Process for working a pile in a pre-needling apparatus and apparatus for doing so

A fleece fabric, pre-needling technology, applied in the direction of needle punching machines, non-woven fabrics, textiles and papermaking, etc., can solve problems such as removal, and achieve the effect of simplifying driving elements and compact mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

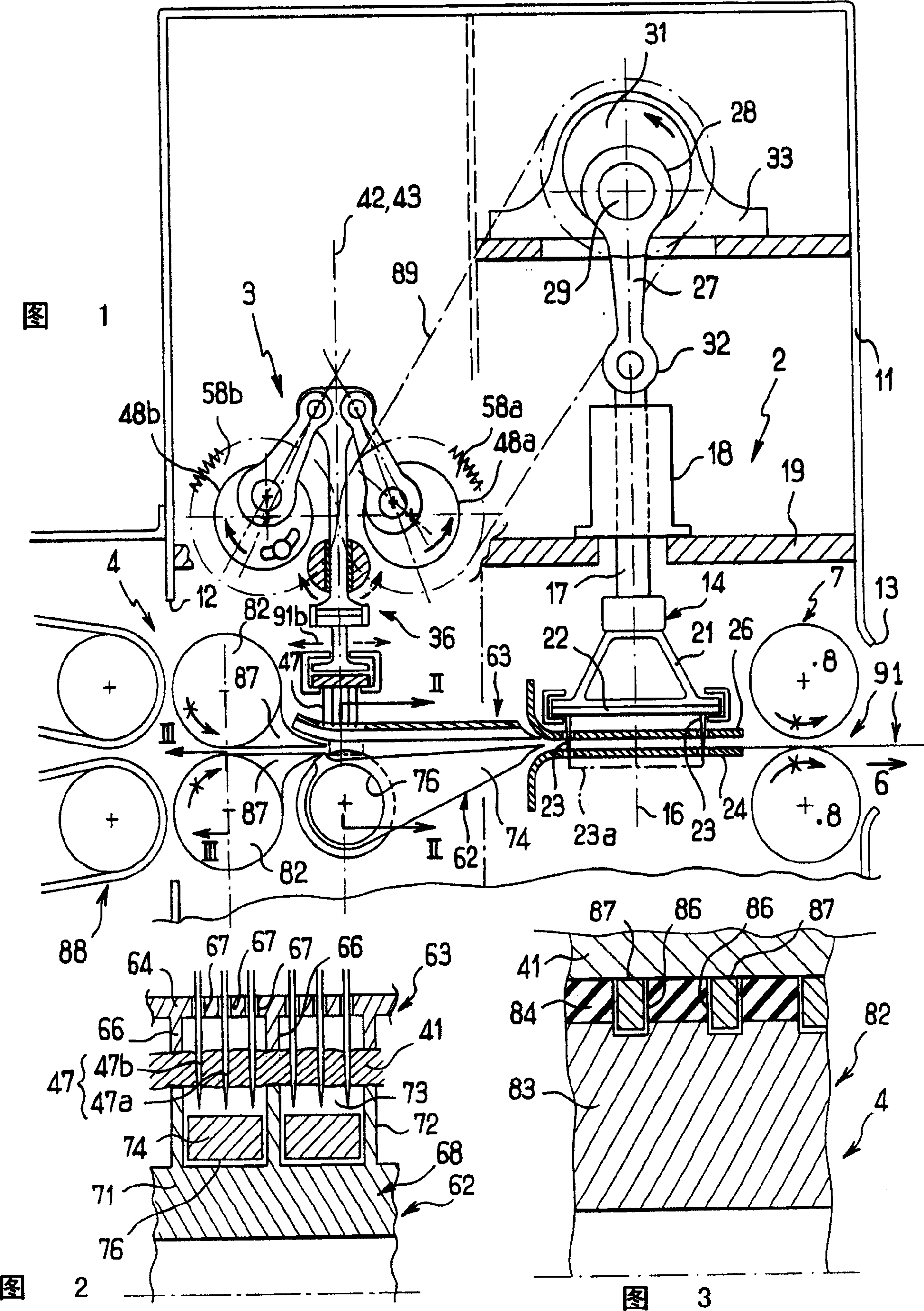

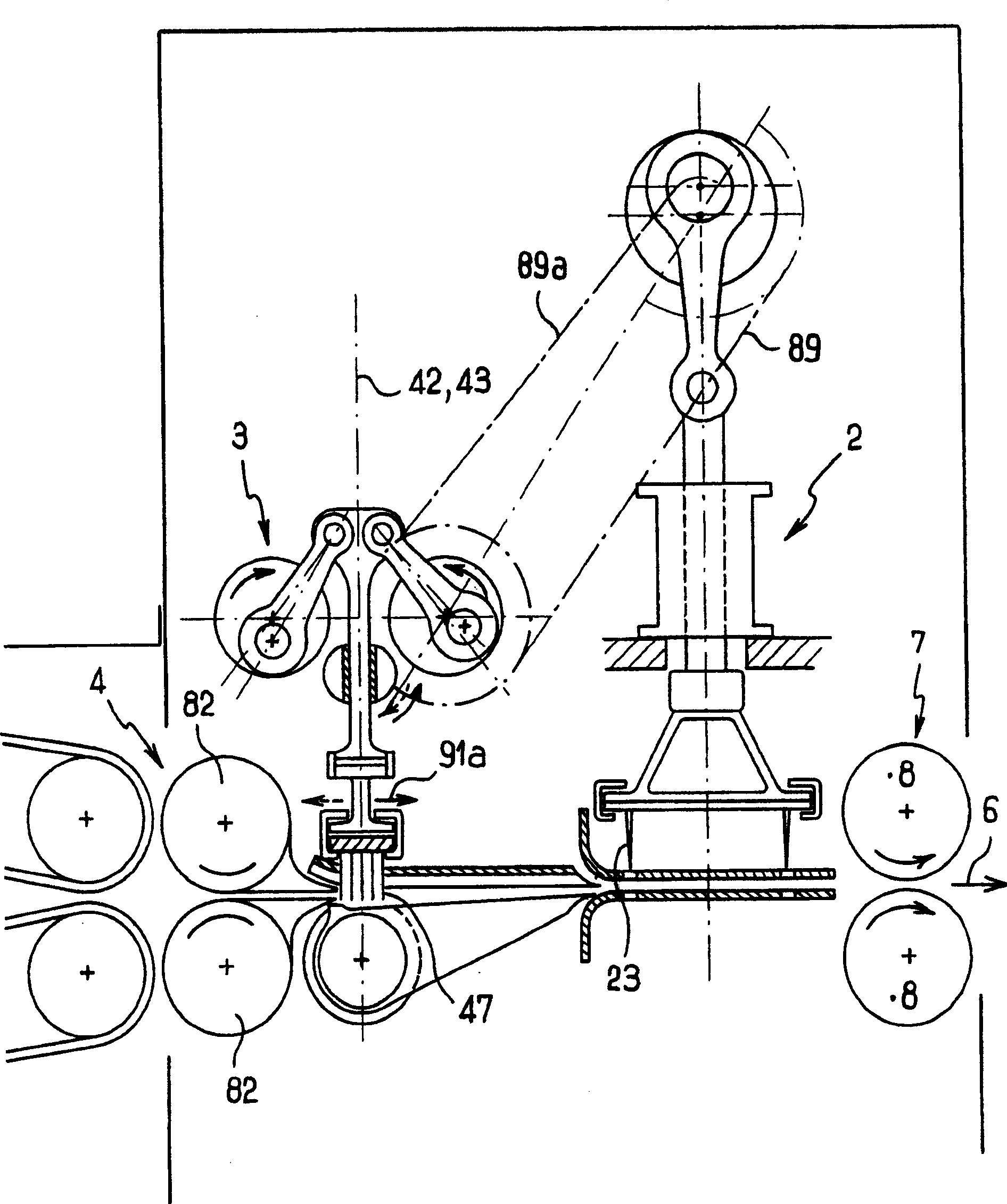

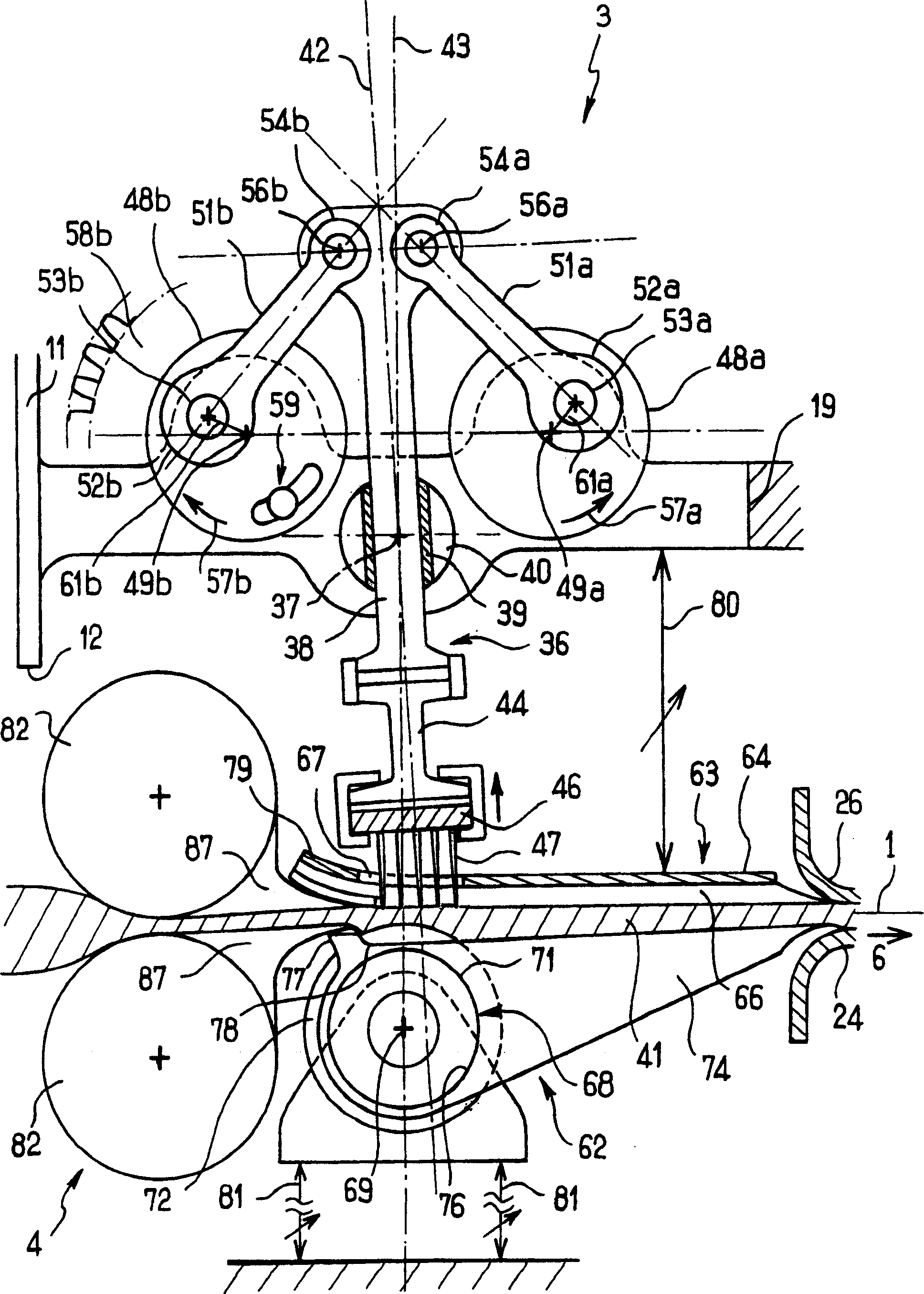

[0047] In the embodiment shown in FIG. 1 , along the path 1 of the fiber fleece (not shown in FIG. 1 ), the device comprises a prepunching device 3 according to the invention directly in front of the consolidation device 2 . In addition, a feeding device 4 is arranged upstream of the prepunching device 3 with respect to the advance direction 6 of the fleece, and an extraction device 7 downstream of the needling device 2 comprises two rotating rollers 8 between which a Gripping wires or jaws 9 for the fleece along a substantially planar path 1 .

[0048] Subsequently, "far" and "near" mean "farther" and "closer" to the plane of path 1, respectively.

[0049] The pre-punching device 3 and the needling device 2 are jointly located in a single cabinet 11 and thus form part of the same machine. The cabinet 11 has an inlet window 12 in which the feeding device 4 is installed and an outlet window 13 in which the extraction device 7 is installed.

[0050] The acupuncture device 2 it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com