LCD panel and method for manufacturing same

A liquid crystal display, liquid crystal layer technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as inability to ensure accuracy, and achieve high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

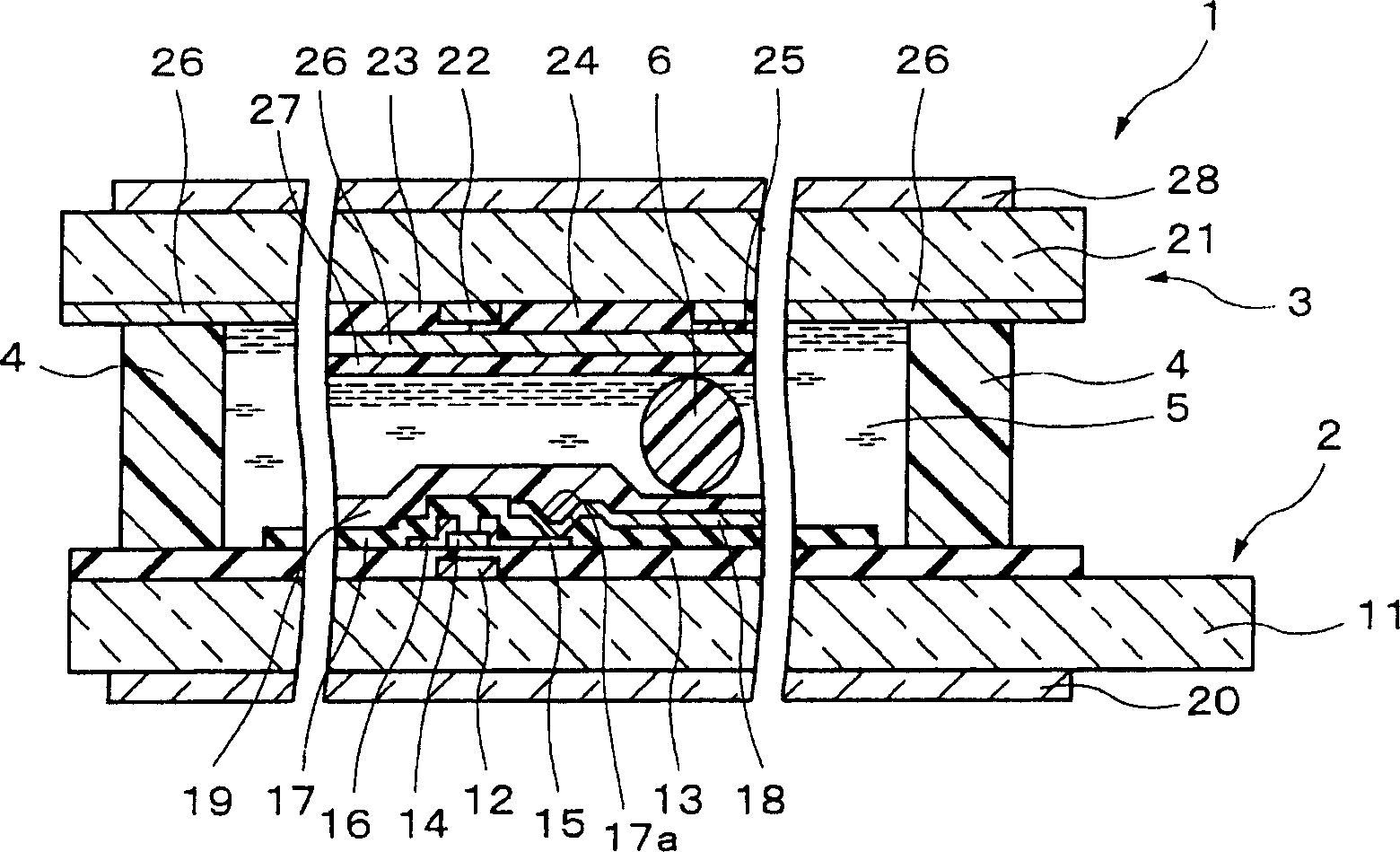

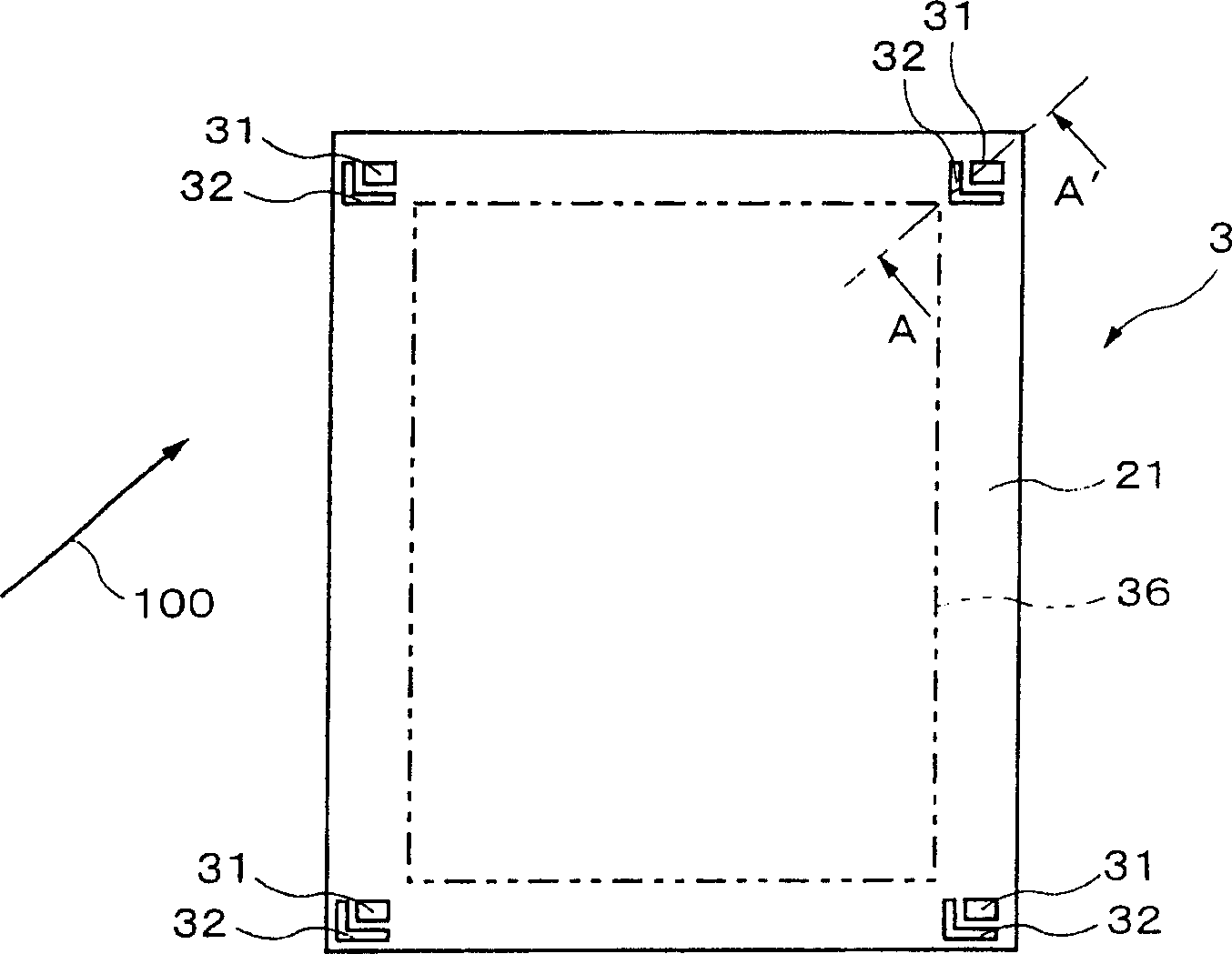

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. A first embodiment of the present invention will be described first. figure 2 A cross-sectional view of the LCD according to the present embodiment is shown; image 3 A plan view of the CF substrate of the present LCD is shown; Figure 4 show image 3 Plan view of the alignment marks and capture pattern of the CF substrate shown; Figure 5 is along image 3 a cross-sectional view along line A-A' as shown; and Figure 6 show Figure 4 Perspective view of alignment marks and capture graphic shown.

[0037] Such as figure 2 As shown, in the LCD panel 1 according to the present embodiment, a TFT substrate 2 and a color filter (CF) substrate 3 are arranged parallel to each other, and a frame-shaped sealing member 4 is arranged between the TFT substrate 2 and the CF substrate 3, to surround the display area of the LCD panel 1 . Liquid crystals ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com