Method for determining tobacco shred ratio in cigarette

A technology for shredded tobacco and cigarette sticks, which is applied in the field of measuring the blending ratio of different types of shredded tobacco to achieve the effect of improving physical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

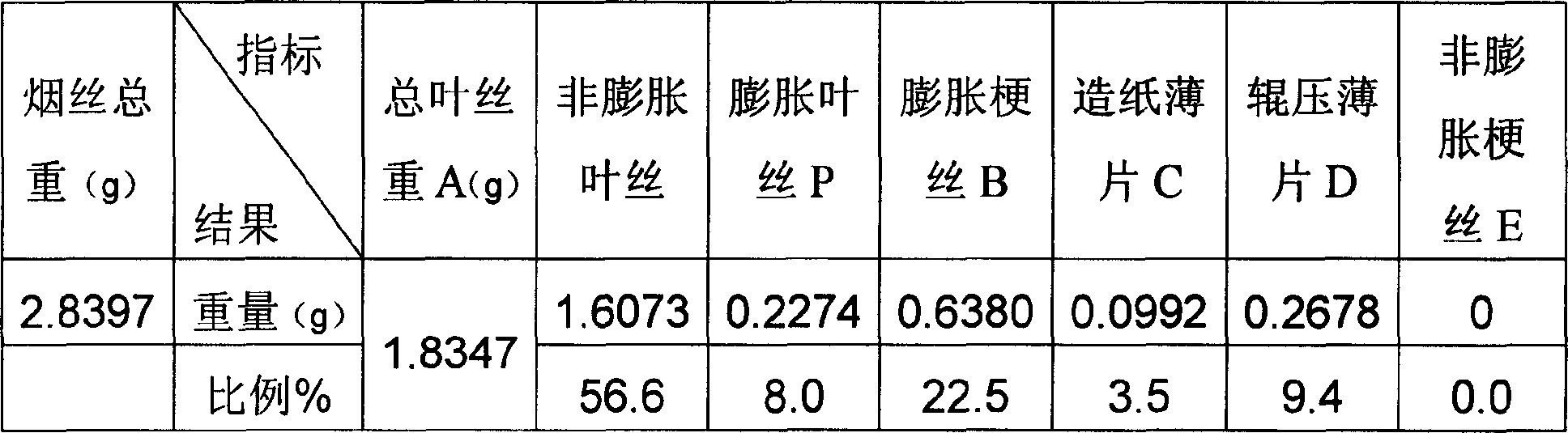

[0022] The sample is a domestic brand of flue-cured tobacco

[0023] a. Take a pack of cigarettes of this brand and place them in an environment with a temperature of 20±2°C and a humidity of 65%±5% to balance for 24 hours, then take 5 cigarettes, take out the shredded tobacco and weigh the net weight as 2.8397g.

[0024] b. Under the magnifying glass, select shredded leaves, expanded stems, paper-making flakes, rolled flakes, and non-expanded stems according to the different appearance characteristics of various shredded tobacco. 0.0g.

[0025] c. Ethyl acetate and cyclohexane are selected as solvents and blended at a volume ratio of 1:2, with a density range of 0.83±0.02.

[0026] d. Put the shredded leaves into a beaker and add about 50ml of solvent. Let stand for about 2 minutes after stirring with a glass rod. Take out the expanded leaf shreds floating on the liquid surface, put it into an oven and dry it for one minute at about 100°C. Weigh and record as 0.2774g

[...

