BIM and VR-based finished house batch hardcover fusion production construction method

A technology for housing batches and finished products, which is applied in the field of batch and hardcover integrated production and construction of finished houses, can solve the problems of inability to quickly sort target areas, uneven levels of laborers, and inability to mass-produce factories, so as to improve factory production efficiency, Achieving mass production, ensuring convenience and standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]In order to describe the technical solution described in this application, the following description is made through specific implementations.

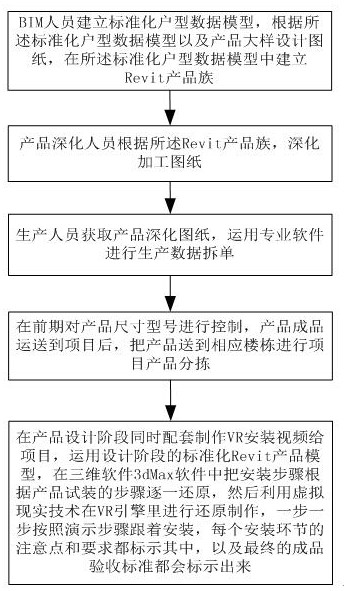

[0024]Seefigure 1, Is a flow chart of an implementation process of the method for batch hardcover fusion production and construction of finished houses based on BIM and VR provided by the embodiments of the present application. For ease of description, only the parts related to the embodiments of the present application are shown.

[0025]This BIM and VR-based batch hardcover integrated production construction method for finished products includes:

[0026]In the early stage of the project, BIM staff used Revit software to establish a standardized house data model, based on the standardized data model technology, design drawings based on product samples, and established Revit product family in the data model. The designer combined the actual project and discussed the formation with the project staff. One or several (no more than 3 sizes) stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com