Microporous unidirectional anti-block self-protective bubbler

A self-protecting, multi-microporous technology, used in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of glass liquid pouring, glass liquid clarification difficulty, blockage and other problems, and achieve ideal clarification effect. Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

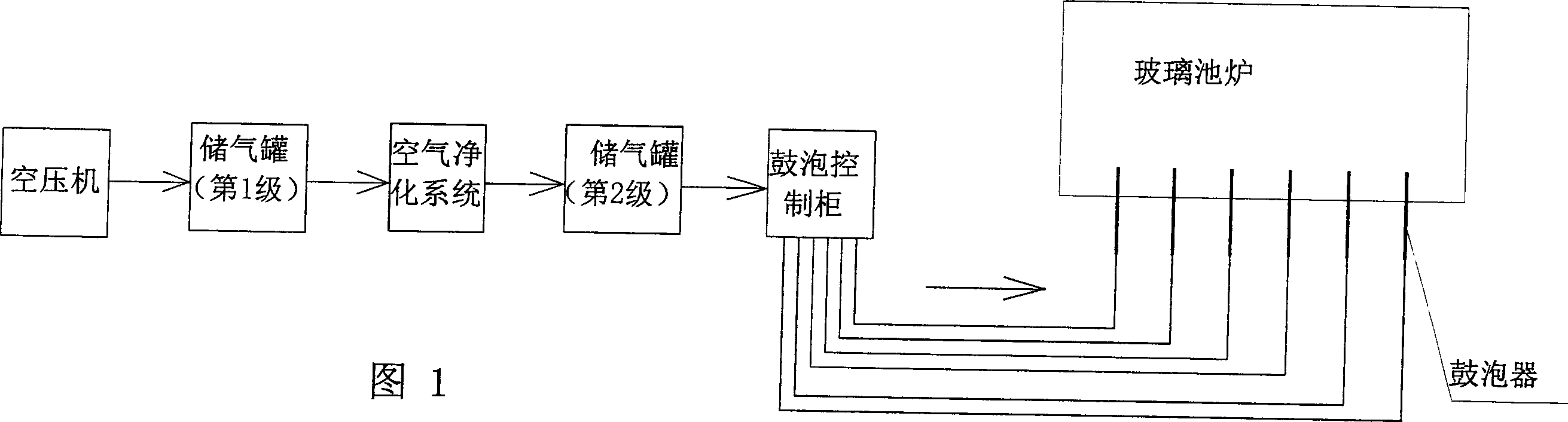

[0021] A 5-year 60M 2 Medium-sized glass pool furnace with 10 bubblers: the original bubbler tube is a single hole with an outer diameter of 18mm and an inner diameter of 2.5mm. Generally, the total cost of recovery due to glass liquid blockage is about 70,000 yuan. The minimum direct loss to production and quality during this period was 200,000 yuan.

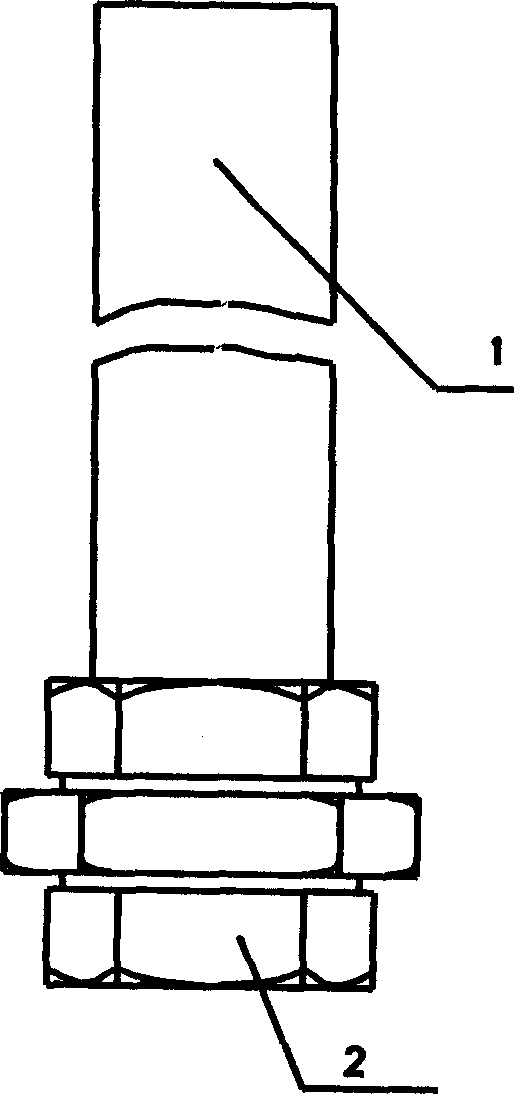

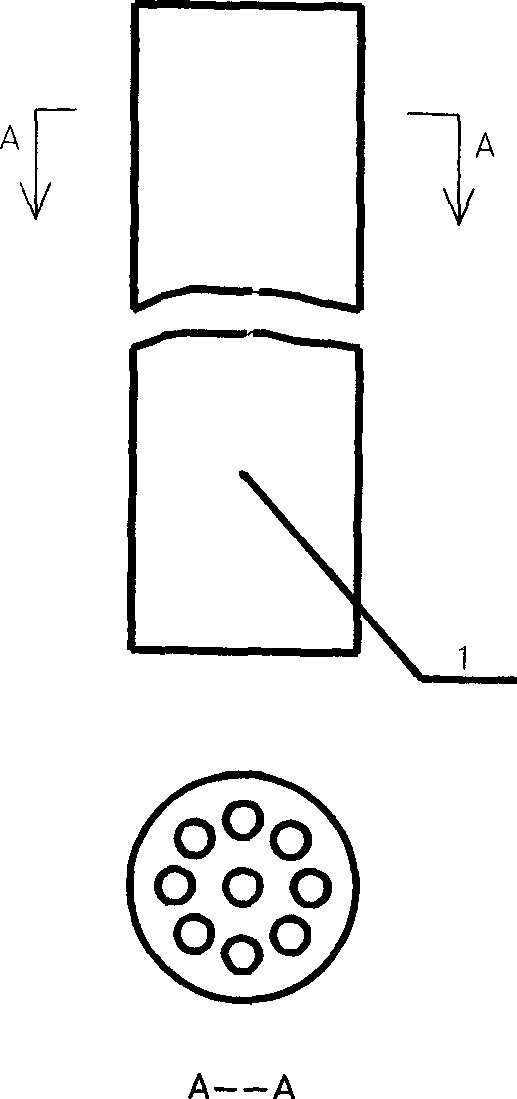

[0022] The bubbling tube 1 used in this embodiment is composed of 9 microporous tubes with a diameter of 0.5-0.8 mm, and a pneumatic check valve 2 is installed at the lower end of the bubbling tube 1 . The interface at the upper end of the pneumatic check valve 2 is ferrule type, which is tightly connected with the bubble tube 1 with a diameter of 18mm, and the lower end is connected with a stainless steel pipe with a diameter of 12mm. The inner diameter of the pneumatic check valve 1 is 5mm, and the working pressure range is 0.05 -0.85MPa. In this embodiment, the bubbling device operates with high precision, so that the qual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com