Electromagnetic type bin level meter

A technology of electromagnetic force and material level meter, applied in the field of material level meter, can solve the problems of not very ideal, measurement error, inconvenient work, etc., and achieve the effect of accurate and reliable signal, long service life and strong sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

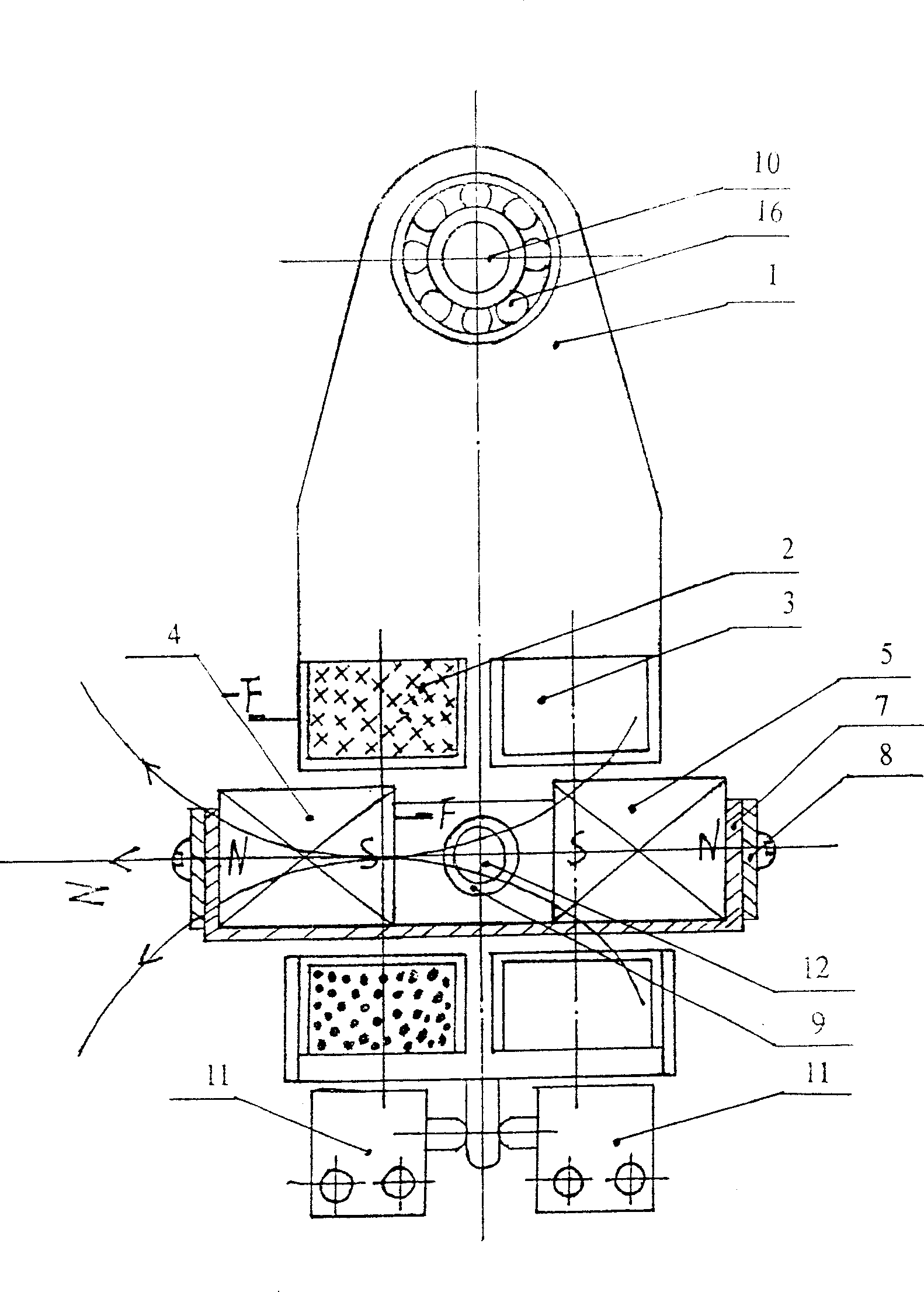

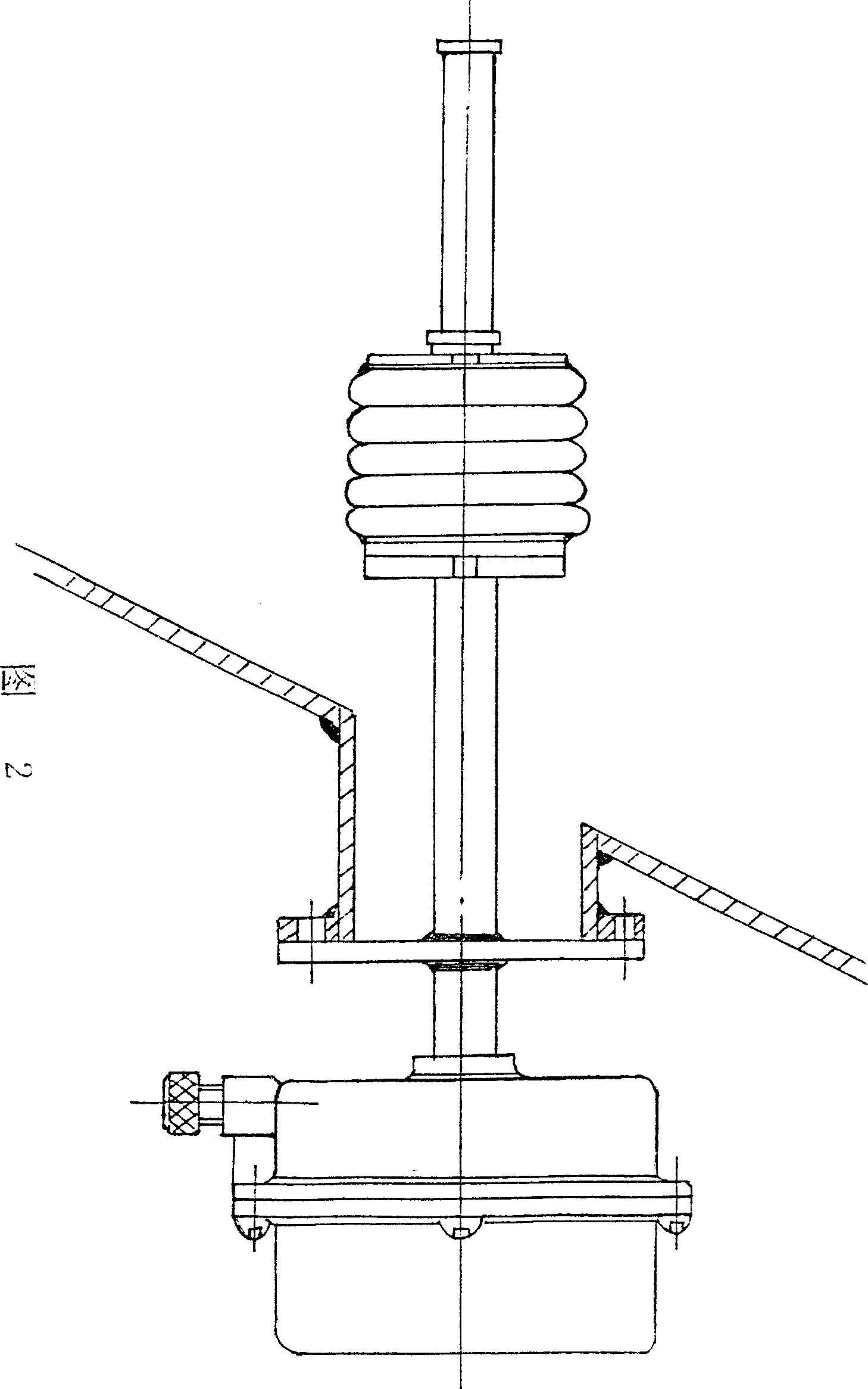

[0024] figure 1 It shows the electromagnetic force type material level gauge and the force transmission mode of the electromagnetic force transmission mechanism.

