Pulsation combustion heating furnace

A technology of pulsating combustion and heating furnace, which is applied in the direction of pulsating combustion, combustion chamber, combustion method, etc. It can solve the problems of affecting the stability of the burner, the failure of the burner to start vibration, and the difficulty of large-scale pulsating burner, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

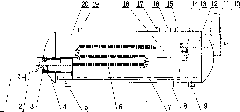

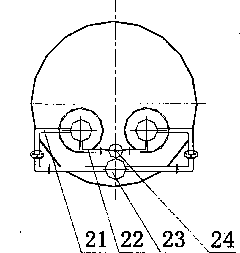

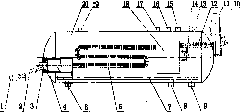

[0007] Such as figure 1 , figure 2 As shown, the above-mentioned pulsating combustion heating furnace is composed of an air inlet 1, a gas inlet 2, an air supply chamber 23, an air pipeline 21, a gas supply chamber 24, a gas pipeline 22, a mixing chamber 3, an ignition device 4, Combustion chamber 5, bent tail pipe 6, decoupling chamber 18, furnace body 20, liquid inlet and outlet pipe 7, smoke pipe 12, flue 10, blower fan 11 form. Among them, the pulsating burner composed of mixing chamber 3, ignition device 4, combustion chamber 5 and curved tailpipe 6 is arranged side by side in two or more sets in the furnace and has the same geometric structure. Two or more sets of pulsating burners share the air supply chamber 23, the gas supply chamber 24 and the decoupling chamber 18, and all smoke pipes are drawn from the decoupling chamber 18.

[0008] Such as figure 1 , figure 2 As shown, the diameters (areas) of the fuel gas supply chamber 24, the gas pipeline 22, the air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com