Flexible carrier having regions of higher and lower energy treatment

A corona treatment and bracket technology, applied in the field of flexible brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

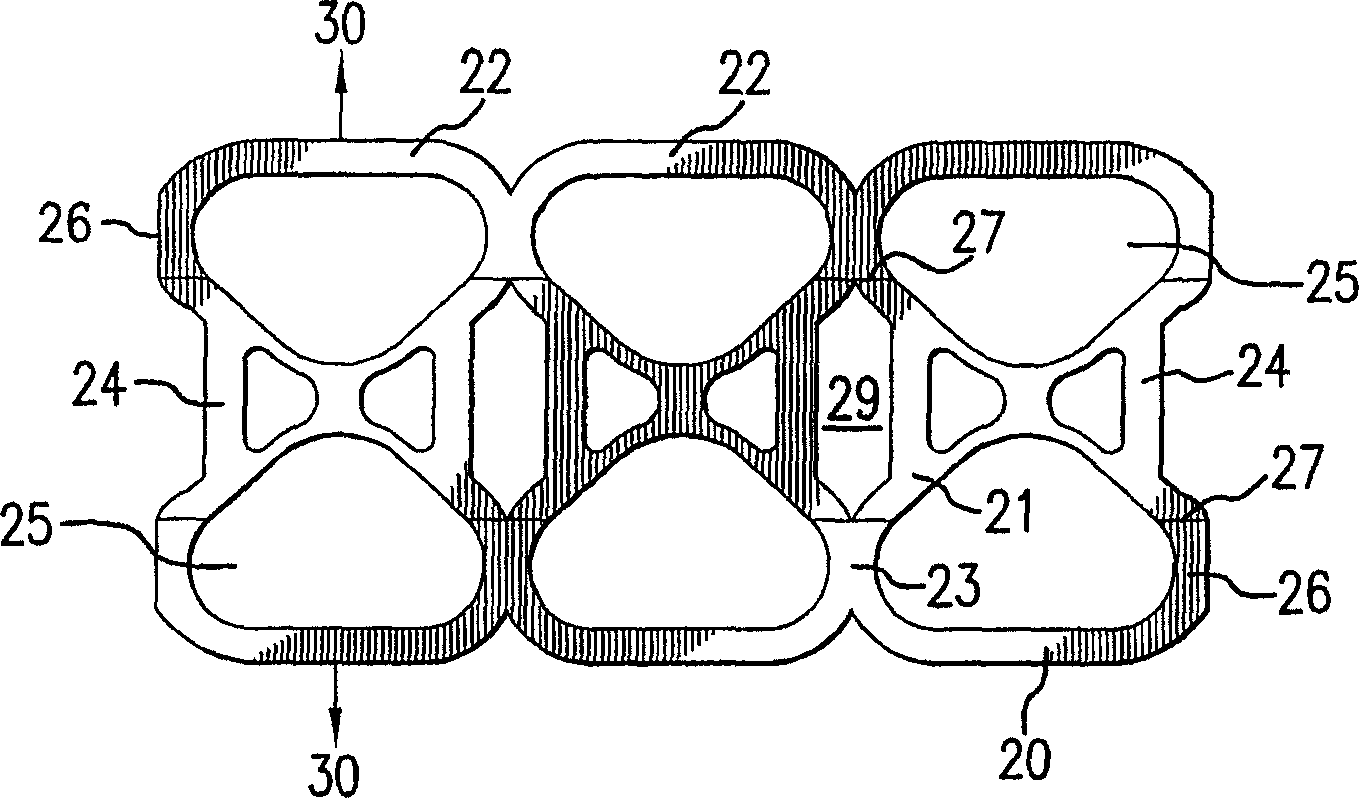

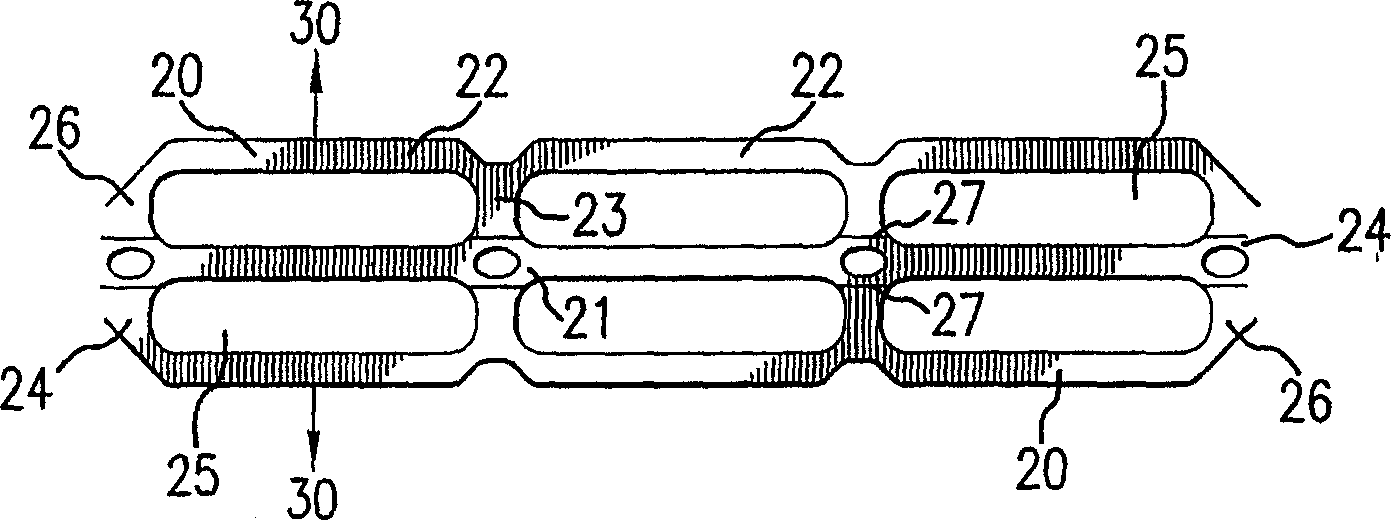

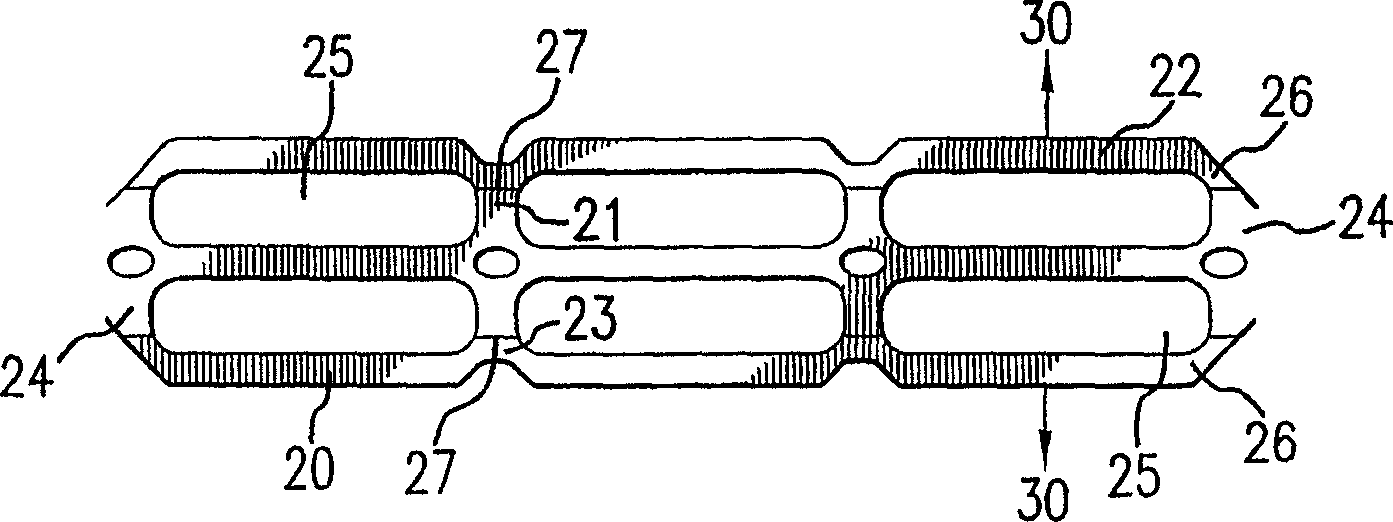

[0048] In the following examples, corona-treated plate samples were useful for making similar image 3 flex bracket shown in . Each flexible carrier plate is formed from ethylene-carbon monoxide copolymer, which has a density of 0.927 g / cm 3 , a melt index of 0.5 g / 10 min., and a carbon monoxide comonomer content of 0.75% by weight. The ethylene-carbon monoxide comonomer was mixed with 500 ppm of oleamide lubricant.

[0049] In Example 1, five samples were prepared with non-corona treatment, and with 1.6KW power, a line speed of 80ft / min. and a dwell time of 0.75 seconds, producing 96watts / ft 2 / min. Watt density, with similar Figure 5 Five samples were corona treated with the corona treatment equipment shown in . Corona treatment equipment is manufactured by Corona Designs under the trade name POWERHOUSE. Corona-treated carrier sheets are corona-treated several days after preparation to allow sufficient lubricant migration prior to corona treatment.

[0050] Estimating t...

Embodiment 3

[0054] Example 3 was performed using a plasma treatment available from Plasmatreat Corp under the trade name FLUME. A narrow band 0.75 inches wide is selectively plasma treated. The full power of the plasma treatment is about 0.25kw. Sample pieces were selectively processed at 20, 40, 60 and 80 feet / min. The resulting process residence times were 0.25 seconds, 0.125 seconds, 0.083 seconds, and 0.0625 seconds, respectively. Selective plasma treatment is done at all speeds, but the treatment is heavy at low speeds. These samples were not further evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com