Patents

Literature

30results about How to "Low mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing quaternary sulfide quantum dot based heterojunction efficient photocatalyst

ActiveCN105727999AFully crystallizedGood dispersionPhysical/chemical process catalystsHeterojunctionThiourea

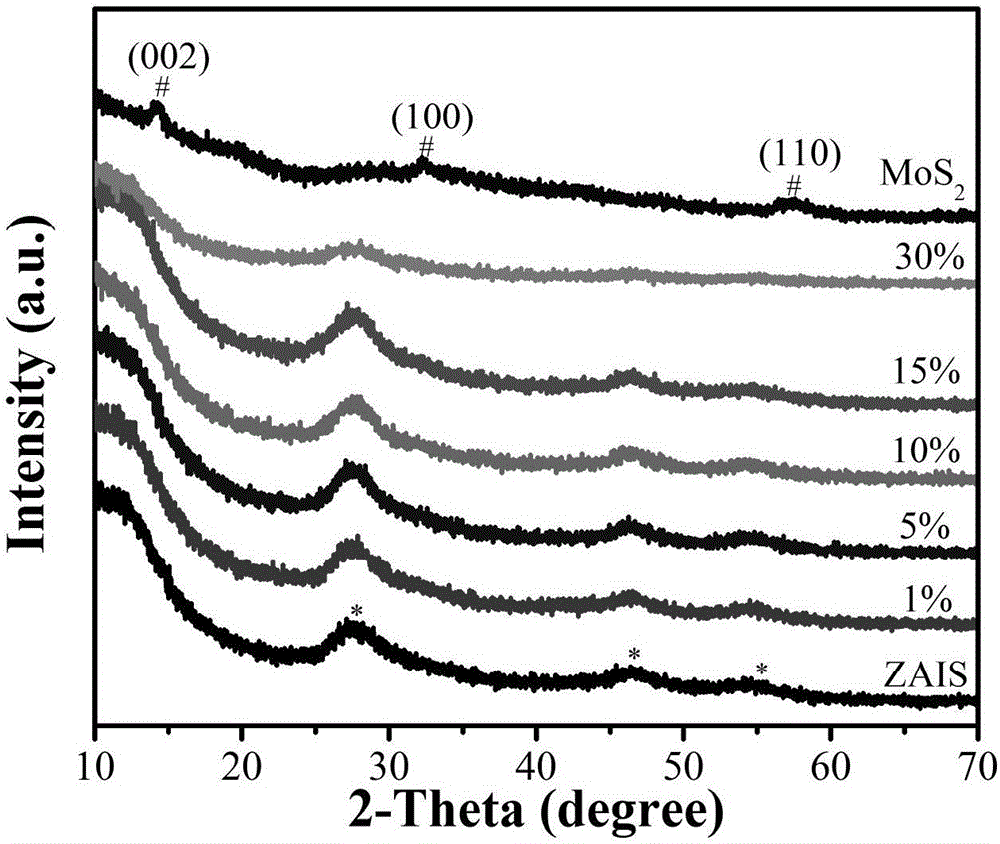

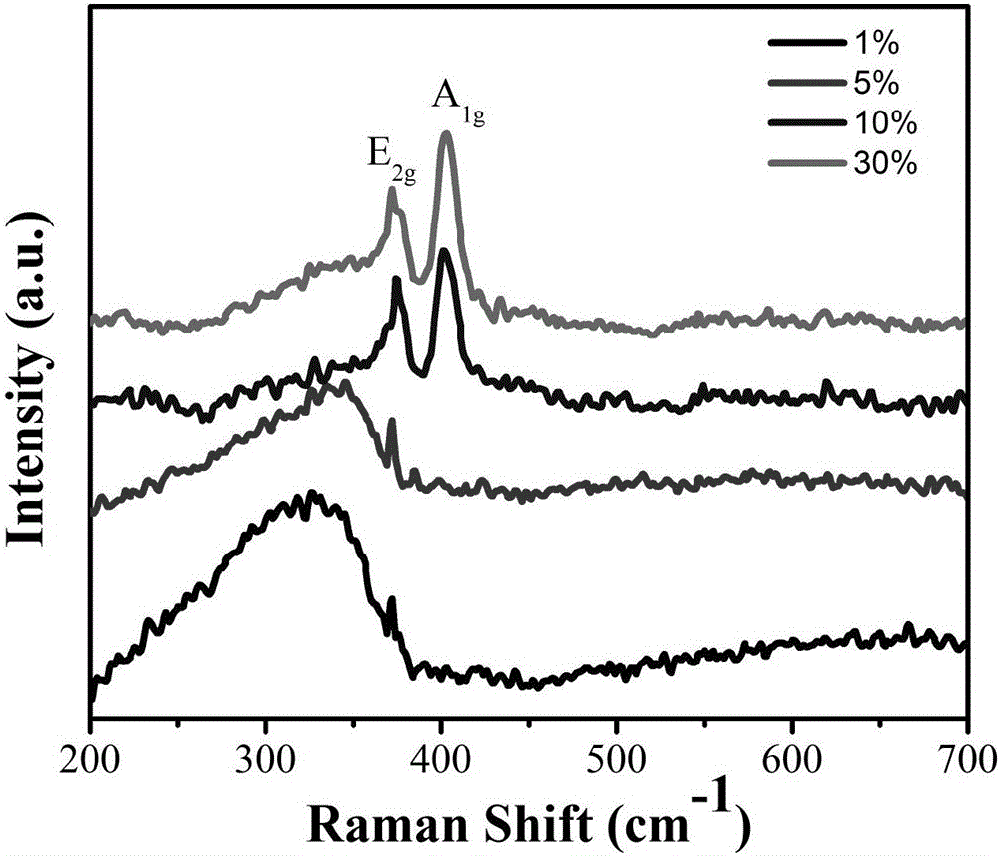

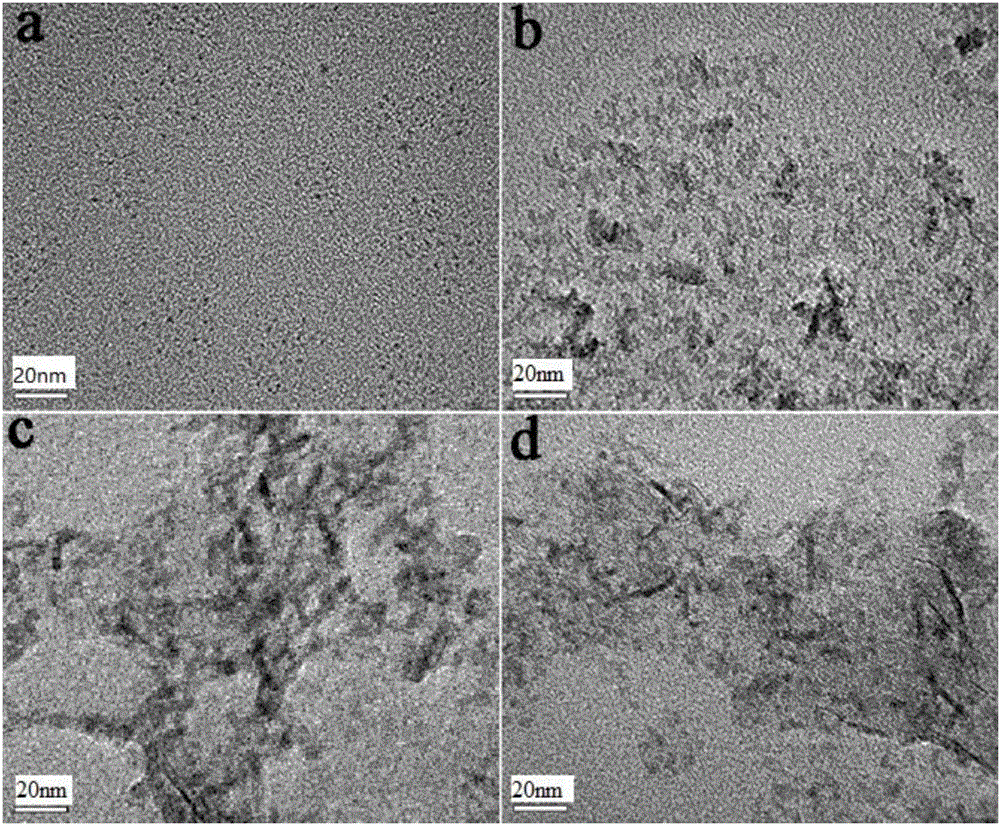

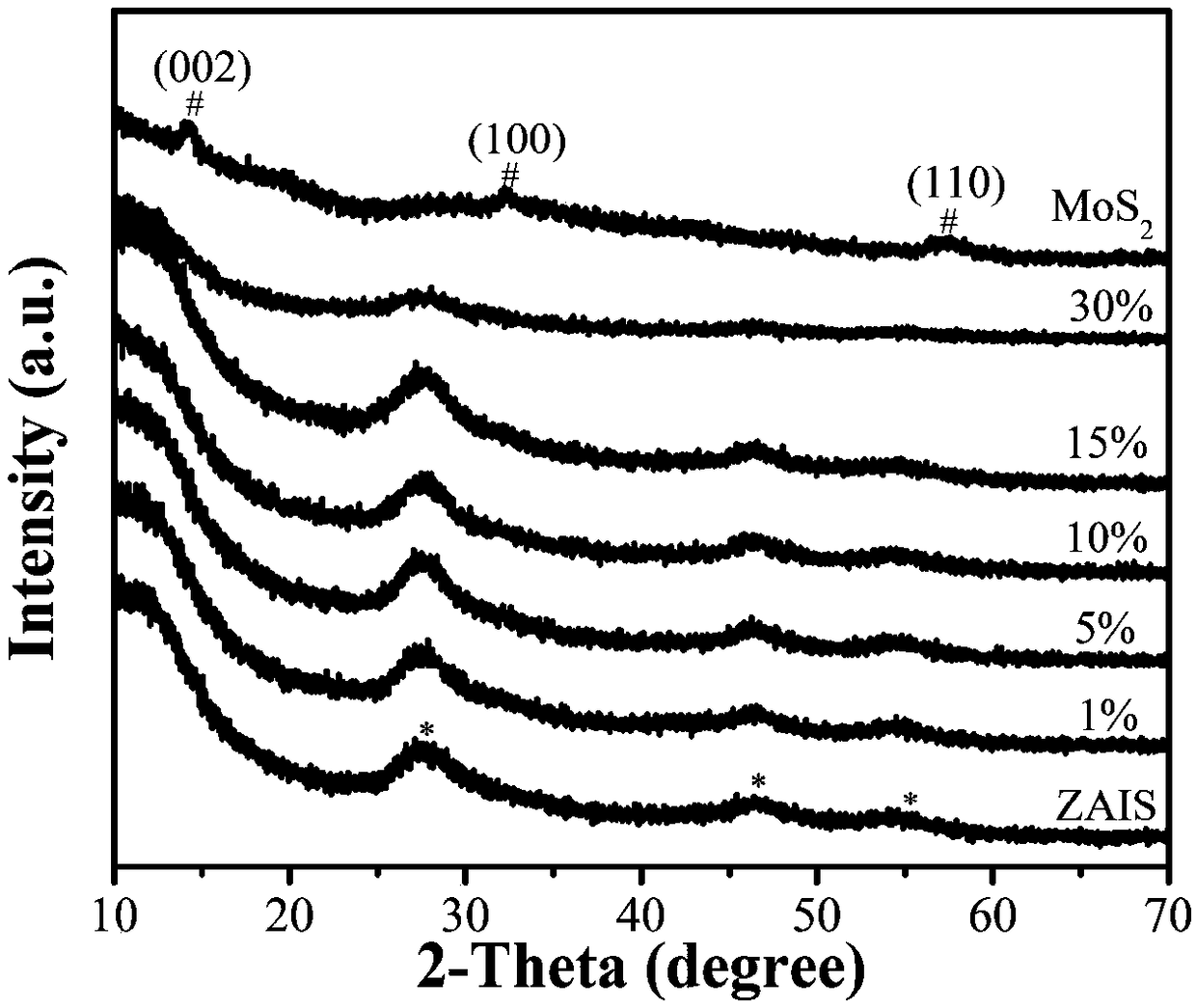

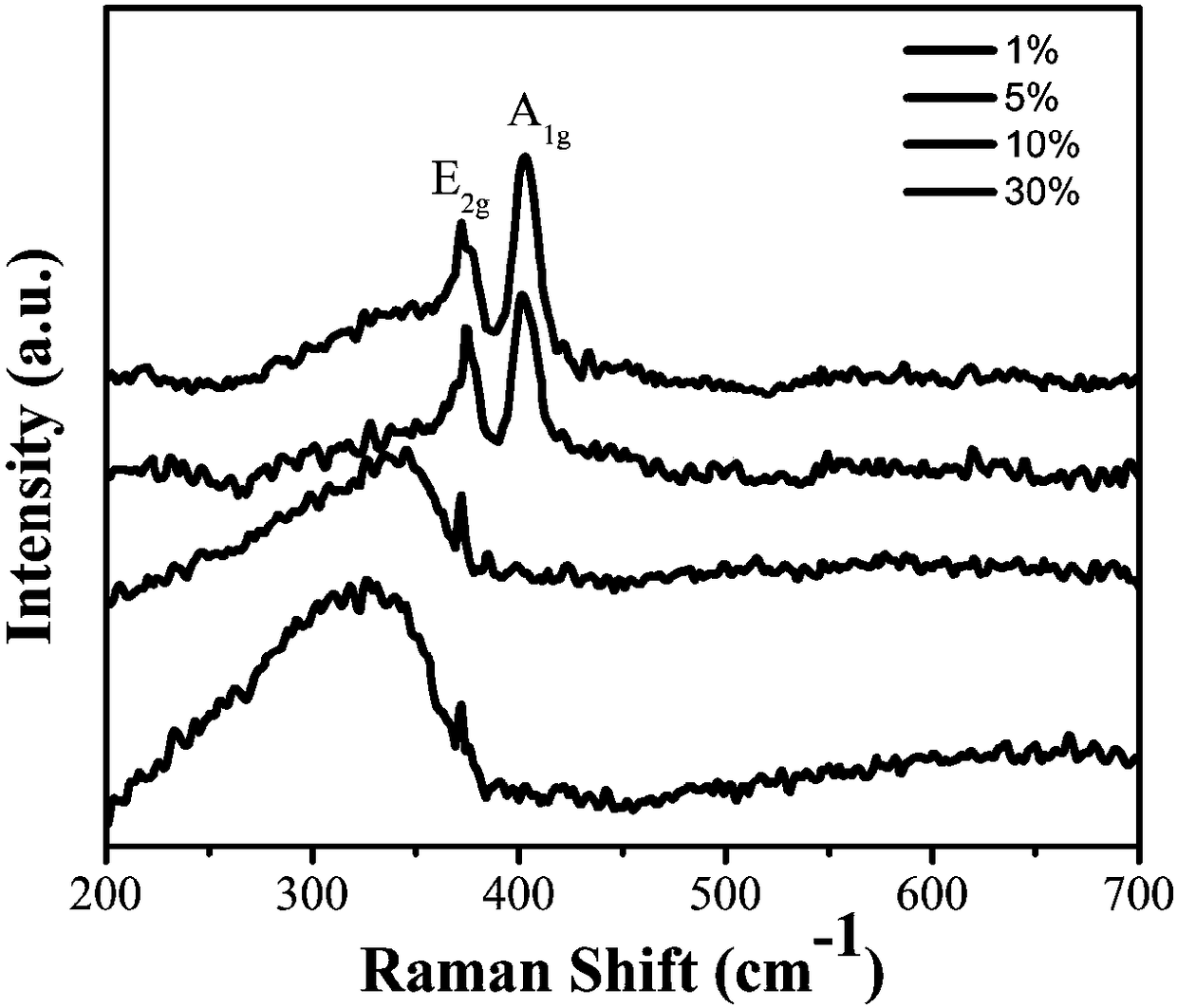

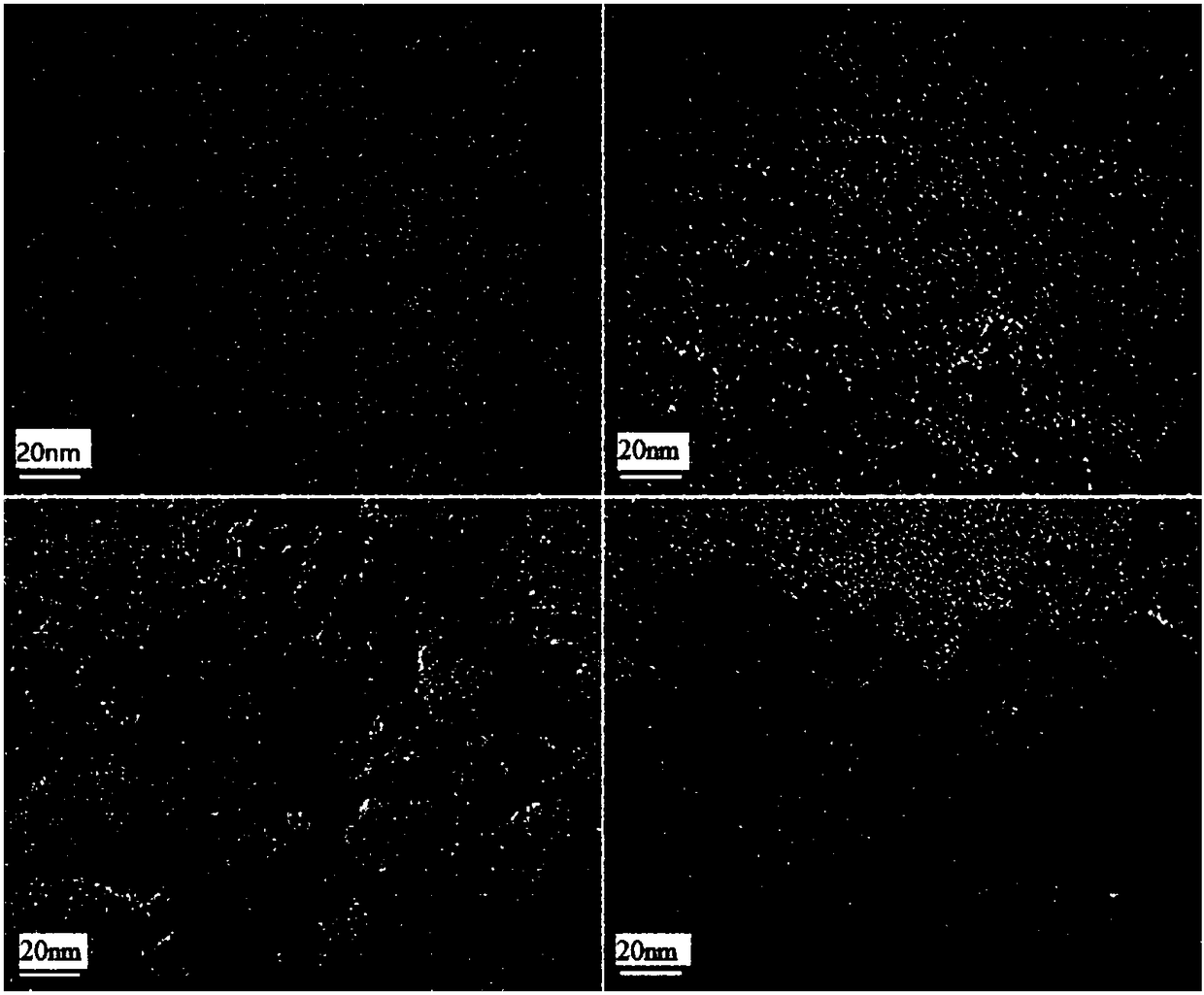

The invention relates to I-III-VI group 2 sulfide and particularly relates to an AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst prepared by utilizing a simple and rapid hydrothermal method. The AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst can be used for degrading a rhodamine B dye under visible light. The AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst is prepared by mixing and stirring AgIn5S8-ZnS nano crystals, ammonium molybdate tetrahydrate and thiourea, carrying out a hydrothermal reaction for 8 hours at 200 DEG C, and filtering, washing and drying after the reaction is finished, wherein the mass ratio of the MoS2 to the AgIn5S8-ZnS nano crystals is 1%-30%, and the optimal mass ratio of the photocatalytic performance is 5%. An experiment of degrading rhodamine B (RhB) under the visible light shows that the prepared composite photocatalyst has good photocatalytic activity.

