Belt type coaxial middle/high frequency loudspeaker

A loudspeaker, high frequency technology, applied in the field of medium and high frequency loudspeakers, can solve the problem of no way to design, achieve the effect of perfect restoration, reduce distortion, and solve phase difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

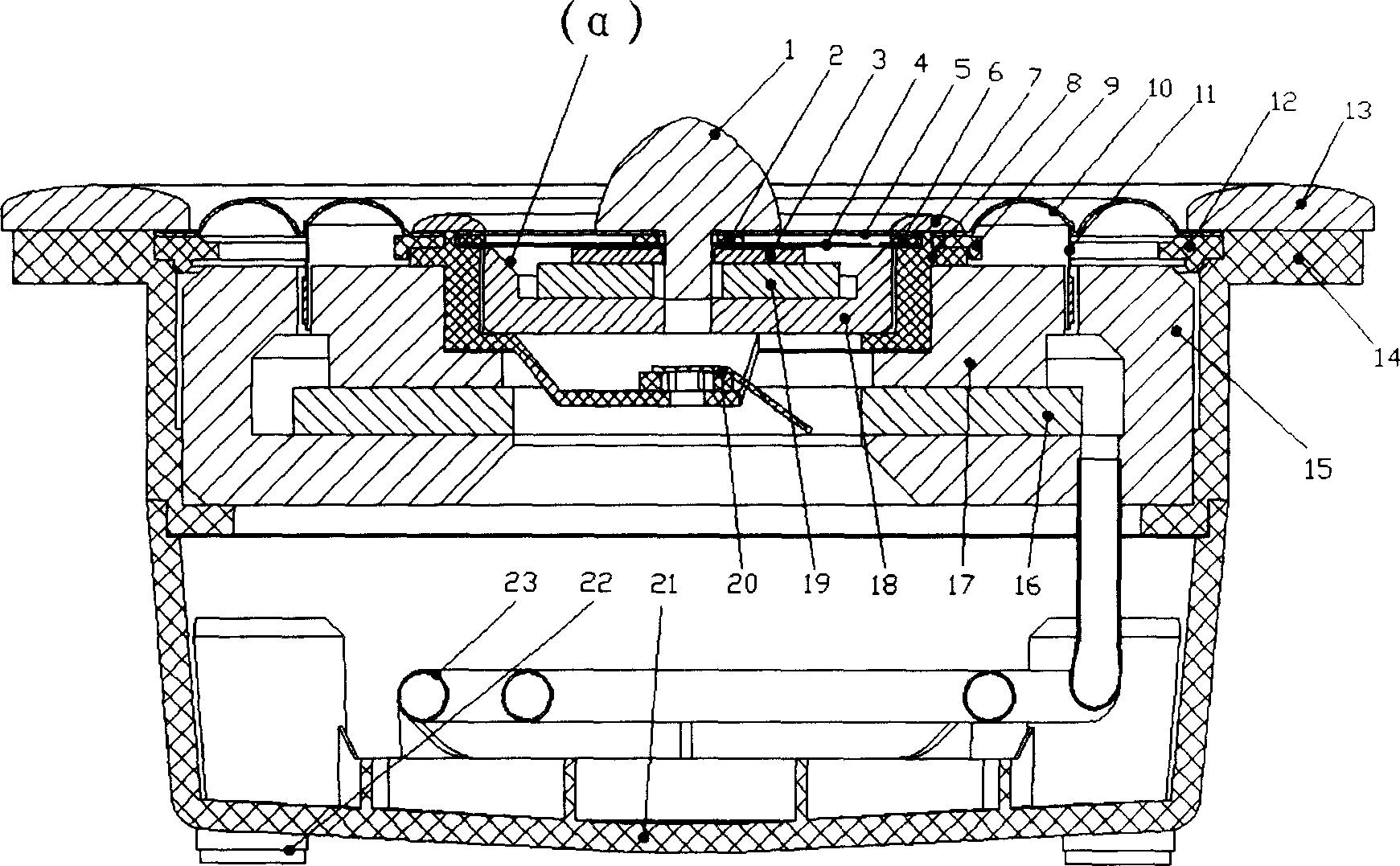

[0016] Below in conjunction with accompanying drawing, the structural details of the embodiment of the present utility model are described in further detail:

