MEMS scan mirror

A scanning mirror and mirror surface technology, applied in the field of MEMS scanning mirrors, can solve the problems of increasing circuit complexity, piezoelectric film breakdown, increasing film deposition difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

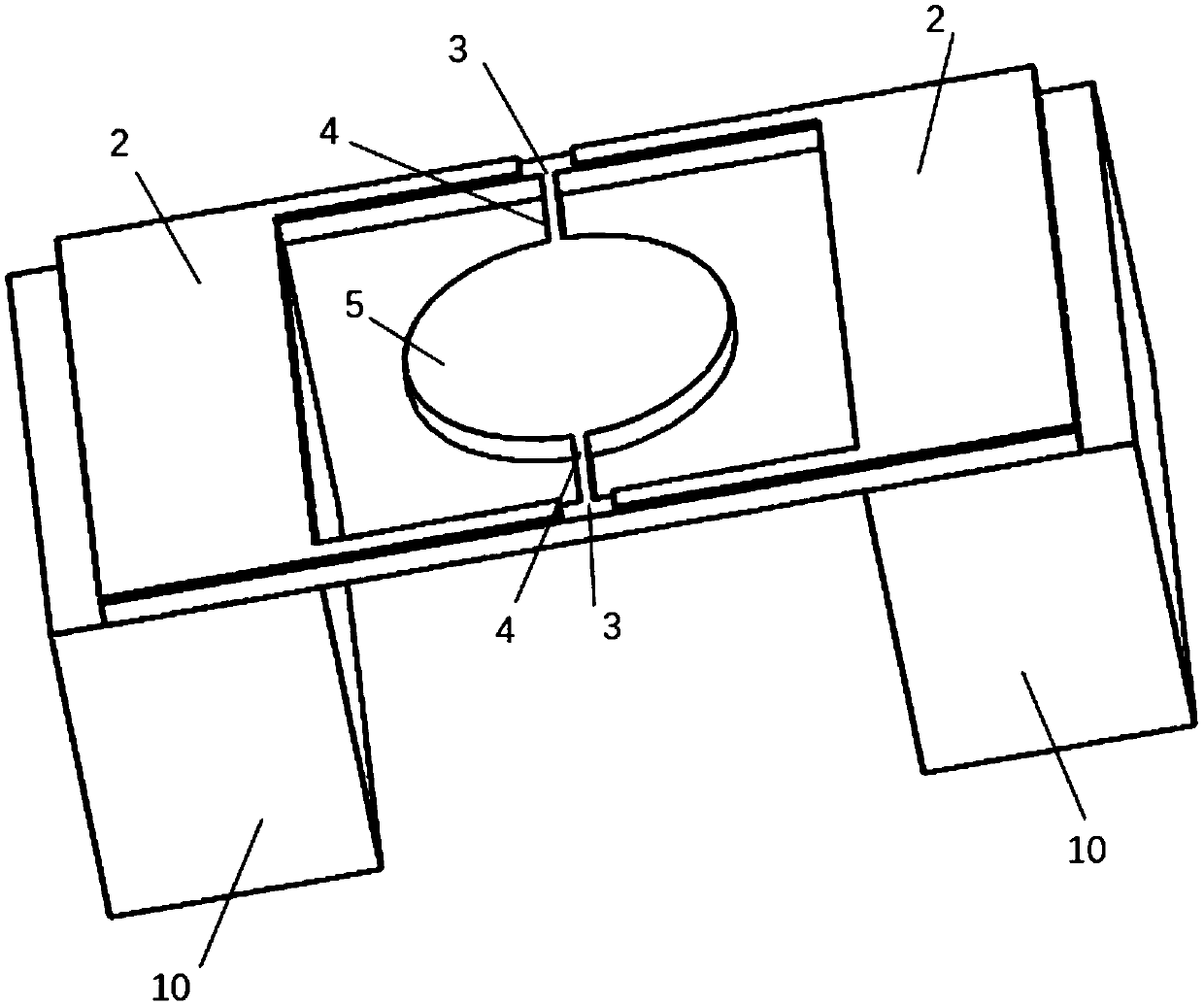

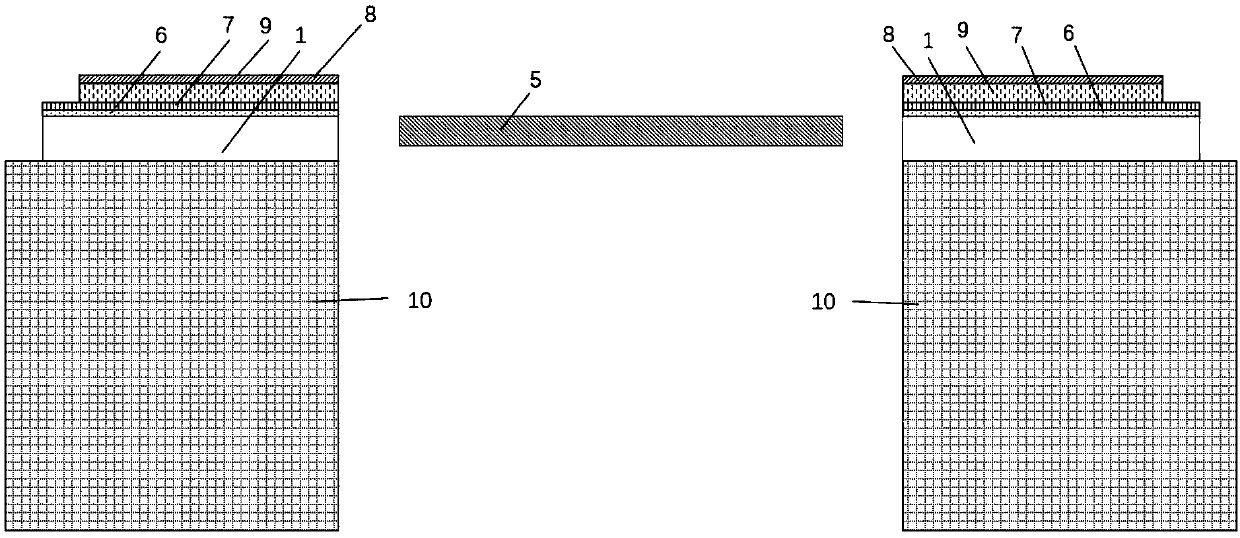

[0023] refer to figure 1 and figure 2 , in one embodiment, a MEMS scanning mirror includes two piezoelectric ceramic blocks 10, two piezoelectric driving arms 2, two beams 3, two torsion beams 4 and a mirror surface 5, the two There is a distance between the piezoelectric ceramic blocks 10, the two piezoelectric driving arms 2 are respectively arranged on the two piezoelectric ceramic blocks 10, and the two beams 3 are connected in parallel to the two piezoelectric driving arms. Between the arms 2, the two torsion beams 4 and the mirror surface 5 are connected in series between the two beams 3, and the mirror surface 5 is connected between the two torsion beams 4; The voltages applied to the two piezoelectric driving arms 2 are opposite, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com