Owner:JIANGSU UNIV

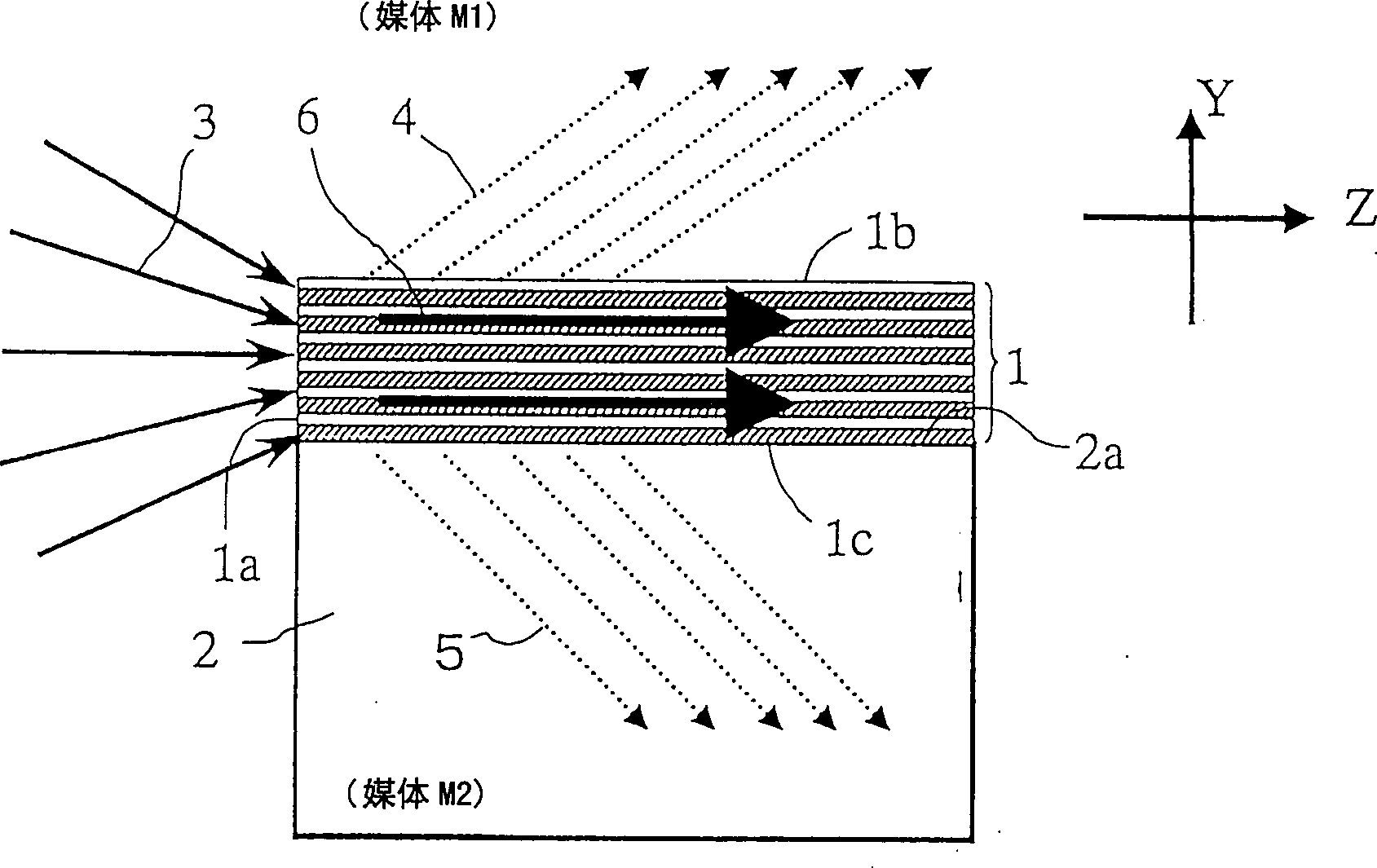

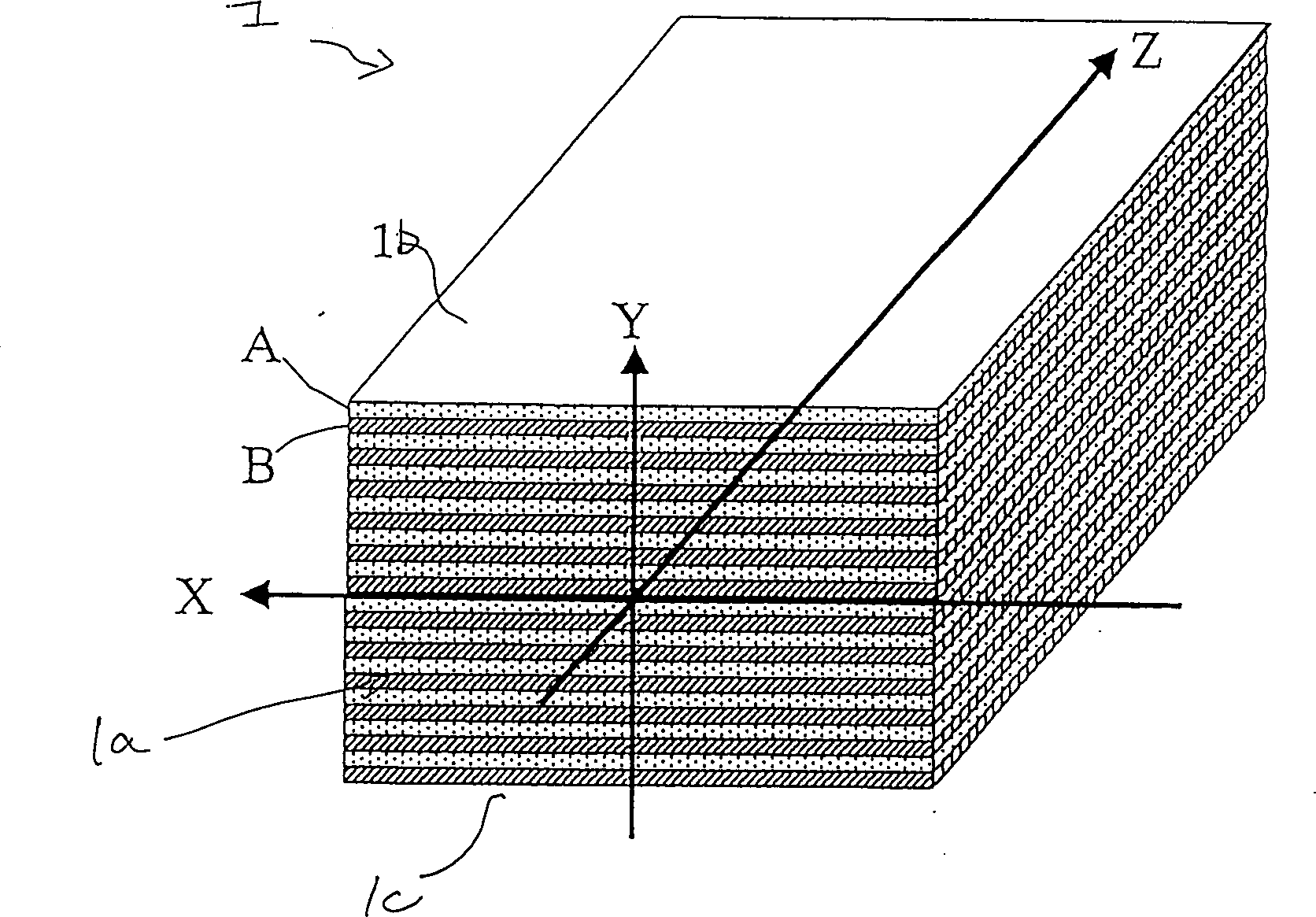

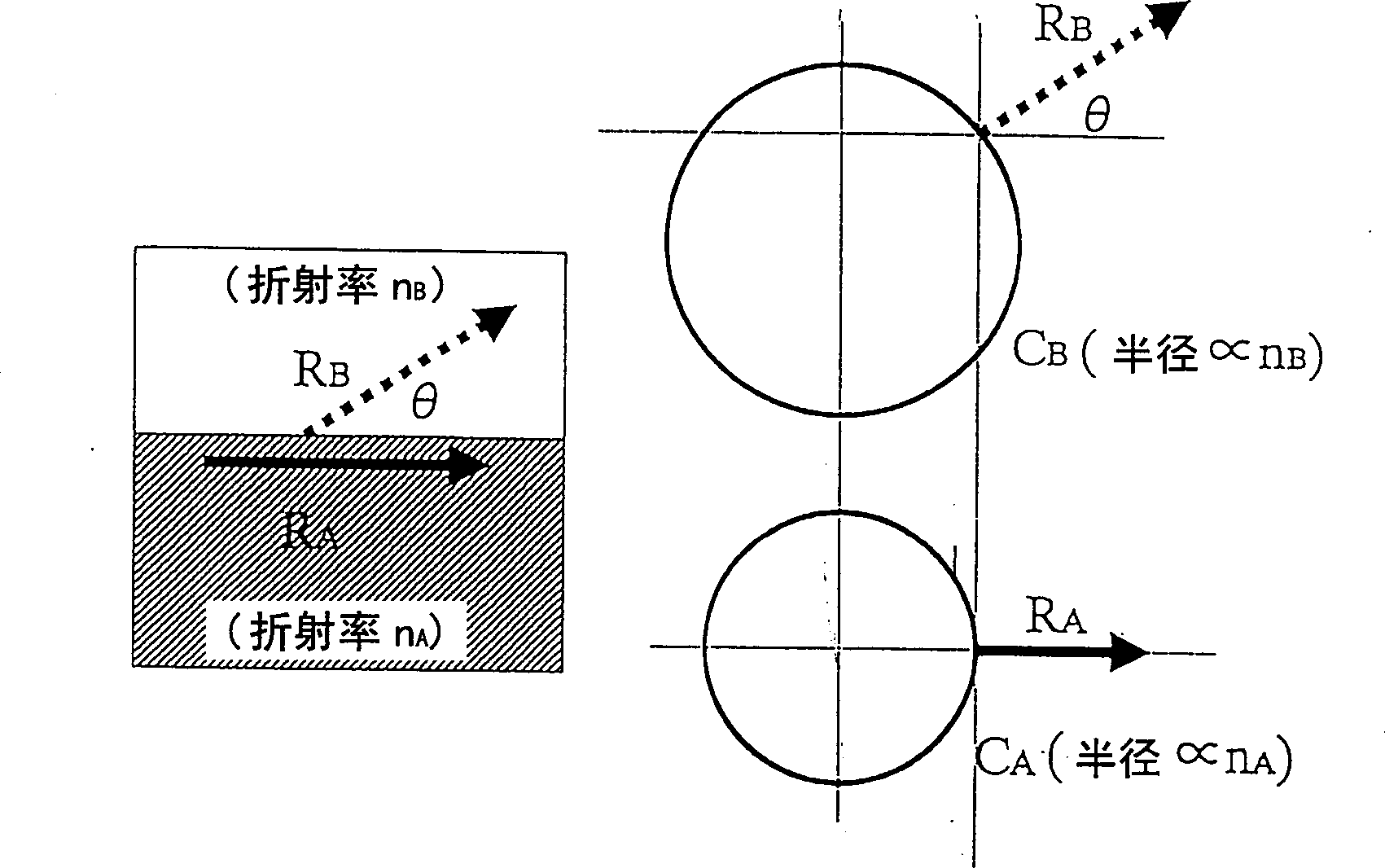

Optical device and spectroscope and polarization separating device using the device

InactiveCN1342910AImprove resolutionLow costPolarisation spectroscopyPolarising elementsLight beamLength wave

An optical device in which an end surface of a periodic multilayer structure is provided as a beam incidence surface or as a beam exit surface. The optical device can realize a high resolving-power spectroscopic apparatus without having any increase in size of the apparatus and by use of good directivity of beam leaked from the multilayer structure and strong wavelength dependence of an angle of the leaked beam.

Owner:NIPPON SHEET GLASS CO LTD

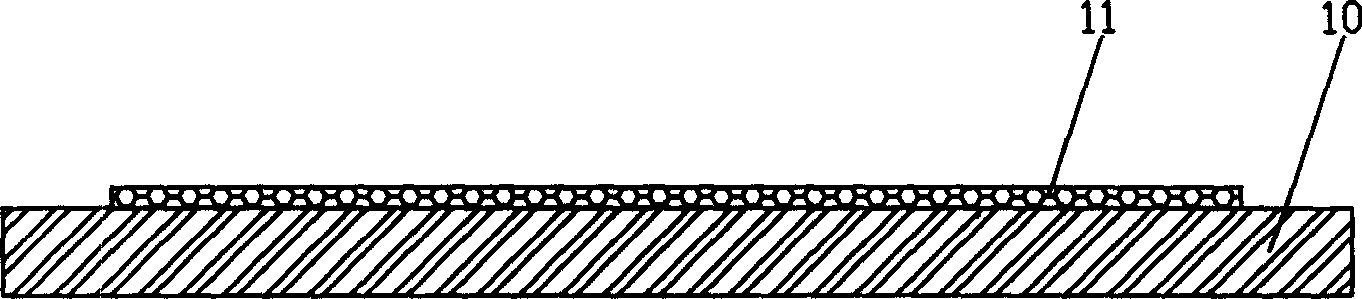

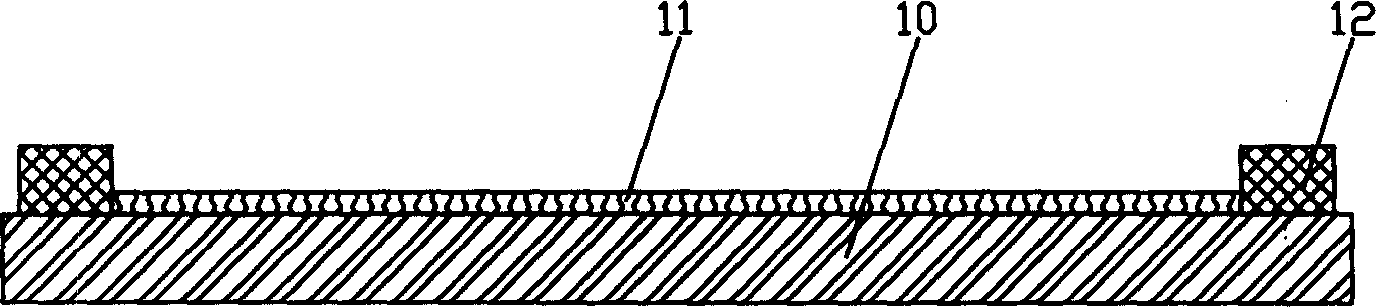

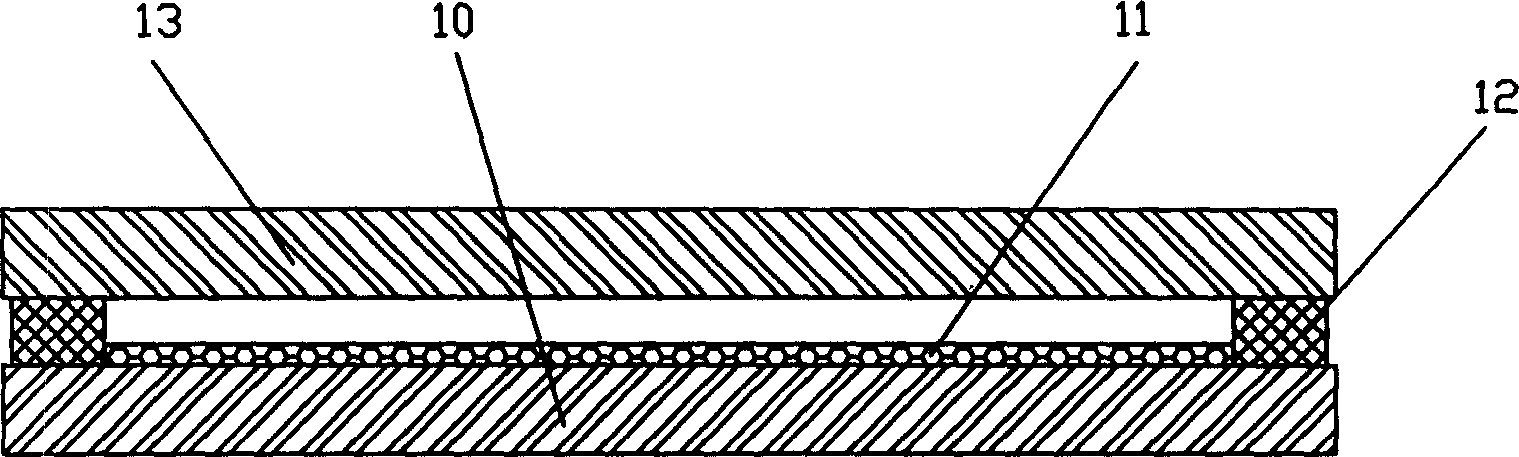

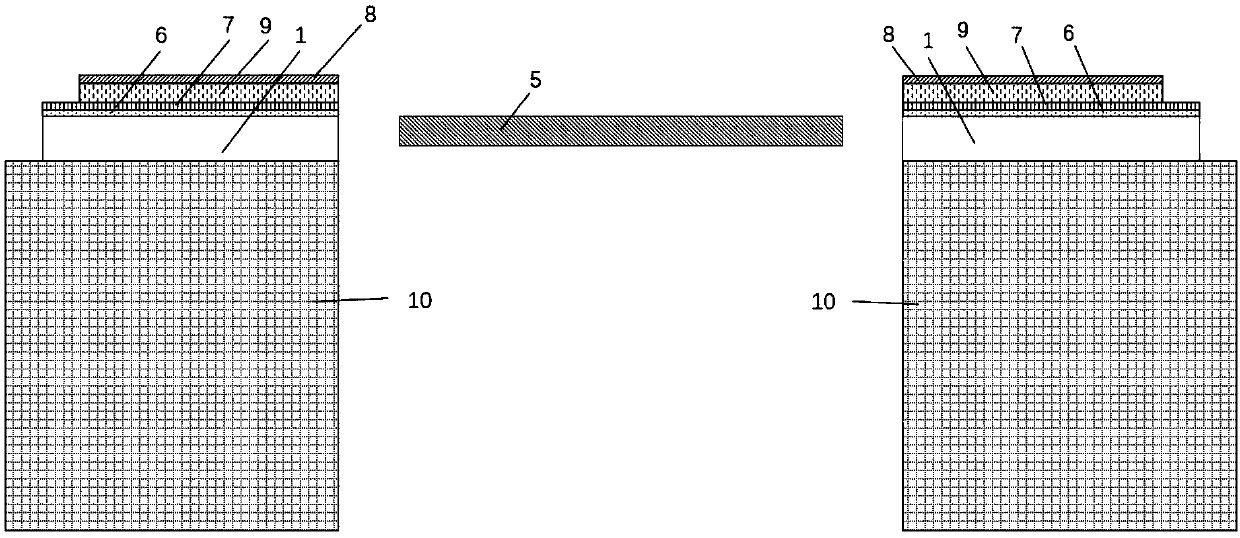

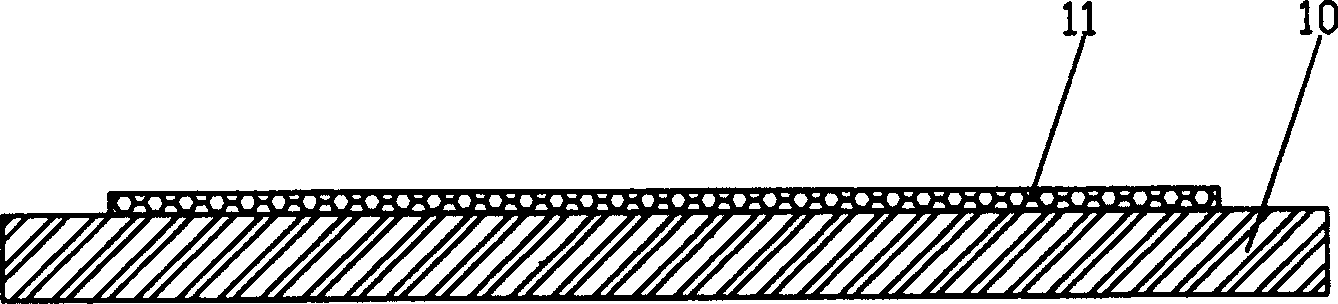

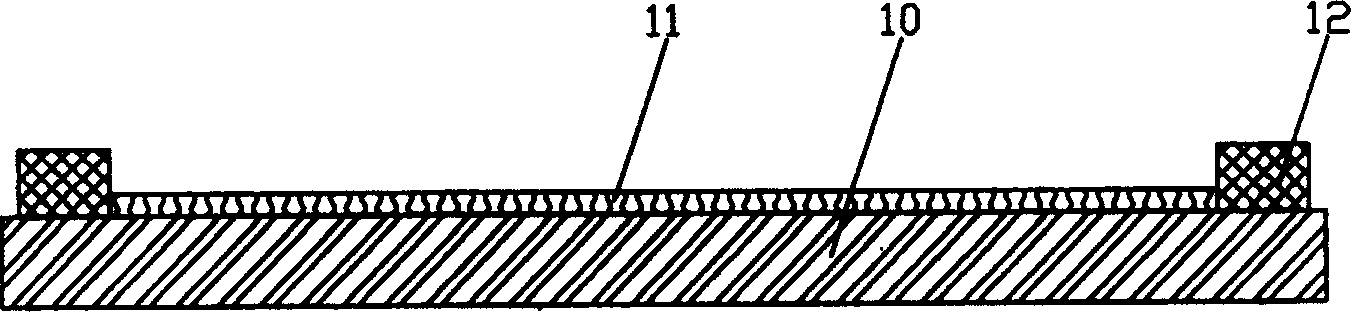

Manufacturing method of liquid crystal display screen

InactiveCN1556434AReduce the chance of occurrenceReduce box thicknessStatic indicating devicesNon-linear opticsCrystallographyLiquid layer

The invention relates to a LCD-making method, especially a LCD-making method of packaging and making liquid crystal material by using the double-layer structure where the liquid layer is covered with polymer film and which is formed in the course that the polymer monomer is separated with the liquid crystal in the polymerization reaction during the no liquid crystal injection course of a single-basal plate. According to the requirement for device structure, it further uses the techniques of coating, splashing, photoetching, etc to complete making the liquid crystal screen. Compared with traditional liquid crystal screen making techniques, it omits the courses of making an empty box and injecting liquid crystal into the empty box. It has obvious advantage in making plastic basal boards and large-sized LCD. It can also use plastic basal plate, thus making the made liquid crystal screen very thin, and further reducing the thickness and weight of the liquid crystal screen box.

Owner:吉林北方彩晶数码电子有限公司

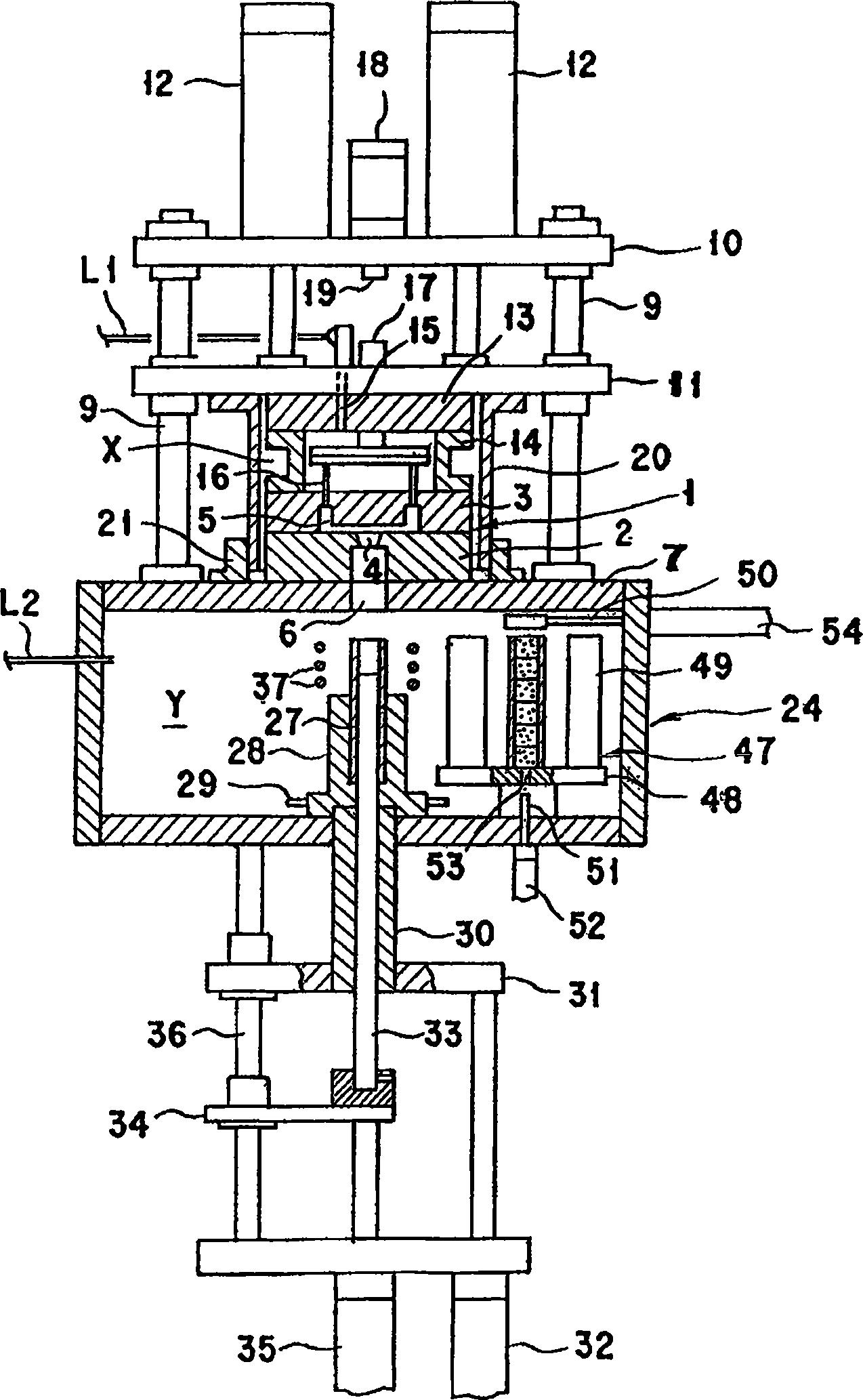

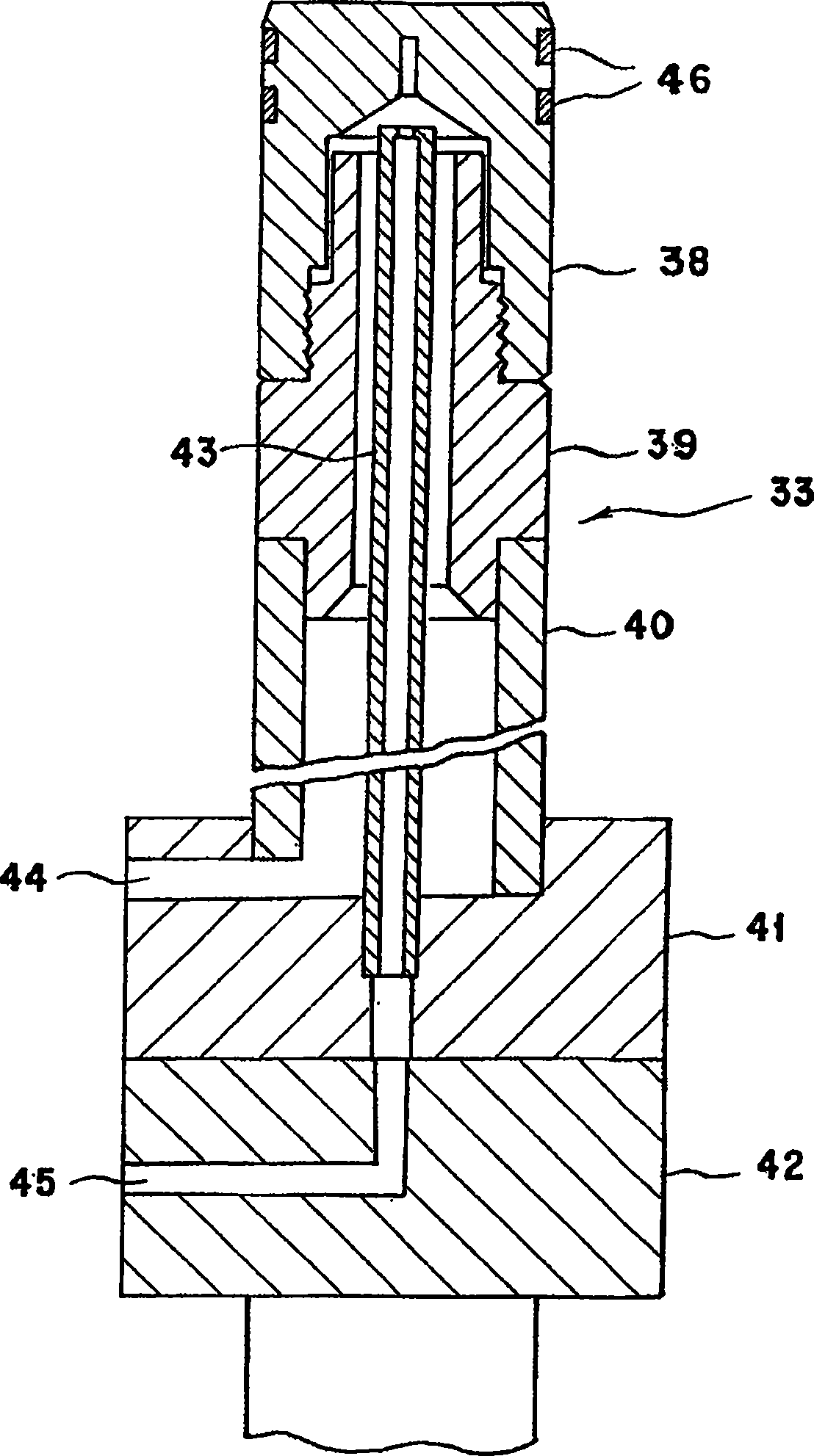

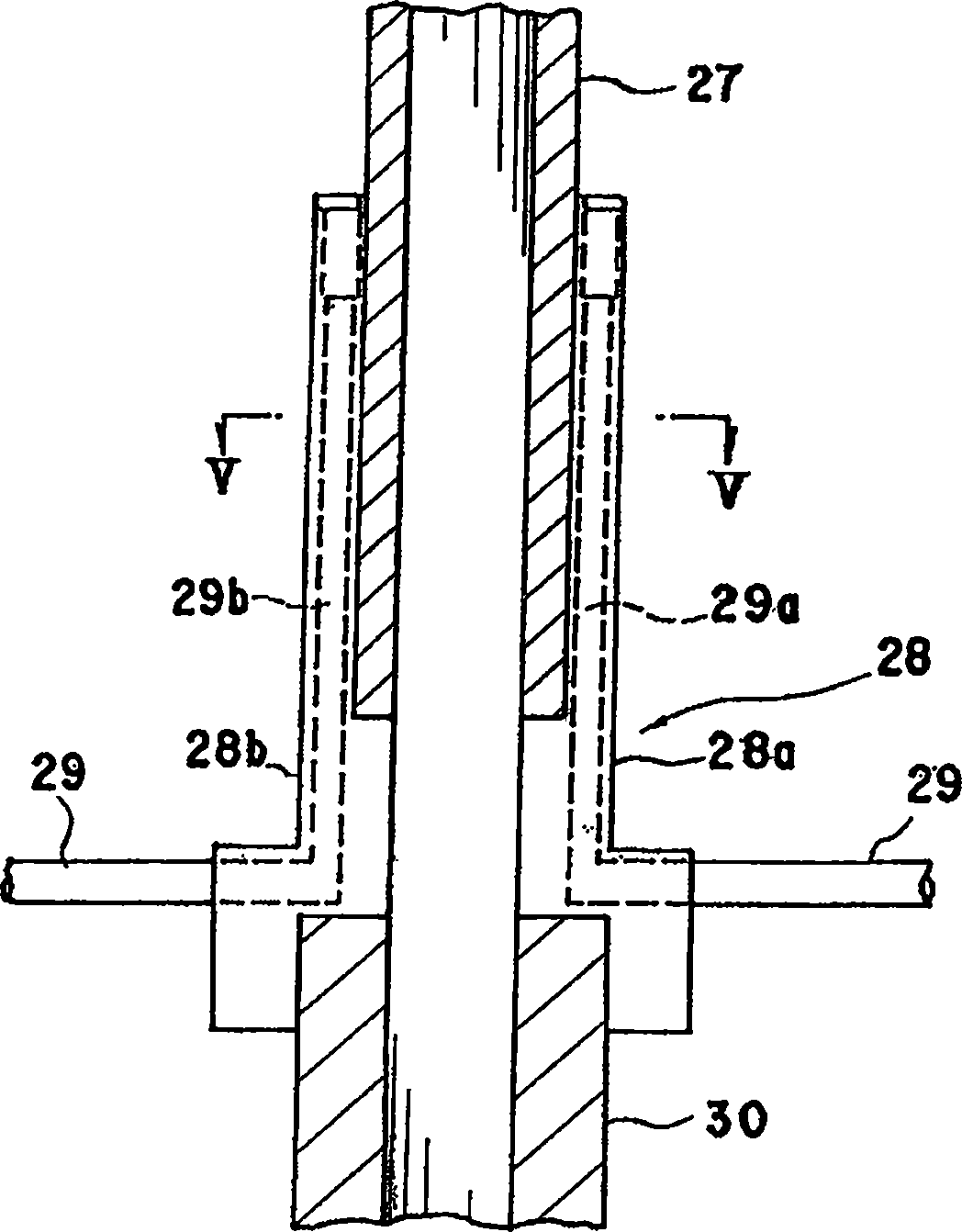

Injection molding device

A device capable of injection molding a metal with a high melting point. The injection molding device has a metal mold (1), a sleeve (27) provided for advance toward and retreat from a downgate (4) of the metal mold, a plunger (33) slidably provided in the sleeve, heating means (37) for heating and melting a raw material block (A) supplied to a raw material receiving section formed by the inner wall of the sleeve and the plunger, and raw material block supplying means (47) for supplying the raw material block from the above to the raw material receiving section. The plunger and / or the sleeve are provided with cooling means for making a molten metal produced by heating and melting a metal to be hard to flow into a gap between the plunger and the sleeve.