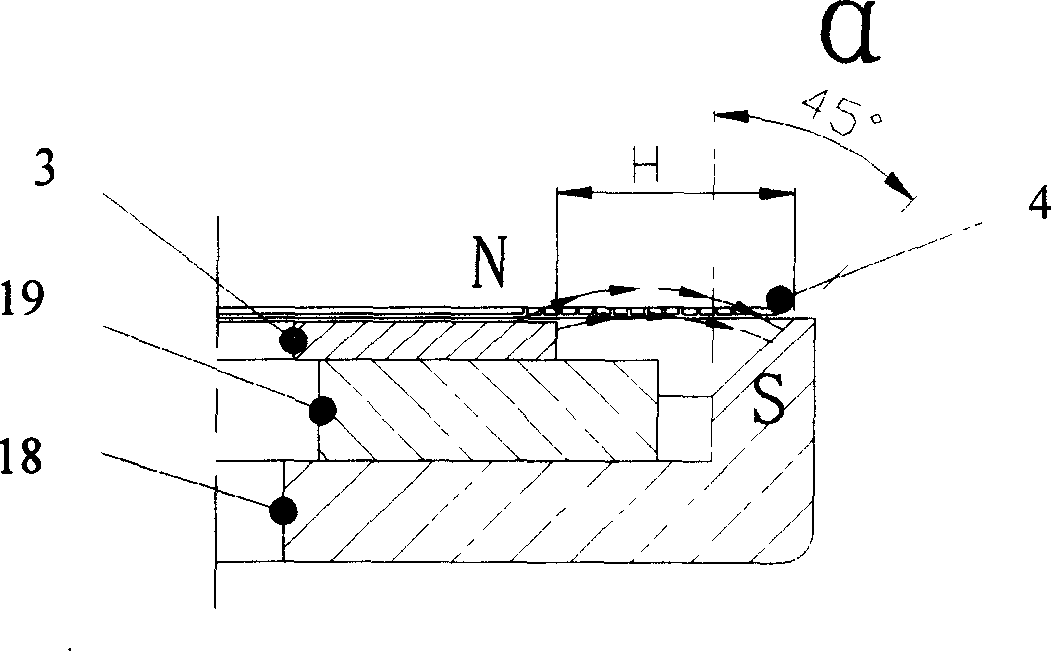

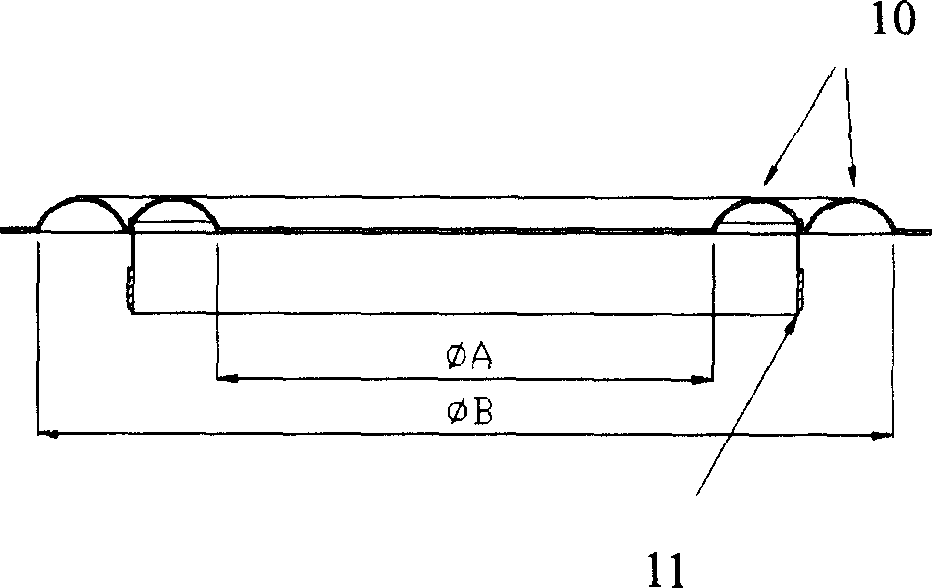

[0017] The basic structure of the ribbon coaxial medium and high frequency loudspeaker embodiment is as follows: figure 1 As shown, it includes a ribbon tweeter unit located in the center and a midrange speaker unit located in the outer ring; the ribbon tweeter unit is composed of an annular upper magnetic plate 3, a treble annular neodymium-iron-boron magnet 19 and a U-shaped magnetic conductor. The plate 18 constitutes the magnetic circuit structure of the working magnetic field of the high-pitch dissipated. On the ring-shaped upper magnetic plate 3, a high-pitched ribbon-type planar diaphragm 4 is installed, and the entire ribbon-type tweeter unit is installed on the tweeter bracket 8. The membrane 4 is fixed on the treble bracket 8 by the treble sound membrane support frame 6, and the belt type tweeter unit is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner ring diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com