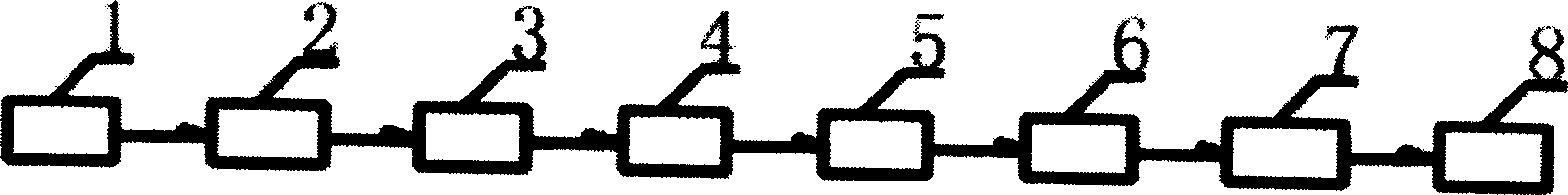

Desulfurization method of rubber and apparatus thereof

A technology for rubber and waste rubber, applied in the field of vulcanized rubber desulfurization, can solve the problem of insufficient utilization of waste rubber, and achieve the effects of high usable value, high efficiency and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

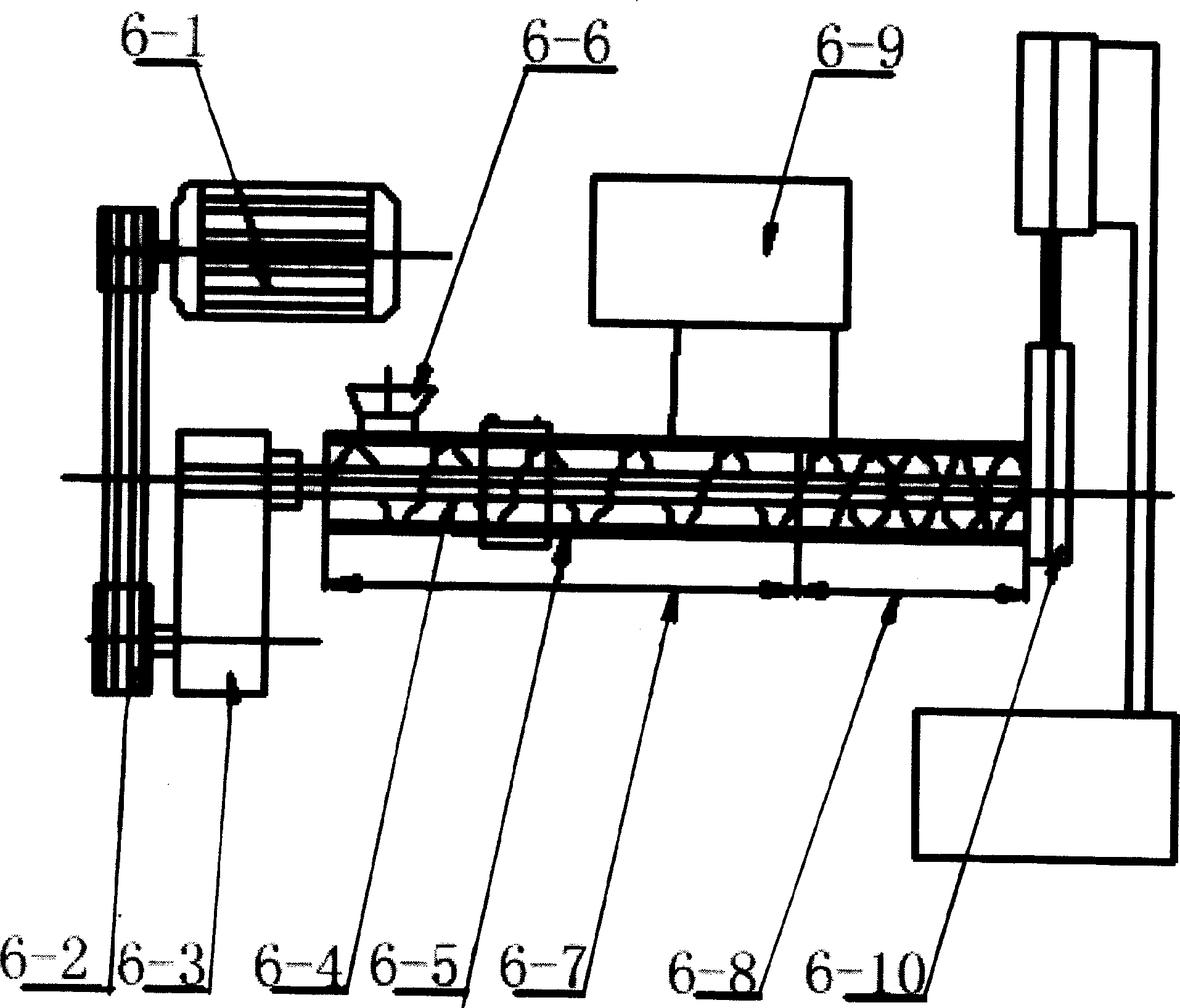

[0023] One embodiment is listed below, and the present invention is further described in conjunction with three accompanying drawings. However, the present invention is not limited to this one embodiment.