Owner:NAMIKI PRECISION JEWEL CO LTD

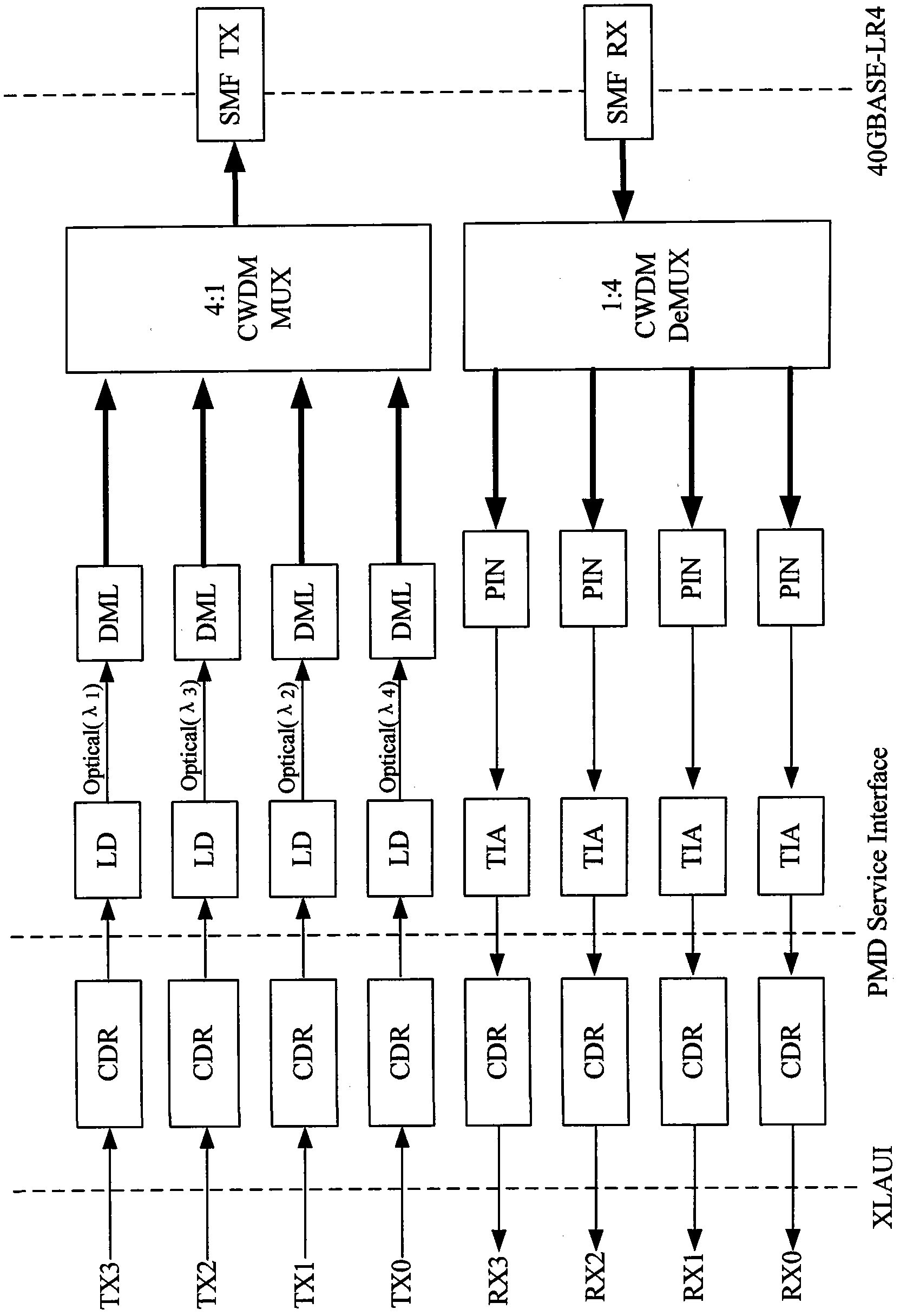

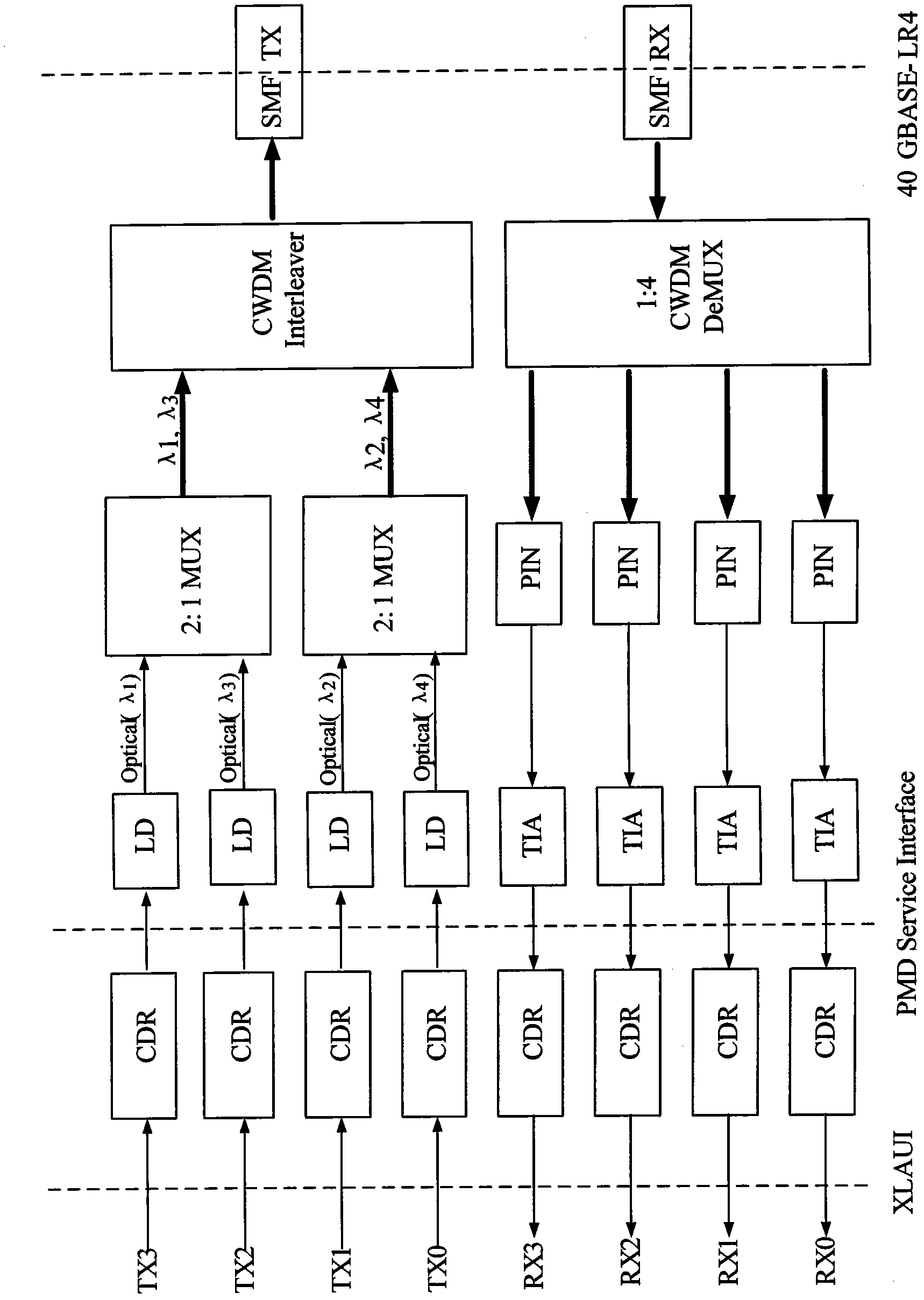

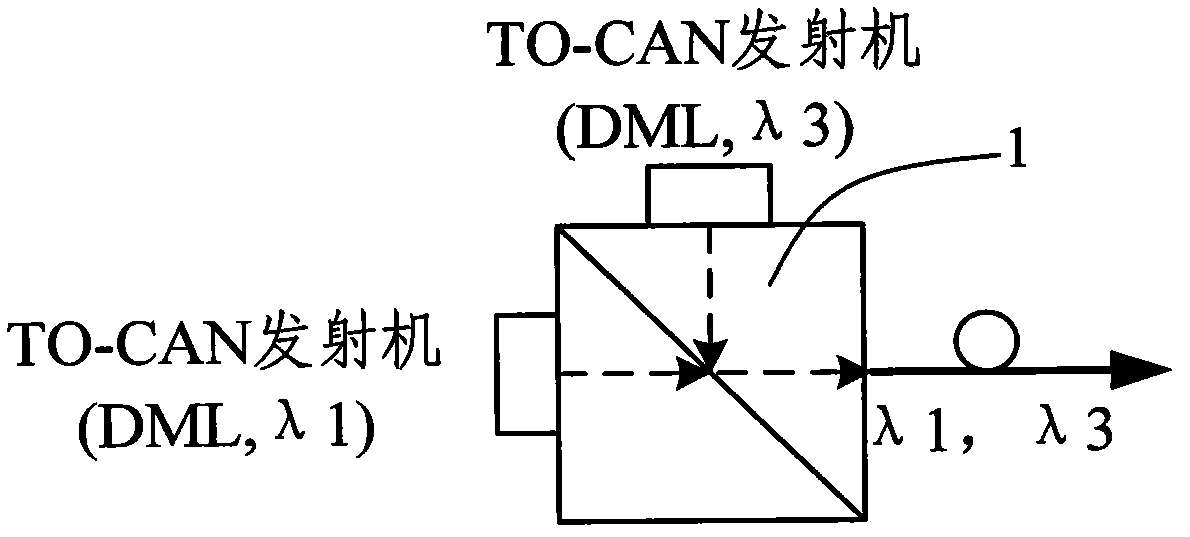

C form-factor pluggable (CFP) optical transceiver with interleaver

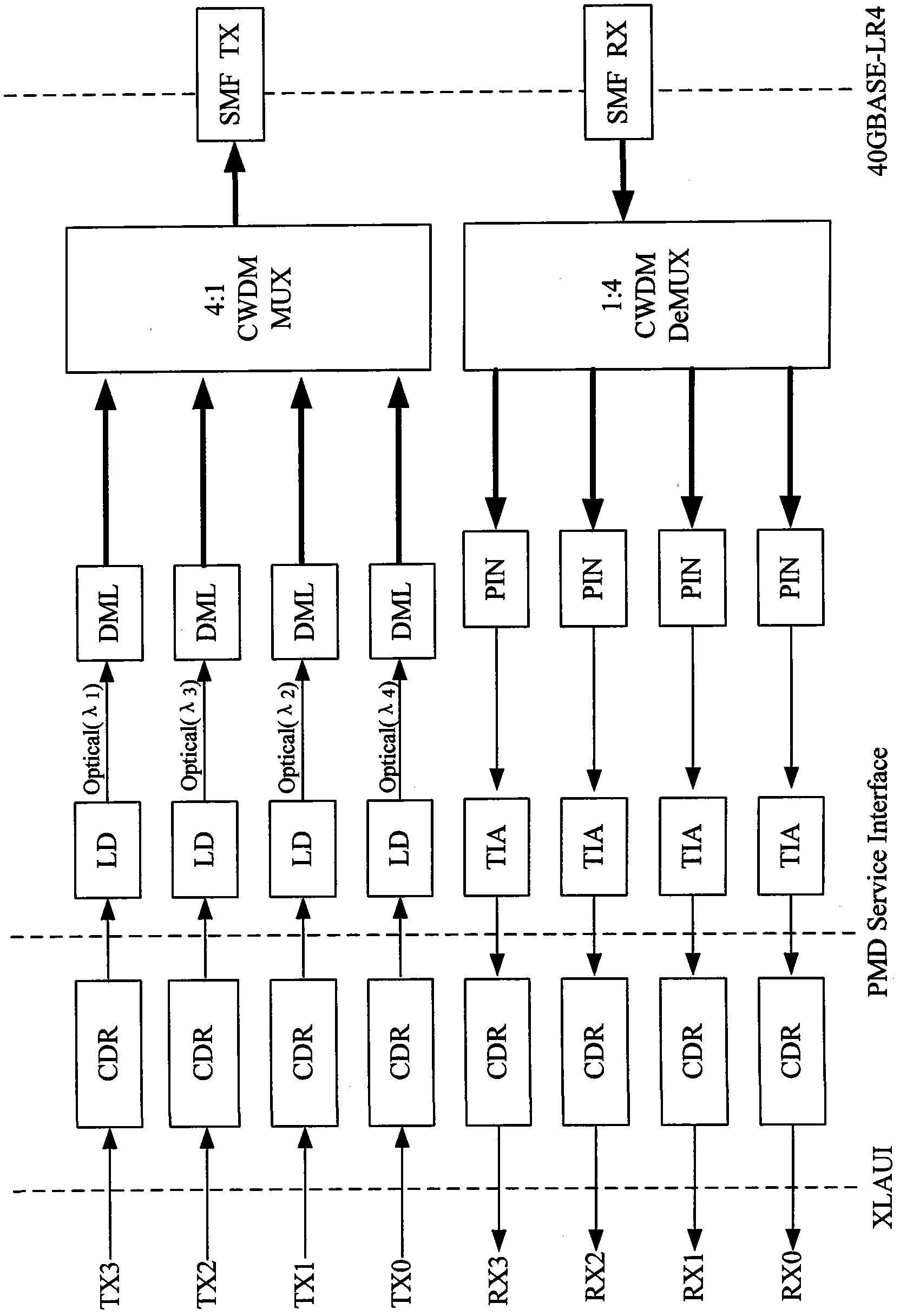

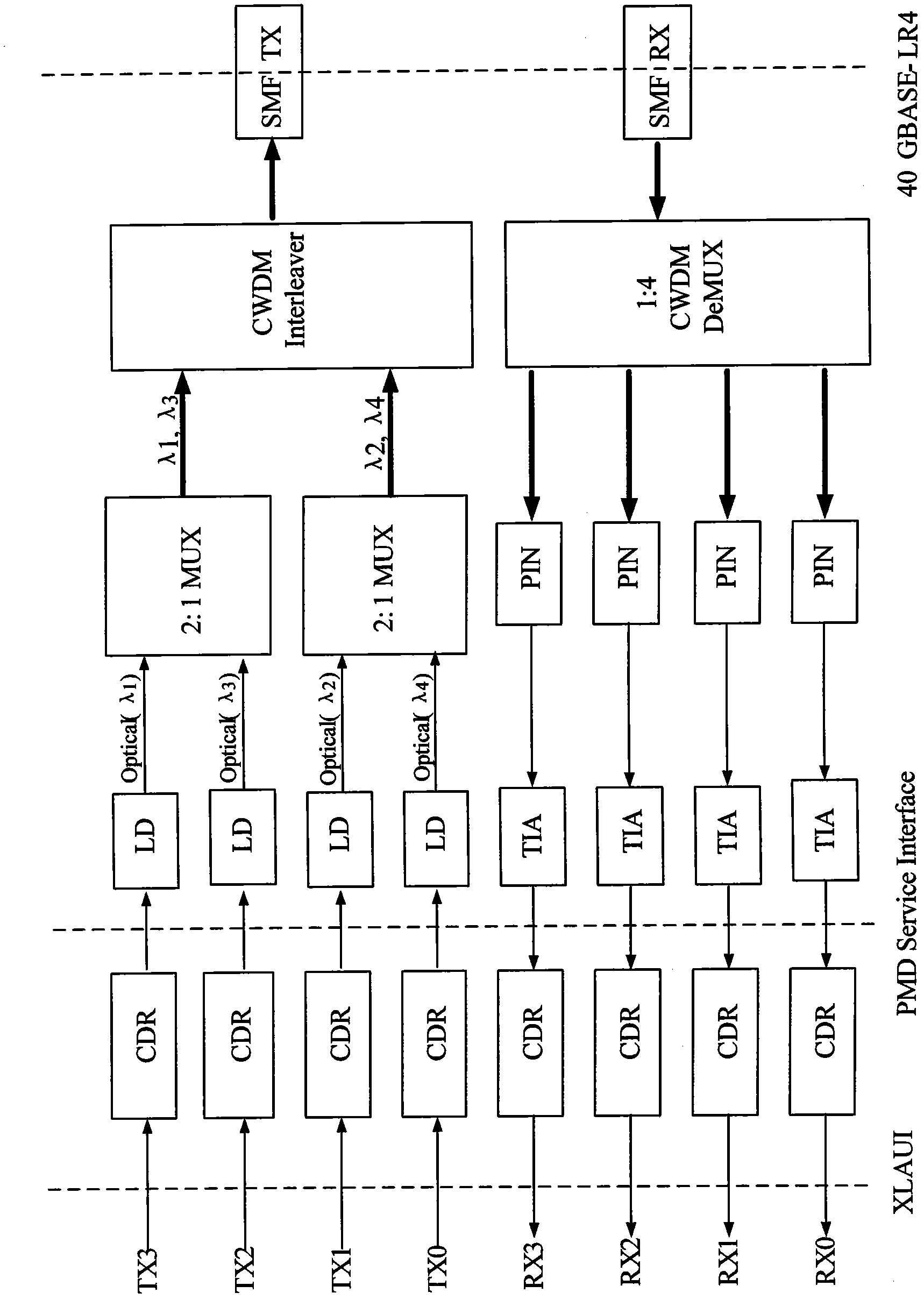

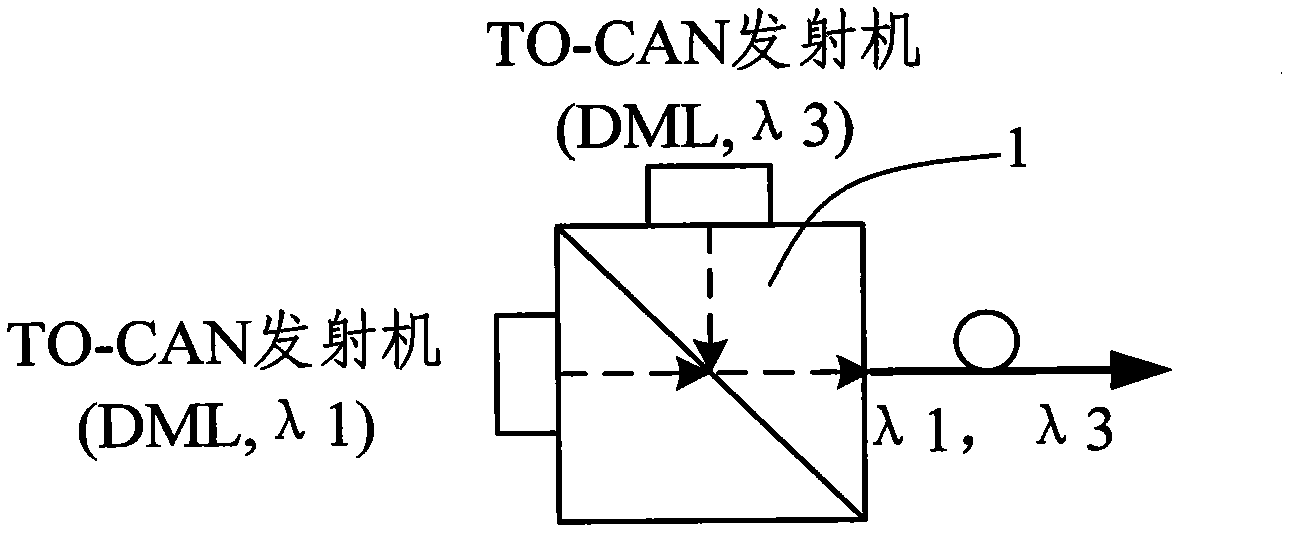

ActiveCN102231652ASimple structureLow costWavelength-division multiplex systemsElectromagnetic transceiversVIT signalsTransceiver

The invention discloses a C form-factor pluggable (CFP) optical transceiver with an interleaver. The CFP optical transceiver comprises a transmitter and a receiver. The transmitter has two groups of 2:1 modified multiplexers and the interleaver connected with the 2:1 modified multiplexers by an optical fiber, wherein the 2:1 modified multiplexers and the interleaver are all used for coupling two paths of optical signals with different wavelengths into the same optical fiber for transmission. The CFP optical transceiver with the interleaver is used for 40G or 100G LR4 and ER4 type CFP communication systems, has the advantages of simple structure and low cost, and is easy to package and produce in batches. In the structure, coarse wavelength division multiplexing (CWDM) / local area network-wavelength division multiplexing (LAN-WDM) optical signals with four wavelengths are multiplexed into two groups of optical signals by the 2:1 modified multiplexers (2:1MUX), and then the two groups of optical signals enter the same optical fiber by the interleaver. By the technology provided by the invention, the cost of the receiver can be reduced to 1 / 5 to 1 / 10 of that of the prior art.

