Extensible protection board of machine tool

A technology for telescopic guards and machine tools, which can be used in maintenance and safety accessories, metal processing machinery parts, large fixed members, etc. It can solve the problem of high cost of the second cover component, improve support and posture retention, and prevent vibration And swing, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

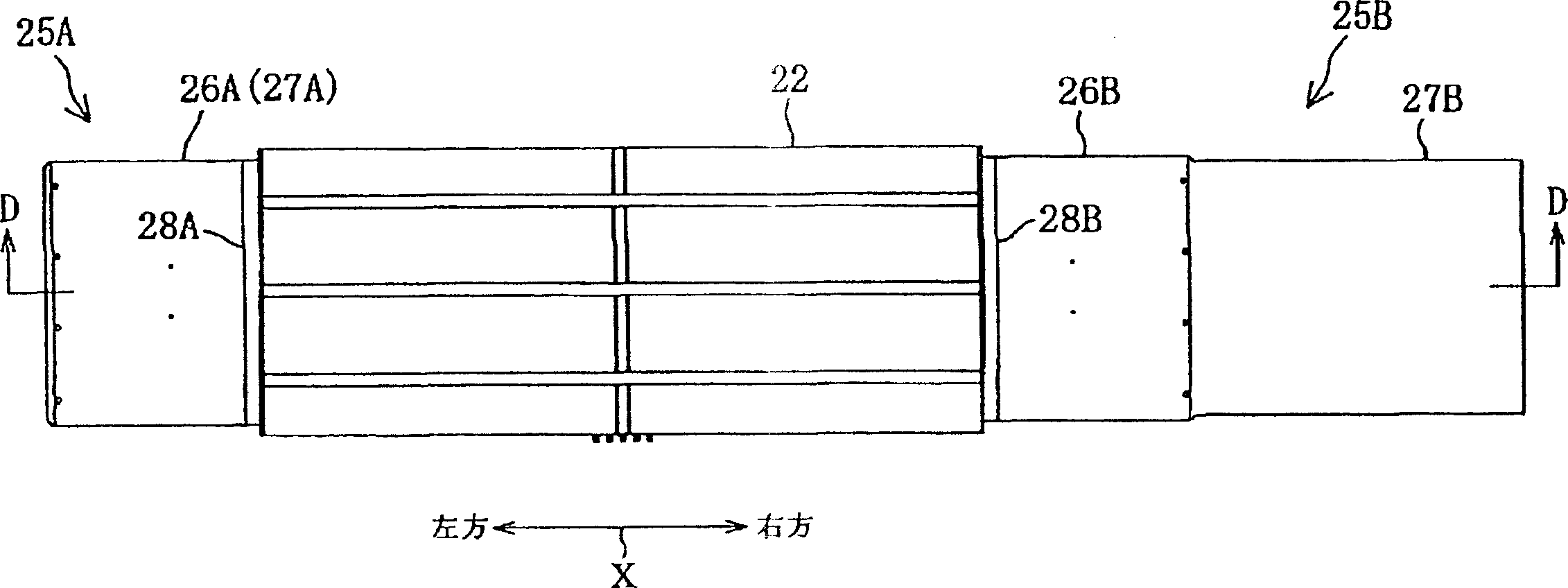

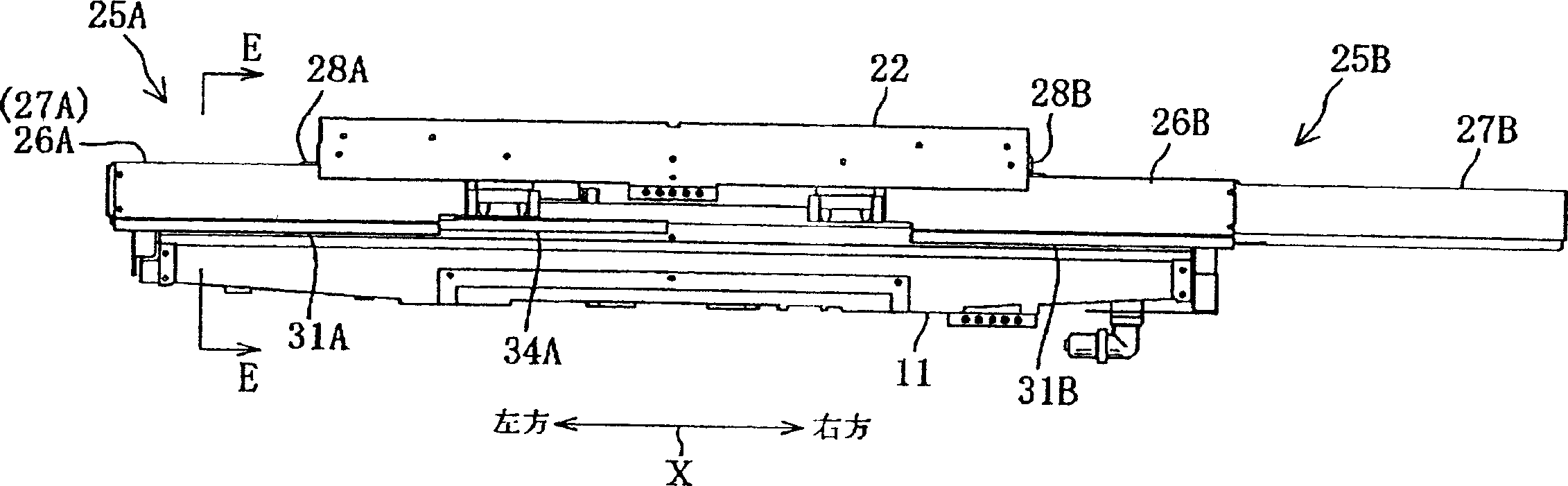

[0041] The telescopic guard plate of the machine tool of this embodiment is provided with a plurality of cover bodies that are assembled so as to be relatively movable, overlap inside and outside, and expand and contract through relative movement. A pair of guide members is provided on the