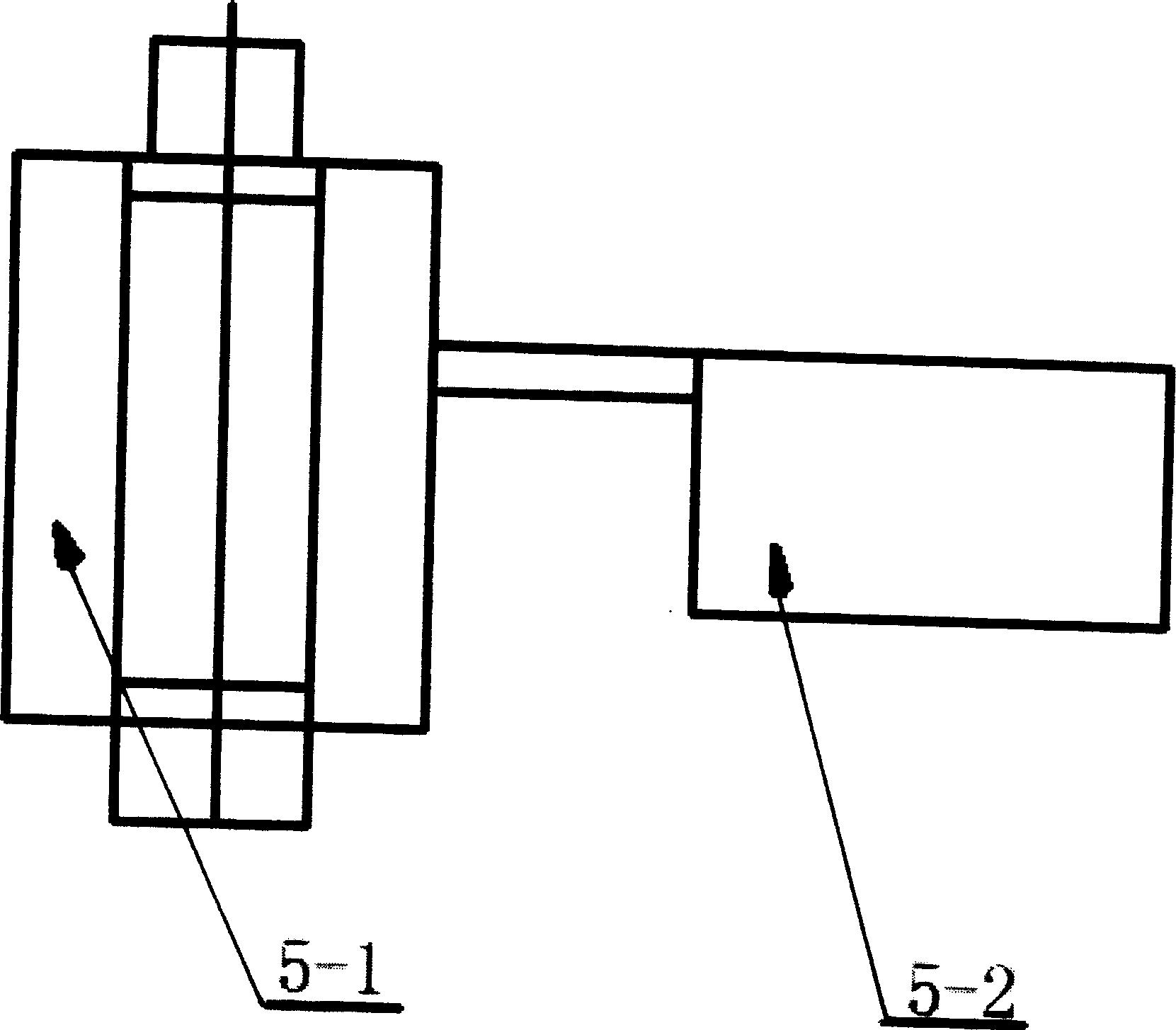

[0024] Taking EPDM vulcanized rubber as an example, put 500 kg of waste EPDM rubber particles into it, after crushing the waste rubber into 4-10mm particles, add the screening, magnetic separation, and feeding devices into the microwave oven, and the temperature of the microwave oven is controlled at 160 ~250 degrees Celsius, use microwave energy to desulfurize rubber particles for ten minutes, and directly discharge them into the feed port of the extruder through the microwave oven outlet, the temperature is controlled at 160-250 degrees Celsius; the temperature of the cooling system of the extruder is controlled at 120-100 degrees Celsius , after plasticizing and filtering through the extruder, the available rubber raw materials are produced. The time used for the trial p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com