Owner:WUHAN TELECOMM DEVICES

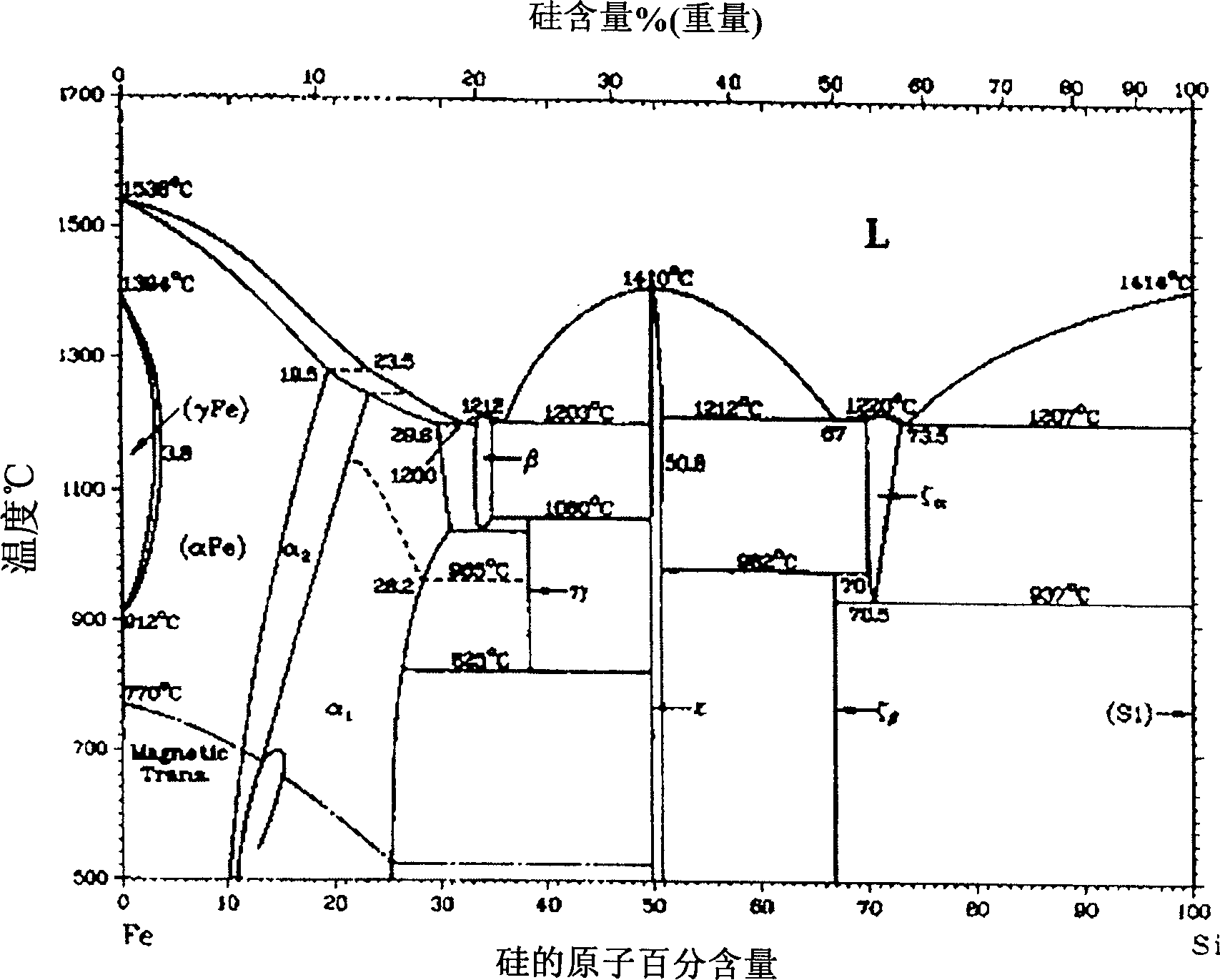

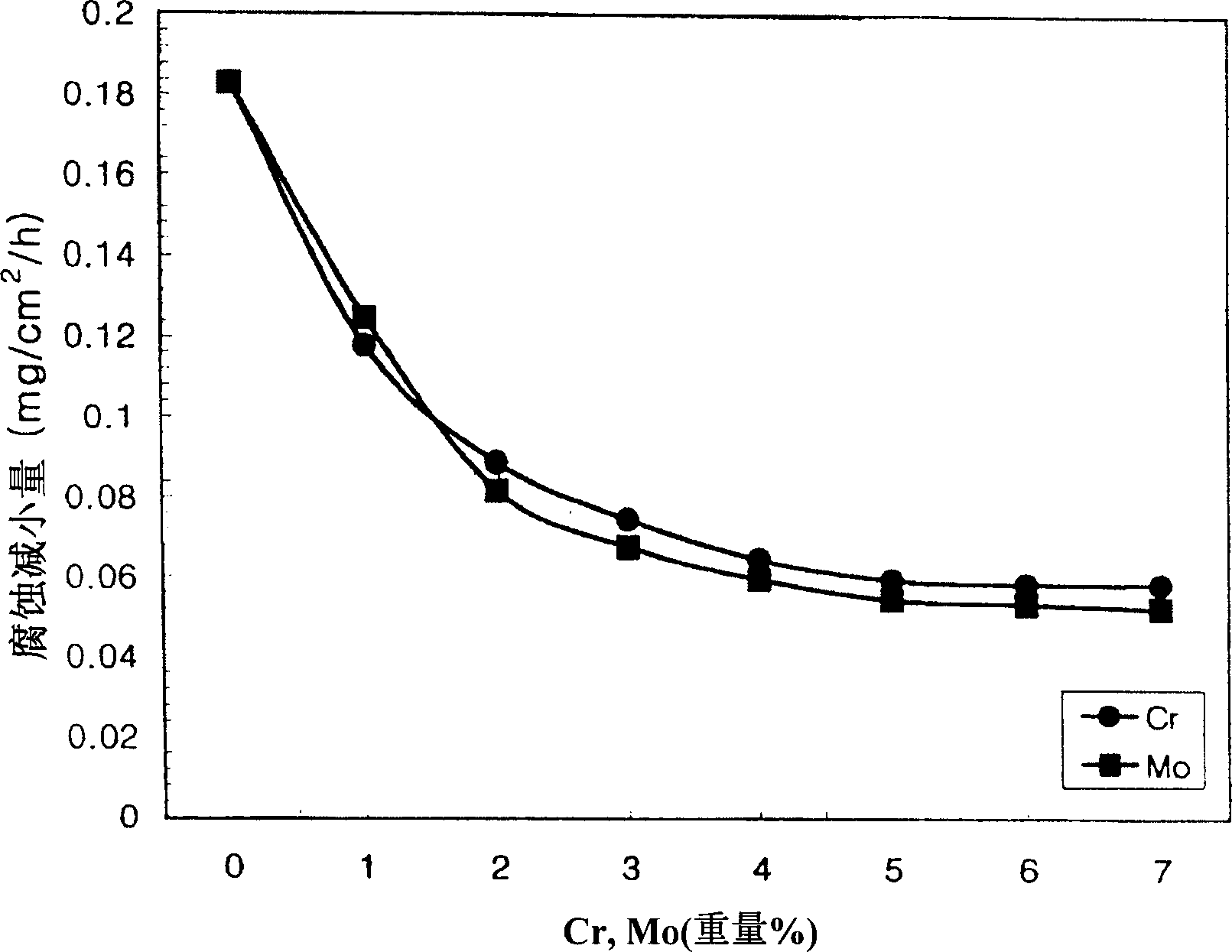

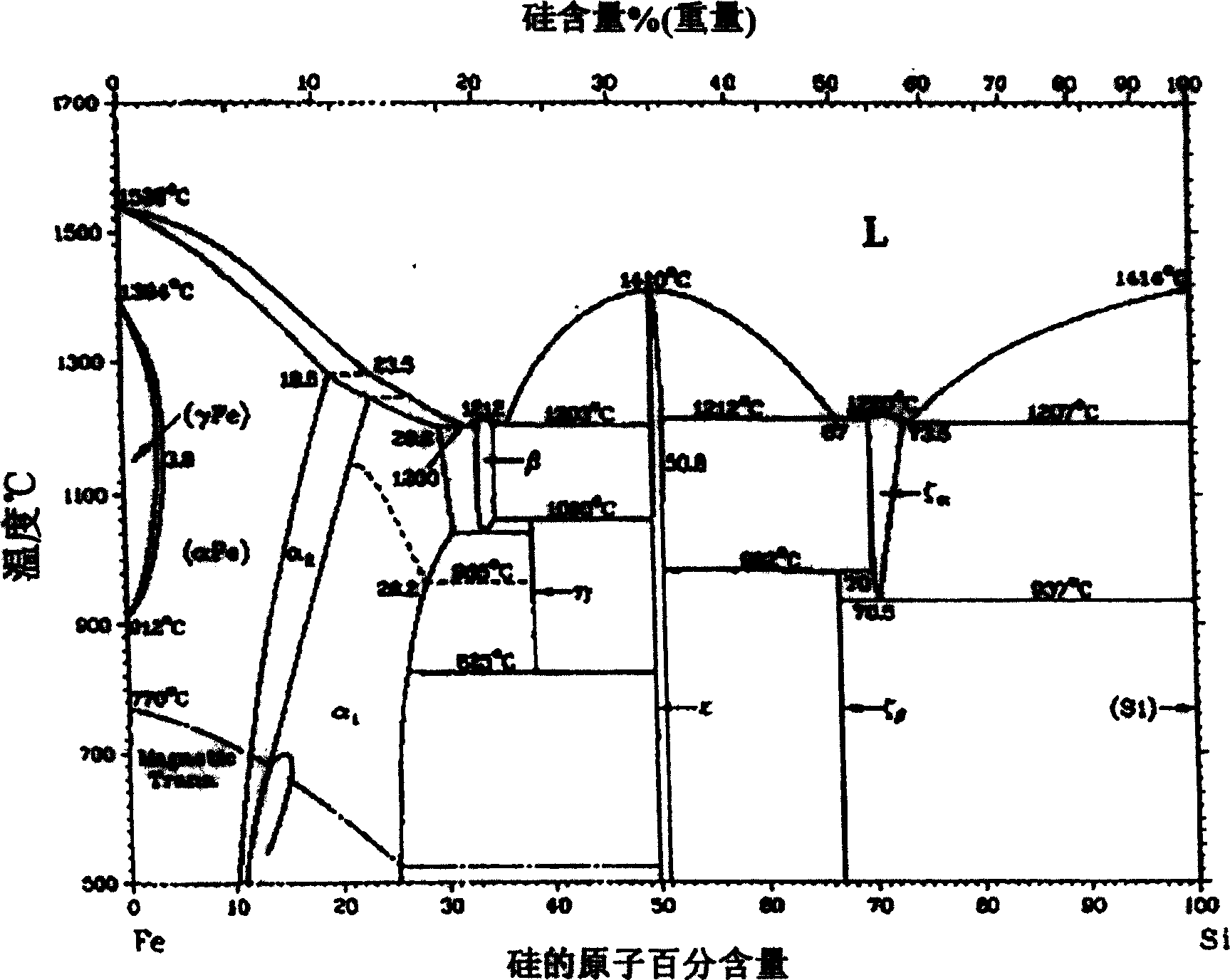

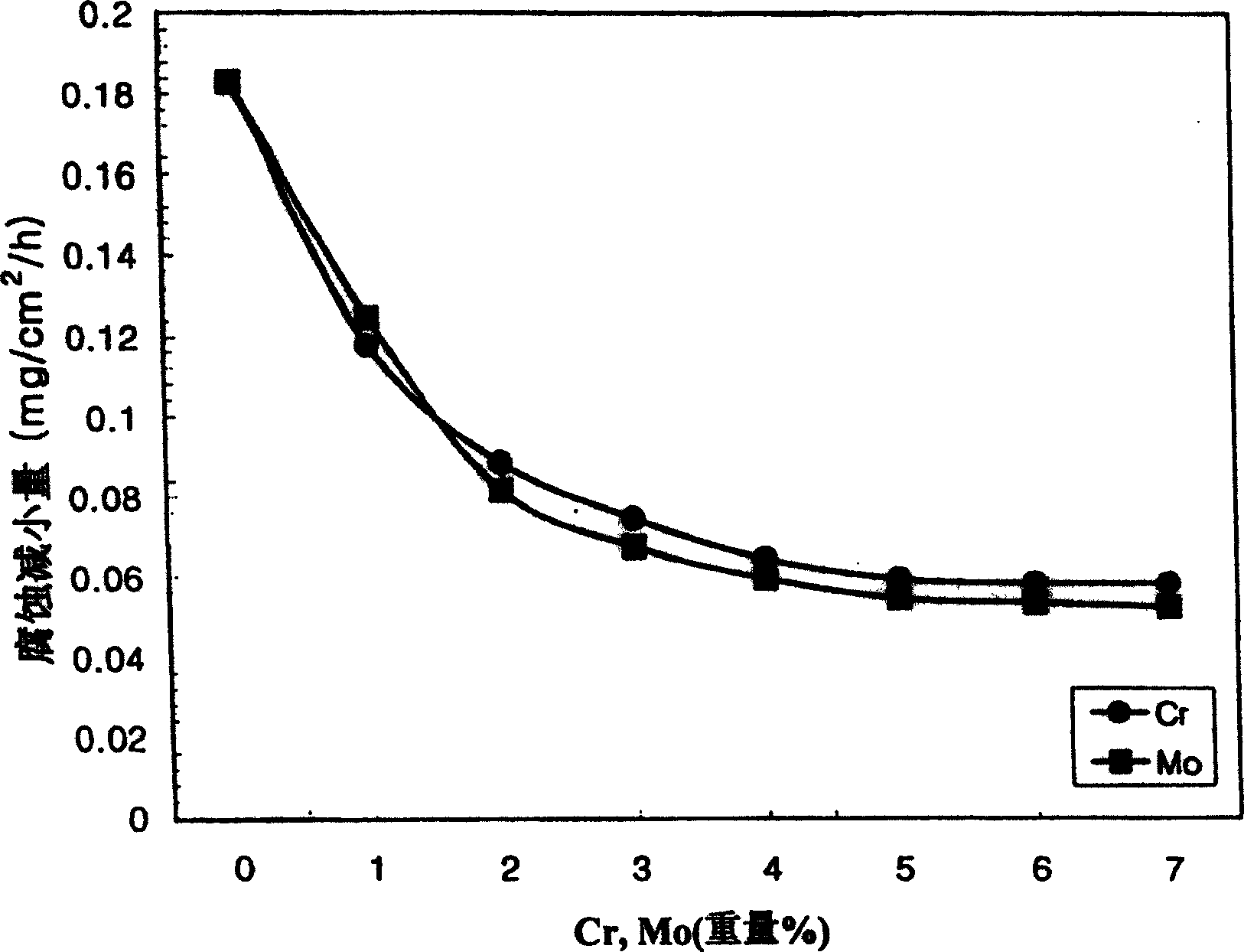

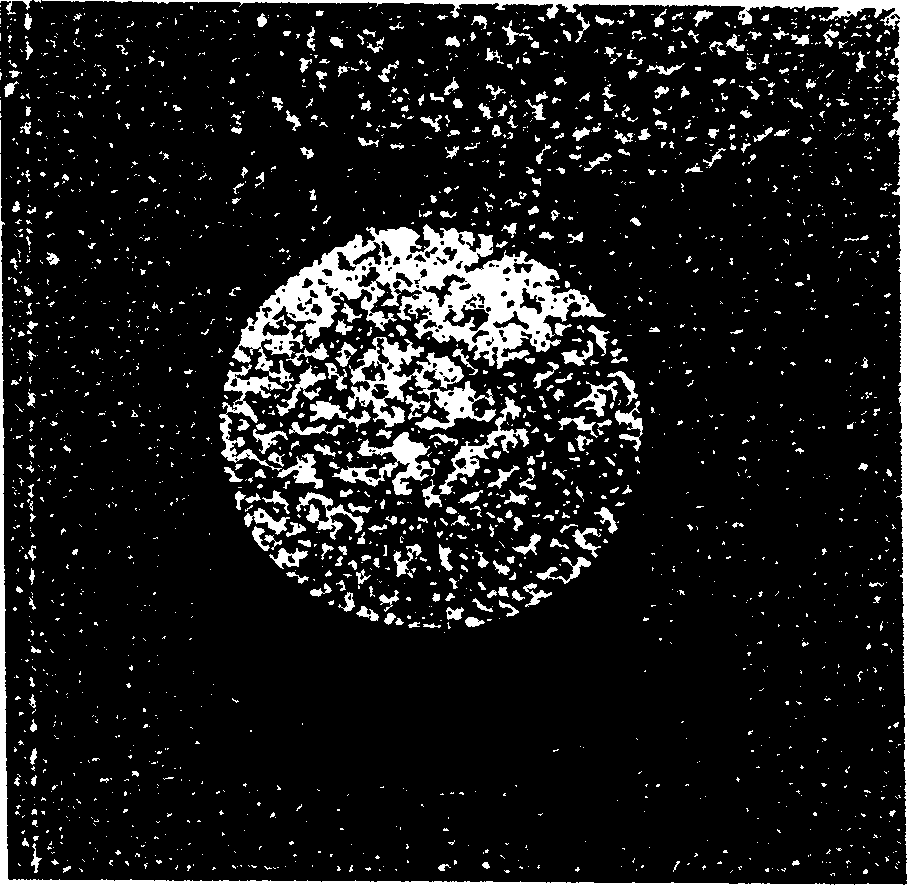

Acid-proof high silicon cast iron and its manufacturing process

The present invention provides a high silicon cast iron superior in acid resistance, which not only possesses improved tensile strength compared to conventional high silicon cast iron, but also is inexpensive and mass producible, by improving the manufacturing process without adding any apparatus, and a manufacturing method thereof. This high silicon cast iron includes silicon(Si) 13.5-15.5 wt.%, carbon(C) 0.7-1.1 wt.%, manganese(Mn) 2.2 wt.% or less, at least one element between chromium(Cr) 1-5 wt.% and molybdenum(Mo) of 1-5 wt.%, and the balance iron(Fe) with unavoidable impurities. The manufacturing method comprises heating a molten metal of the above composition at a temperature of 1,650 DEG C. or higher to remove impurities, tapping it into a ladle in which a misch metal 0.1-0.4 wt.% against the weight of the molten metal is added, and casting the molten metal while controlling it to the lowest castable temperature, namely 1,270-1,350 DEG C..

Owner:WOOJIN

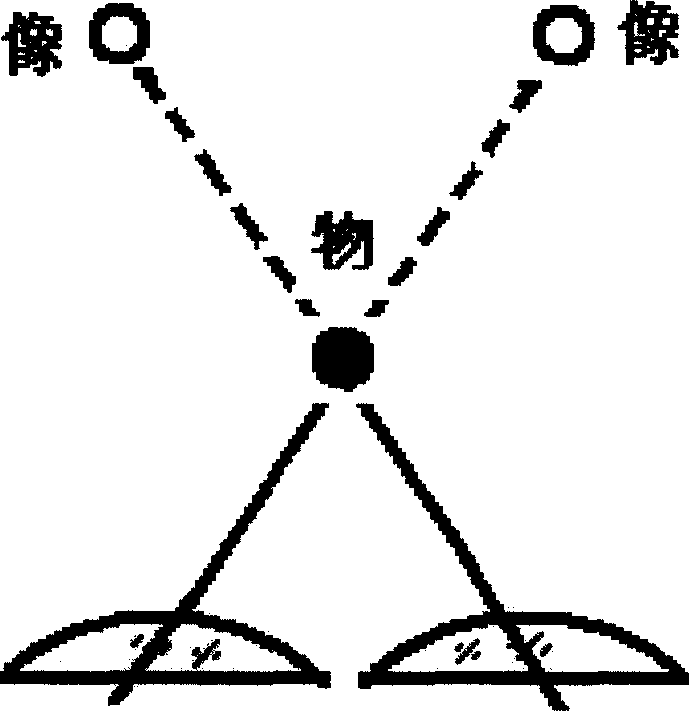

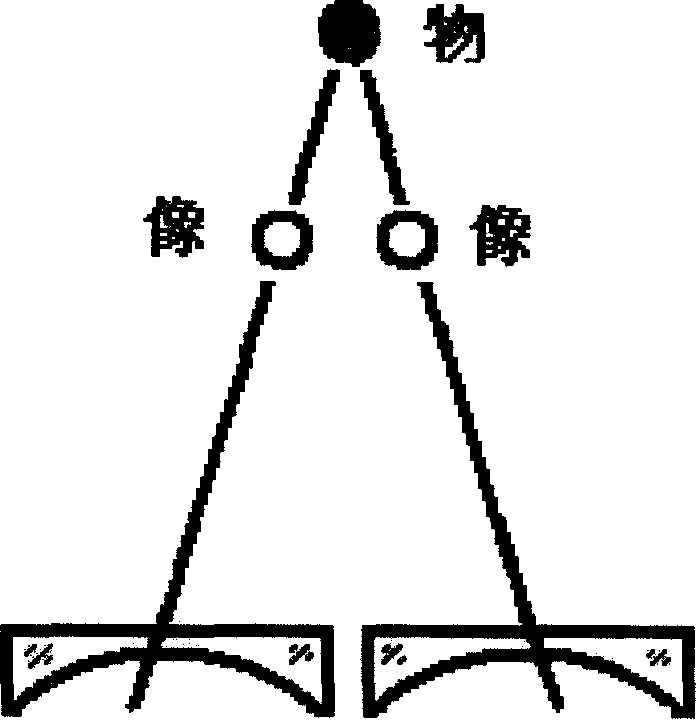

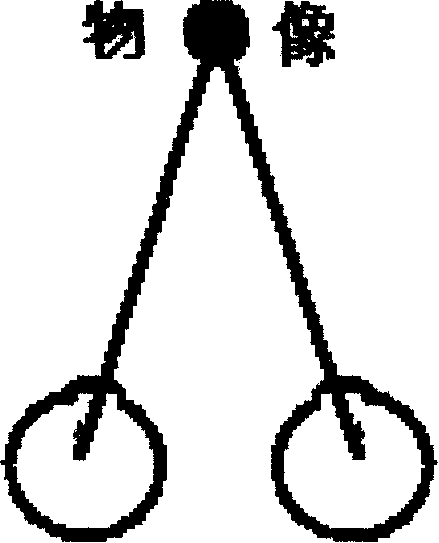

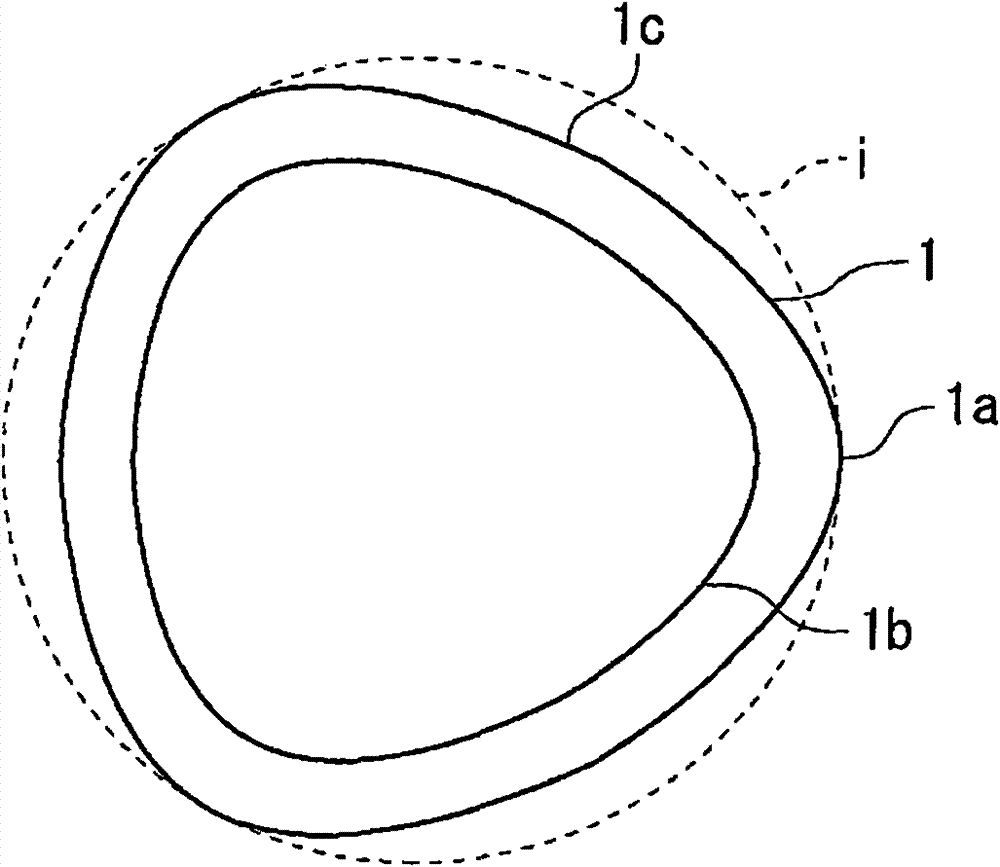

Collections glasses piece, collections glasses and uses thereof

InactiveCN101201465AImprove versatilityNot easy to fatigueSpectales/gogglesNon-optical partsPresbyopiaUses eyeglasses

The invention provides a collection spectacle lens, a collection eyeglasses and an application thereof and belongs to the technical field of the eyeglasses. The invention is characterized in that the spectacle lens of the collection eyeglasses is the collection spectacle lens and the collection eyeglasses changes binoculus collection with the collection spectacle lens, moreover, the collection glasses can match with a presbyopia eyeglasses or myopia eyeglasses of the prior art and improves the shortcomings thereof; the invention can make the eyes feel comfortable without fatigue when in watching. The invention is a comfortable type presbyopia eyeglasses or comfortable type myopia eyeglasses. The teenager can keep out myopia when in learning with the invention.

