Rotating joint for the mutual connection of two shaft ends in particular in the drive train of a motor vehicle

A technology for motor vehicles and drive trains, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve complex problems, shorten the service life and prevent rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

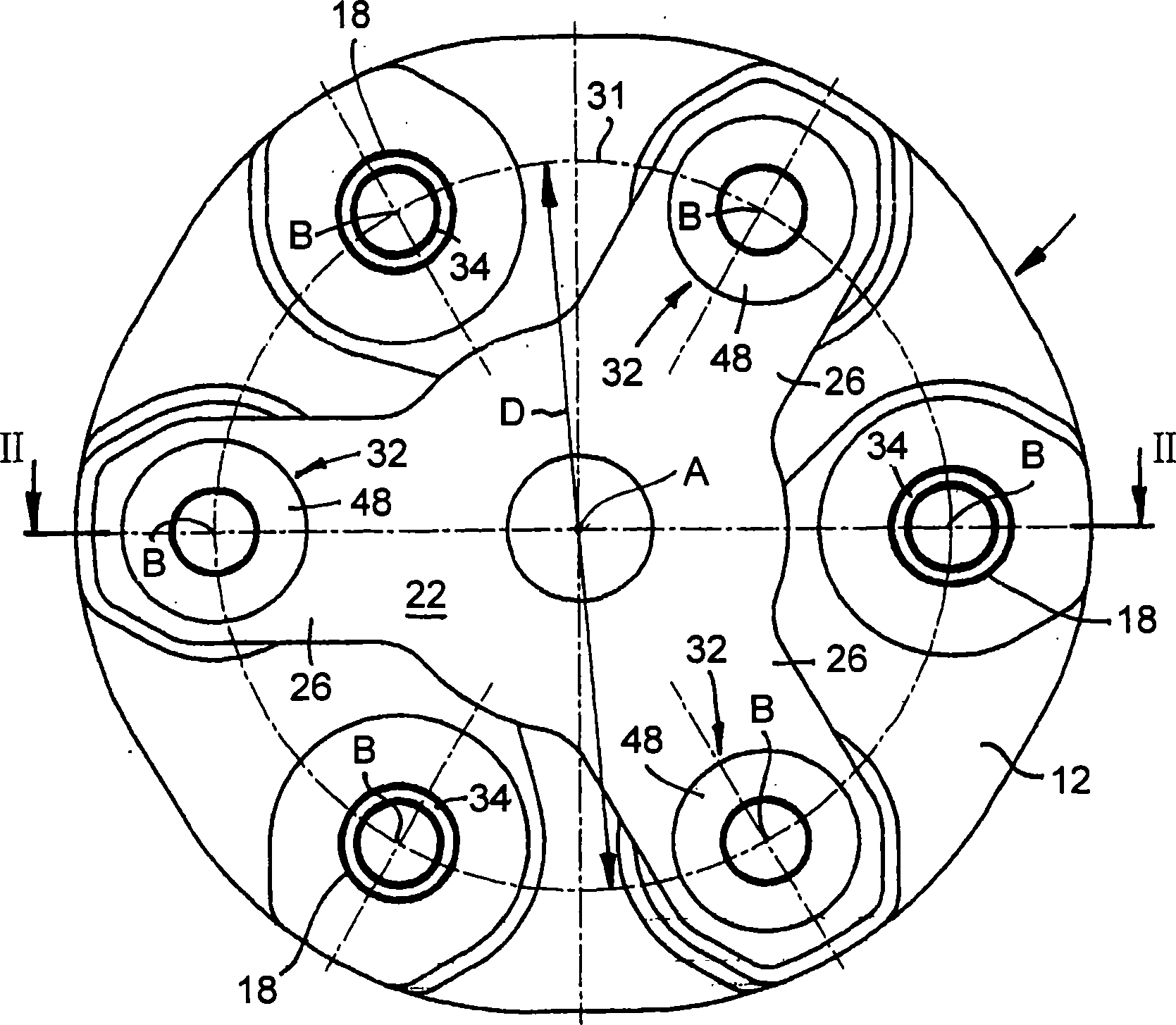

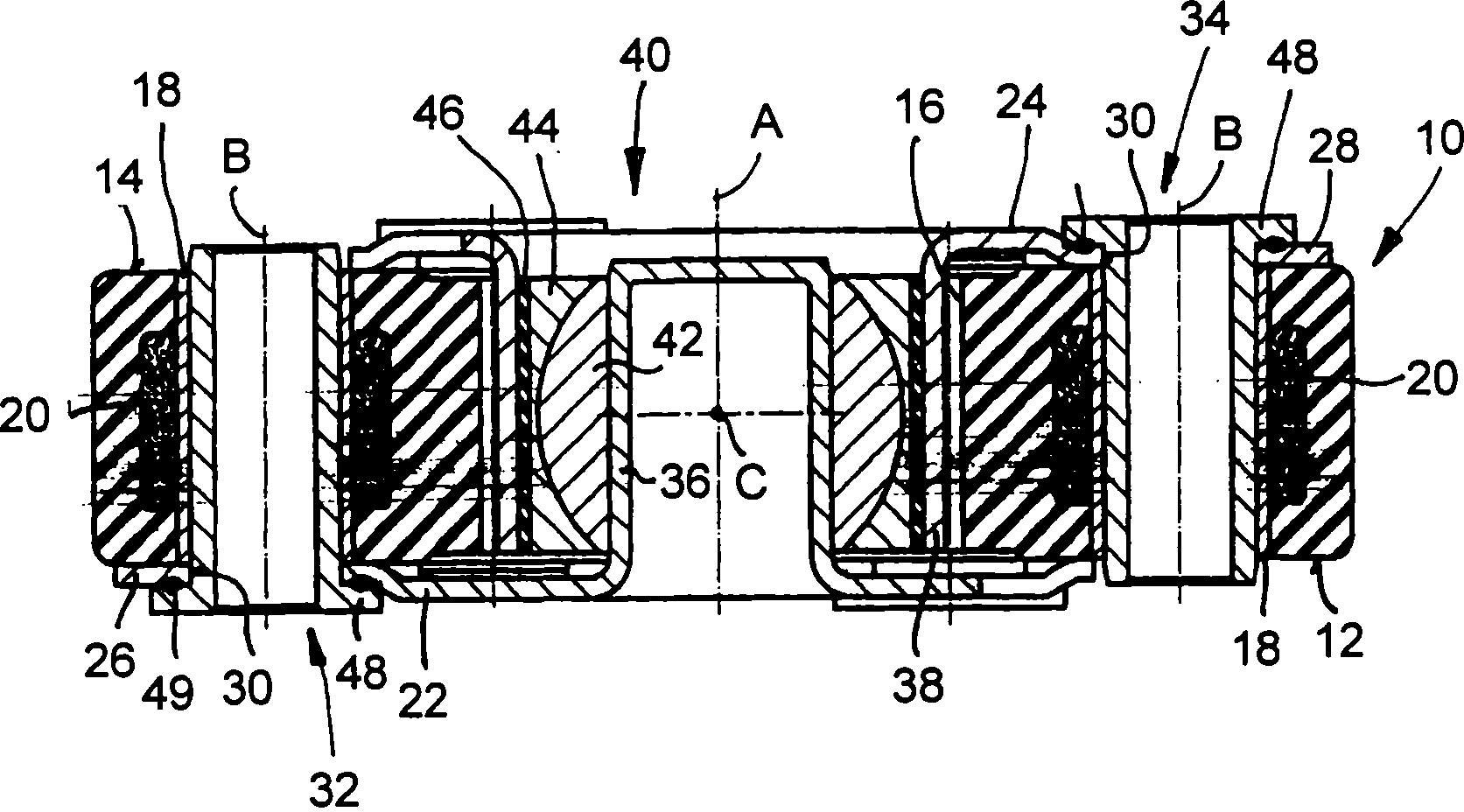

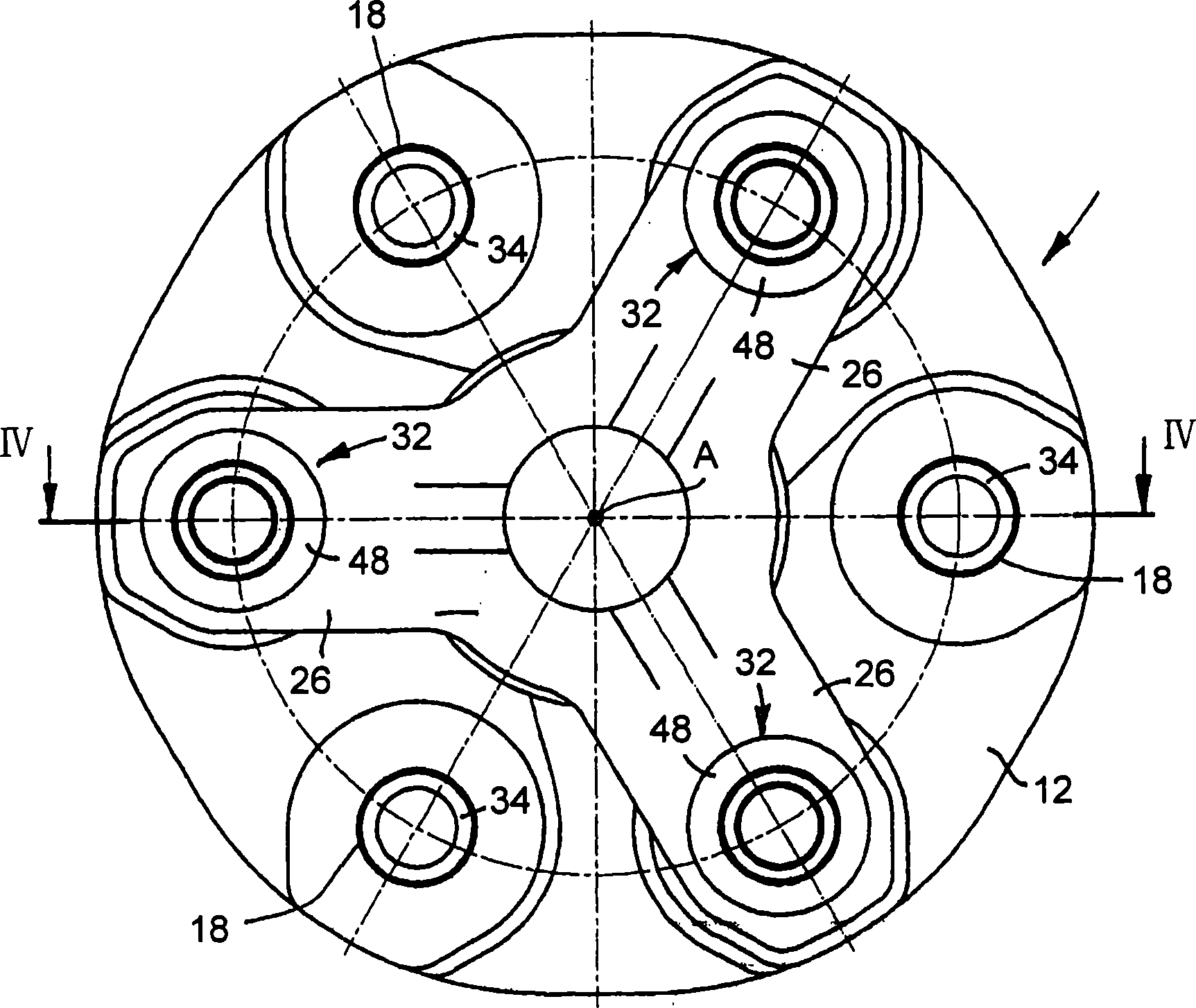

[0019] exist figure 1 with figure 2 The flexible coupling shown in has as the basic torque transmitting part a flexible disk 10, which is basically made of rubber or some other rubber-like elastic material, and is formed to be substantially rotationally symmetrical with respect to a central axis A, and is formed by a vertical Delimited by two substantially planar end faces on this axis, a first end face 12 and a second end face 14 , have a circular central recess 16 . Six cylindrical sleeves 18 are vulcanized into the flexible disk 10, the axis B of these sleeves being parallel to the central axis A and arranged at uniform angular intervals of 60° on a common reference circle. Wrapped around each sleeve 18 and adjacent sleeves 18 are coil-shaped flexible inserts 20 which are likewise vulcanized into the material of the flexible disc 10 . In this sense, the flexible disk 10 is conventional in design.

[0020] The flexible disk 10 is arranged between two end plates, a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com