Aritifical stone polished brick and its producing method

A production method and technology for polishing tiles, which are used in grinding/polishing equipment, grinding machines, machine tools suitable for grinding workpiece planes, etc., and can solve the problems of no natural effect, lack of jade feeling, lack of three-dimensional effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

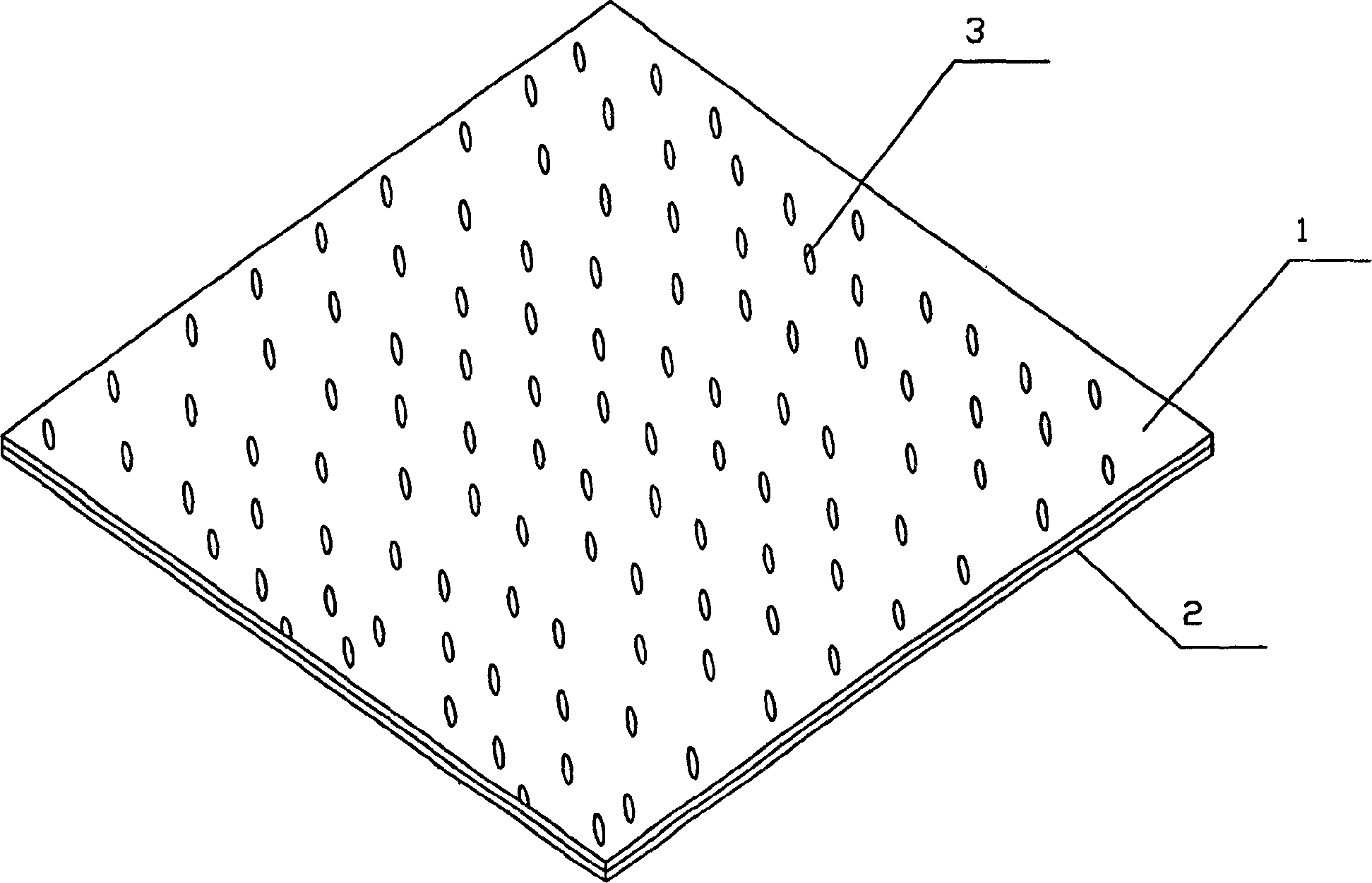

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0014] The production method of the imitation stone polished tile of the present invention is realized in this way, including powder preparation, multi-tube cloth, ceramic tile body molding, drying, firing, and polishing steps in sequence, and its special feature is that the powder is made of transparent formula powder Composed of traditional ceramic powder, the transparent formula powder is mainly composed of one or more materials containing one or more chemical components of SiO2, Al2O3, MgO, K2O, Na2O, which are ball milled, sieved to remove iron, It is made by milling, stale, and micronized powder, wherein the content of SiO2 in the transparent formula powder is 66-75%wt, the content of Al2O3 is 16-25%wt, the content of MgO is 0.6-2.5%wt, and the content of K2O 0.5-2.5%wt, the content of Na2O is 4.5-10%wt, and the content of transparent formula powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com