Owner:王霖华

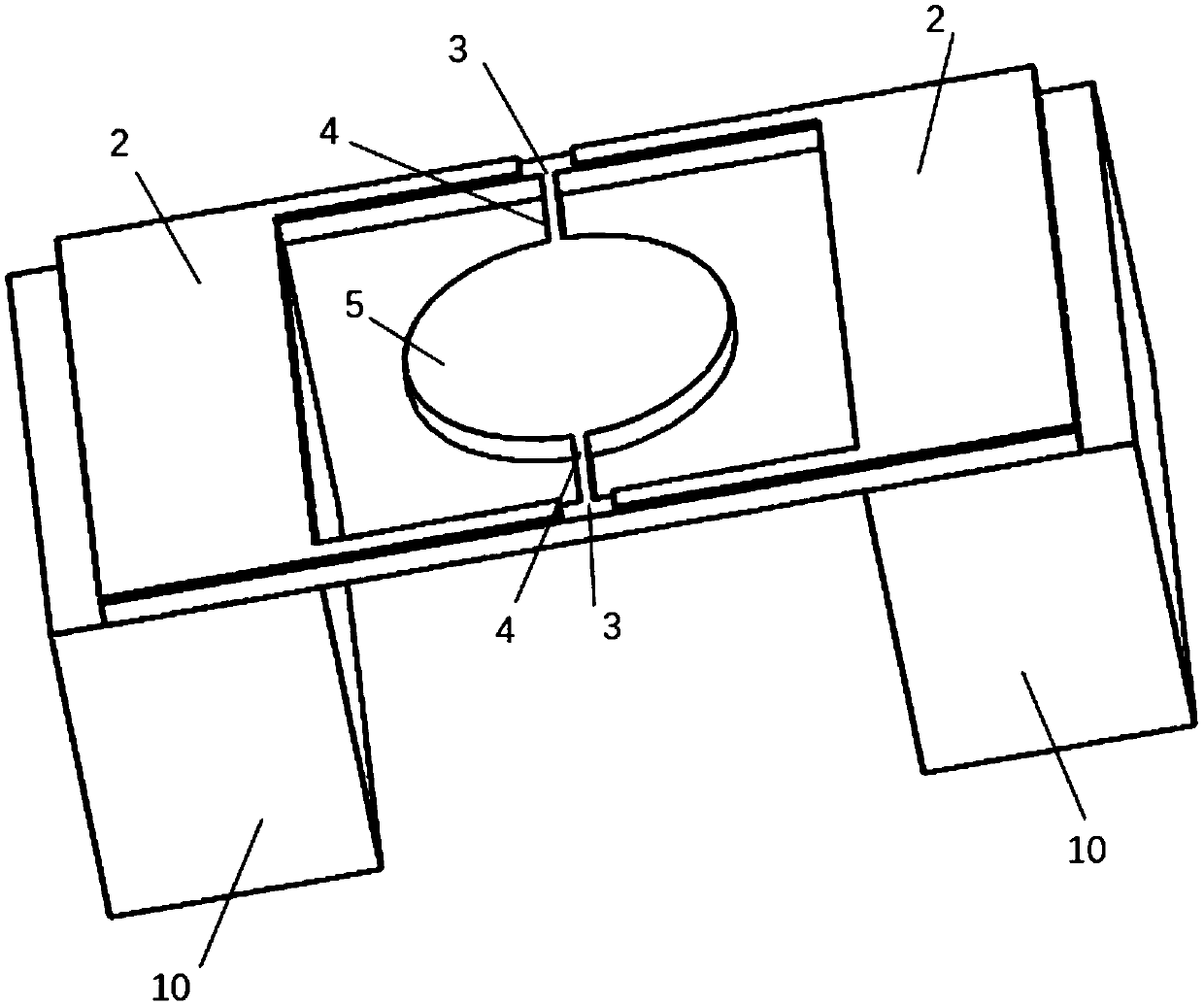

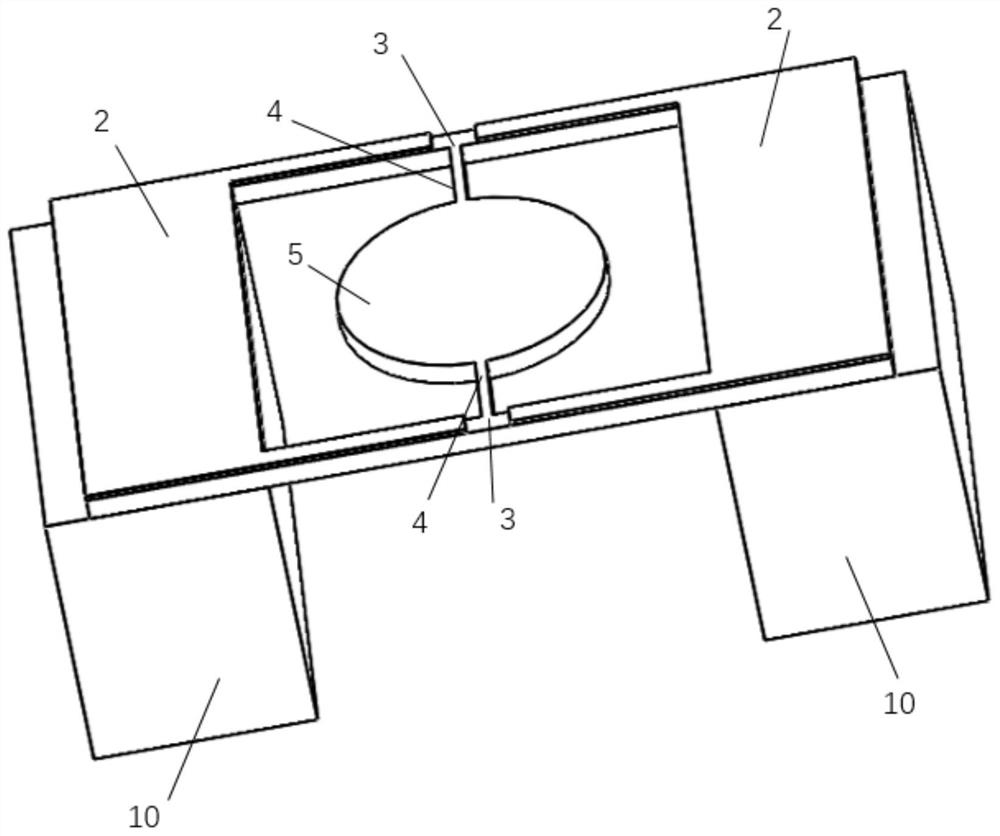

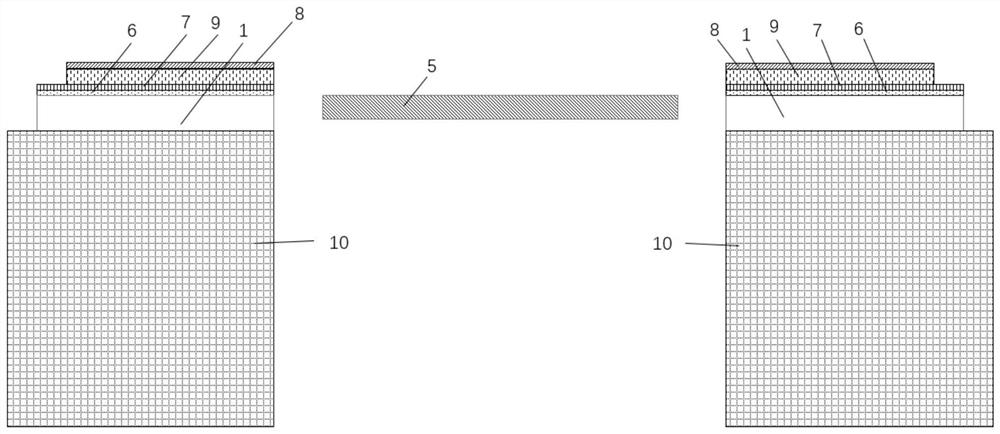

MEMS scan mirror

The invention discloses a MEMS scan mirror. The MEMS scan mirror comprises two piezoelectric ceramic blocks, two piezoelectric driving arms, two cross beams, two torsion beams and a reflecting mirrorsurface, wherein an interval distance is arranged between the two piezoelectric ceramic blocks, the two piezoelectric driving arms are separately arranged on the two piezoelectric ceramic blocks, thetwo cross beams are connected in parallel between the two piezoelectric driving arms, the two torsion beams and the reflecting mirror surface are connected in series between the two cross beams, and the reflecting mirror surface is connected between the two torsion beams; the voltage applied by the two piezoelectric driving arms are opposite, so that the two piezoelectric driving arms bend in opposite directions, and the reflect mirror surface is driven to deflect; and the voltages applied by the two piezoelectric ceramic blocks are opposite, so that the deformation of the two piezoelectric ceramic blocks in opposite directions in the direction perpendicular to the reflecting mirror surface drives the reflecting mirror surface to deflect and is superposed with a deflection angle of the reflecting mirror surface caused by the piezoelectric driving arms to amplify the deflection angle of the reflecting mirror surface. The scan mirror can realize the large deflection angle, and has smallvolume, high reliability and simple structure and manufacturing process.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

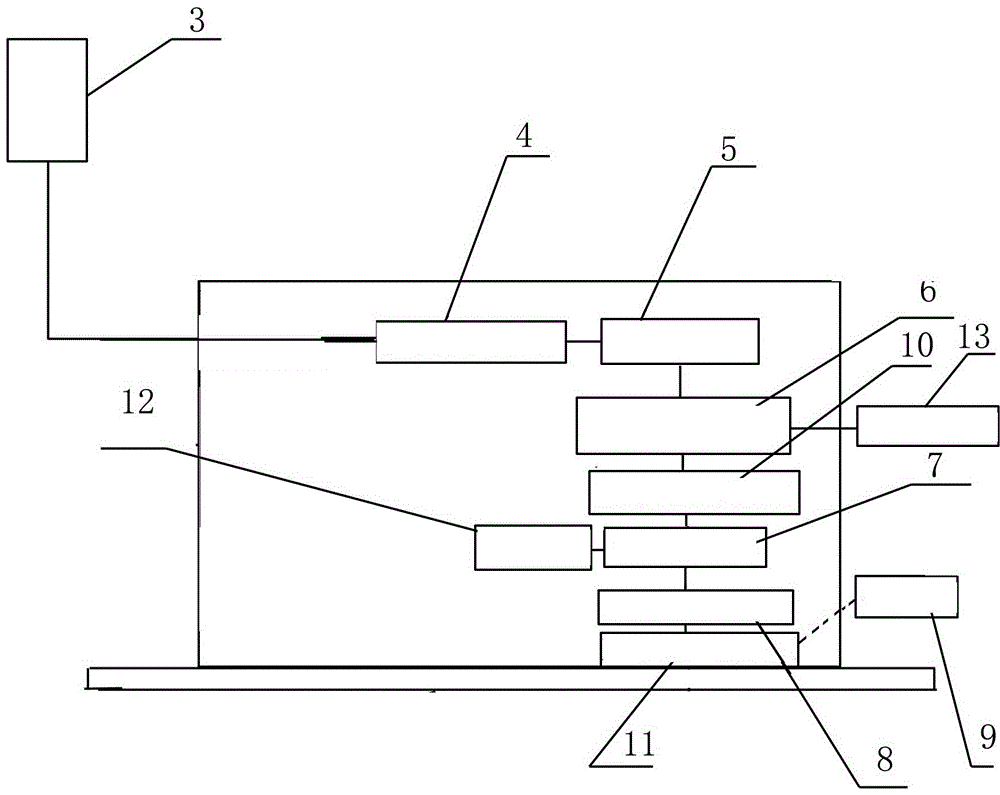

Device assembly for power line fault testing

InactiveCN105911432AControllable parametersAmplitude controllableTransmission systemsFault locationAnalog-to-digital converterElectric power

The invention discloses a device assembly for power line fault testing. An output end of a travelling wave sensor (3) is connected with an input end of a signal amplifying circuit (4), an input end of an analog-digital converter (5) is connected with an output end of the signal amplifying circuit (4), an output end of the analog-digital converter (5) is connected with a central processor (6), an input end of the central processor (6) is connected with the output end of the analog-digital converter (5), an output end of the central processor (6) is connected with a short message server (7), an input end of the short message server (7) is connected with the output end of the central processor (6), an output end of the short message server (7) is connected with a short message acquisition module (8), an input end of the short message acquisition module (8) is connected with the output end of the short message server (7), and an output end of the short message acquisition module (8) is connected with a mobile phone receiving terminal (9).

Owner:兴化市唐刘兽医站牲畜交易所 +2

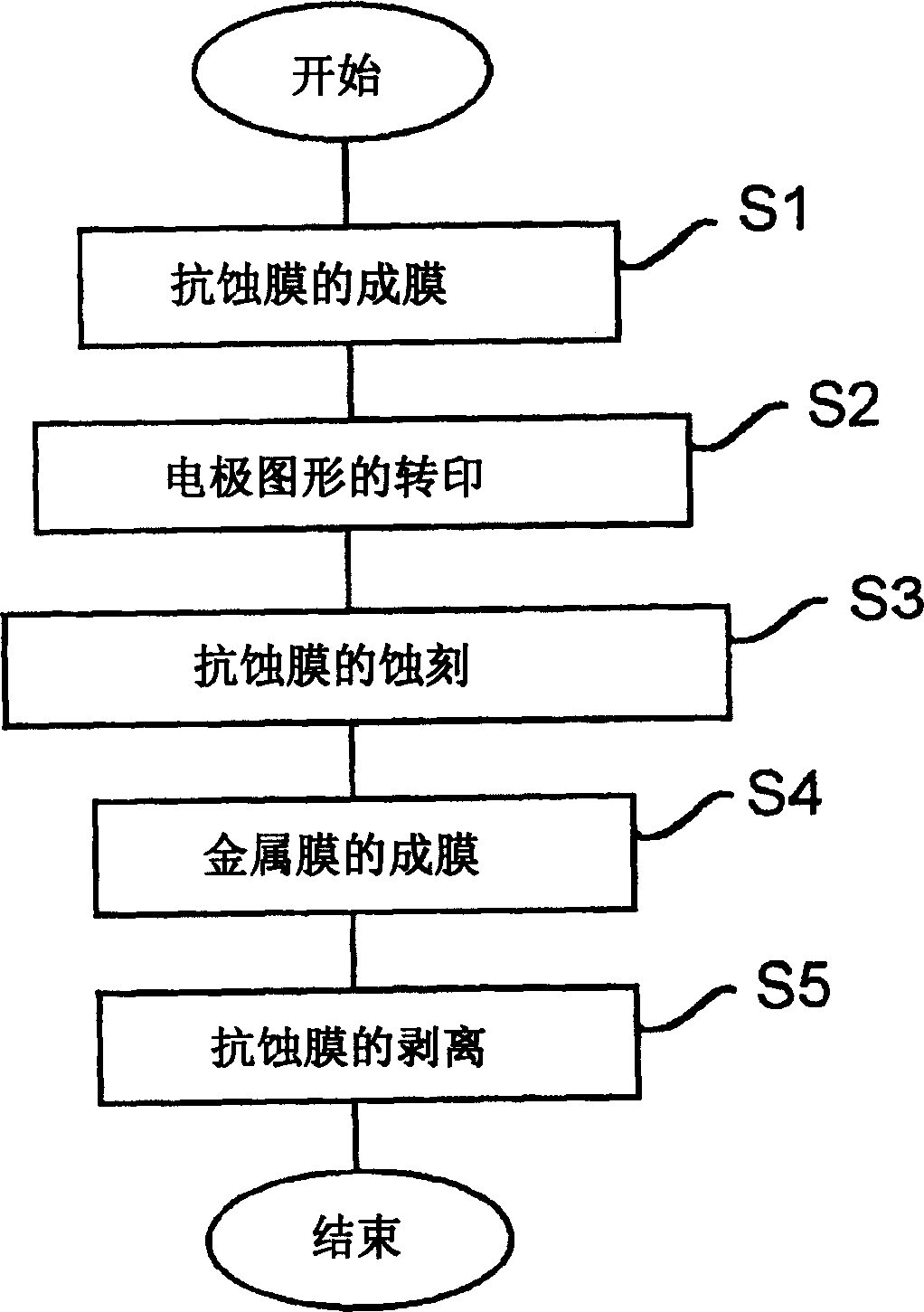

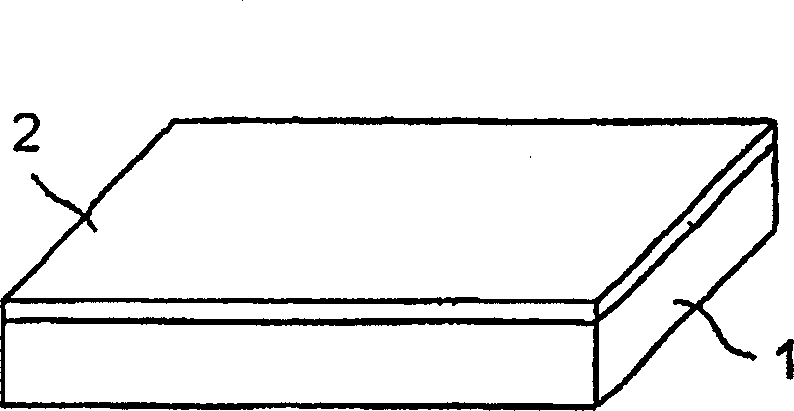

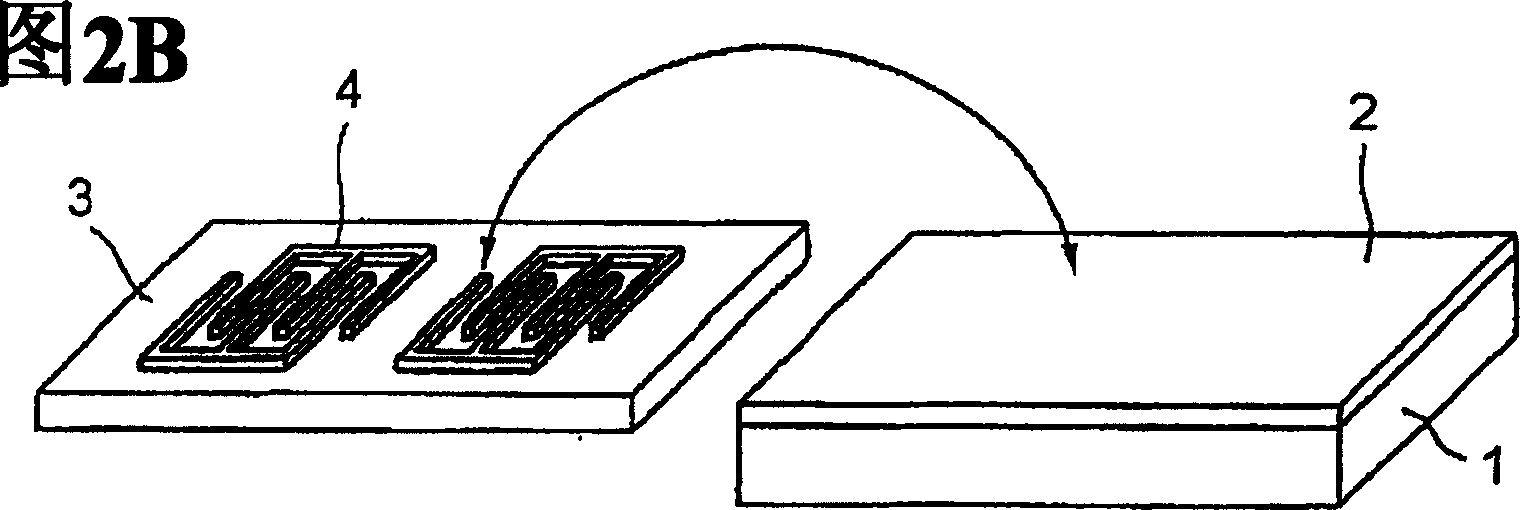

Surface acoustic wave element and method for fabricating semiconductor device

A method for manufacturing surface acoustic wave elements and semiconductor devices, in which a template (3) with high-precision concavities and convexities manufactured in advance by photolithography technology using electron beams is pressed onto a substrate (1) coated with a resist film (2) ), transfer the resist pattern (5). Then, on the resist film pattern (5) formed by transfer printing, a metal thin film (6) is formed and peeled off together with the resist film (2) by a lift-off method.

Owner:NEC CORP

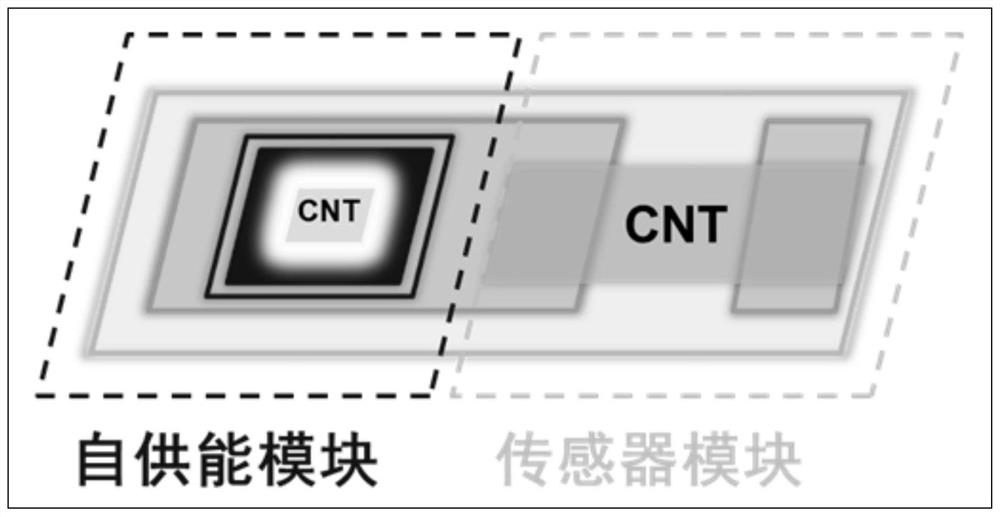

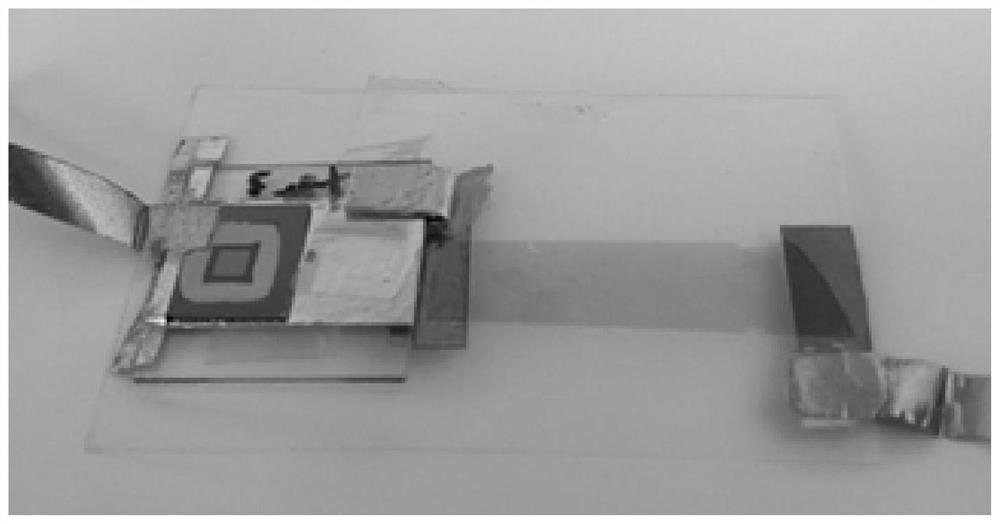

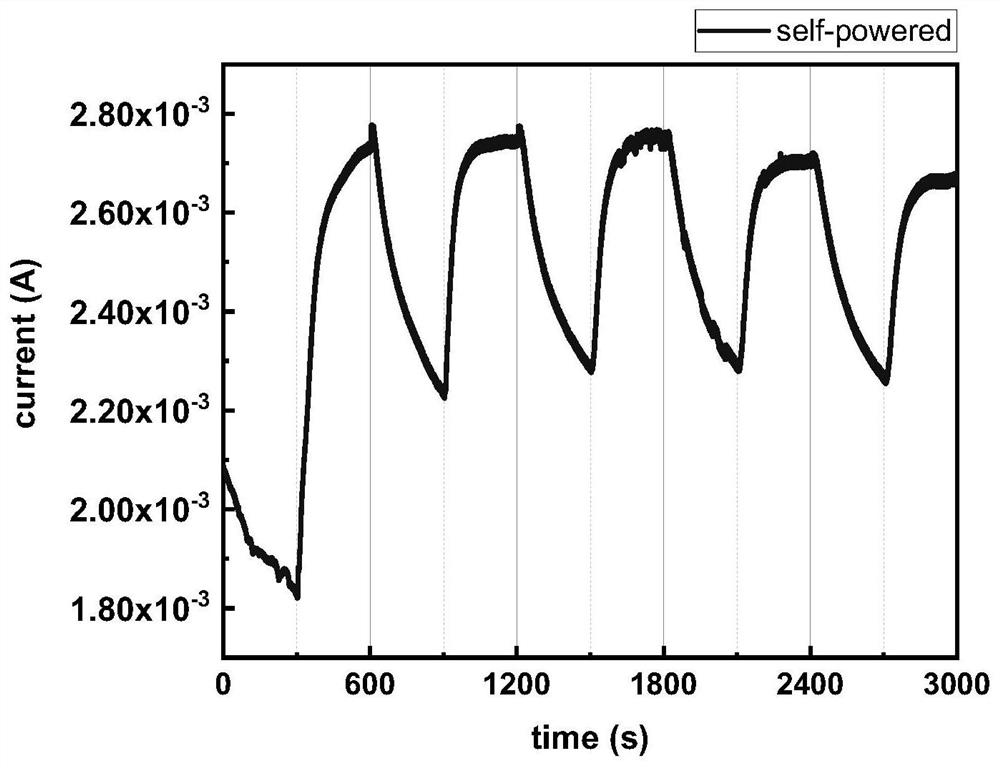

Fabrication method of self-powered gas sensor based on single-walled carbon nanotubes

ActiveCN112485296BThe effect is not weakGood effectMaterial analysis by electric/magnetic meansPhotovoltaic energy generationEvaporation (deposition)Ptru catalyst

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

C form-factor pluggable (CFP) optical transceiver with interleaver

ActiveCN102231652BSimple structureLow costWavelength-division multiplex systemsElectromagnetic transceiversTransceiverCommunications system

The invention discloses a C form-factor pluggable (CFP) optical transceiver with an interleaver. The CFP optical transceiver comprises a transmitter and a receiver. The transmitter has two groups of 2:1 modified multiplexers and the interleaver connected with the 2:1 modified multiplexers by an optical fiber, wherein the 2:1 modified multiplexers and the interleaver are all used for coupling two paths of optical signals with different wavelengths into the same optical fiber for transmission. The CFP optical transceiver with the interleaver is used for 40G or 100G LR4 and ER4 type CFP communication systems, has the advantages of simple structure and low cost, and is easy to package and produce in batches. In the structure, coarse wavelength division multiplexing (CWDM) / local area network-wavelength division multiplexing (LAN-WDM) optical signals with four wavelengths are multiplexed into two groups of optical signals by the 2:1 modified multiplexers (2:1MUX), and then the two groups of optical signals enter the same optical fiber by the interleaver. By the technology provided by the invention, the cost of the receiver can be reduced to 1 / 5 to 1 / 10 of that of the prior art.

Owner:WUHAN TELECOMM DEVICES

Myopia glasses and lens

ActiveCN101211019BLess discomfortReduce fatigueNon-optical partsOptical partsUses eyeglassesMultifocal lenses

The invention relates to a myopic eyeglass, and belongs to the eyeglass technical field. The myopic eyeglass includes a spectacle lens and a support for supporting the spectacle lens, and is characterized in that the distance between an optical center of the spectacle lens facing a left eye and that of the spectacle lens facing a right eye is smaller than a near pupillary distance of a user, equivalent to the myopic spectacle lens in the prior art combined with a prism with an external base, wherein the spectacle facing the left eye and the spectacle facing the right eye may be separated compound spectacle lenses or compound spectacle lenses united as one, or may be bifocal lenses or multifocal lenses. The myopic eyeglass not only improves the adjustment of the eyes but also improves the binocular gather, improves the observation effect of the eye, and enables the eye to feel comfortable and antifatigue.

Owner:王霖华

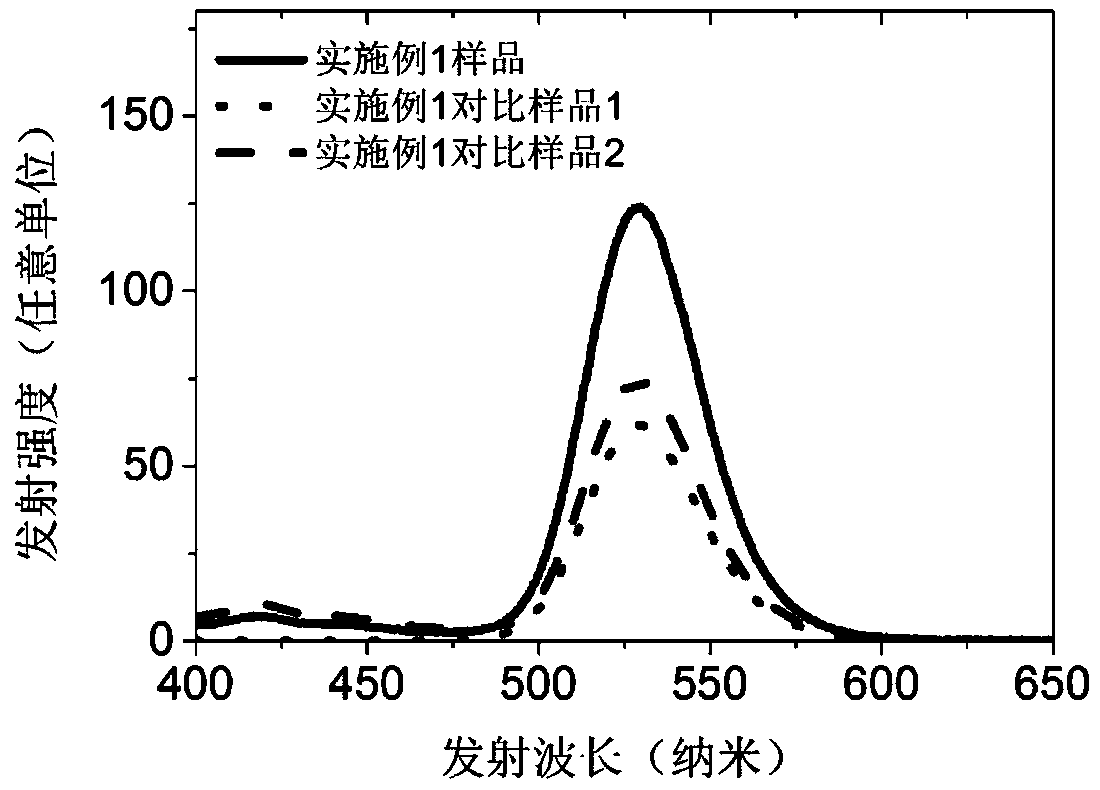

A kind of quantum dot composite scintillator material and preparation method thereof

ActiveCN106947468BHigh flicker efficiencyLow mass productionLuminescent compositionsEnergy transferHigh energy

The invention relates to a quantum dot composite scintillator material, and a preparation method thereof. The quantum dot composite scintillator material comprises an organic plastic matrix, and 1 to 5wt% of an organic high atomic number material, 5 to 15wt% of an organic luminophor, and 10 to 20wt% of a quantum dot luminescent material which are dispersed in the organic plastic matrix. Compared with the prior art, the quantum dot composite scintillator material possesses following advantages: doping of the organic high atomic number material is capable of improving blocking capacity on high energy photons; establishment of energy transferring between a matrix material and a quantum dot material is capable of achieving high scintillation efficiency of the quantum dot luminescent material under radiation excitation.

