Multifunctional sander

A sanding machine, multi-functional technology, applied in the direction of grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of troublesome work, inconvenient, large vibration, etc., and achieve cost reduction, simple structure, and few parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

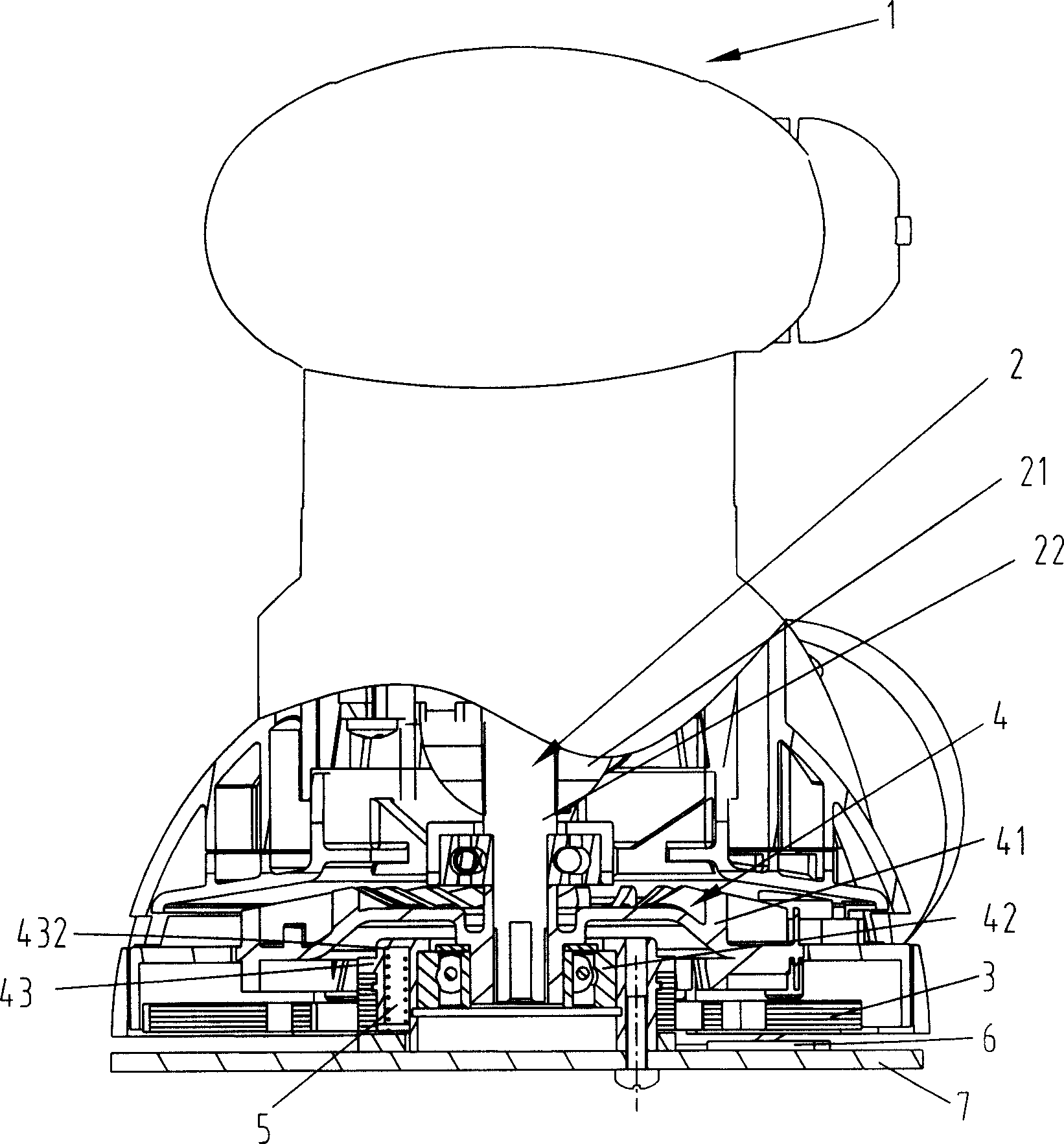

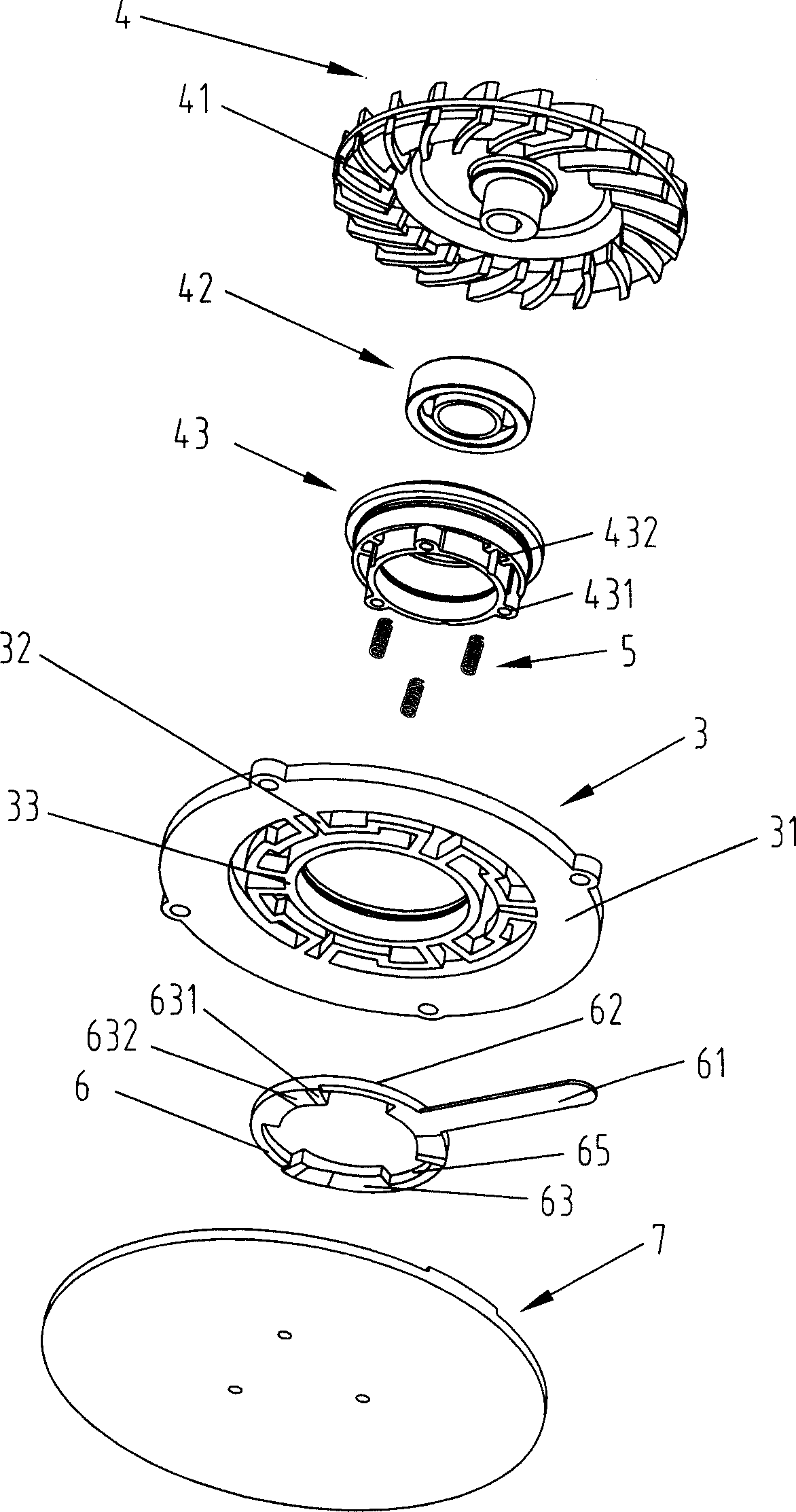

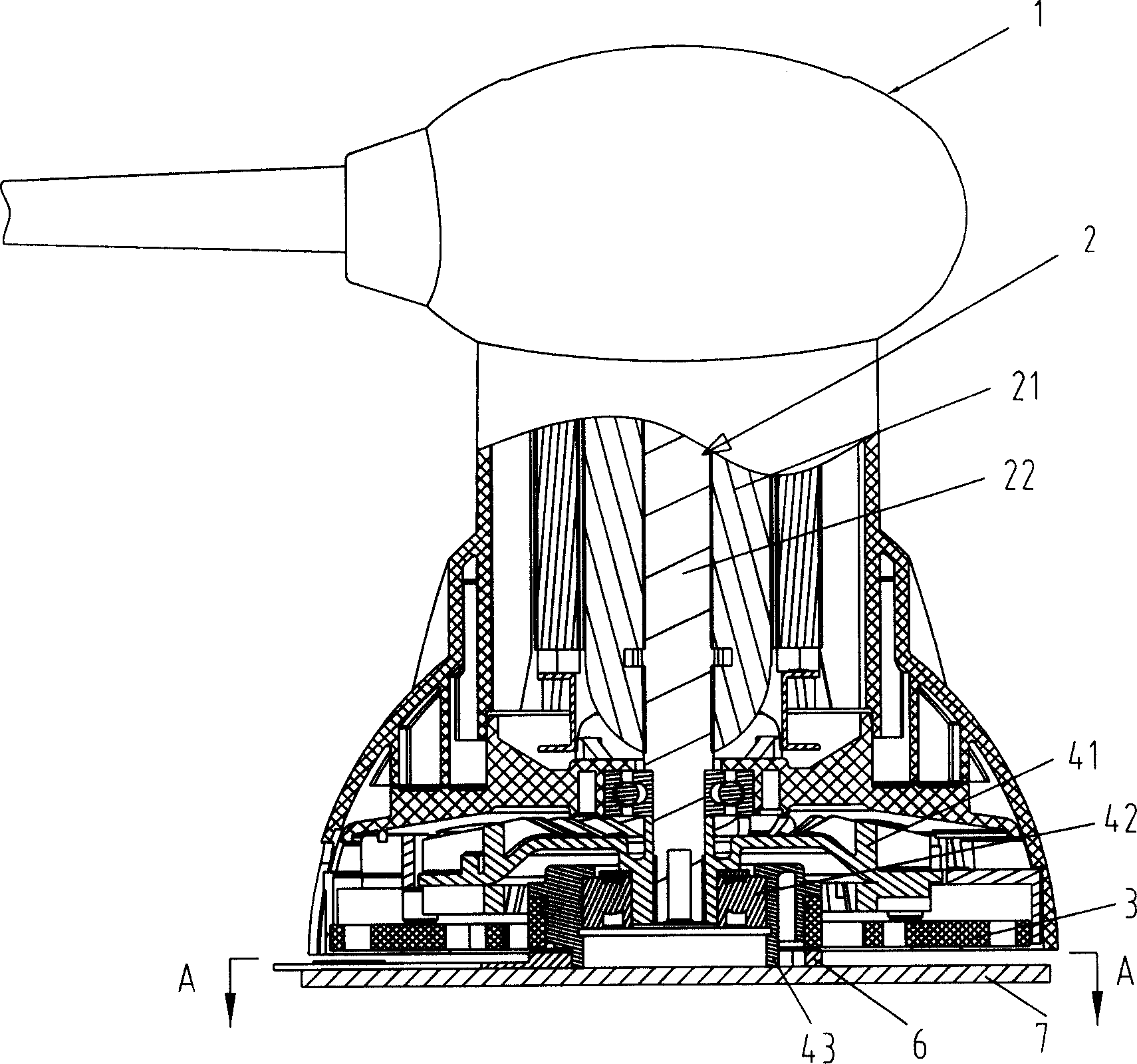

[0049] The essence of the invention lies in that a conversion part is added to the multifunctional sander, and the mating relationship between the brake part and the bottom plate can be changed through the conversion part, thereby realizing the two functions of circular sand and plate sand . When the conversion part is arranged between the base plate and the brake part, moving the conversion part can change the indirect mating relationship between the base plate and the brake part; when the conversion part is arranged between the housing and the brake part, moving the conversion part will The direct mating relationship between the base plate and the brake can be varied.

[0050] The creative concept of the present invention will be described below with regard to the best embodiment, and certainly can not be limited to the structure of the specific embodiment listed below, and the structures based on the concept of the present invention all belong to the scope of protection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com