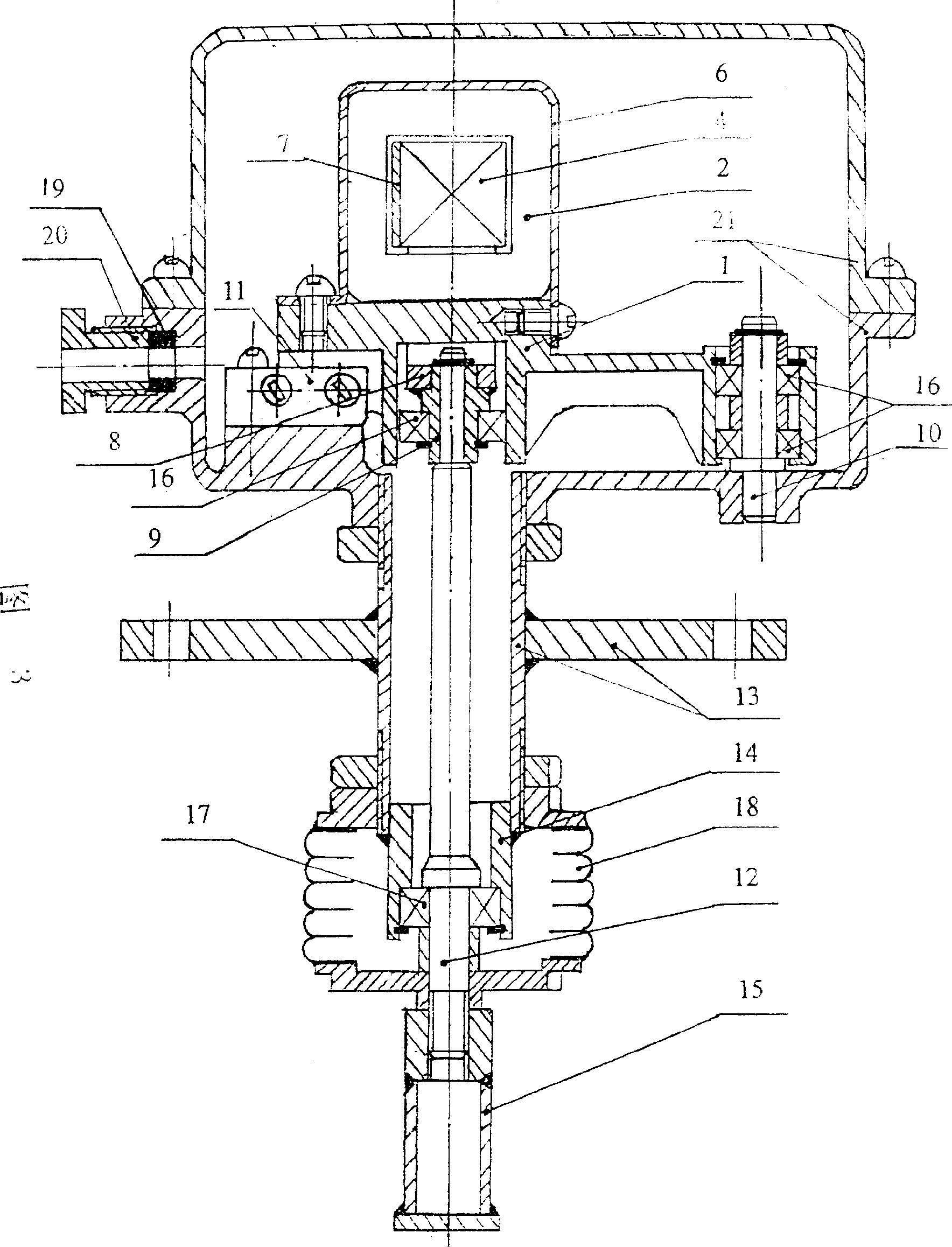

[0025] The electromagnetic force transmission mechanism consists of a coil support 1, a left coil 2, a right coil 3, a left magnet 4, a right magnet 5, a hoop 6, a magnet support 7, a toggle bracket 8, a toggle shaft 12, a detection shaft 15, Supporting shaft 10, bearing 16, electrical switch 11, etc., left coil 2, right coil 3, the two coil through holes at the lower part of coil support 1 are aligned, clamped on the coil support with clamp 6 and screws Fixing, drill holes in the center of left magnet 3 and right magnet 5, fix them on both sides of the magnet bracket with screws, put them into the through holes of left coil 2 and right coil 3, and fix magnet bracket 7 on the toggle bracket with screws On 8 both sides wing arms, toggle support 8 is contained on the axle nose of toggle shaft 12 by supporting axle sl...

Embodiment 2

[0030] When the electromagnetic force transmission mechanism, its coil is a single coil type, and its magnet is a single magnet type, other structural connection modes are the same as example 1.

Embodiment 3

[0032] As the electromagnetic force transmission mechanism, its coil is a multi-coil type, its magnet is a multi-magnet, and other structural connection methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com