Whole-metal stator screw drilling tool

A screw drilling tool and all-metal technology, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes, etc., can solve the problems that screw drilling tools cannot meet production requirements, and achieve improved rock-carrying capacity and heat dissipation performance , heat deformation uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

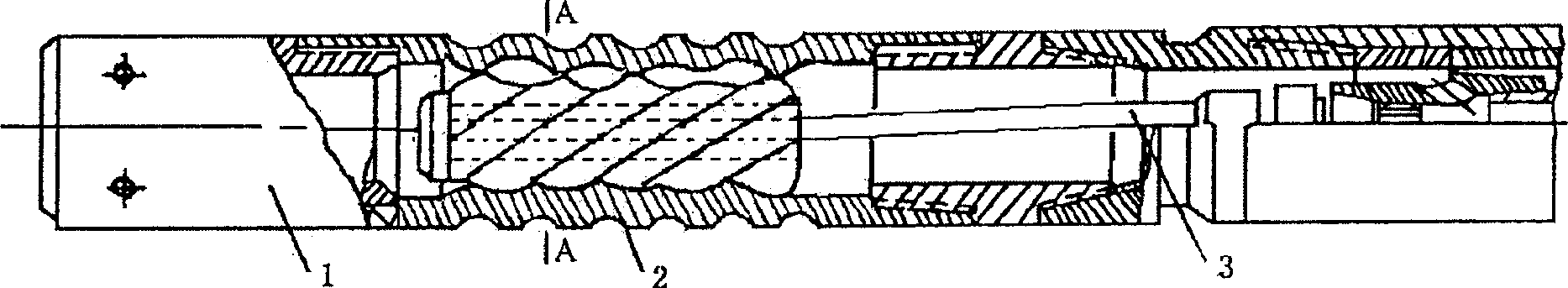

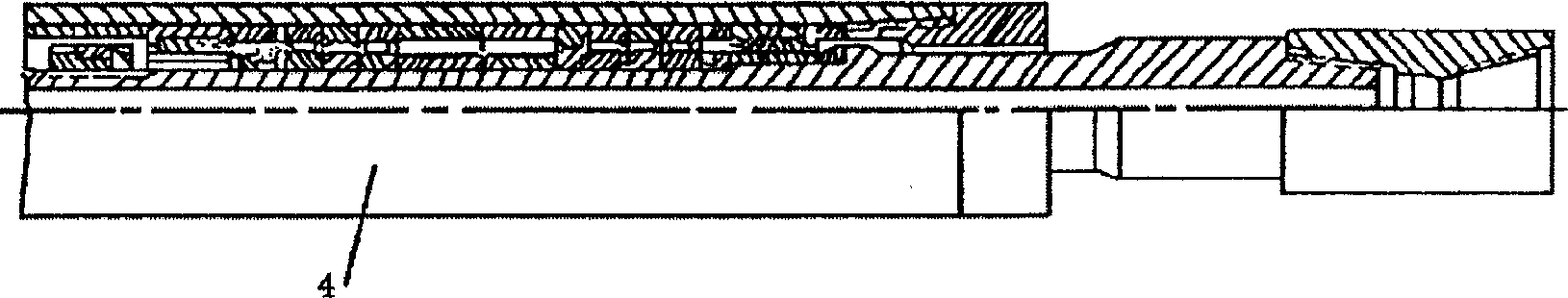

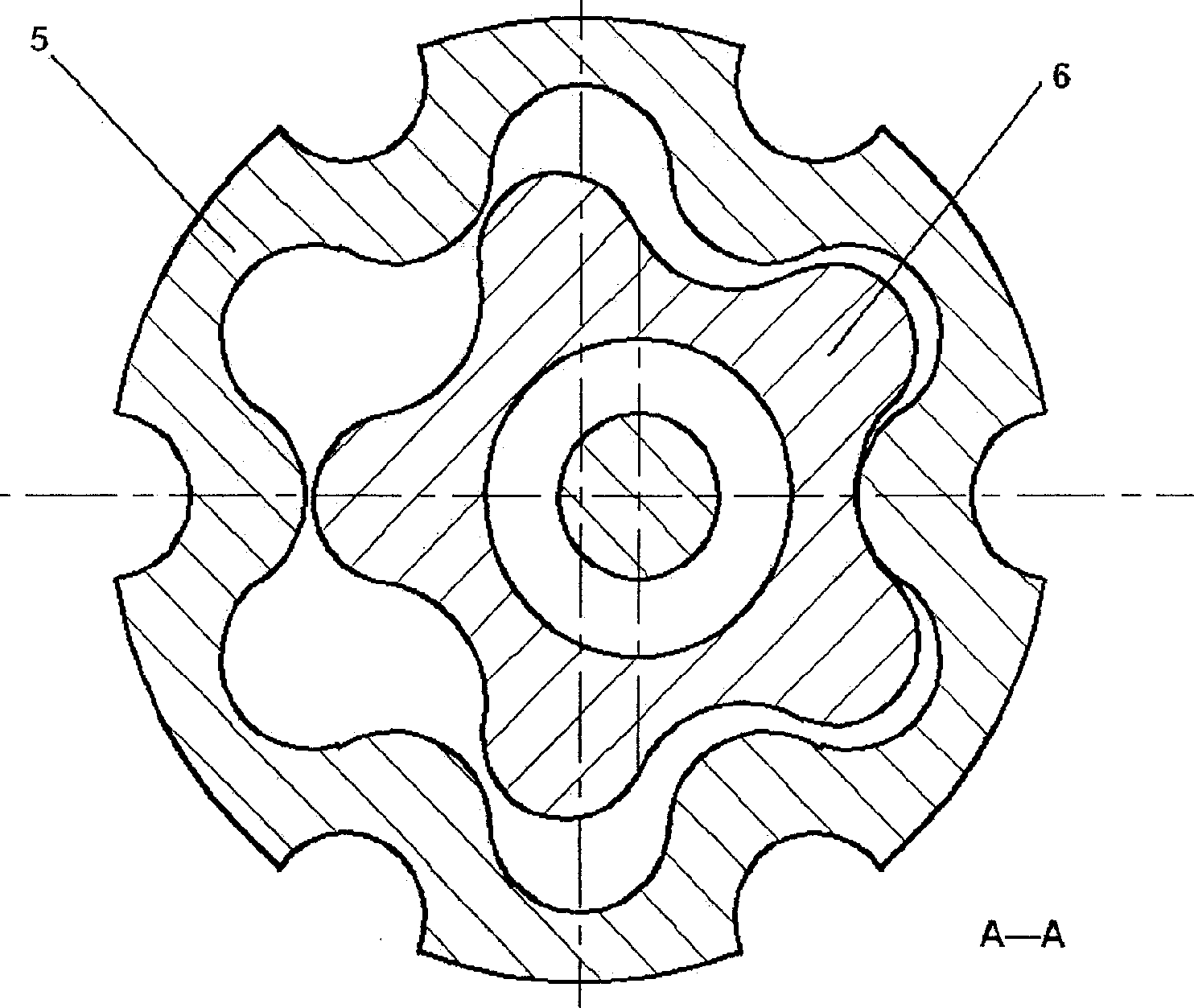

[0010] See figure 1 , figure 2 , image 3 . The screw drilling tool of the present invention is composed of a bypass valve assembly 1, a screw motor assembly 2, a flexible cardan shaft assembly 3, a drive shaft assembly 4, and the like. The motor is a positive displacement power machine driven by a drilling fluid, which consists of an all-metal stator 5 and a rotor 6. The rotor 6 is a hollow steel screw plated with abrasion-resistant material, and the stator 5 is a steel tube with spiral curved surfaces inside and outside. The upper end of the rotor 6 is connected with the cardan shaft, and the lower end of the cardan shaft is connected with the transmission shaft. The stator 5 is fixed, and the rotor 6 makes a planetary movement around the axis of the stator 5 under the driving of the pressure drilling fluid. The cardan shaft transmits the autotransmission part of the planetary motion of the rotor 6 to the transmission shaft, so that the transmission shaft rotates as a fixed sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com