Multi-station electric operation mechanism

A technology of electric operation and operation mechanism, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of inability to realize, low transmission speed, etc., and achieve convenient operation and maintenance, good reliability, and small overall volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

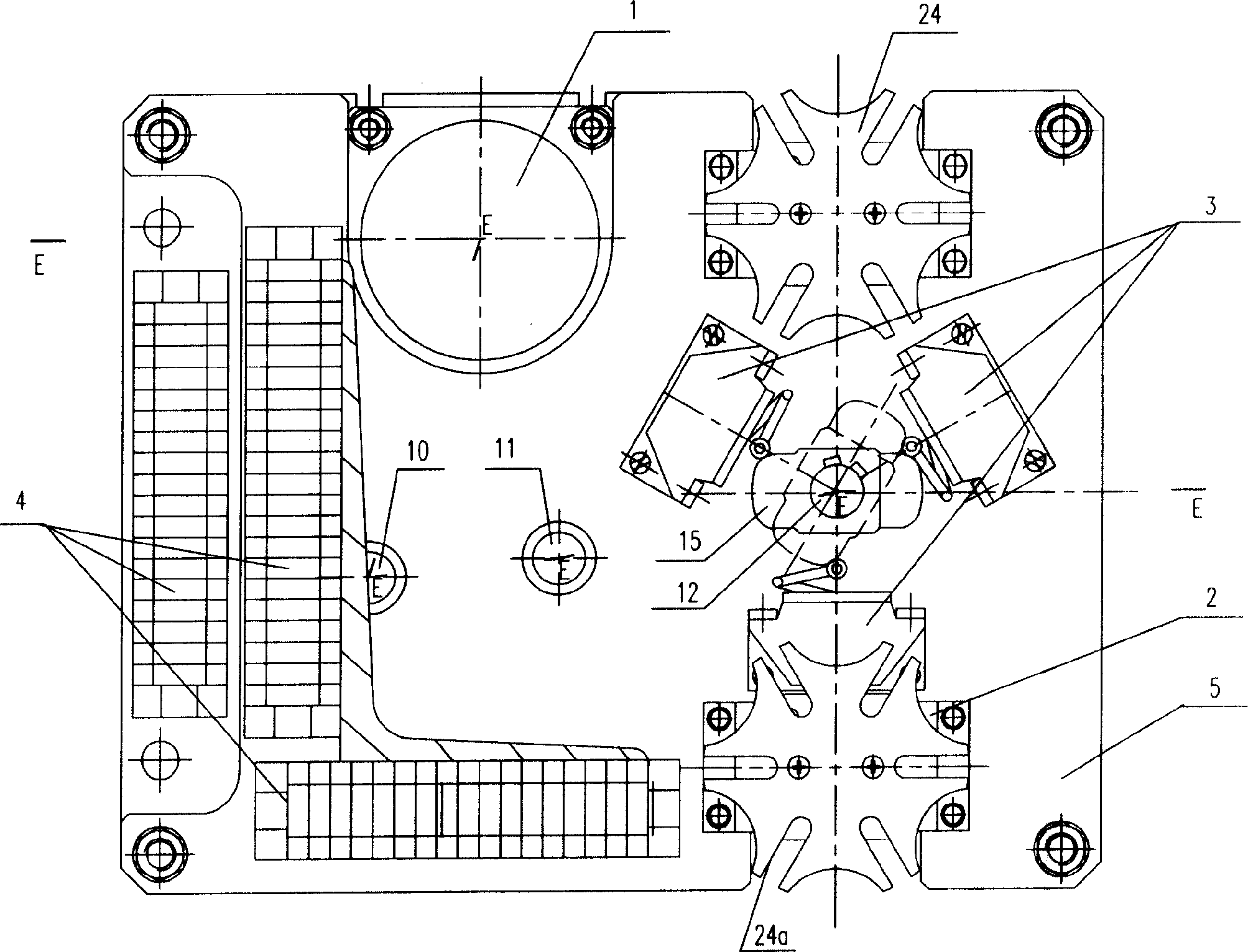

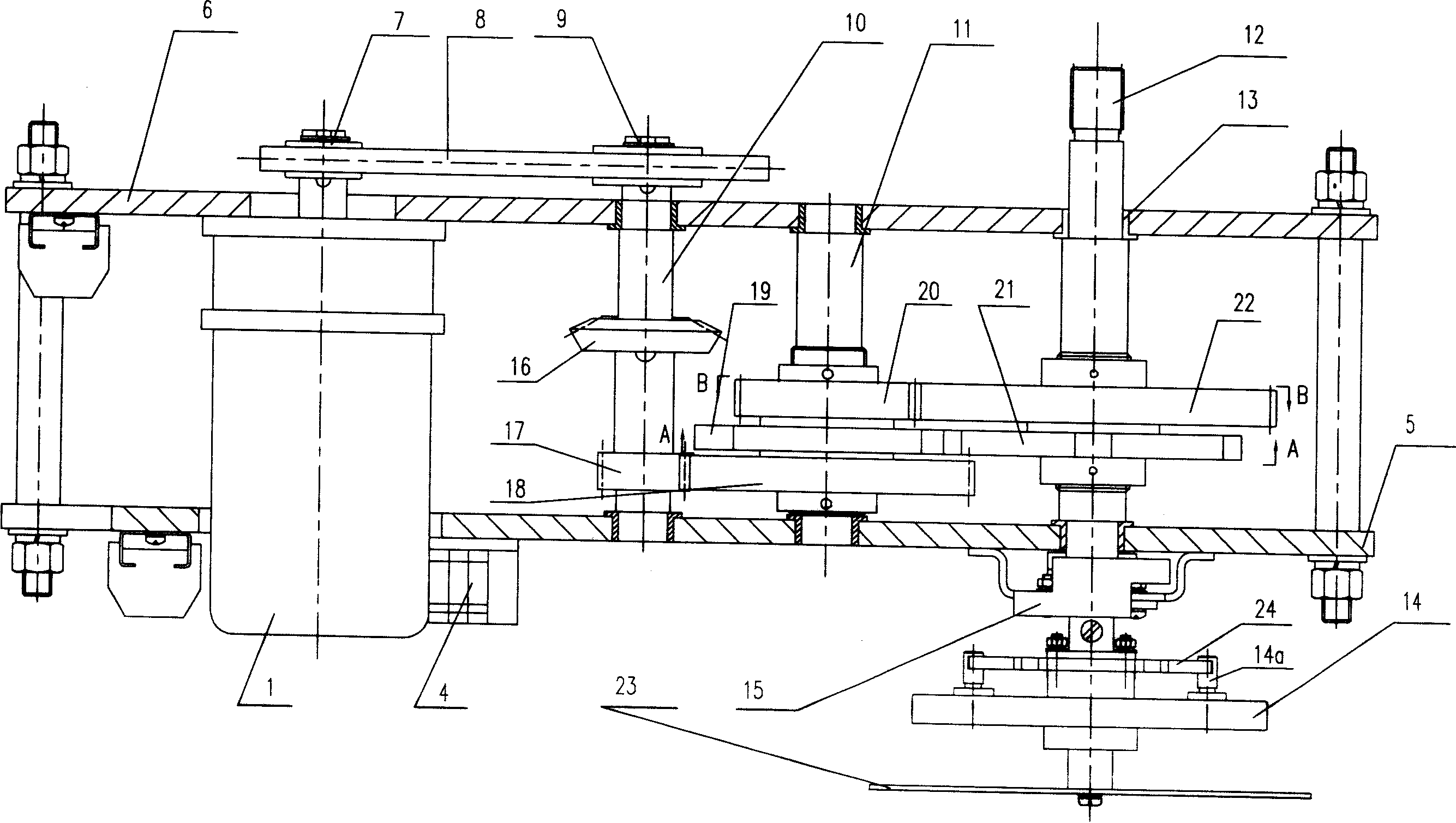

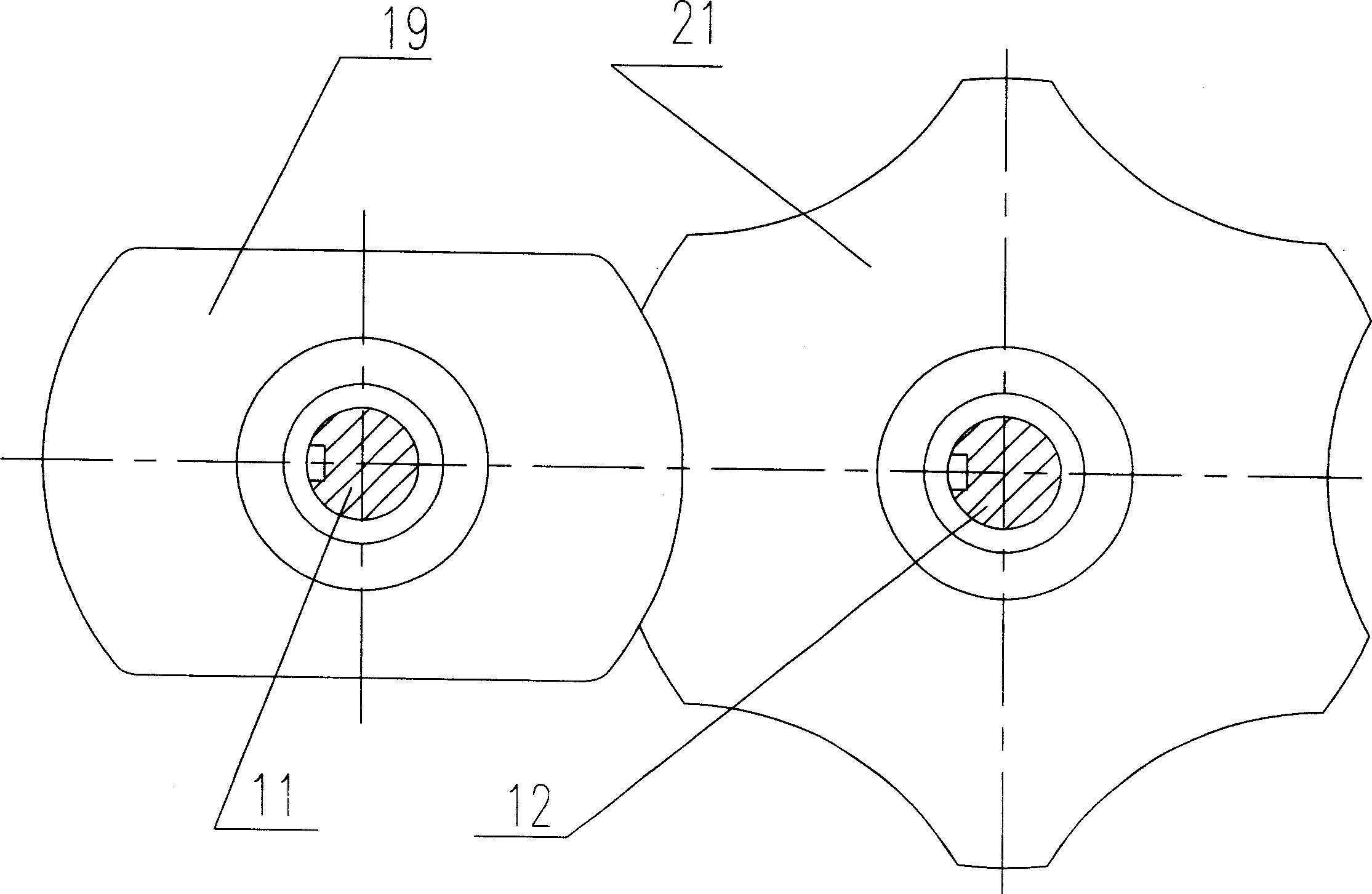

[0020] Figure 1-7 Shown is an embodiment of a five-station electric operating mechanism. The front panel 5 and the rear panel 6 constitute the support of the operating mechanism, and the front panel and the rear panel are fixed together by four studs. The motor 1 is fixed on the rear panel 6, and a reducer can be installed at the output end of the motor 1 to play the role of one-stage speed change. A sprocket 7 is also installed on the output shaft. The deceleration transmission shaft 10, the transmission main shaft 11 and the operating shaft 12 are connected in parallel between the front panel 5 and the rear panel 6 at a certain distance. The two ends of each shaft are provided with copper sleeves to form a rotating friction pair. . A sprocket 9 is provided at one end of the reduction drive shaft 10, and the sprocket 7 is connected with the sprocket 9 through a chain, and plays a two-stage deceleration function. A bevel gear 16 and a spur gear 17 are arranged in the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com