Improved structure of spiral anger and profiled semi screw pole body

A technology for improving the structure and auger pipe, applied in drill pipe, infrastructure engineering, drill pipe, etc., can solve problems such as easy blockage of the outlet, large drilling resistance, drill pipe damage, etc., to improve transmission efficiency and reduce workload. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

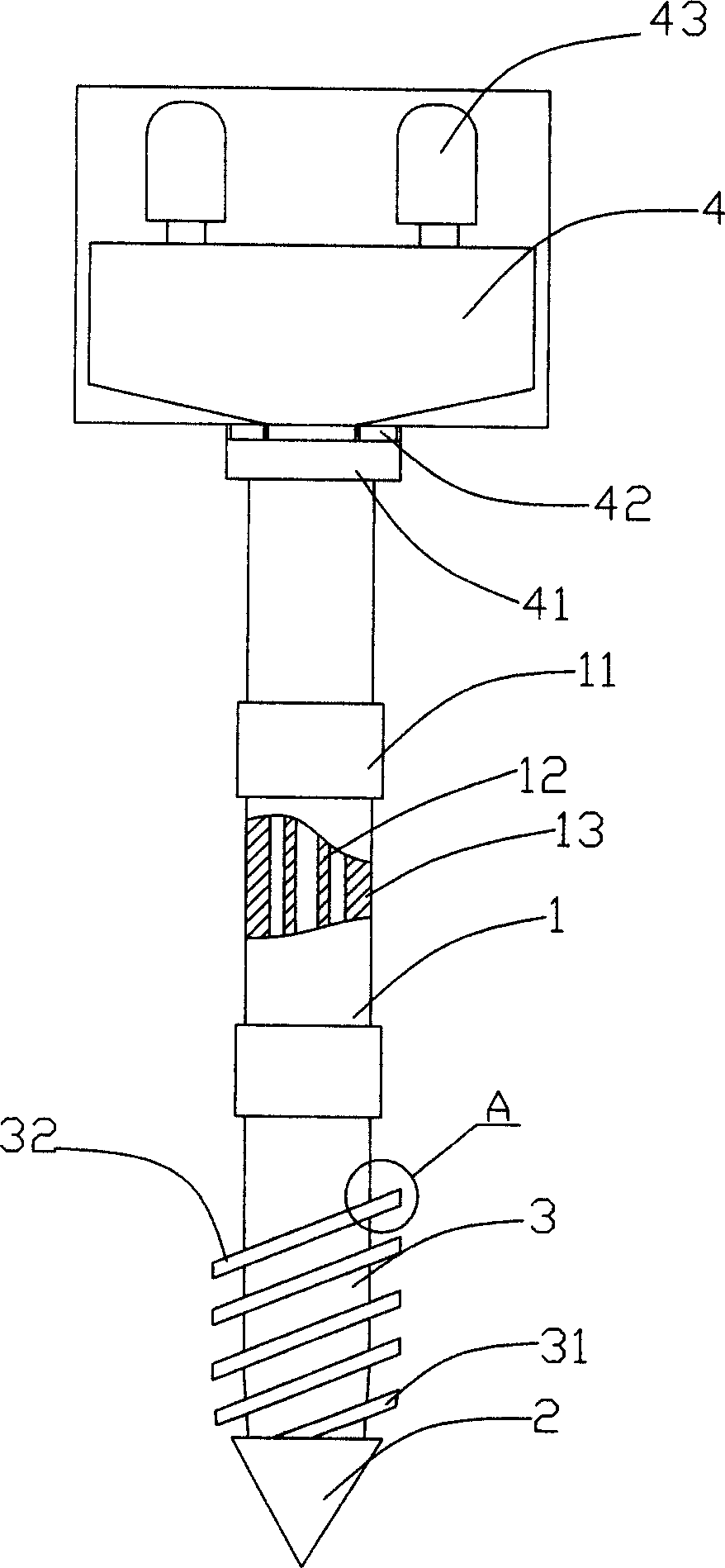

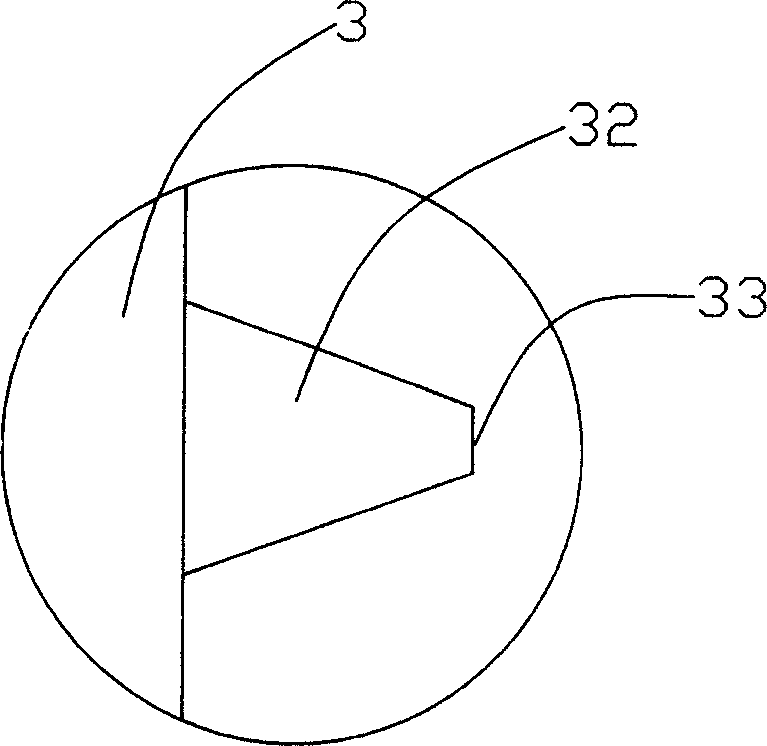

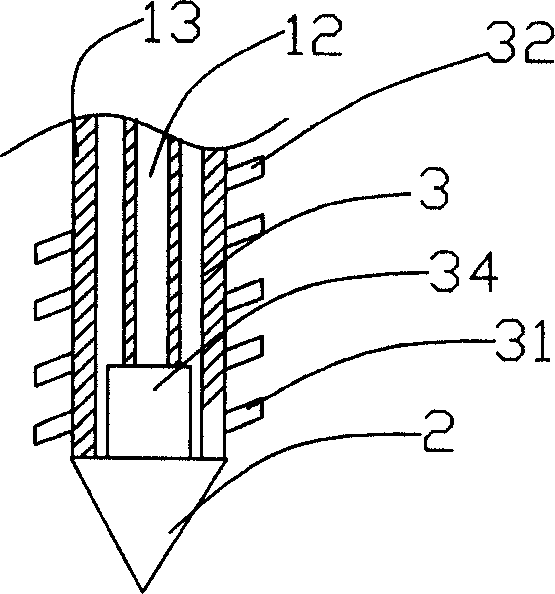

[0056] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0057] figure 1 As shown, the present invention is an improved structure of an auger drill rod, which includes a drill rod and a drill bit 2, and at least a part of the drill rod is a helical part. In this embodiment, the lower part of the drill rod is designed as a helical part 3, and the drill rod The top of the drill rod is a cylindrical part 1, and the top of the drill rod has a fixed support bearing 42 (the lower part of the bearing 42 is a fixed sleeve 41, so that the bearing 42 is fixed on the frame of the power unit 4), and the bearing 42 has two. The rod is fixedly connected with the power unit 4 (the top of the power unit is two motors 43), so that the directional force produced by the soil layer can be transferred and unloaded on the whole tower by the power unit 4 when the drill pipe is drilled down.

[0058] The above-mentioned bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com