Embodiment 2

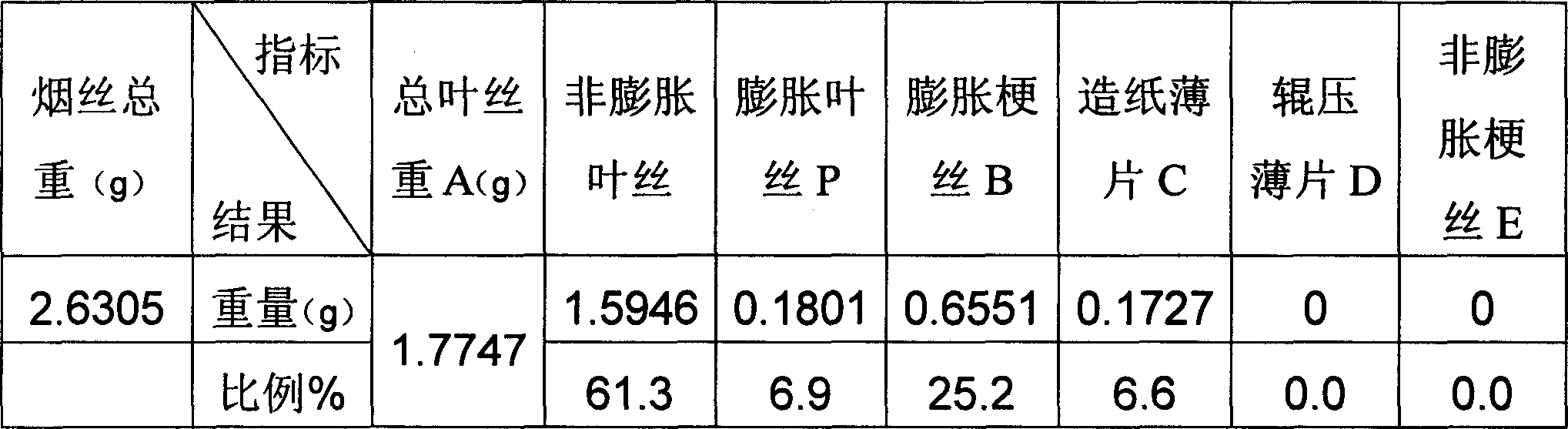

[0030] The sample is a domestic brand of mixed cigarettes

[0031] a. Take a pack of cigarettes of this brand and place it in an environment with a temperature of 20±2°C and a humidity of 65%±5% to balance for 24 hours, then take 5 cigarettes, take out the shredded tobacco and weigh the net weight as 2.6305g.

[0032] b. Under the magnifying glass, select shredded leaves, expanded stems, paper sheets, rolled sheets, and non-expanded cut stems according to the different appearance characteristics of various shredded tobacco, and weigh them in order of 1.7747g, 0.6551g, 0.1727g, 0.0g, 0.0g.

[0033] c. Ethyl acetate and ethanol are selected as solvents and blended at a volume ratio of 2:1, with a density range of 0.83±0.02.

[0034] d. Put the shredded leaves into a beaker and add about 50ml of solvent. Let stand for about 2 minutes after stirring with a glass rod. Take out the expanded leaf shreds floating on the liquid surface, put it into an oven and dry it for one minute ...

Embodiment 3

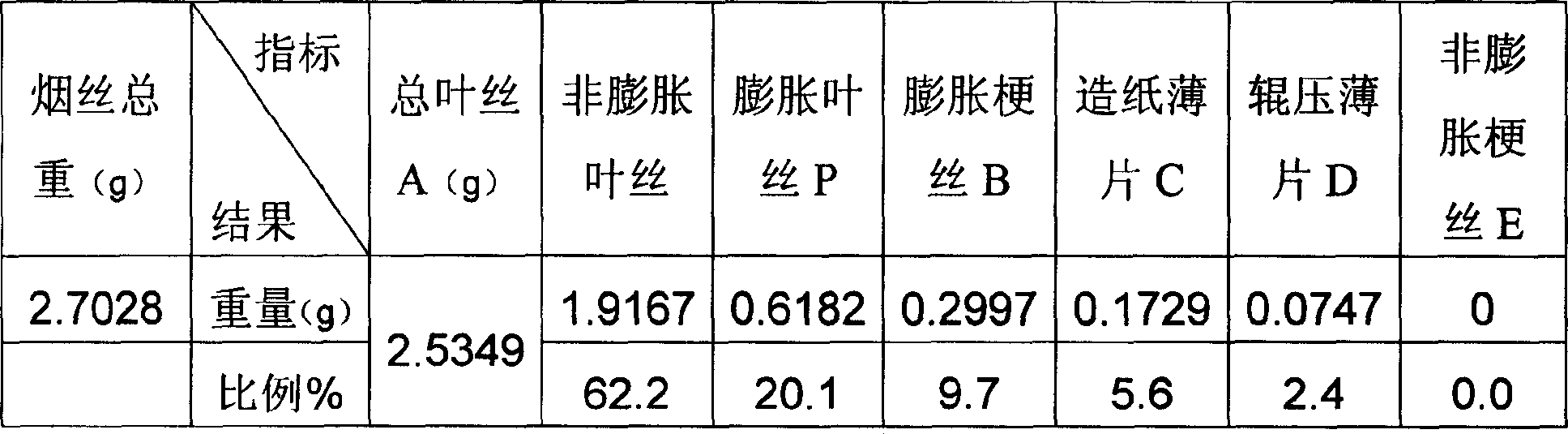

[0038] The sample is a foreign brand of mixed cigarettes

[0039] a. Put a pack of cigarettes of this brand in an environment with a temperature of 20±2°C and a humidity of 65%±5% to balance for 24 hours, then take 5 cigarettes, take out the shredded tobacco and weigh the net weight as 2.7028g.

[0040] b. Under the magnifying glass, select shredded leaves, expanded cut stems, papermaking sheets, rolled sheets, and non-expanded cut stems according to the different appearance characteristics of various shredded tobacco. 0.0g.

[0041] c. Acetone and dichloromethane are selected as solvents and blended at a volume ratio of 7:1, with a density range of 0.83±0.02.

[0042] d. Put the shredded leaves into a beaker and add about 50ml of solvent. Let stand for about 2 minutes after stirring with a glass rod. Take out the expanded leaf shreds floating on the liquid surface, put it into an oven and dry it for one minute at about 100°C. Weigh and record as 0.6182g

[0043] 4. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com