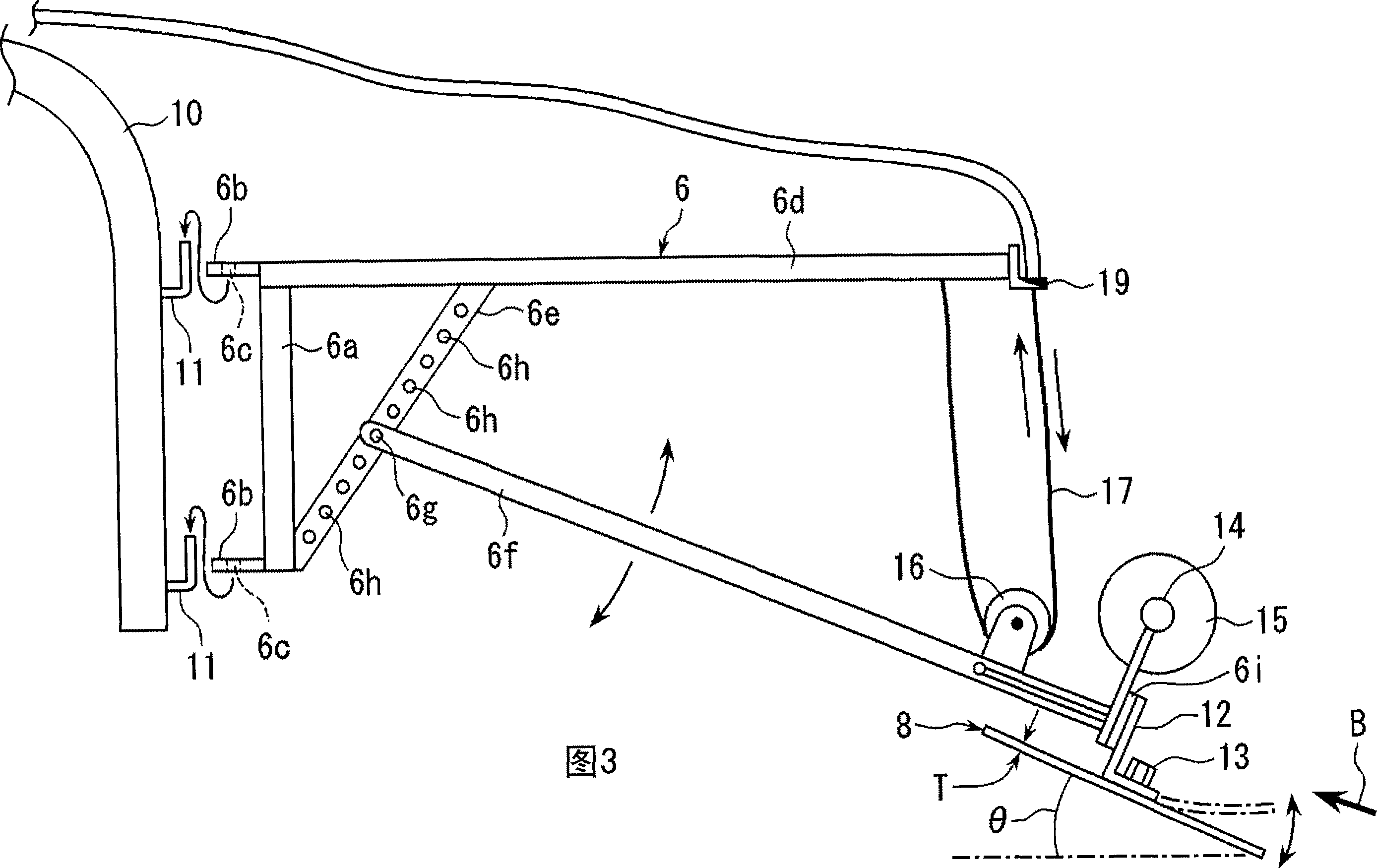

[0051] Below, refer to Figure 1 ~ Figure 4 A floor polishing device according to a first embodiment of the present invention will be described. Such as figure 1 , figure 2 As shown, the floor polishing device 1 of the present embodiment includes: a surface leveler 5 having a plurality of rotating trowels 4 that rotate spirally by the driving force of the prime mover 3 while contacting the floor 2 to be polished. a planar smoothing trowel 8 arranged on a part of the outer peripheral region of the rotating surface 7 of the rotating trowel 4 in a state connected to the surface leveler 5 through the connecting member 6 ; In addition, on the side opposite to the trowel 8 of the surface leveling machine 5, an operating handle 9 for operators to operate the floor trowel 1 is installed.

[0052] As shown in FIG. 3 , an inverted L-shaped pillar 10 is erected in front of the prime mover 3 of the plane leveling machine 5 , and L-shaped hooks 11 are fixed at two places up and down on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com