Injection molding device

A storage device and sleeve technology, applied in the field of injection casting devices, can solve problems such as the dilemma, lack of plunger and sleeve cooling, and inability to perform injection, etc., so as to prevent the formation of gaps and produce high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Hereinafter, embodiments of the present invention shown in the drawings will be described, and other features, operations, and effects of the present invention will also be described.

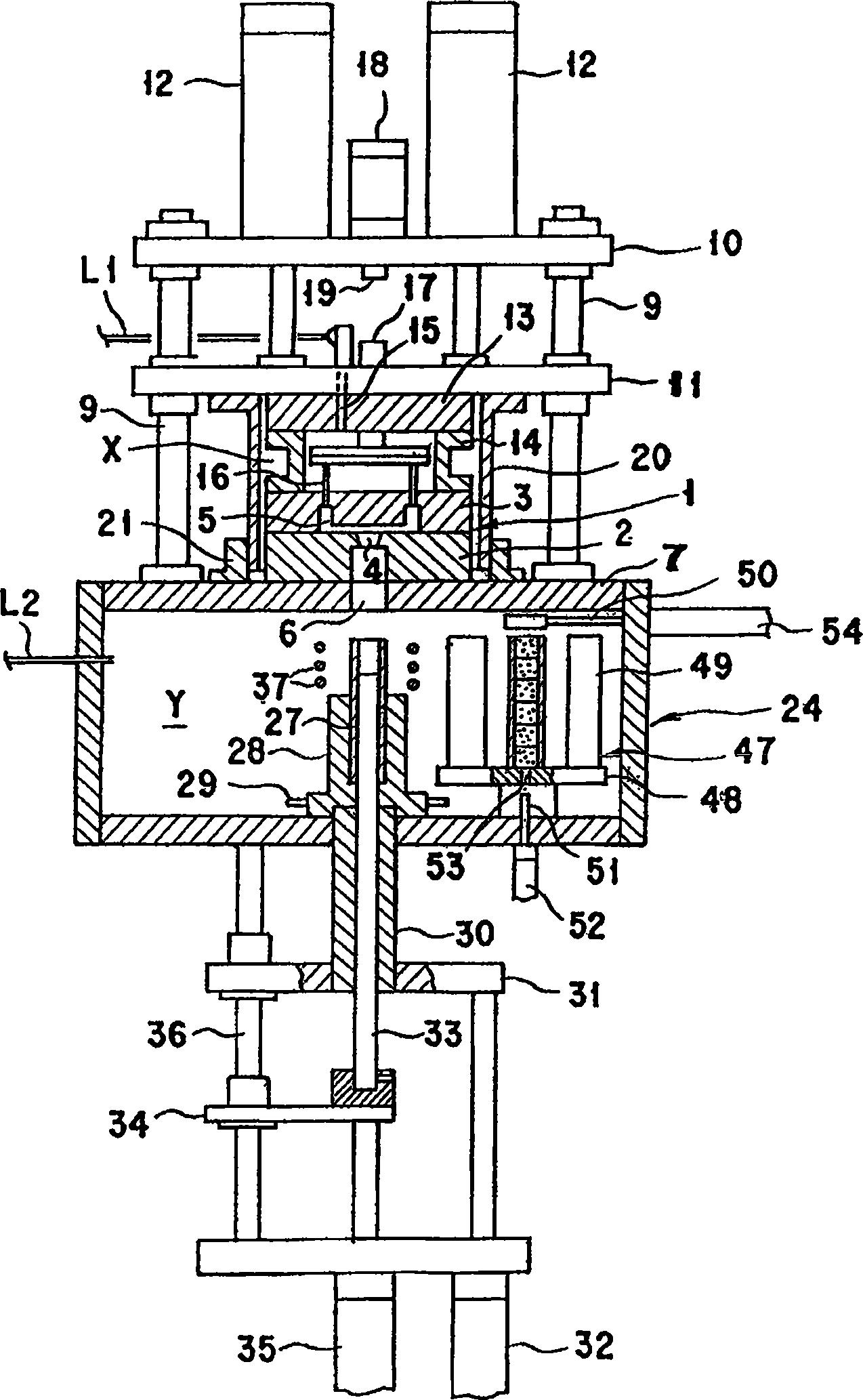

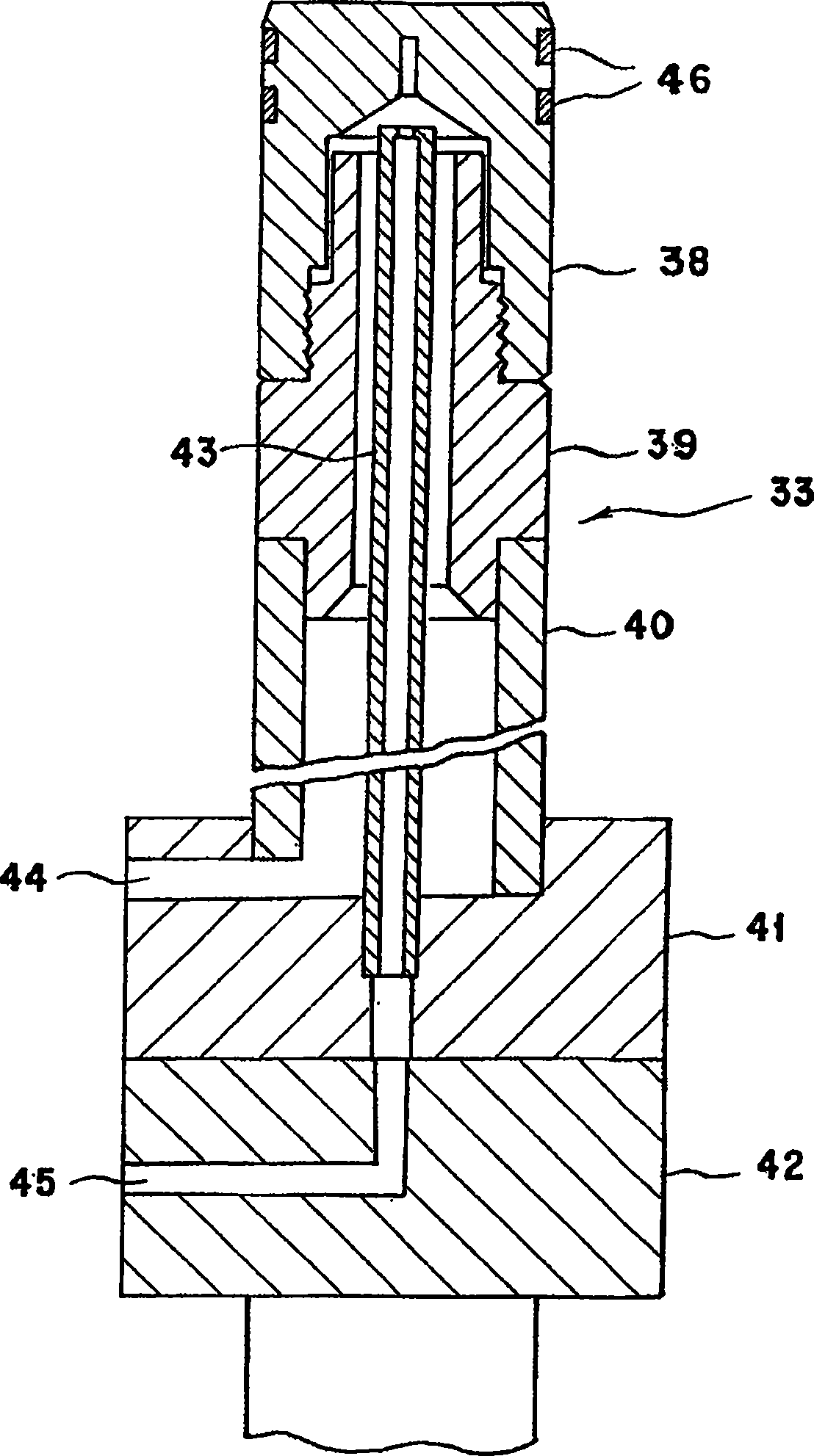

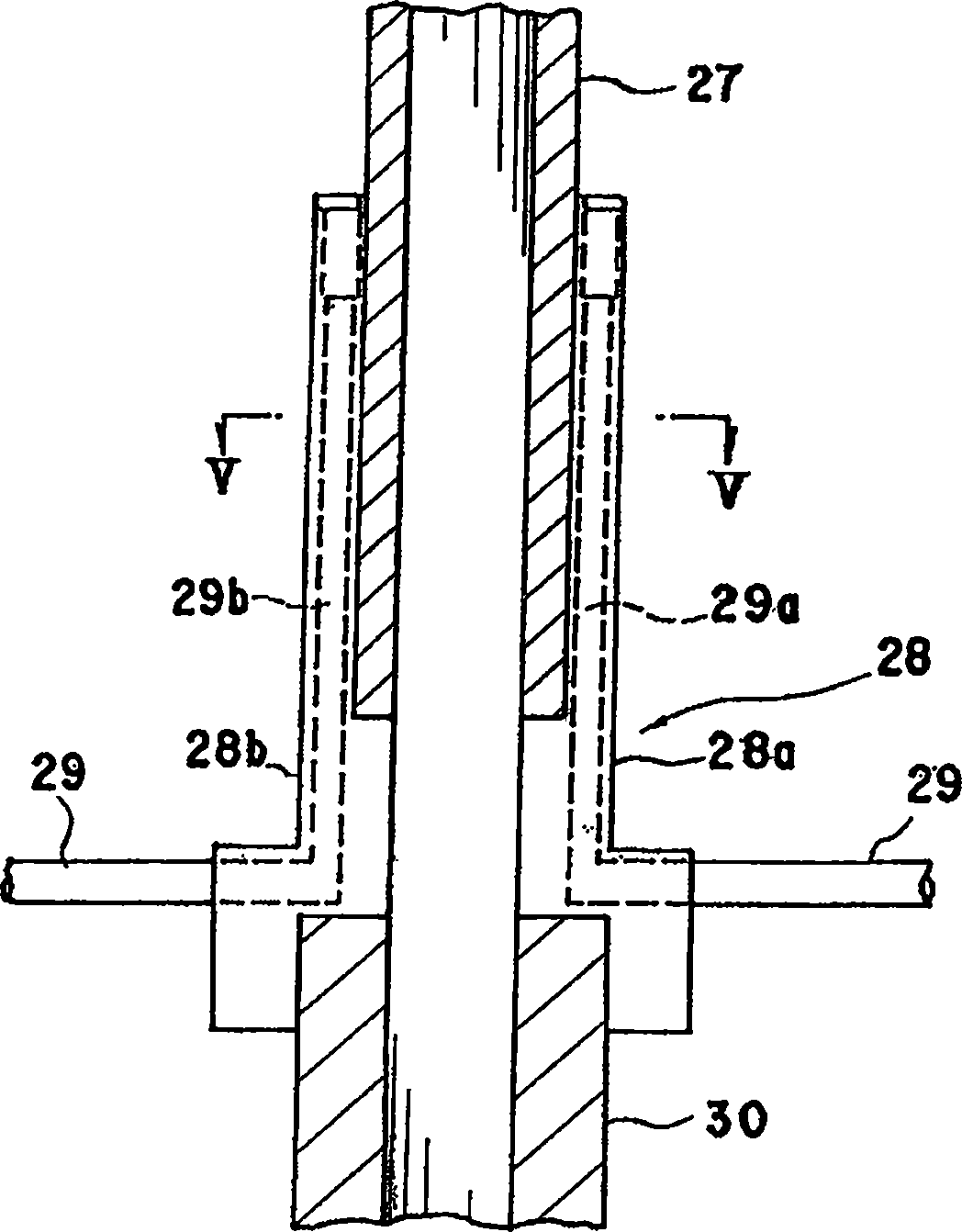

[0035] Figure 1 to Figure 9 An embodiment of the vacuum injection casting apparatus of the present invention is shown. In the figure, symbol 1 is a metal mold, which includes a fixed lower mold 2 and a movable upper mold 3 . The lower mold 2 with the gate 4 is fixed on the main mold base 7, and seals are performed between them by sealing components (not shown) such as O-rings, and the main mold base 7 has a circular opening at the corresponding position. 6. A plurality of upright columns (タイバ) 9 are erected in parallel on the main mold base 7, and a fixed plate 10 is fixed to the upper end thereof. The number of columns 9 is 4 in this embodiment, but of course it is not limited thereto, it may be 3 or 2, or more than 4. The movable platen 11 attached to the column 9 is raised and low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com