Owner:TONGJI UNIV

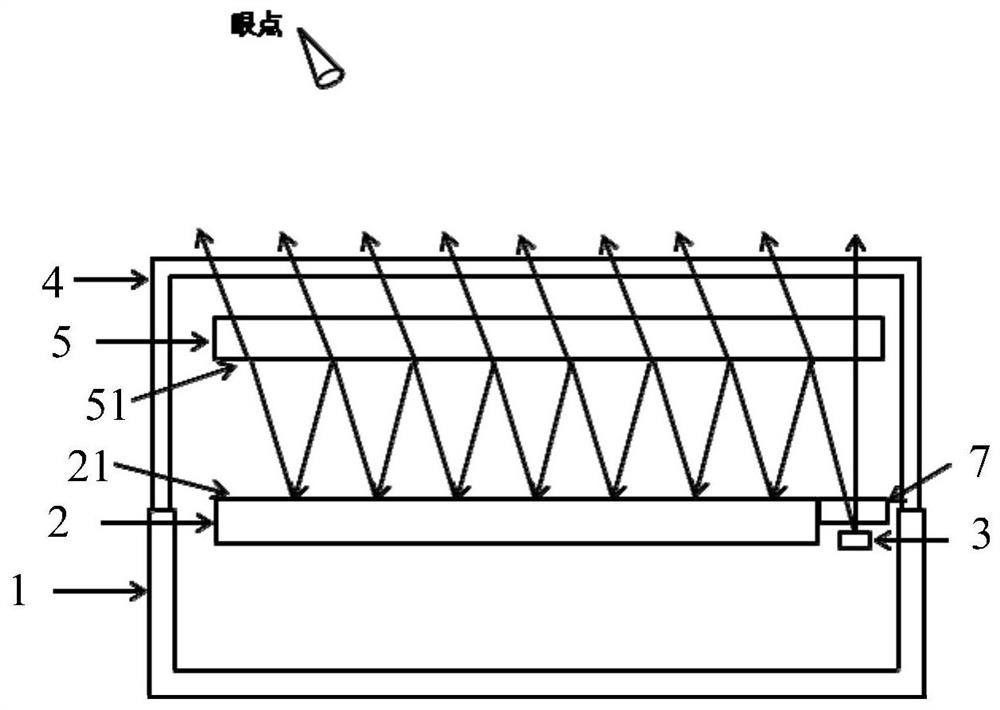

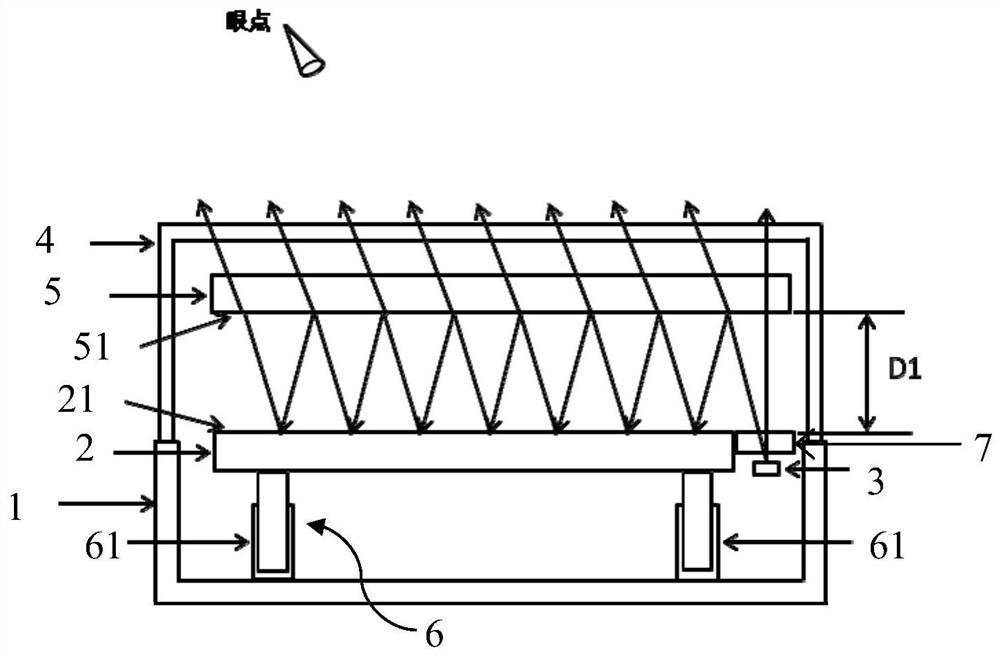

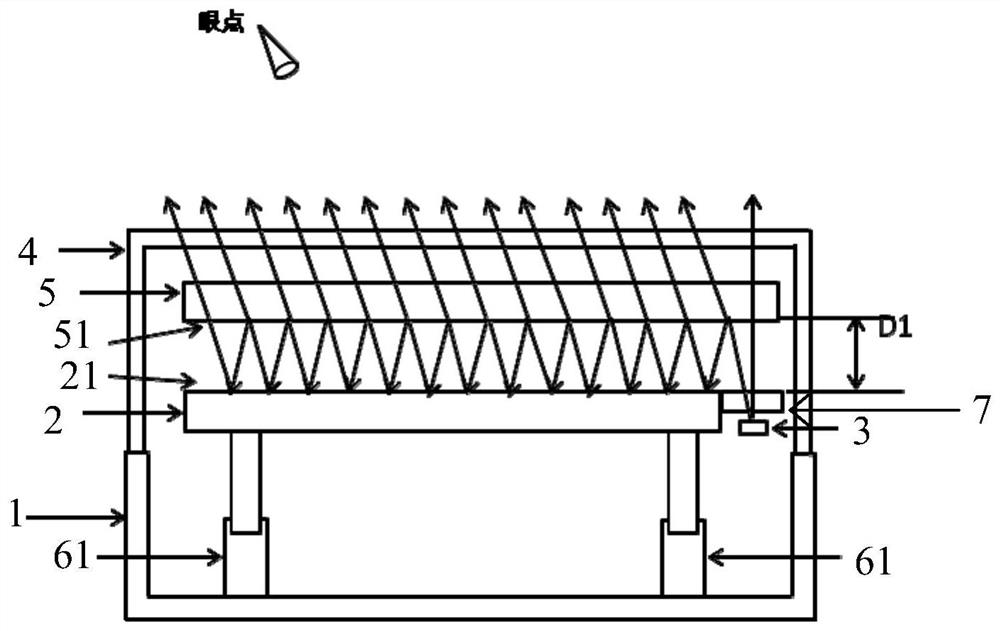

deep sense light emitting device

ActiveCN111765427BLow costEasy to mass produceVehicle headlampsLighting and heating apparatusBeam splitterMirror reflection

The invention discloses a light-emitting device with a sense of depth, which comprises a lampshade, a lamp housing, a decorative ring and LEDs. The LED is installed in the cavity of the outer lampshade and the lamp housing, the inner surface of the inner lampshade is provided with a light-splitting film, the outer surface of the decorative ring is a reflective surface, and the light-splitting film and the The reflective surfaces are arranged at relative intervals, the LED is located next to the bezel, the LED emits light toward the light splitting film, part of the light passes through the light splitting film and the inner lampshade, and part of the light is emitted by the light splitting film. The film reflects and shoots to the reflective surface, and the light splitting film and the reflective surface alternately reflect light as above. The present invention achieves a profound visual effect through alternate times of specular reflection between the light splitting film and the reflective surface. This application only needs at least one set of LEDs, which greatly saves the cost; and the LEDs are easy to mass-produce and the cost is low.

Owner:DONGFENG MOTOR CO LTD

Manufacturing method of liquid crystal display screen

InactiveCN1292298CReduce the chance of occurrenceReduce box thicknessLiquid crystal compositionsStatic indicating devicesLiquid layerCrystallography

The invention relates to a LCD-making method, especially a LCD-making method of packaging and making liquid crystal material by using the double-layer structure where the liquid layer is covered with polymer film and which is formed in the course that the polymer monomer is separated with the liquid crystal in the polymerization reaction during the no liquid crystal injection course of a single-basal plate. According to the requirement for device structure, it further uses the techniques of coating, splashing, photoetching, etc to complete making the liquid crystal screen. Compared with traditional liquid crystal screen making techniques, it omits the courses of making an empty box and injecting liquid crystal into the empty box. It has obvious advantage in making plastic basal boards and large-sized LCD. It can also use plastic basal plate, thus making the made liquid crystal screen very thin, and further reducing the thickness and weight of the liquid crystal screen box.

Owner:吉林北方彩晶数码电子有限公司

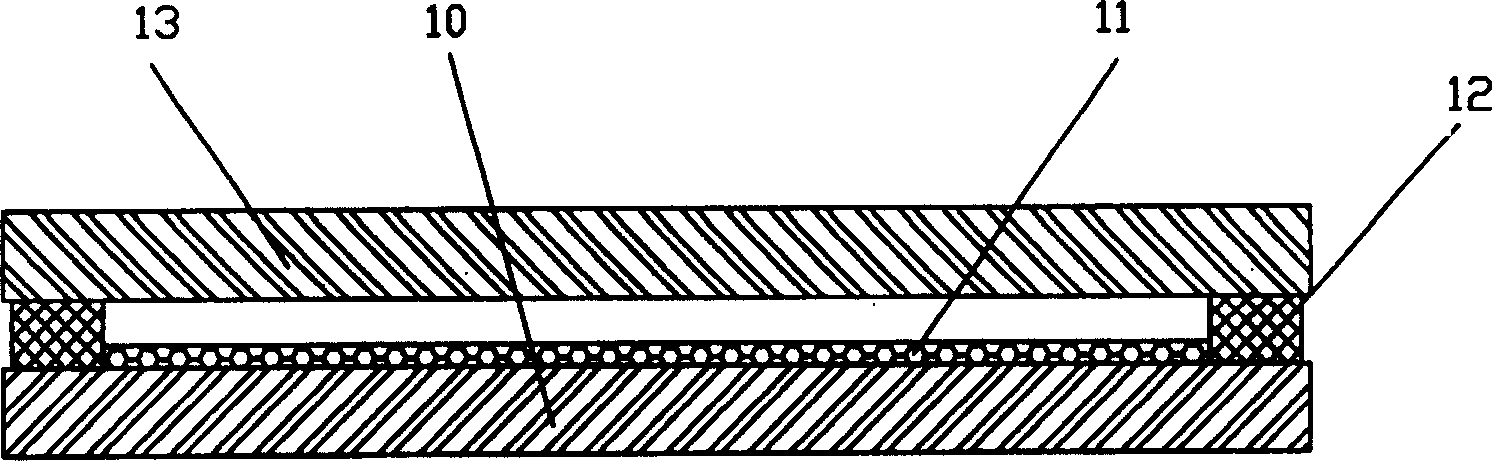

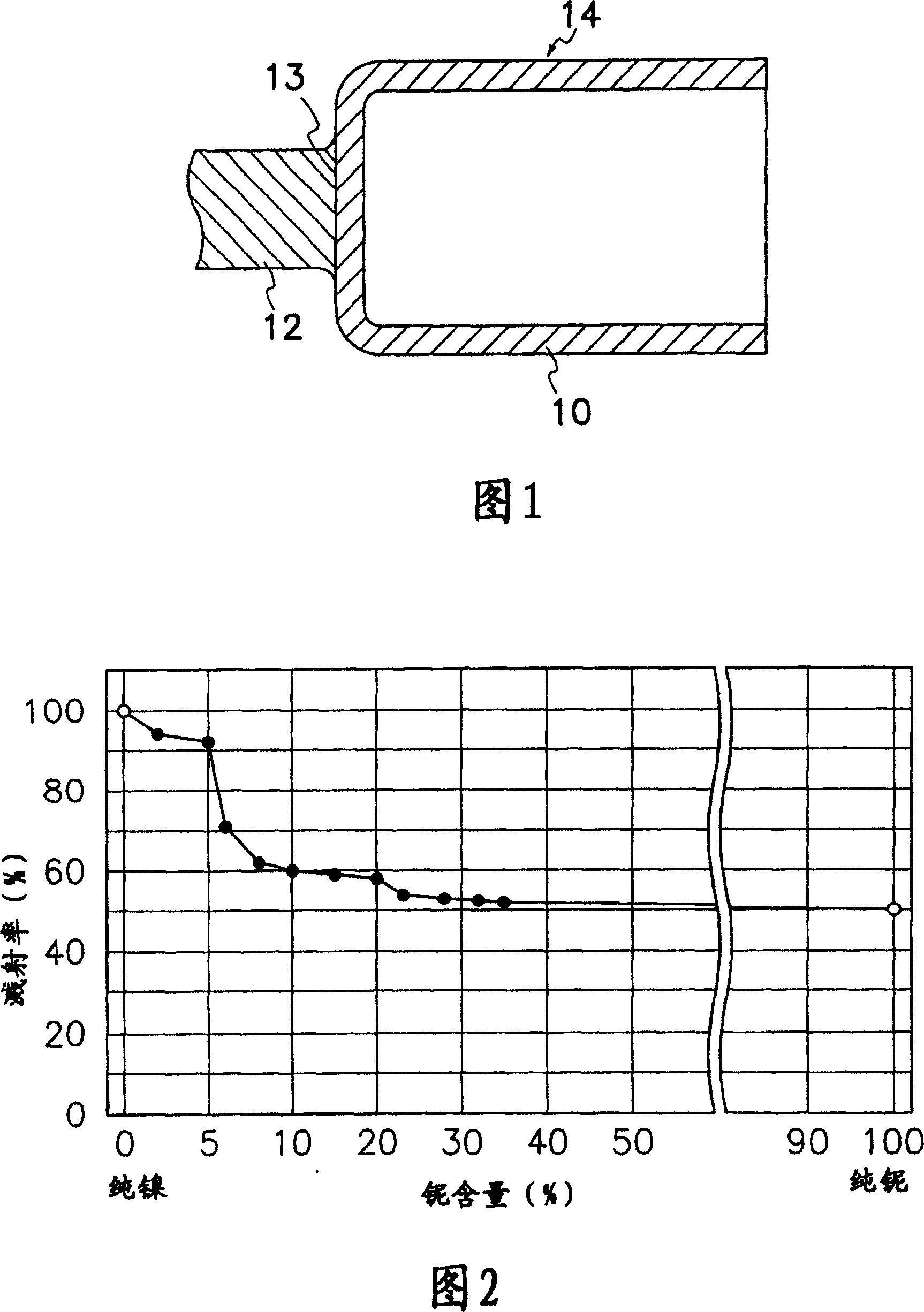

Electrode for cold cathode discharge tube and electrode assembly for cold cathode discharge tube

InactiveCN1322540CExcellent sputtering resistanceExtended service lifeElectric discharge tubesDischarge tube cold cathodesHigh resistanceNiobium

Provided is an electrode for a cold-cathode discharge tube and an electrode assembly for a cold-cathode discharge tube each having high resistance to sputtering, capable of extending the electrode service life, using an inexpensive material and is thereby capable of reducing the electrode cost, and having proper workability. This electrode for a cold-cathode discharge tube is formed of a Ni-Nb alloy, containing 6-32 wt.% of Nb and having a composition of unavoidable impurities and Ni in the remaining part. This electrode assembly for a cold-cathode discharge tube is composed of a cup-shaped electrode, formed of a Ni-Nb alloy containing 6-32 wt.% of Nb and having a composition of unavoidable impurities and Ni in the remaining part, and a lead fixed to the bottom surface of the electrode.

Owner:SANKEN ELECTRIC CO LTD

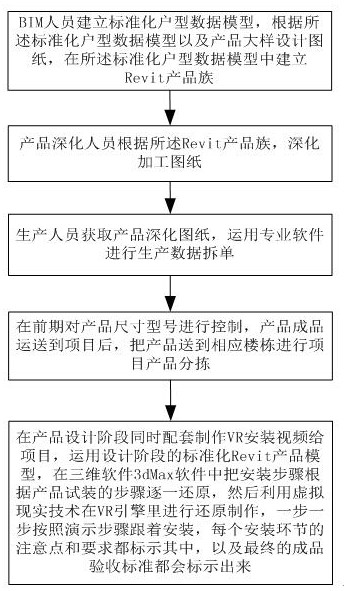

BIM and VR-based finished house batch hardcover fusion production construction method

PendingCN112182715AReduce generationEnsure consistencyGeometric CADData processing applicationsLink dataVisual sensitivity

The invention relates to a BIM and VR-based finished house batch hardcover fusion production construction method, which comprises the following steps of: establishing a standardized house type data model through BIM, simultaneously manufacturing VR installation videos to a project in a matching way in a product design stage, restoring installation steps one by one according to product trial assembly steps in three-dimensional software 3dMax software, then using a virtual reality technology to carry out reduction manufacturing in a VR engine, and following installation according to demonstration. In production links, production data and projects are matched, production personnel can pay more attention to the production links, a large amount of time does not need to be spent in processing the production data, generation of a large amount of production data is avoided, and production efficiency is improved. According to the method, three links of design, production and installation are broken through, the consistency of production and project installation link data is guaranteed through BIM data, installation specifications are converted into visual images and experience through the visual sensitivity of the VR technology, the quality of finished house batch fine decoration projects is improved, the production efficiency is improved, the production cost is reduced, and the productquality is guaranteed.

