Manufacturing method of liquid crystal display screen

A manufacturing method, liquid crystal display technology, applied in the direction of static indicators, nonlinear optics, instruments, etc., can solve the problems of pressure difference, affecting product quality and batch production, plastic substrate deformation, etc., to reduce the generation of air bubbles and reduce the thickness of the box and weight, the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the purpose, features and advantages of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

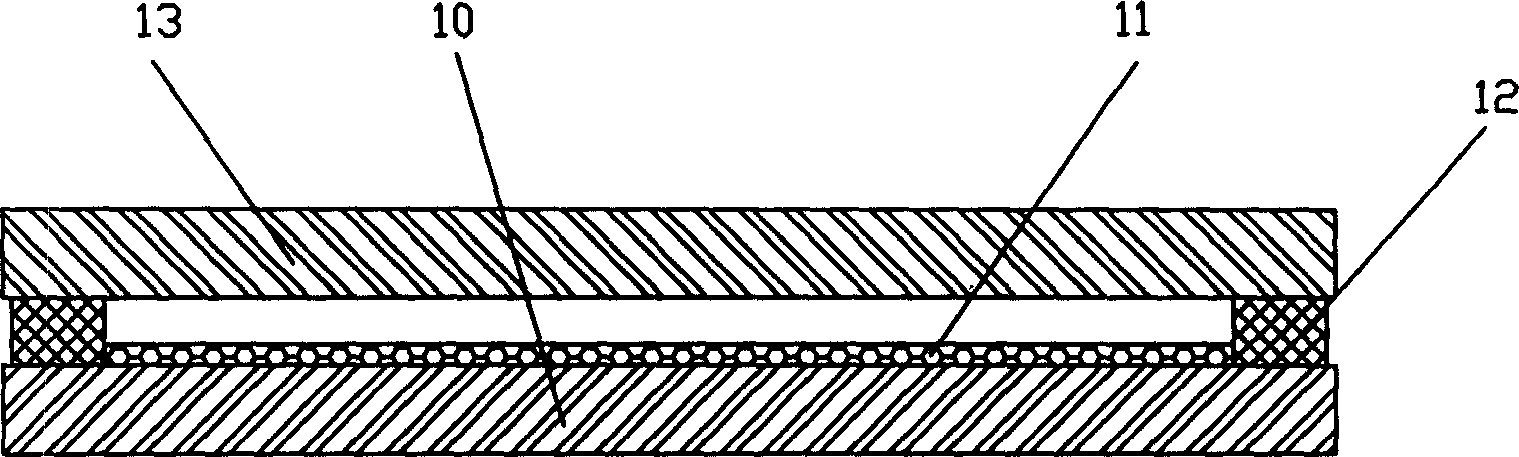

[0034] See Figure 2a ~ 2g It is a structural schematic diagram of an embodiment of the present invention.

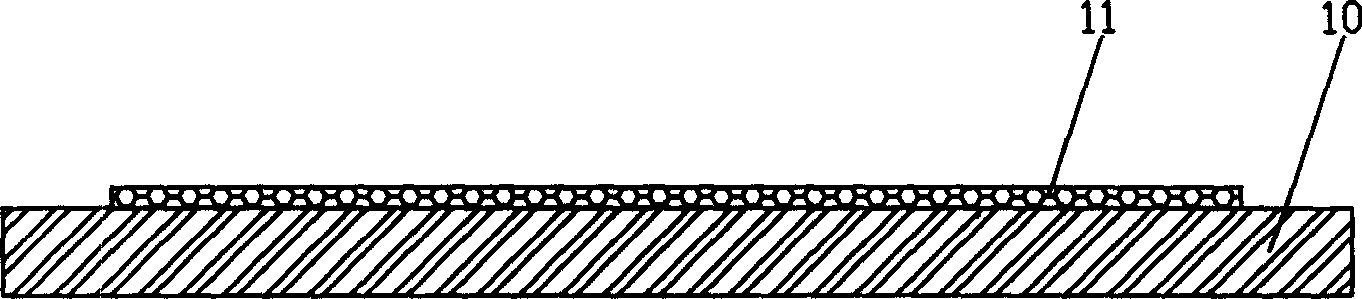

[0035] Such as Figure 2a As shown: a PI alignment film 21 (which may be polypropylene resin or polyimide resin) is printed on the surface of the TFT array substrate 20 to form an alignment film for controlling the alignment of liquid crystal molecules.

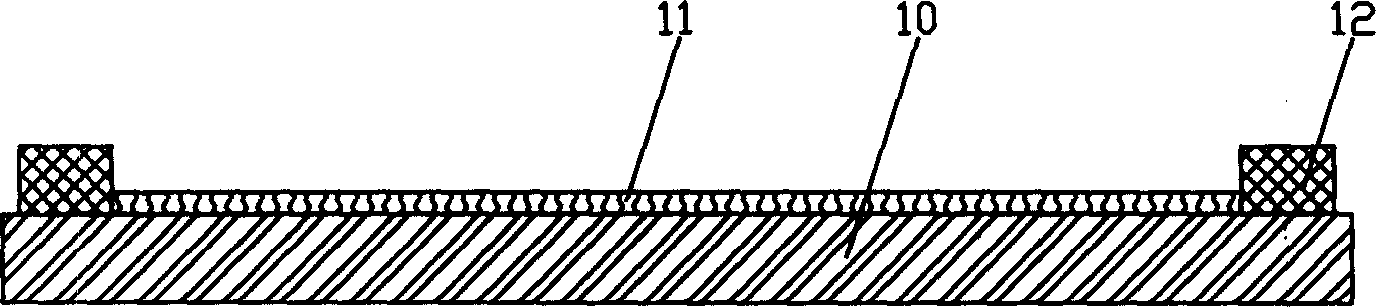

[0036] Such as Figure 2b As shown: a thickness-controlled frame glue wall 22 (which can be heat-curable epoxy resin or ultraviolet-curable epoxy resin) is coated at a certain height on the periphery of the array substrate 20 where the alignment film is formed. The scattered spacers are used to control the thickness of the liquid crystal layer (not shown), so that a uniform gap is formed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com