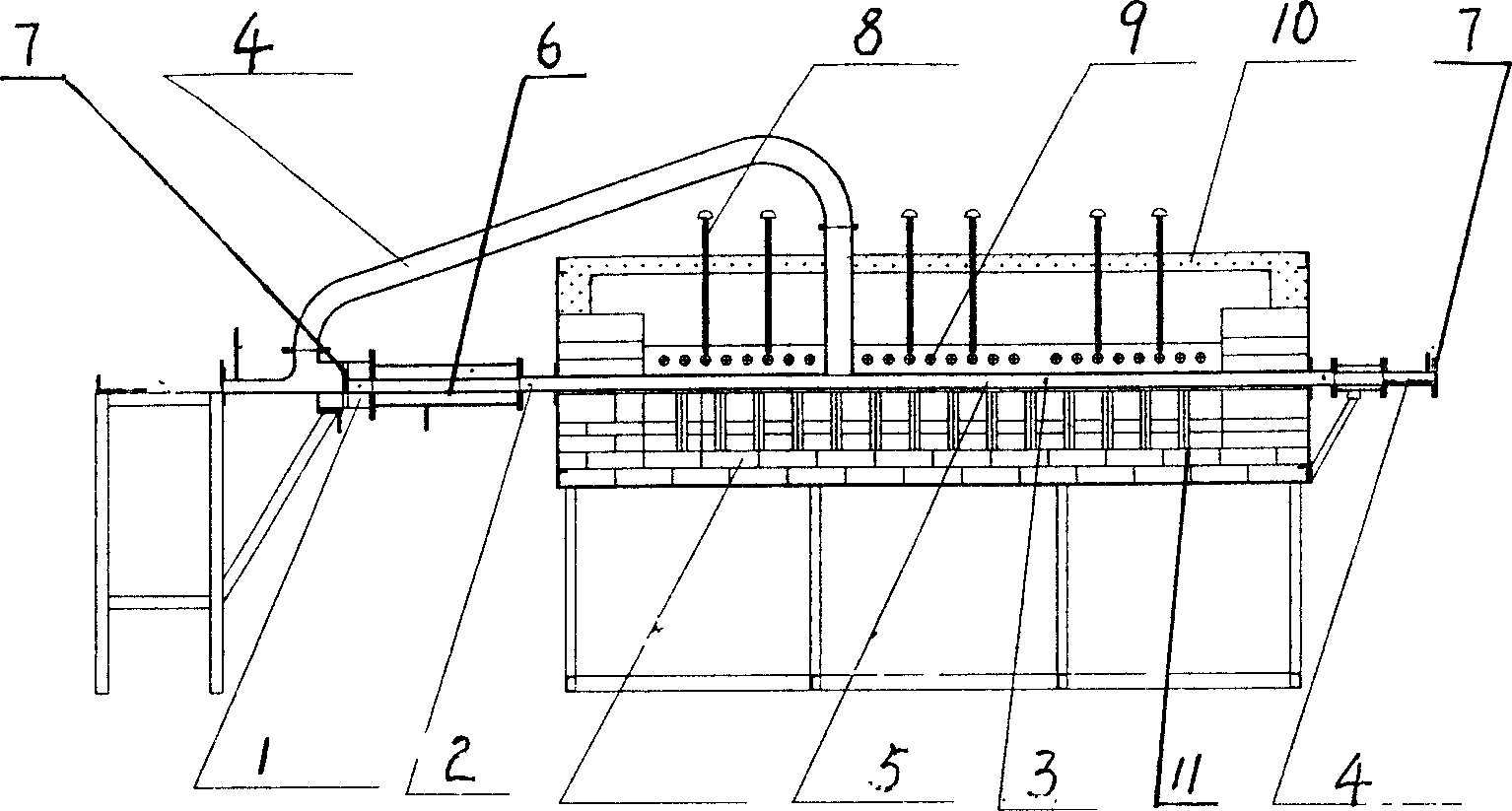

Three-section type atmosphere controlled heat treatment furnace

A heat treatment furnace, three-stage technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of limited use, uncontrollable atmosphere, impossible intermittent steel strips, etc., to achieve convenient use, low cost, and guaranteed The effect of using safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] After a certain high magnetic induction oriented silicon steel is smelted, billet cast, hot rolled, and cold rolled, the hot-rolled plate is subjected to the following heat treatment in the three-stage controllable atmosphere heat treatment furnace of the present invention: the sample is debonded in the first stage. Carbon annealing at 840°C×3min, annealing atmosphere 5LH2 / min+4LN2 / min, dew point 65°C; followed by reduction treatment in stage II at 920°C×1min, atmosphere 5LH2 / min+4LN2 / min. After the sample was released from the furnace, it was coated with magnesium oxide coating and subjected to secondary recrystallization high-temperature annealing. The magnetic properties of the sample were tested as B8: 1.93T; P17: 1.12W / kg, which met the performance requirements of HiB steel.

Embodiment 2

[0033]A certain oriented silicon steel hot-rolled plate, after cold rolling, is subjected to the following heat treatment in the three-stage controllable atmosphere heat treatment furnace of the present invention: the sample is heated in the third stage without oxidation, and the atmosphere is 1LH2 / min+5LN2 / min+ 2LAr / min, followed by decarburization annealing in the second stage at 840℃×3min, annealing atmosphere 2LH2 / min+4LN2 / min, dew point 55℃; then nitriding treatment in the first stage 750℃×30s, atmosphere 5LH2 / min +5LN2 / min+0.2LNH3 / min, PH2O / PH2=0.05. After the sample was released from the furnace, it was coated with magnesium oxide coating and subjected to high-temperature annealing for secondary recrystallization. The magnetic properties of the sample were tested as B8: 1.90T; P17: 1.137W / kg, which met the performance requirements of HiB steel.

Embodiment 3

[0035] A certain high-grade non-oriented silicon steel hot-rolled plate is subjected to the following heat treatment in the three-stage controllable atmosphere heat treatment furnace of the present invention after cold rolling: the sample is heated in the third stage without oxidation, and the atmosphere is 3LH2 / min+1LN2 / min, followed by annealing in the second stage at 850°C×3min, annealing atmosphere 2LH2 / min+4LN2 / min, dew point 35°C, then annealing in stage I at 950°C×1min, annealing atmosphere 2LH2 / min+4LN2 / min , The magnetic properties of the sample were tested as B50: 1.74T; P15: 2.58W / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com