Owner:河南建祥装饰工程有限公司

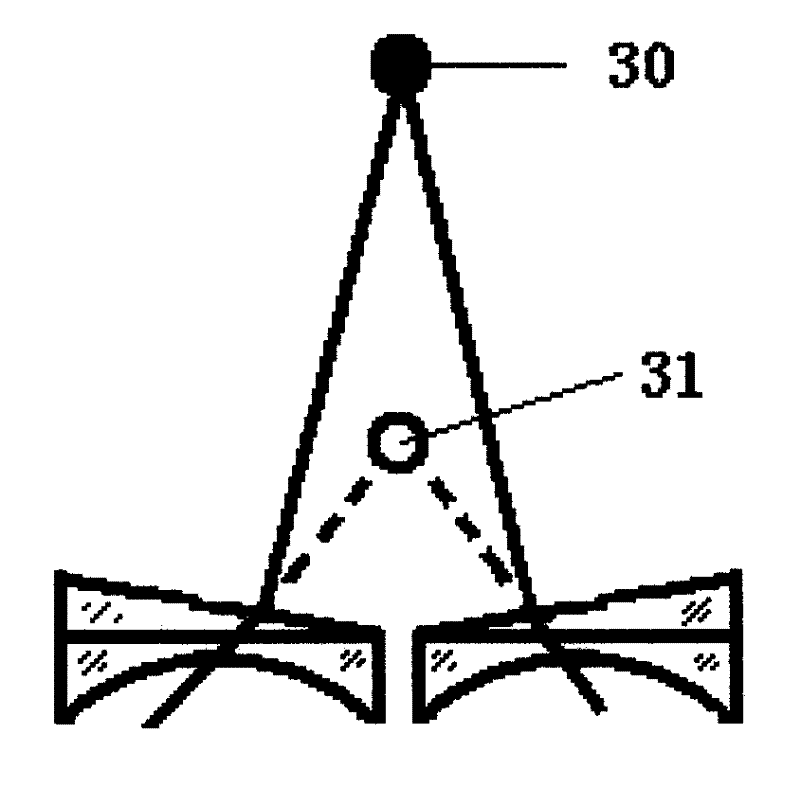

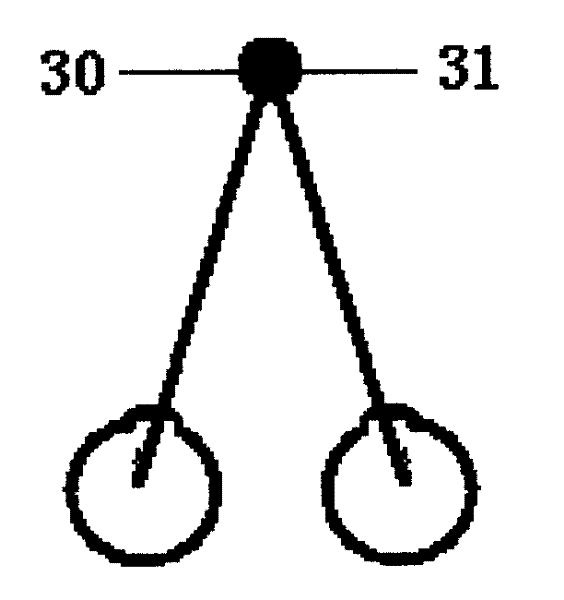

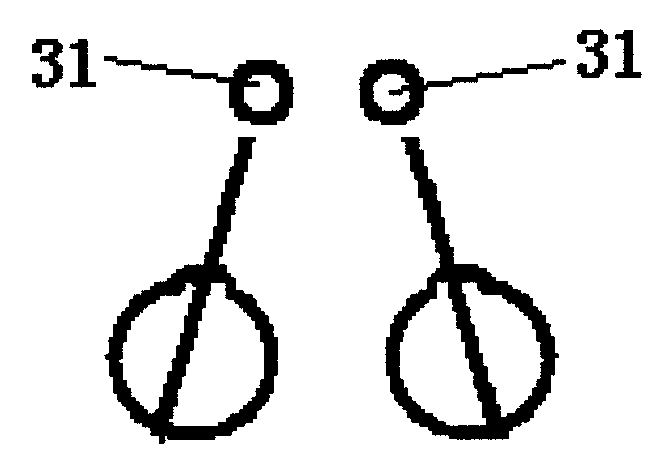

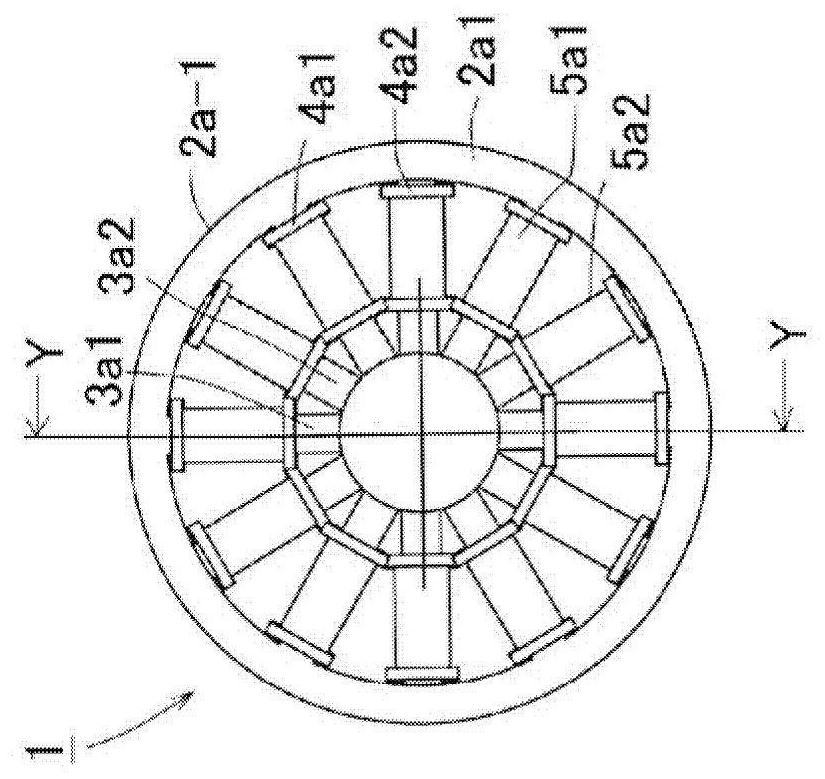

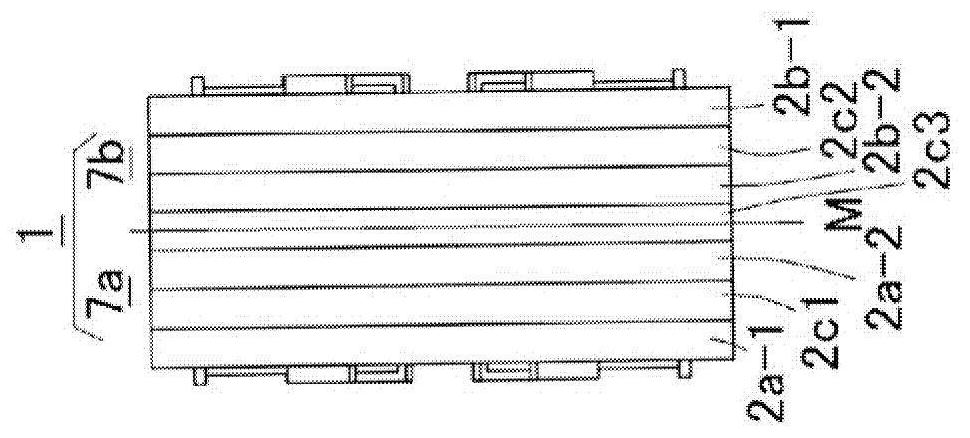

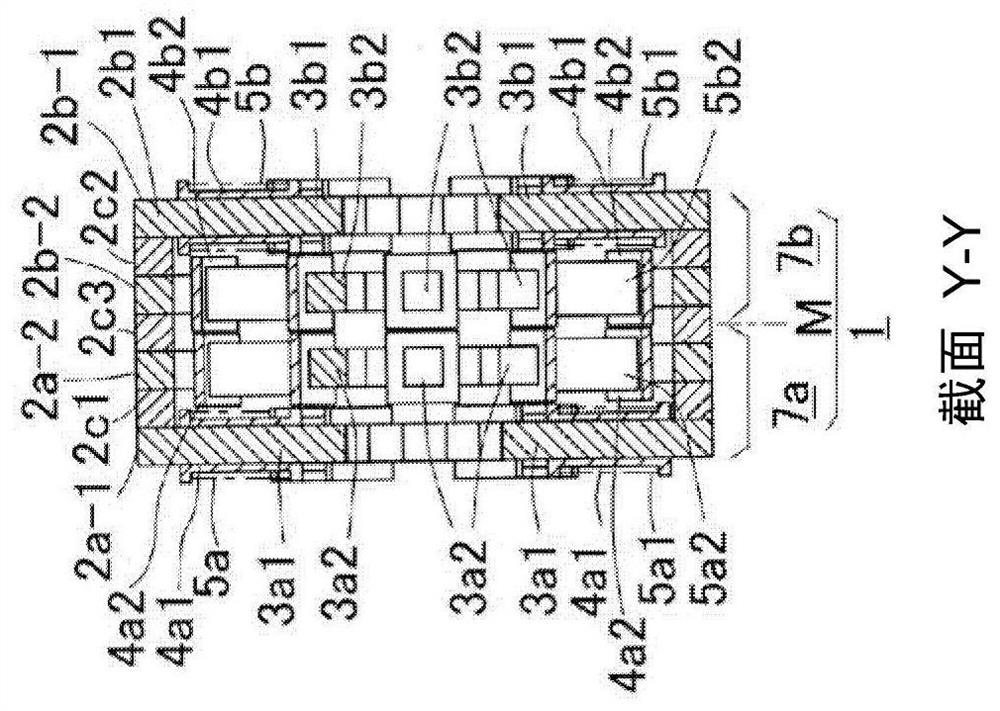

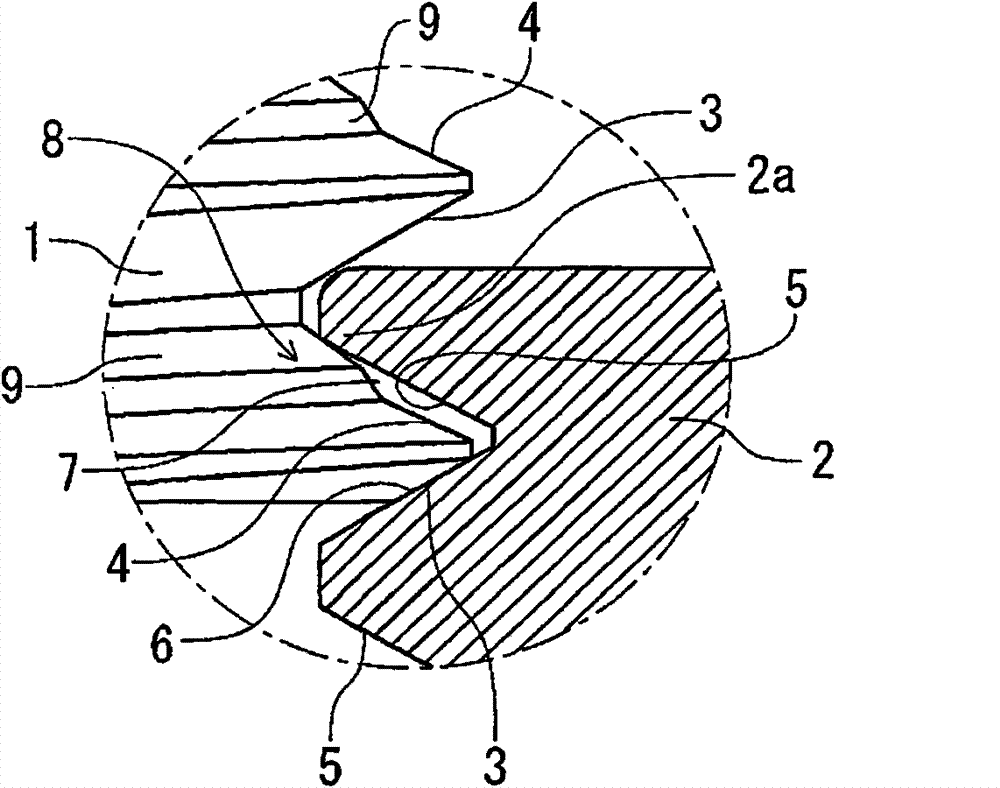

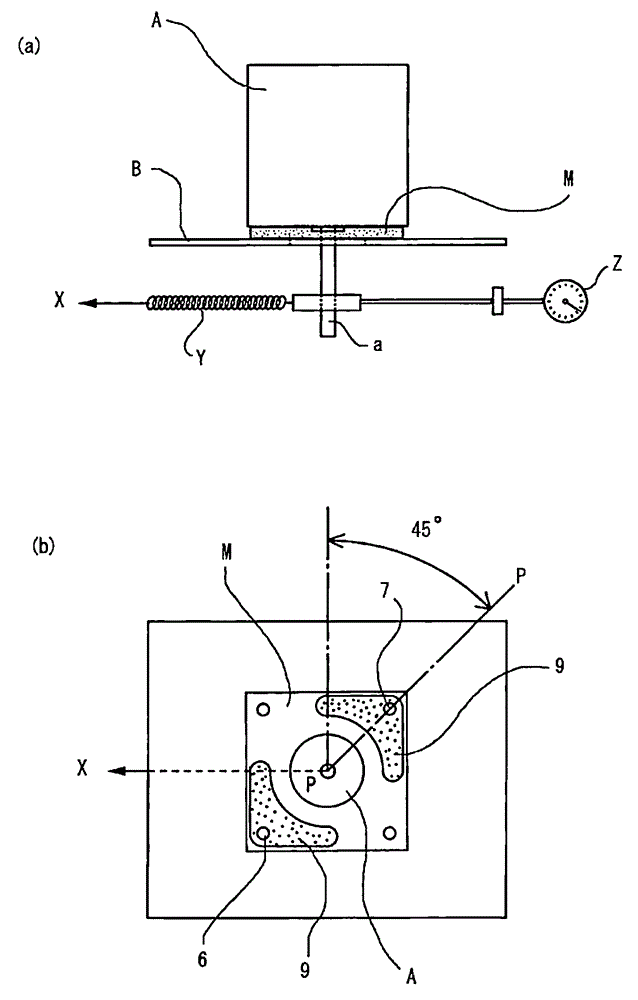

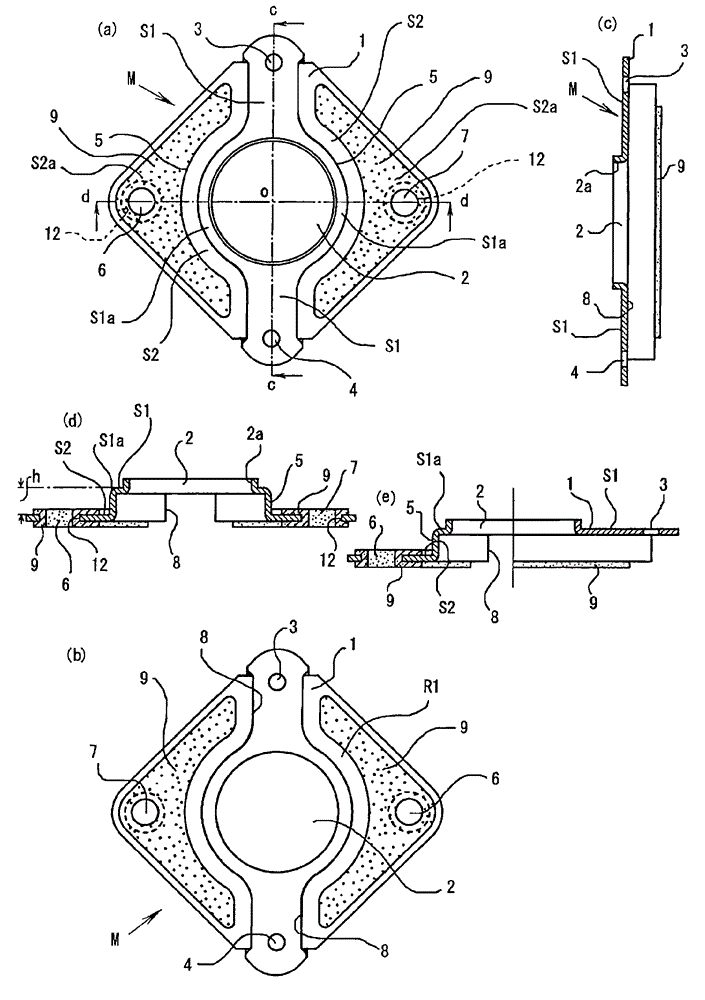

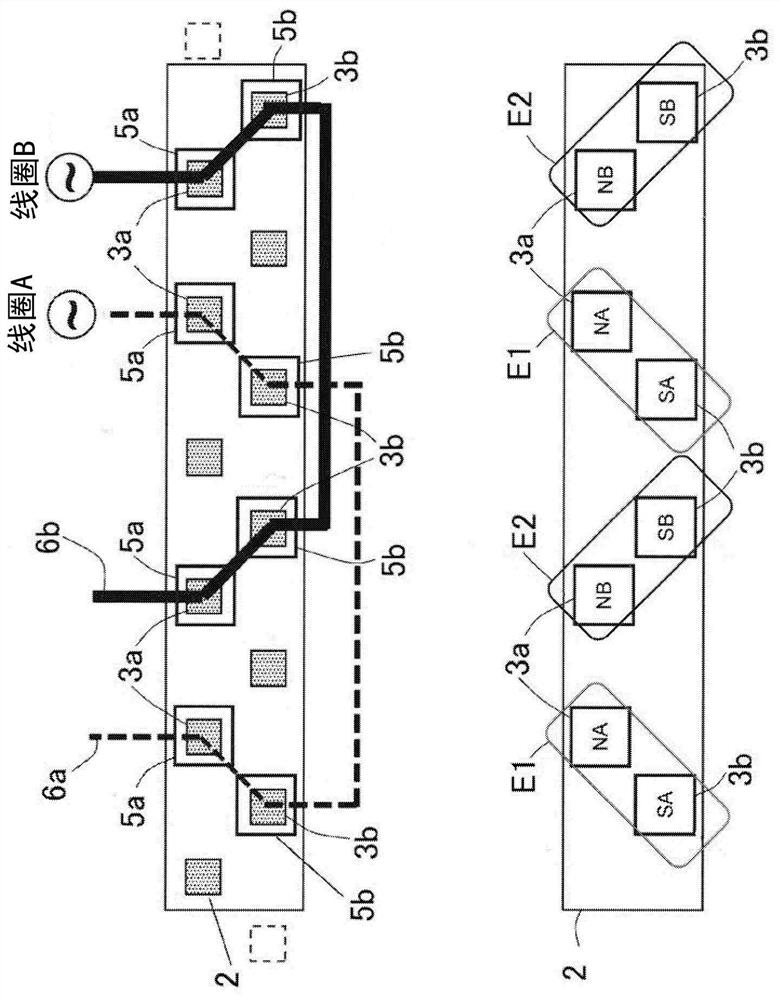

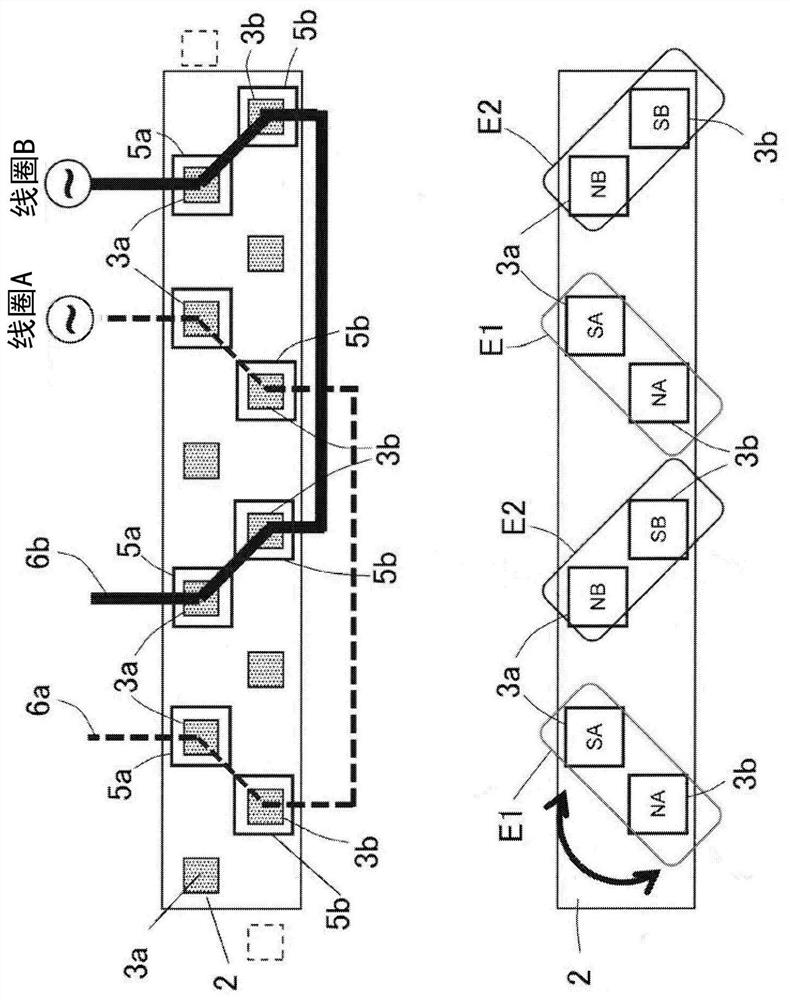

Torque detection sensor

InactiveCN113945311ALow mass productionWork measurementTorque measurementEngineeringMechanical engineering

The invention provides a self-excitation type torque detection sensor which can increase a magnetic circuit effective for torque detection and can detect the compression stress and the tensile stress generated at the whole periphery of a detected body in a very fine manner. A first torque detection unit (7a) and a second torque detection unit (7b) are laminated such that a first energization circuit (6a1) and a third energization circuit (6b1) are disposed on a center mirror surface with a plane of symmetry (M) orthogonal to the axial direction of the object to be detected, and a second energization circuit (6a2) and a fourth energization circuit (6b2) are disposed on a center mirror surface with a plane of symmetry (M) orthogonal to the axial direction of the object to be detected. A plurality of magnetic circuits are respectively formed between the pole teeth having an inclination of plus or minus 45 degrees in the first torque detection part (7a) and the second torque detection part (7b).

Owner:SHINANO KENSHI

A mems scanning mirror

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method of fiber-base-fabric foamed epoxy resin cloth

InactiveCN104099736ASimple equipment and processLess investmentFibre treatmentLiquid/gas/vapor textile treatmentTextileFiber

The invention discloses a preparation method of fiber-base-fabric foamed epoxy resin cloth. The preparation method is characterized in that raw materials include fiber base fabric, foaming agent, epoxy resin, auxiliaries and organic solvent. The preparation method comprises the following steps: respectively adding the foaming agent, the epoxy resin and auxiliaries into organic solvent to be stirred and mixed until the foaming agent, the epoxy resin and the auxiliaries are completely dissolved to form a mixed solution, then impregnating the fiber base fabric into the mixed solution, and drying, reeling, packaging and warehousing the fabric after the fiber base fabric is fused with the mixed solution. The preparation method is convenient to operate and has the advantages of less investment, high efficiency, low cost and the like.

Owner:杨贤斌

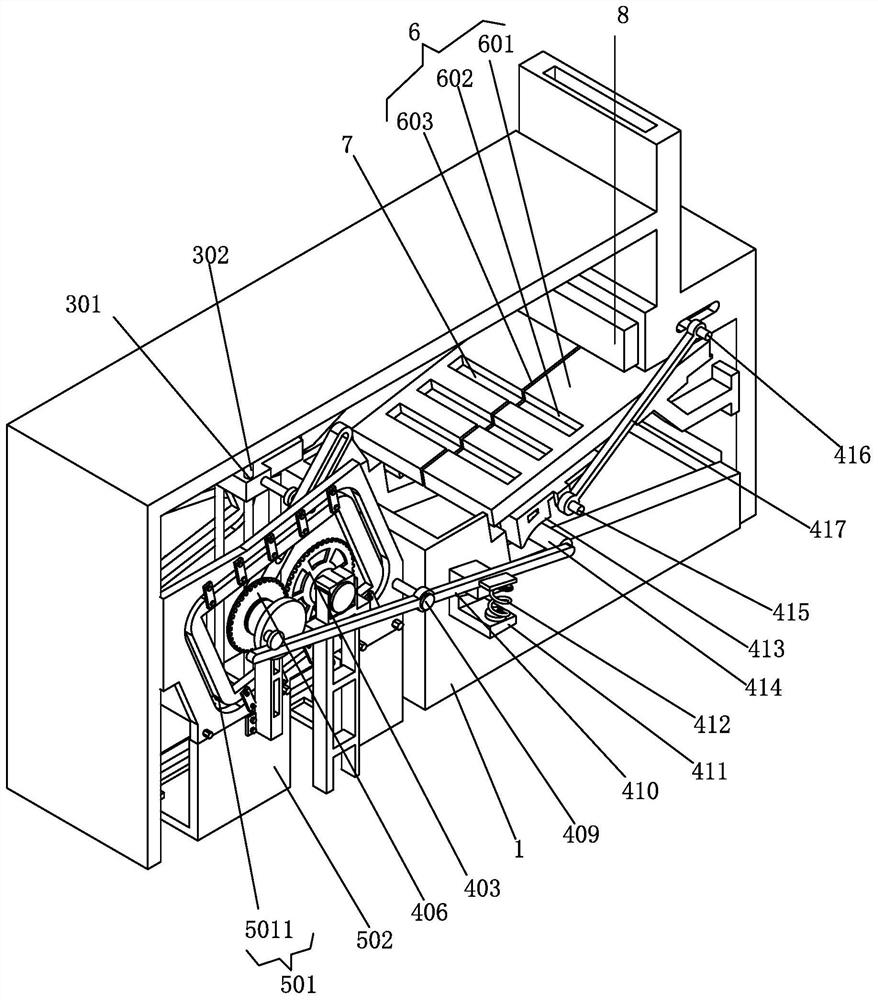

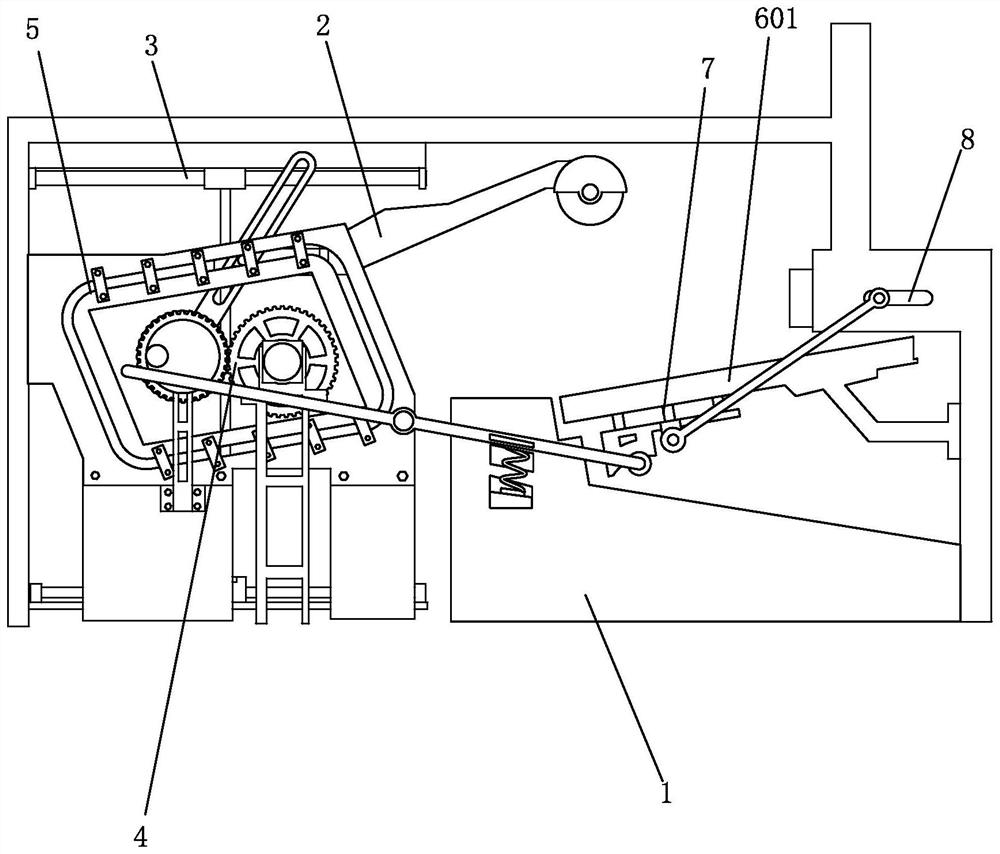

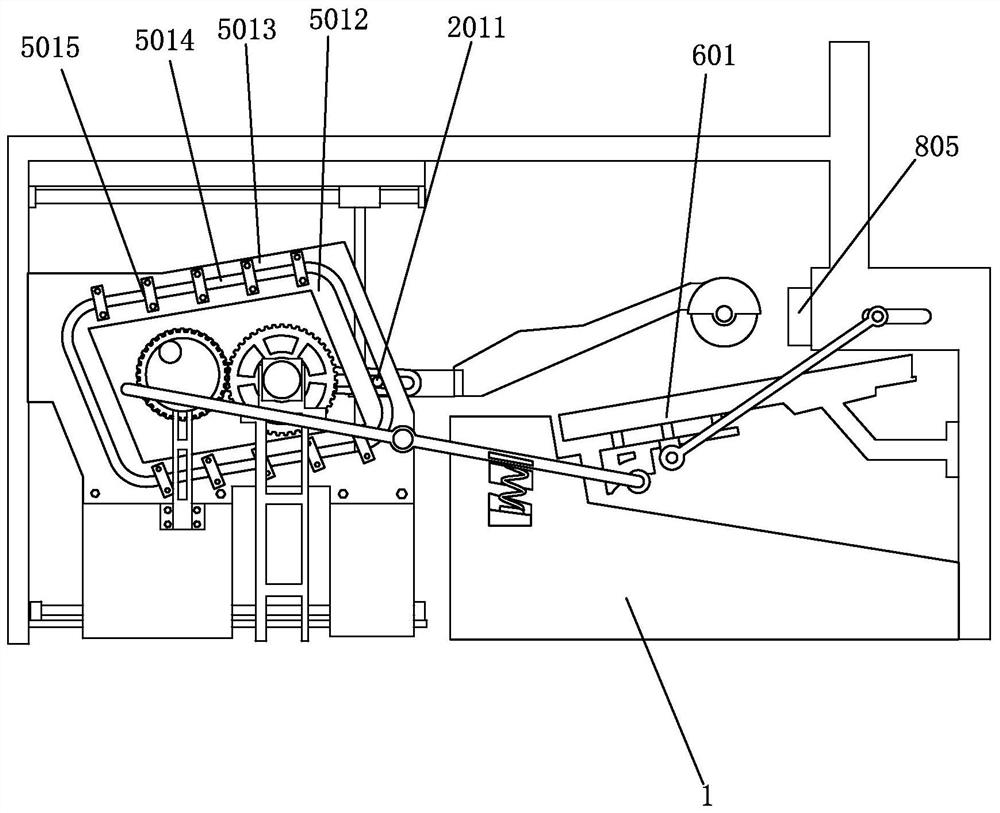

Linkage-type batch processing cutting-off manufacturing equipment applied to wood industry

ActiveCN113771143AReduce equipment costsImprove stabilityProfiling/shaping machinesConveyor partsProcess engineeringBatch production

The invention discloses linkage-type batch processing cutting-off manufacturing equipment applied to the wood industry. The linkage-type batch processing cutting-off manufacturing equipment applied to the wood industry comprises an equipment body, wherein a guide rail assembly, a movable cutting assembly, a parallel assembly, a material positioning assembly, a material ejecting assembly, a material quantitative feeding assembly and a linkage driving assembly are arranged in the equipment body. The linkage-type batch processing cutting-off manufacturing equipment applied to the wood industry has the following advantages that following actions are completed by adopting an independent drive, the equipment cost and the maintenance cost are reduced, the stability is improved, meanwhile, a series of coherent actions of automatic material preparing, automatic feeding, automatic cutting knife feeding, automatic cutting knife disengaging, automatic ejecting and the like can be achieved through one drive, the overall production efficiency is improved, the equipment manufacturing cost is reduced, investment of manpower and material resources is reduced, batch production is achieved, the structure is simple, and use is convenient.

Owner:TAIZHOU YUANDA HOME FURNITURE CO LTD

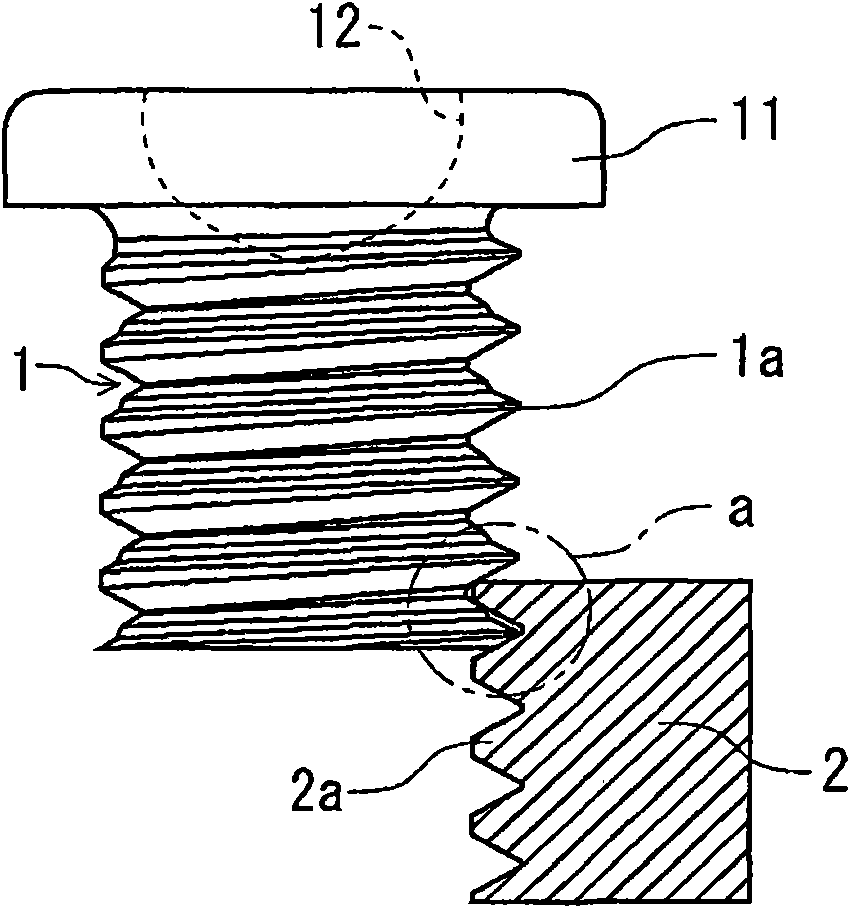

Lock screw

ActiveCN101994742BEffective anti-loosening functionFlexible fastening workNutsBoltsSlope angleEngineering

A lock screw is capable of being screwed easily, being used as an adjusting screw of a small screw, flexibly responding variation of temperature and fastening operation, and being of bulk production by a mechanical process at a low cost. The lock screw is used for locking when an external thread is screwed into an internal thread which has an arced triangular section, where a sloping angle of a side face on an opposite side is less than that of a side face on an advance side of the external thread, a material opening space is formed between side faces of the internal thread facing to the sideface, a projecting deflection angle part is arranged nearby an inner diameter side of the side face of the external thread on the side of the material opening space, simultaneously, when the externalthread is screwed into the internal thread, a material part being of crimp connection by the deflection angle part is formed nearby an inner diameter side of ridge of the internal thread in moving tothe material opening space, and the screw is locked by the crimp connection of side faces of the material part of the internal thread formed by the movement and the other side faces of the internal thread.

