Constant velocity buffering exhaust valve

An exhaust valve and valve body technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of pipeline burst and poor exhaust, and achieve the effect of reducing vibration and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

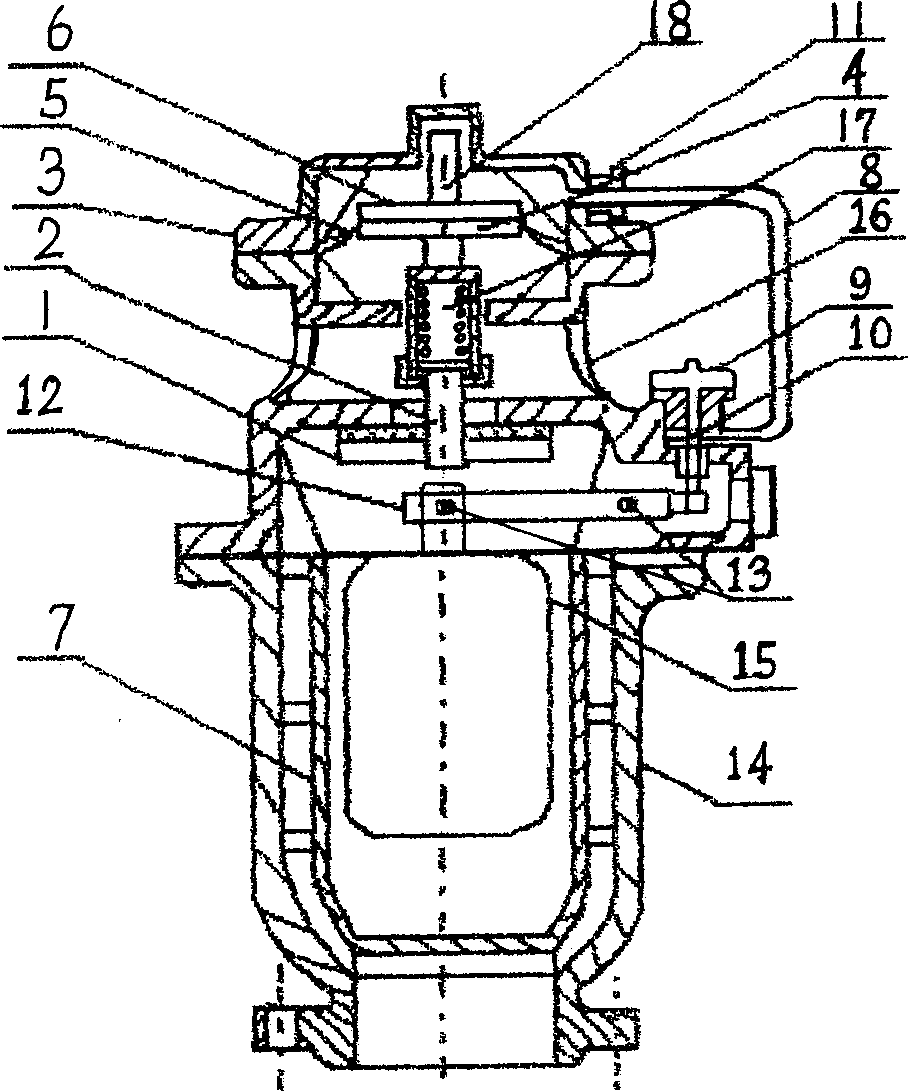

[0011] according to figure 1 As shown, the present invention mainly consists of lower valve body 14, middle valve body 16, float 15, float rod 12, small valve core 10, cover plate 1, lower slide bar 2, upper slide bar 18, pressure sensitive spring 17 and diaphragm 5 and valve cover 3, the middle valve body 16 is integrated with the lower valve body 14 through bolts, the valve cover 3 is installed on the upper end of the middle valve body 16, and the feature is that the buoy 15 is located in the casing 7 inside the lower valve body 14 Inside, the buoy 15 is hinged with one end of the buoy rod 12, and the other end of the buoy rod 12 is hinged on the middle valve body 16 through the main shaft installed on the middle valve body 16, and controls the valve mounted on the middle valve body 16 through a small groove on itself. The lifting of the small valve core 10; the cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com