Method for optimising the operation of a hydrodynamic component integrated into a drive train of a vehicle

A transmission system and motor vehicle technology, applied in hydraulic brakes, mechanical equipment, rotary couplings, etc., can solve the problem that the torque cannot be fully utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

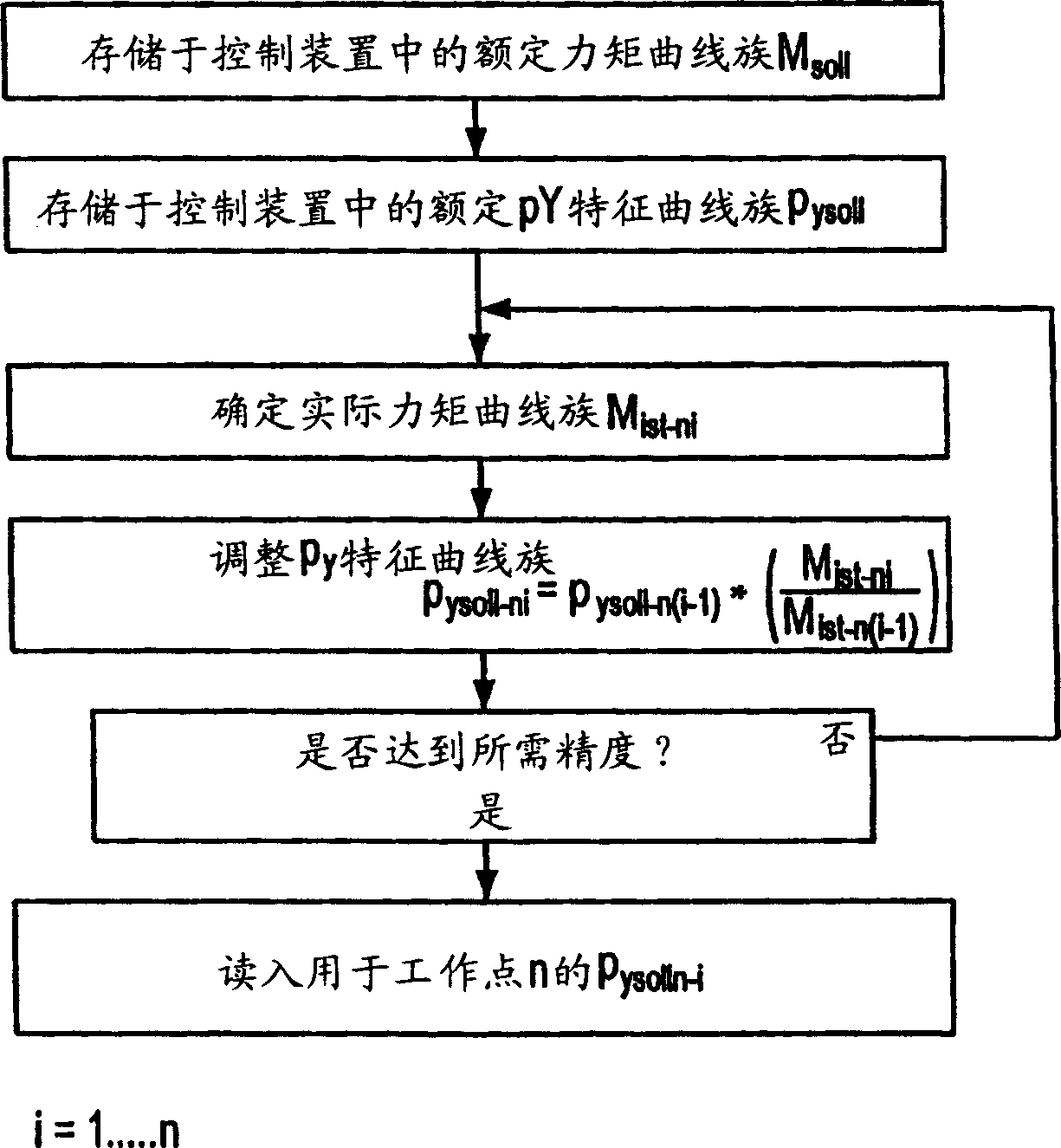

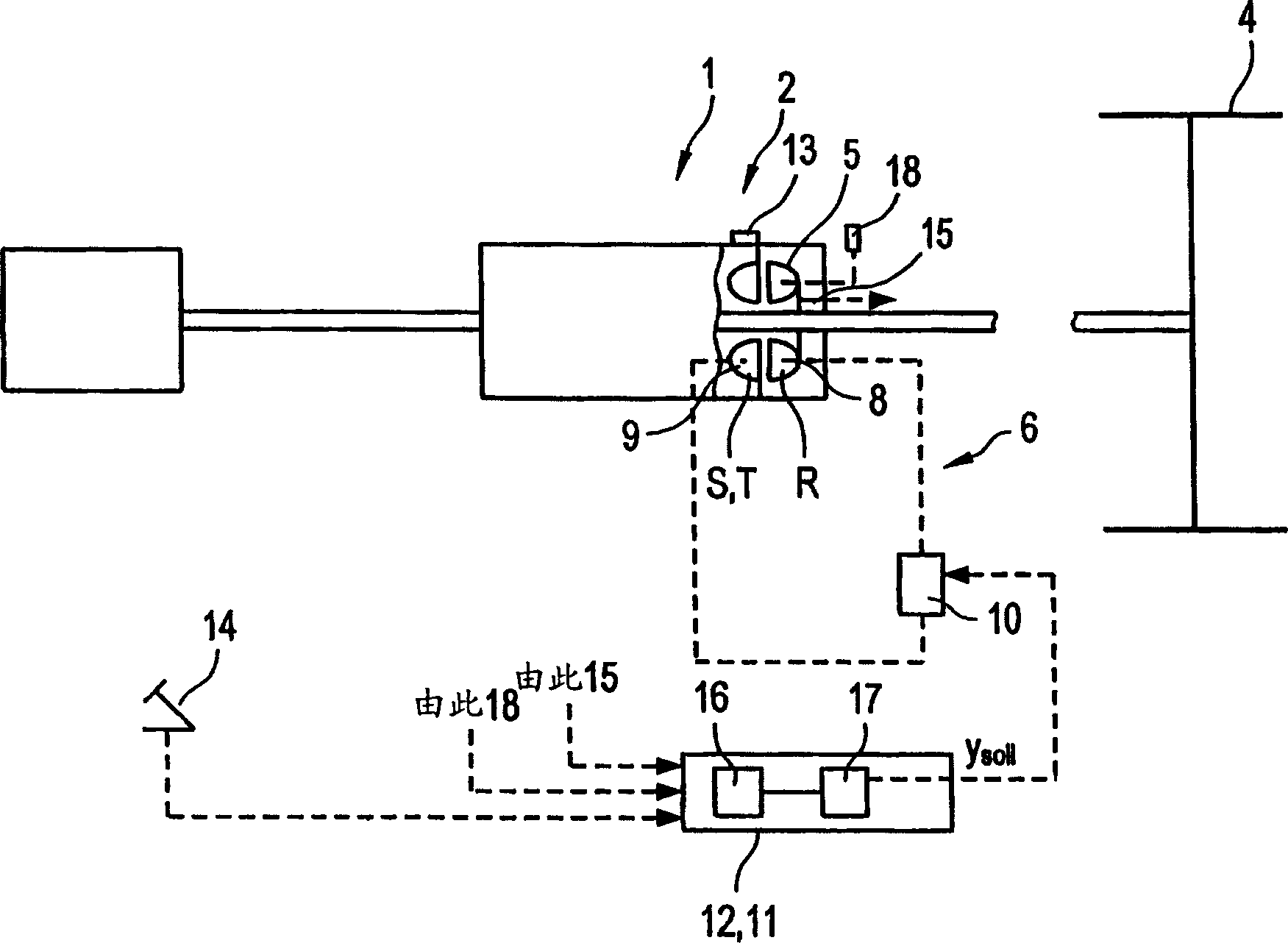

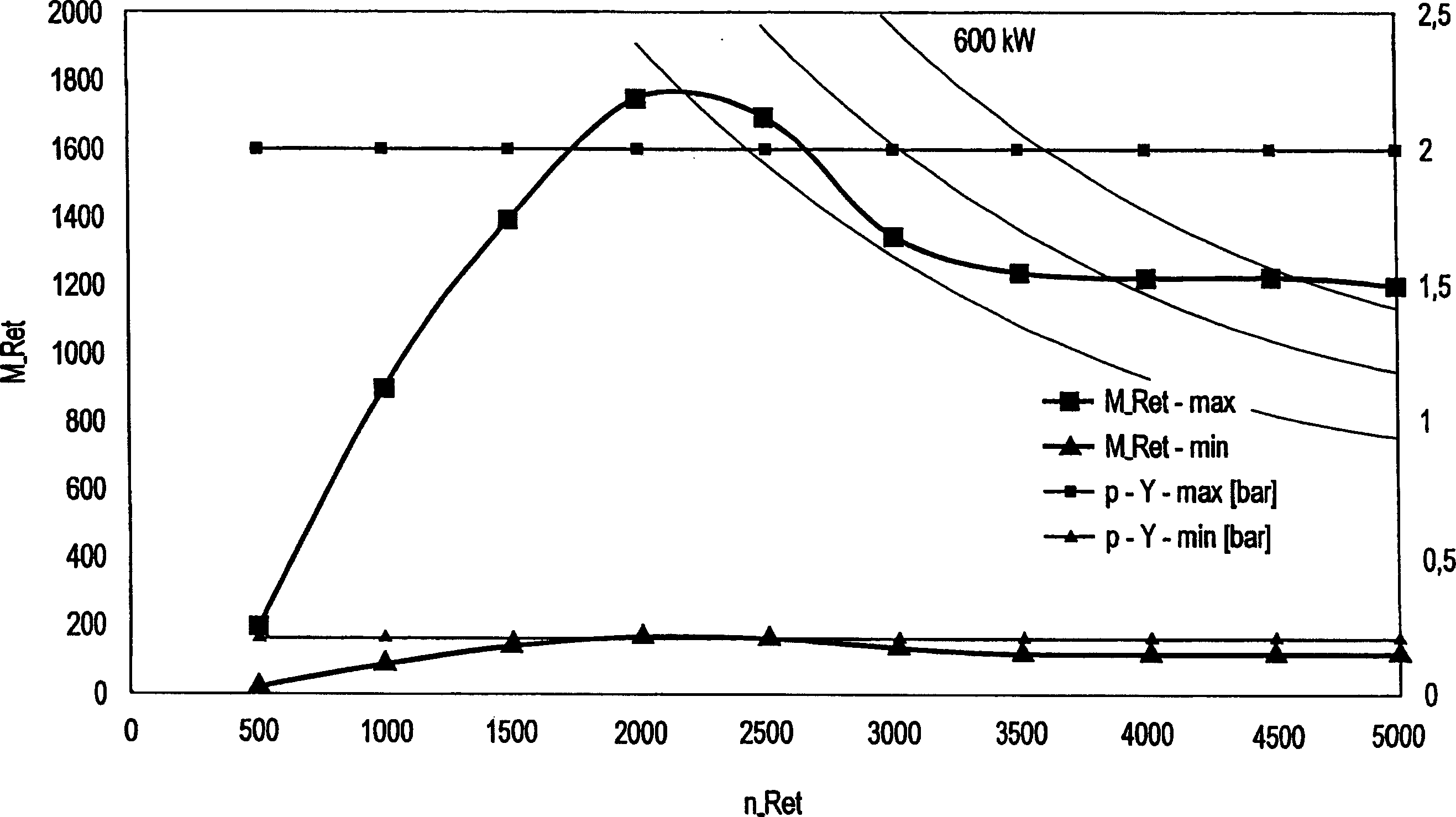

[0020] Taking the optimization of the braking power supply in the motor vehicle 1 as an example, figure 1 The basic sequence of the method according to the invention is shown in a simplified schematic diagram, the motor vehicle comprising a drive train 2 with a drive machine 3 which is at least indirectly connected to the wheels 4 to be driven. A hydrodynamic component, in the illustrated case a hydrodynamic braking device 5 in the form of a hydrodynamic retarder, is arranged in the drive train 2 . exist figure 2 The functional interrelationships of the drive train 2 are shown schematically and greatly simplified in . The hydrodynamic component in the form of a speed reducer 5 comprises a primary wheel P acting as a rotor wheel R and a secondary wheel T acting as a stator wheel S. Here, the secondary impeller T is stationary. A working medium supply system 6 with at least one adjusting device 10 is assigned to the gear unit 5 . Because the braking power of the hydrodynami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com