A kind of quantum dot composite scintillator material and preparation method thereof

A scintillator material and quantum dot technology, applied in the field of nuclear radiation detection, can solve the problems of low density of porous materials, inability to transmit energy absorption, and low detection efficiency, and achieve the effects of high scintillation efficiency, easy popularization and application, and cheap mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

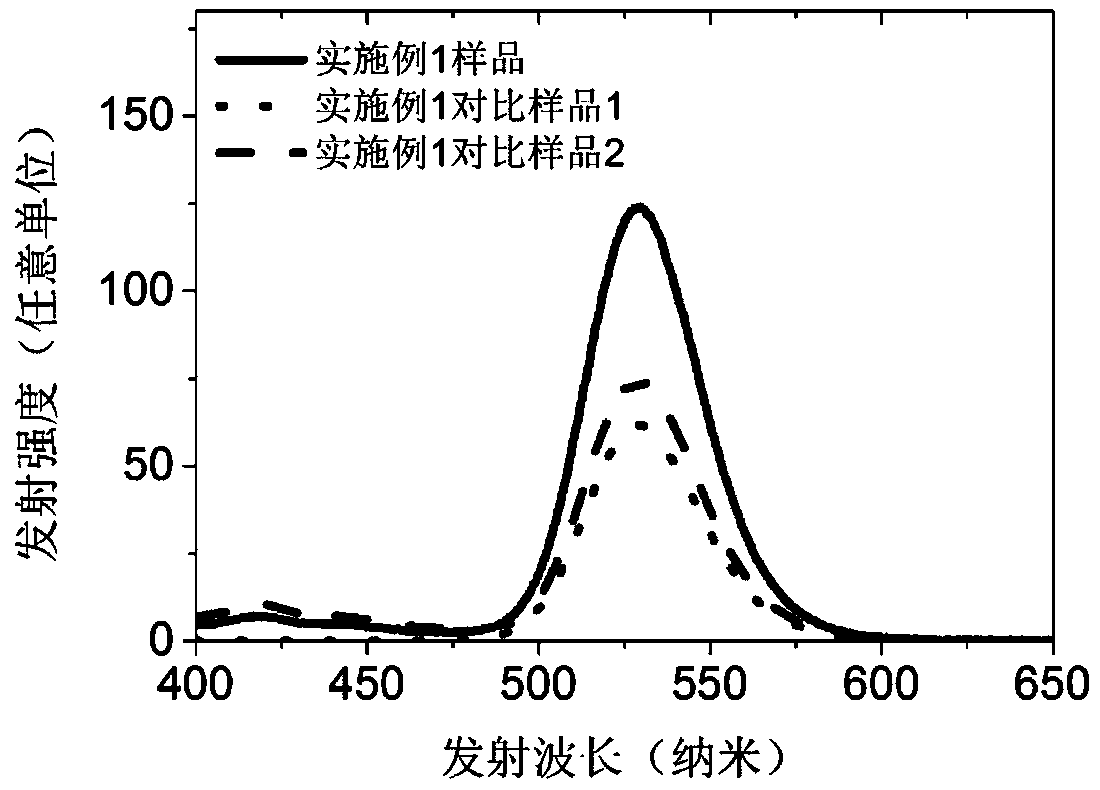

[0029] Take 2g of styrene (styrene), 40mg of dialkyl lead, 200mg of organic luminescent agent p-TP, and an oil-soluble quantum dot CdSe / ZnS luminescent material with a solid content equivalent to 200mg that has been distilled under reduced pressure (take 10ml of liquid, the content per milliliter is 20mg). In an anaerobic bottle, vacuum and flush with nitrogen, and mix with ultrasound for 2 hours. Keep warm at 30°C for 100 hours in an incubator, then slowly raise the temperature (2°C / h) to 50°C and keep it for 50 hours, then slowly raise the temperature (2°C / h) to 100°C and keep it for 50 hours to make it completely polymerized solidified. Finally, it was naturally cooled to room temperature. The final sample is obtained by removing the sample from the anaerobic bottle and cutting and polishing.

[0030] In order to fully illustrate the impact of the introduction of lead and organic luminescent agents on the scintillation characteristics, we prepared samples containing only...

Embodiment 2

[0033] A quantum dot composite scintillator material, including an organic plastic matrix PS and organic high atomic number materials dispersed in the organic plastic matrix, an organic luminescent body and a quantum dot luminescent material, wherein the organic high atomic number material used is dialkyl Lead, the content is 1wt%, the organic luminescent body is p-TP, the wavelength range is 340-380nm, the content is 5wt%, the quantum dot luminescent material is CdSe, the size is 2nm, the light emission range is 400-750nm, the content is 10wt%.

[0034] The preparation method of quantum dot composite scintillator material adopts the following steps:

[0035] (1) Disperse the vacuum-distilled organic plastic substrate, organic high atomic number material, and organic light-emitting body in a non-polar solution, quantum dot light-emitting material, in an anaerobic bottle, vacuumize and flush with nitrogen, and use ultrasonic mixing;

[0036] (2) Keep warm at 30°C in a thermosta...

Embodiment 3

[0039]A quantum dot composite scintillator material, comprising an organic plastic matrix PMMA and an organic high atomic number material dispersed in the organic plastic matrix, an organic luminescent body and a quantum dot luminescent material, wherein the organic high atomic number material used is bismuth carboxylate , the content is 3wt%, the organic luminescent body is PPO, the wavelength range is 340-380nm, the content is 10wt%, the quantum dot luminescent material is a core-shell structure quantum dot is CdSe / ZnS, the size is 5nm, and the luminous range is 400-750nm, The content is 15wt%.

[0040] The preparation method of quantum dot composite scintillator material adopts the following steps:

[0041] (1) Disperse the vacuum-distilled organic plastic substrate, organic high atomic number material, and organic light-emitting body in a non-polar solution, quantum dot light-emitting material, in an anaerobic bottle, vacuumize and flush with nitrogen, and use ultrasonic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com