Liquified natural gas pressure raising gasification process conprehensive energy using system in gas station

A technology for liquefied natural gas and gas filling stations, which is applied in gas/liquid distribution and storage, pressure vessels, fixed-capacity gas storage tanks, etc. It can solve the problems of installing complex purification systems and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

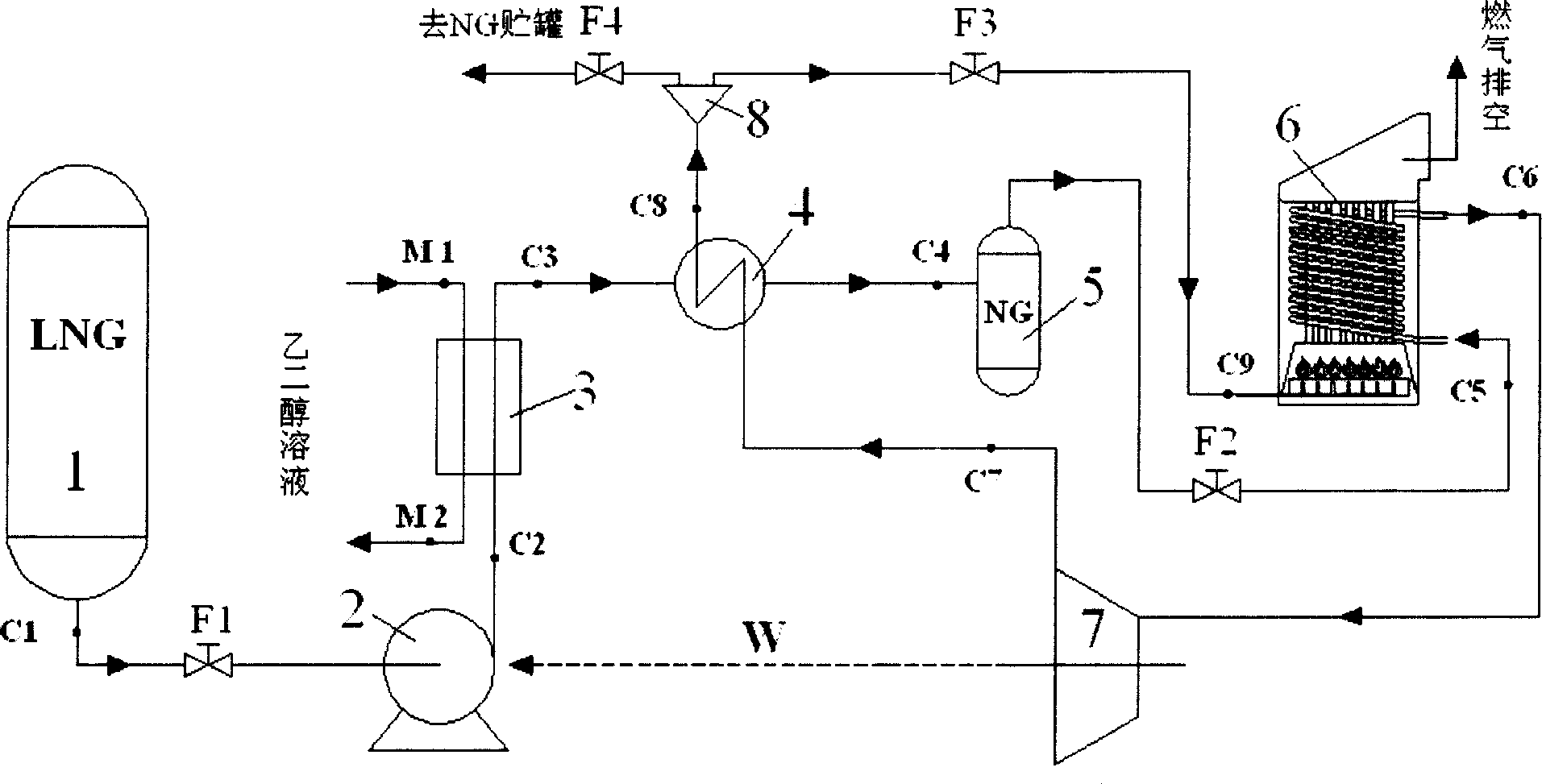

[0010] The comprehensive energy utilization system for LNG boosting gasification process in the gas filling station of the present invention comprises: LNG storage tank 1, low temperature liquid pump 2, low temperature heat exchanger 3, regenerator 4, high pressure gas storage tank 5, combustion chamber 6, Expander 7, diverter 8, LNG flow control valve F1, fuel gas regulating valve F3, flow control valves F2, F4 and connecting pipelines, etc.;

[0011] The sequence of connection methods of the above devices is: from the LNG outlet C1 at the bottom of the LNG storage tank 1, through the LNG flow control valve F1, connected to the cryogenic liquid pump 2, connected to the high-pressure LNG heat exchange channel C2→C3 of the cryogenic heat exchanger 3, connected to The high-pressure natural gas heat exchange channel C3→C4 of the regenerator 4 is connected to the high-pressure natural gas storage tank 5, through the flow control valve F2, connected to the high-pressure natural gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com