Owner:KOFU SEIBYO

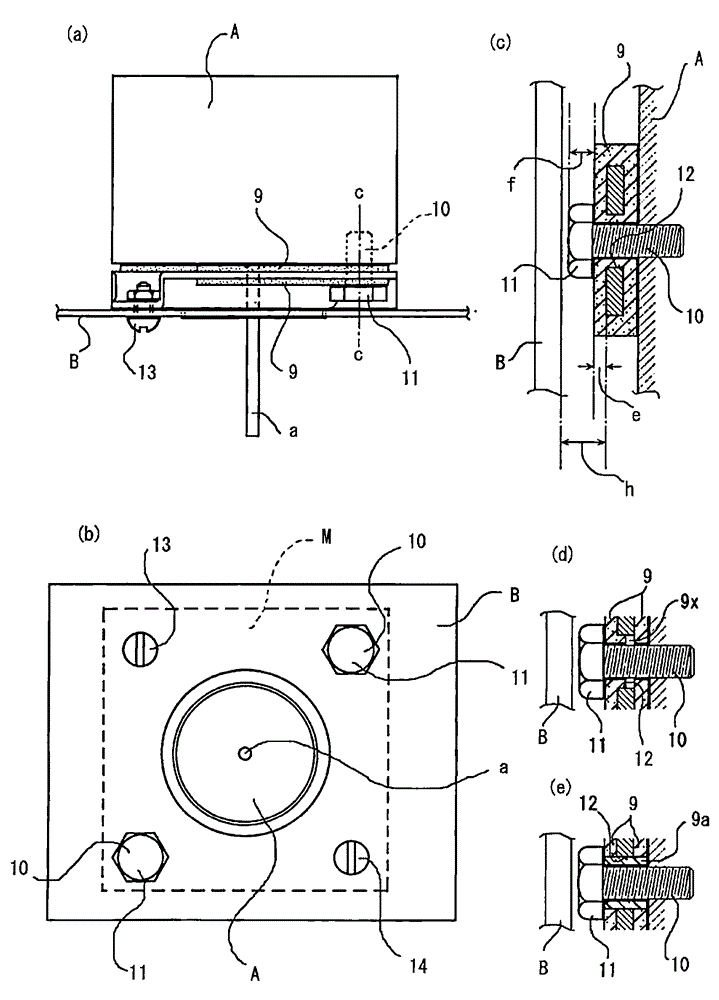

Anti-vibration mount

The invention provides an anti-vibration assembling set, being characterized in that the single material of a metal plate is enough,only part of an anti-vibration elastic body is covered on part of the plate so as to save the size of the metal plate as much as possible and to reduce the usage amount of the elastic body,and the elastic body for antivibration, and anti-vibration mounting piece which can form thin wall integrally are arranged in the inner surface of the mounting hole of a clamping screw. The anti-vibration assembling set is an nti-vibration assembling set formed by a hard plate and is characterized in that the hard plate is provided with a central hole, and is formed by a high-post surface which is provided with mounting holes up and down and is propped to a mounting body, and a low-post surface which is provided with mounting holes left and right formed by jump, thus forming an inner surface of the left and right mounting holes, the low-post surface including the inner surface, and the adhered elastic body on the opposite back surface of the inner surface,and the anti-vibration assembly is propped to the other vibration part through the elastic body, and can be fixed through a fastening part inserted in the mounting hole.

Owner:KOKOKU INTECH CO LTD +1

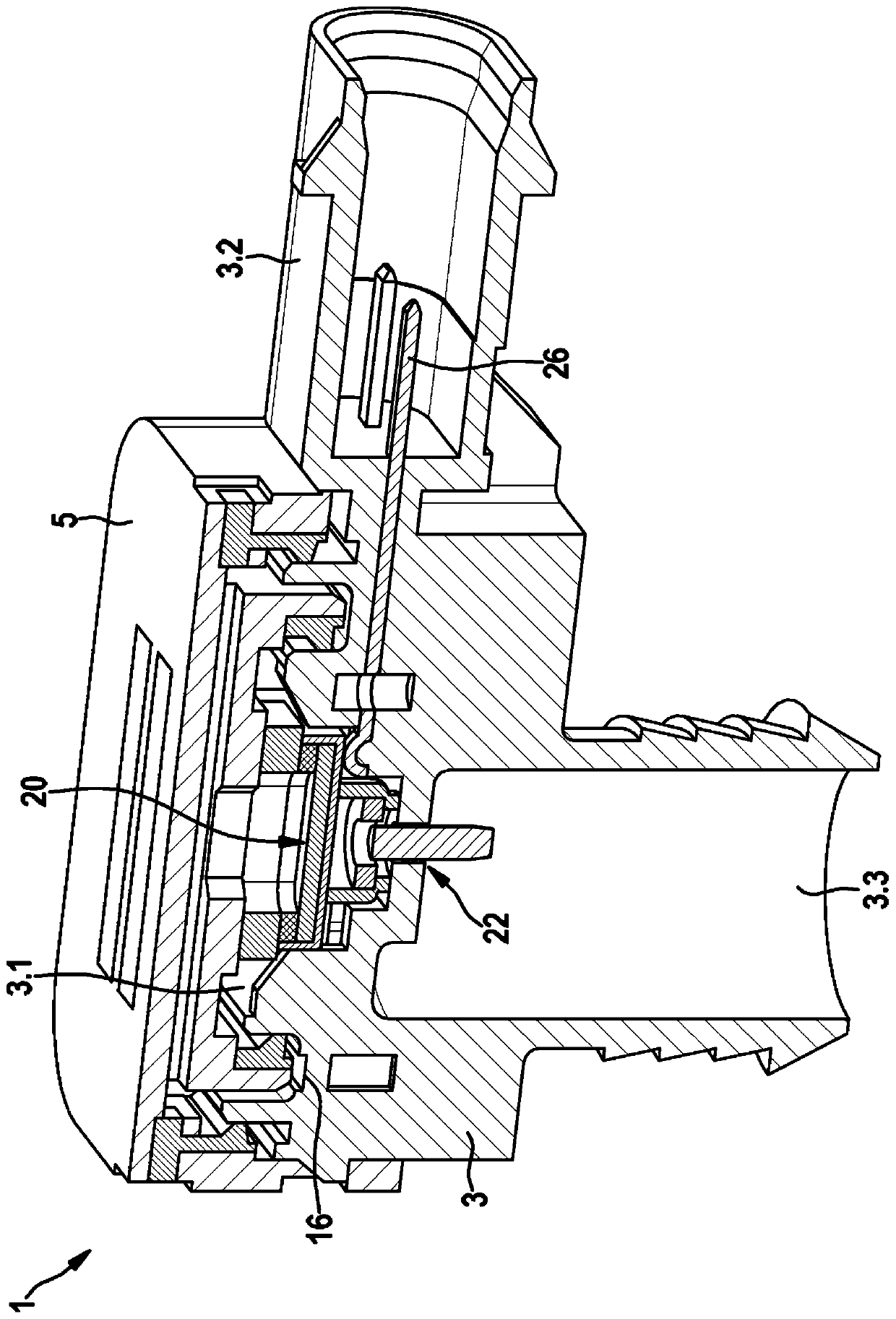

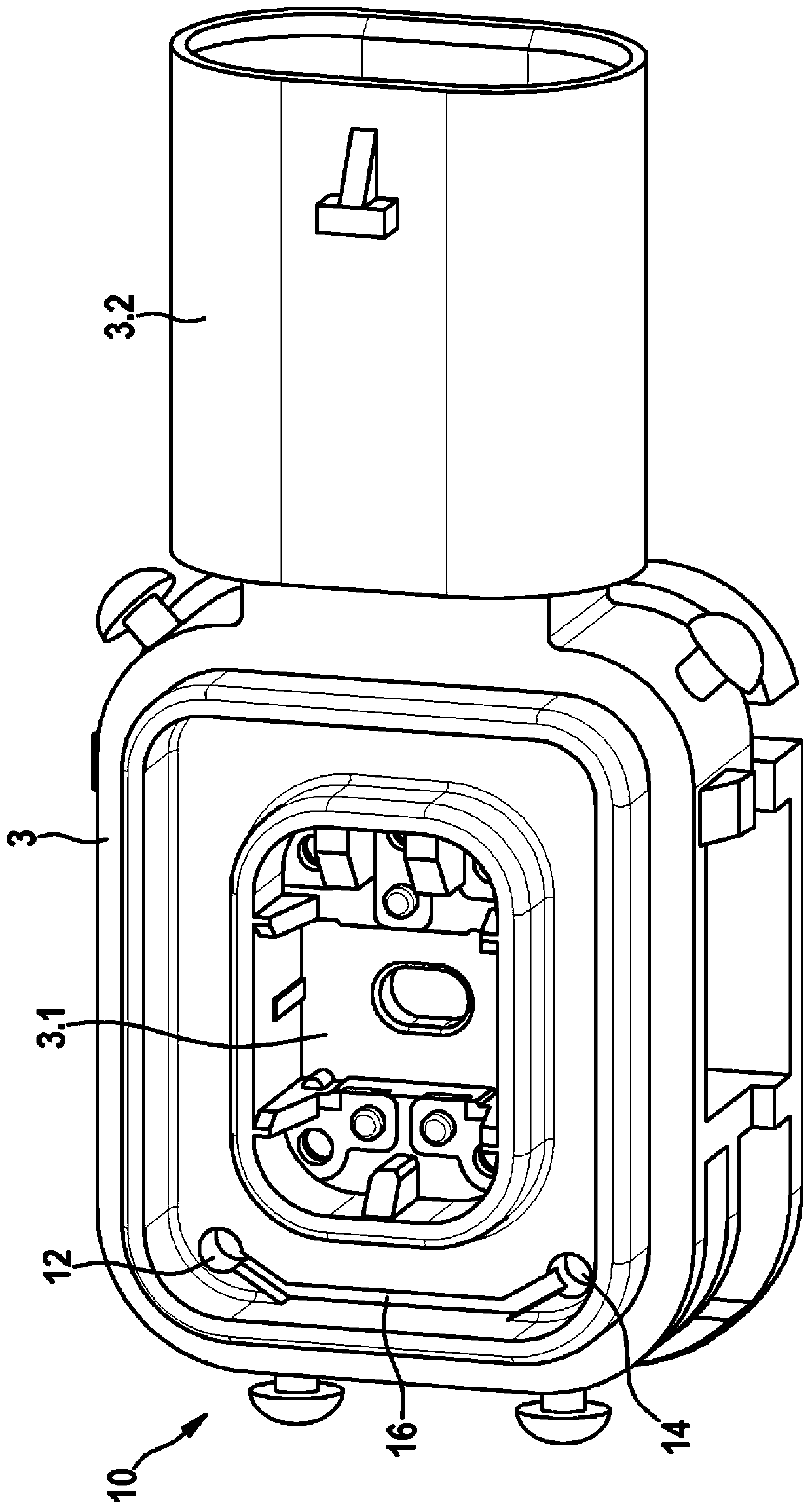

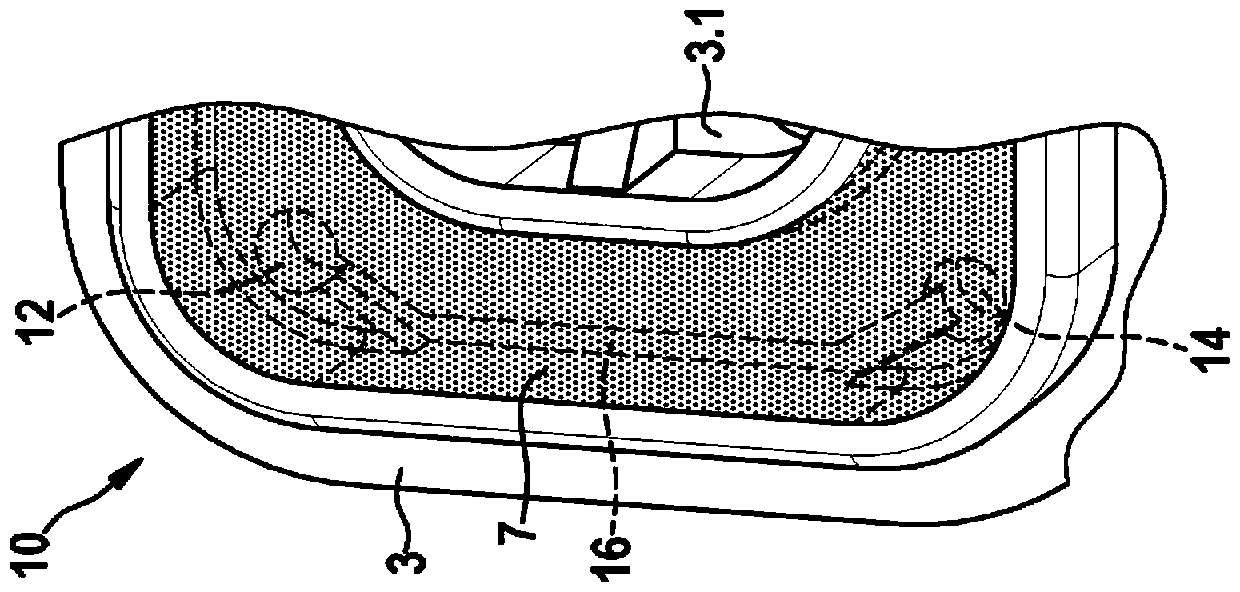

Pressure sensor for vehicle

ActiveCN111163986AImproved braking systemLower the water levelPressure difference measurement between multiple valvesBraking pressure measurementsEngineeringMechanical engineering

The invention relates to a pressure sensor for a vehicle, comprising a housing (3), in which at least one sensor unit is arranged, which determines a pressure difference between a pressure at a measurement connection point and atmospheric pressure, wherein the at least one sensor unit senses the atmospheric pressure at at least two reference pressure bores (12, 14). The invention further relates to a braking system for a vehicle, comprising at least one such pressure sensor. A sensor dewatering means (10) comprises a connection channel (16), which connects the at least two reference pressure bores (12, 14) to each other.

Owner:ROBERT BOSCH GMBH

A kind of preparation method of planar triode chip

ActiveCN105428234BSolve the voltage dropThe effect of spreadingSemiconductor/solid-state device manufacturingSemiconductor devicesPlatinumMetal impurities

The invention relates to the field of triode manufacturing, and particularly relates to a preparation method of a planar triode chip. According to the preparation method of the planar triode chip, the surface of a silicon wafer is cleaned, and then oxidation and photoetching processing is performed on the surface of the silicon wafer; boron diffusion, phosphorus diffusion and platinum diffusion are performed on the obtained silicon wafer so that a composite center is formed; metal impurities on the surface of the composite center are removed by a phosphorus diffusion impurity absorption technology; and steam aluminum, alloy, passivation, back thinning and back metallization processing is performed on the silicon wafer of which the metal impurities are removed so that the planar triode chip is obtained. A triode is prepared by the platinum diffusion technology so that production cost is greatly reduced, and the preparation method is suitable for batch production of the triode.

Owner:CHINA ZHENHUA GRP YONGGUANG ELECTRONICS CO LTD STATE OWNED NO 873 FACTORY

A method for preparing quaternary sulfide quantum dot-based heterojunction high-efficiency photocatalysts

ActiveCN105727999BMeets friendly requirementsImprove photocatalytic activityPhysical/chemical process catalystsHeterojunctionThiourea

The invention relates to group I-III-VI2 sulfides, and specifically refers to the preparation of AgIn5S8-ZnS / MoS2 heterojunction composite photocatalyst by a simple and rapid hydrothermal method, which can be used to degrade rhodamine B dye under visible light. AgIn5S8‑ZnS nanocrystals were mixed and stirred with ammonium molybdate tetrahydrate and thiourea for a hydrothermal reaction at 200 degrees for 8 hours. After the reaction was completed, they were filtered, washed and dried to obtain the AgIn5S8‑ZnS / MoS2 heterojunction composite photocatalyst, in which The mass ratios of MoS2 and AgIn5S8-ZnS nanocrystals are 1%-30% respectively, and the optimal mass ratio for photocatalytic performance is 5%. The experiment of degrading rhodamine B (RhB) under visible light proved that the prepared composite photocatalyst has good photocatalytic activity.

Owner:JIANGSU UNIV

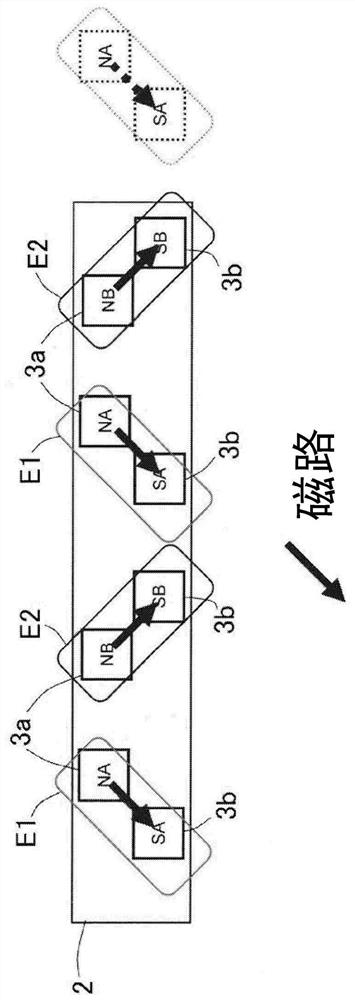

Torque detection sensor

The invention provides a self-excitation type torque detection sensor, which can be miniaturized and mass-produced at low cost, and can detect the compression stress and tensile stress generated at the whole periphery of a detected body without reducing detection sensitivity. The self-excitation type torque detection sensor comprises a plurality of first pole teeth (3a) and second pole teeth (3b) which are provided so as to protrude in a comb-tooth arrangement in the circumferential direction of an annular core (2); and a plurality of energizing circuits (6a, 6b) connected in series to a first coil (5a) and a second coil (5b) wound around the first pole tooth (3a) and the second pole tooth (3b) in different winding directions, wherein a plurality of magnetic circuits having an inclination of + 45 degrees and a plurality of magnetic circuits having an inclination of -45 degrees with respect to the axial direction formed by the object to be detected are respectively formed between the first pole tooth (3a) and the second pole tooth (3b) by energizing the plurality of energizing circuits (6a, 6b).

Owner:SHINANO KENSHI

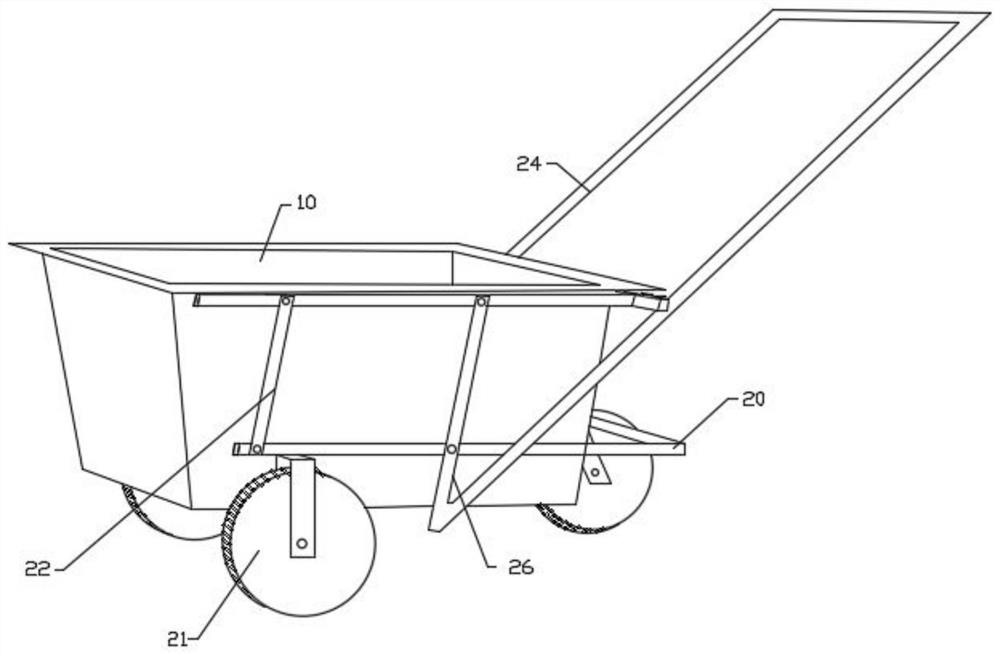

Intelligent modular building self-mixing mortar transportation device and operation method

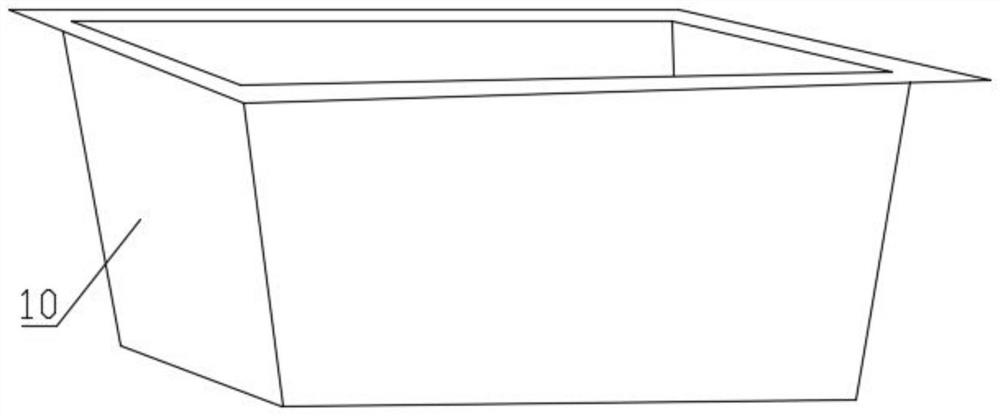

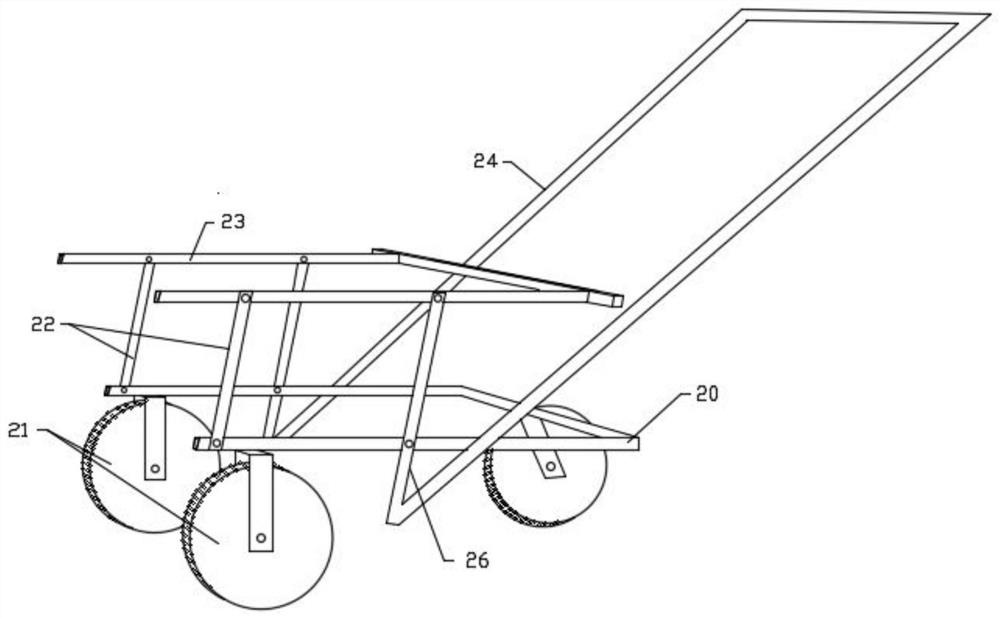

PendingCN113581264AReduce waiting timeGuaranteed ease of useHand carts with multiple axesModular designStructural engineering

The invention discloses an intelligent modular building self-mixing mortar transportation device and an operation method, and belongs to the field of building engineering decoration branch engineering construction. The modular box transportation device comprises a modular box, a transportation body, a moving mechanism installed on the transportation body and a carrying mechanism for moving the modular box to the position above the transportation body. The device is novel in design, simple in structure, easy to install and easier to use. In the construction process, one carrier loader and a plurality of modular box bodies can form a group, and high-turnover and zero-waiting mortar transportation work is achieved. The mortar box is light in weight, high in strength and low in manufacturing cost, the modular design is more beneficial to batch production, and universality is guaranteed; the resource configuration that one vehicle is provided with multiple boxes can enable an operator to concentrate on mortar turnover transportation, so that the waiting time of people and the vehicle is greatly saved, and the working efficiency is invisibly improved; and due to high-efficiency transportation, the waiting exposure time of the building mortar is reduced to the maximum extent, so that the best workability of the mortar during use is ensured, and multiple purposes are achieved.

Owner:CHINA MCC17 GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com