upper portion, and a pair of guided members engaged with the pair of guide members is provided so as to extend cantilever from the base end portion of the outer cover of the inner cover toward the outer cover side.

[0042] (Example)

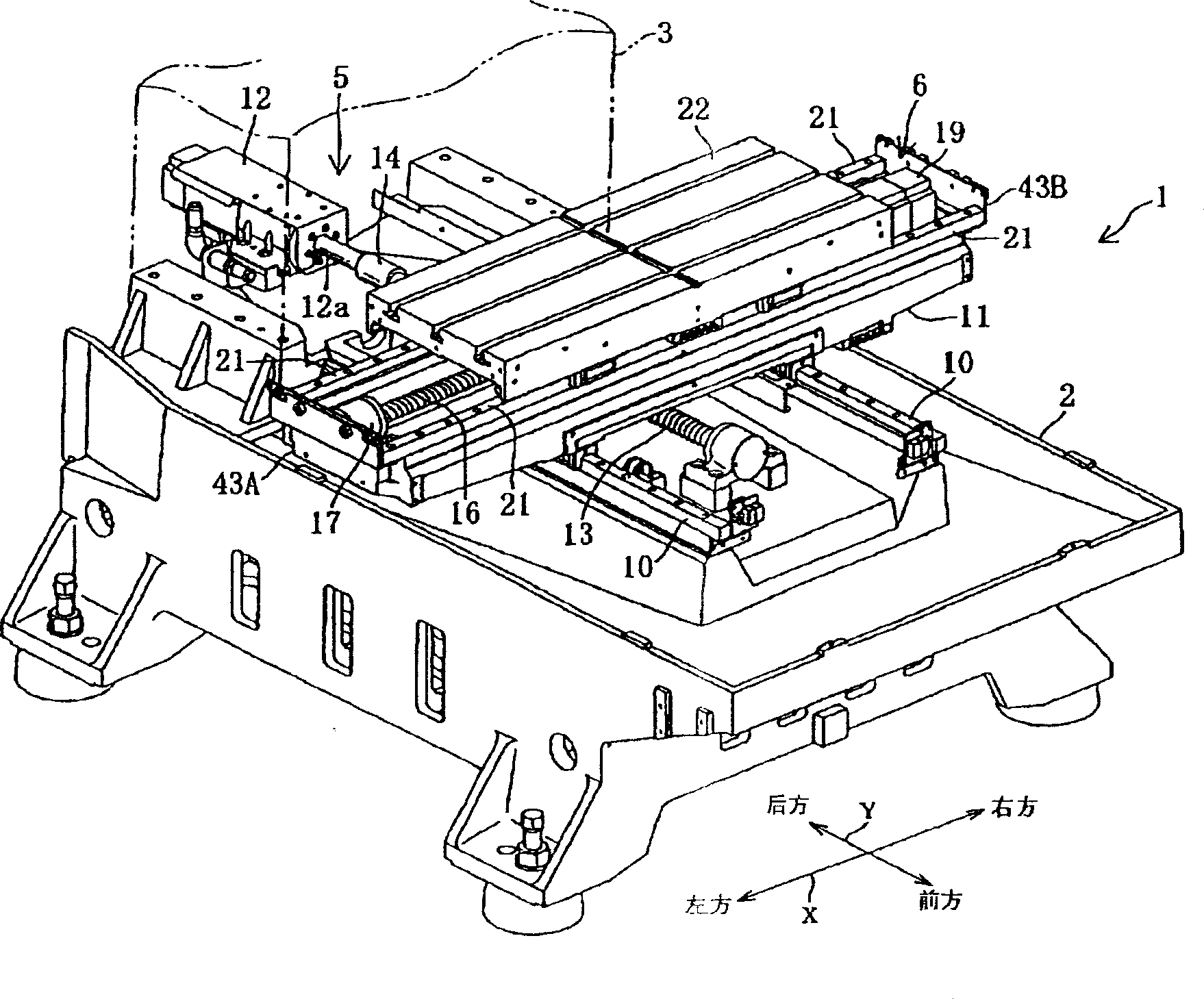

[0043] The machine tool 1 as a general vertical machining center will be described. Such as figure 1 As shown, the base body 2 has a column 3 erected on its rear side. On the front side of the column 3, the base body 2 is equipped with a Y direction drive mechanism 5 for moving the movable table 22 in the Y direction and an X drive mechanism 5 for moving the movable table 22 in the X direction orthogonal to the Y direction. Directional drive mechanism 6.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com