Method for discriminating cable-assembly production

A cable assembly and identification method technology, applied in the field of cable assembly production identification, can solve problems such as detecting unqualified products, and achieve the effects of improving process, improving product qualification rate, and maintaining neat and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the implementation and accompanying drawings.

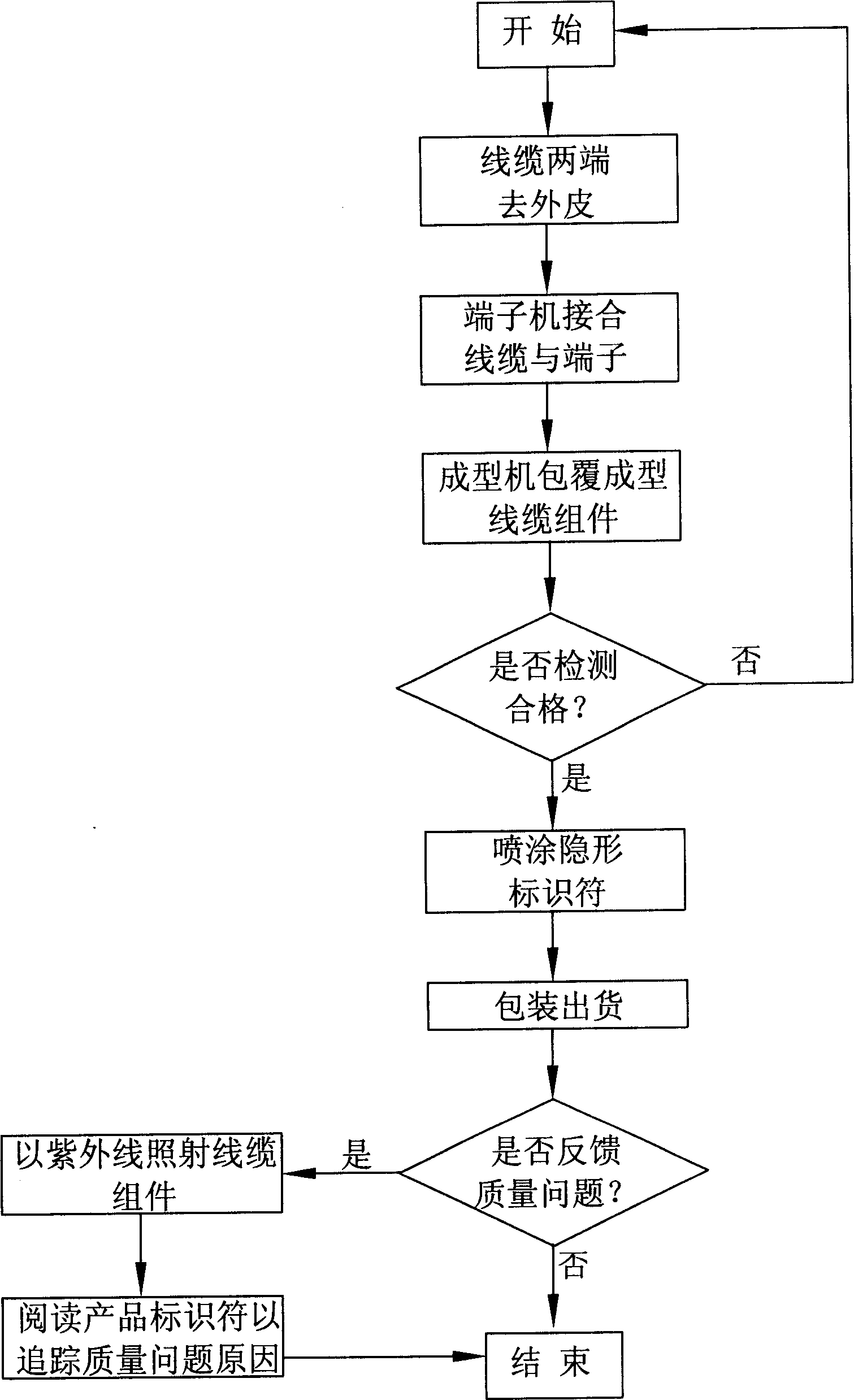

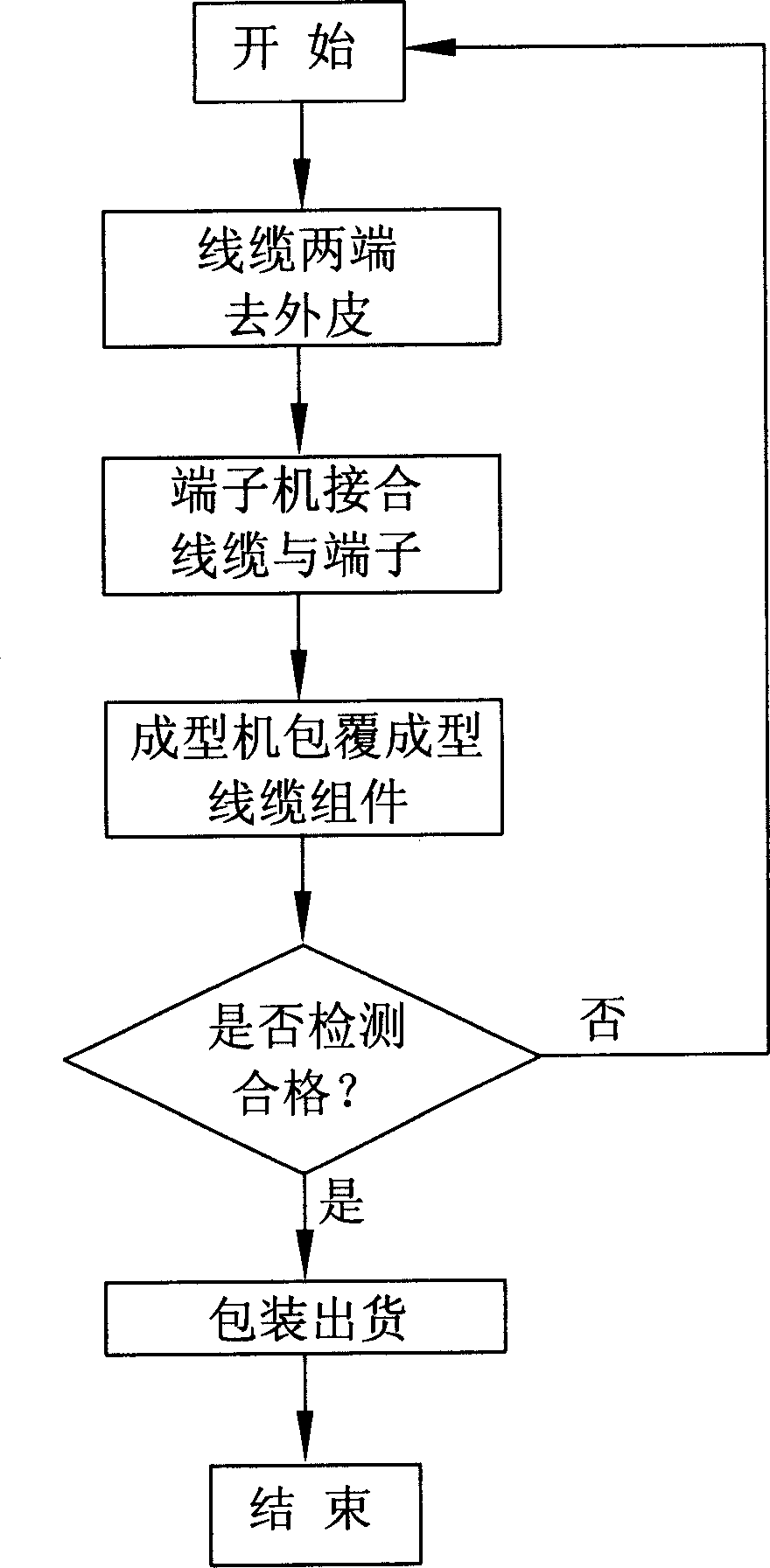

[0016] see figure 1 , the production identification method of the cable assembly of the present invention comprises the following steps:

[0017] Firstly, the cable assembly is assembled and tested, that is, the following steps are performed: peel off the sheath at both ends of the cable, and then use the terminal machine to join the terminal and the two ends of the cable into one, and then use the molding machine to overmold the cable assembly. , such as a cable assembly that is formed into a cable with plugs at both ends; the completed cable assembly begins to enter the inspection process, and the unqualified products will be inspected and reworked.

[0018] The surface of the qualified cable assembly will be sprayed with an invisible identifier, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com