Improvements of braking systems

A technology of brake disc and brake pad, which is applied in the direction of brake actuator, application, harvester, etc., can solve the problems of complex mechanism and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

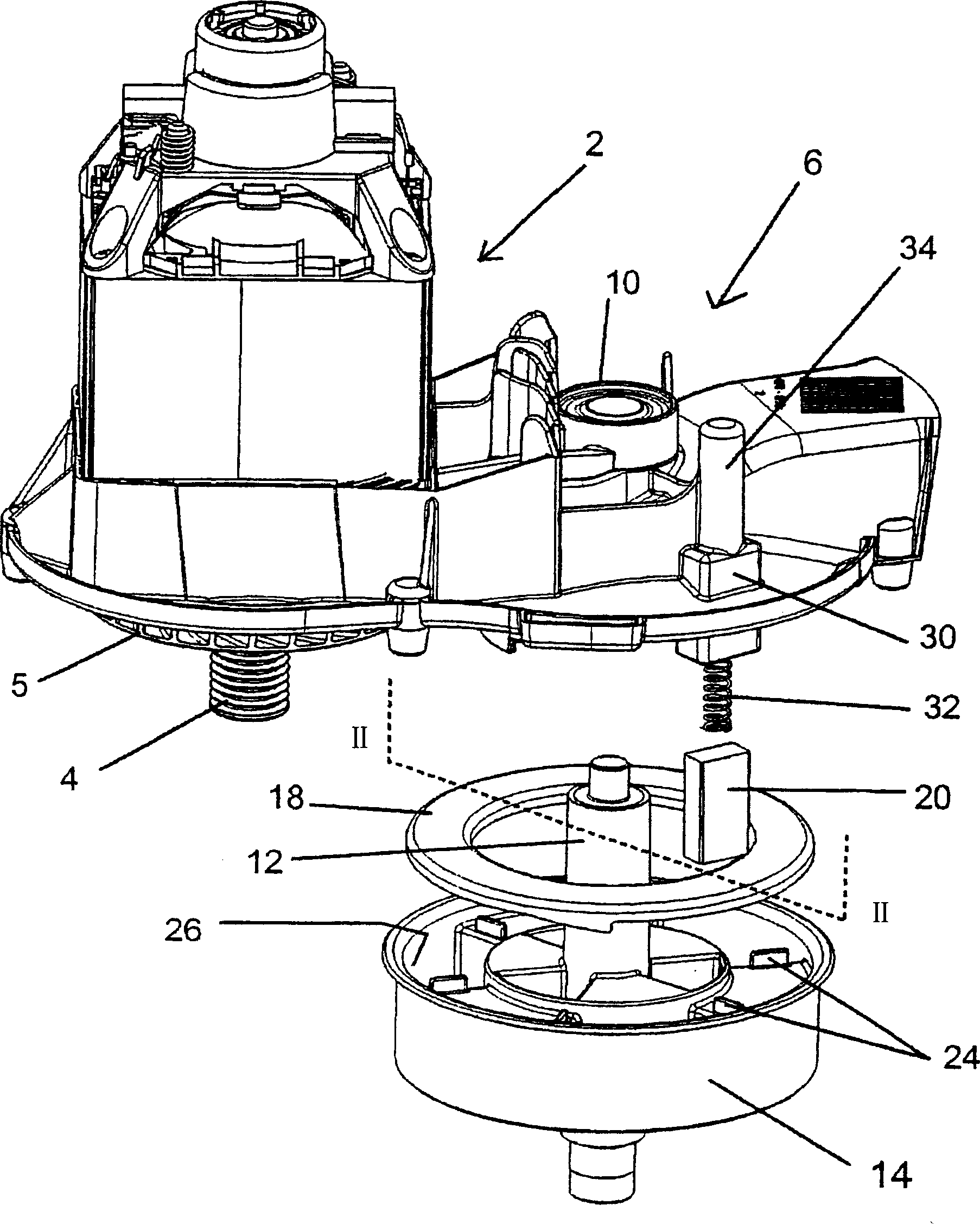

[0020] figure 1 The shown device comprises a motor housing 2 in which the motor is housed. A rotating drive shaft 4 protrudes from the motor through the motor housing 2 . A rotating fan or impeller 5 is mounted on the drive shaft 4 and is used to draw air through the motor 2 to cool the motor. The airflow is then directed to the braking components before being exhausted into the atmosphere.

[0021] A spindle mounting portion 6 is provided and connected or integrated with the motor housing 2 . The bearing 8 is provided in a bearing housing 10 on the spindle mounting portion 6 .

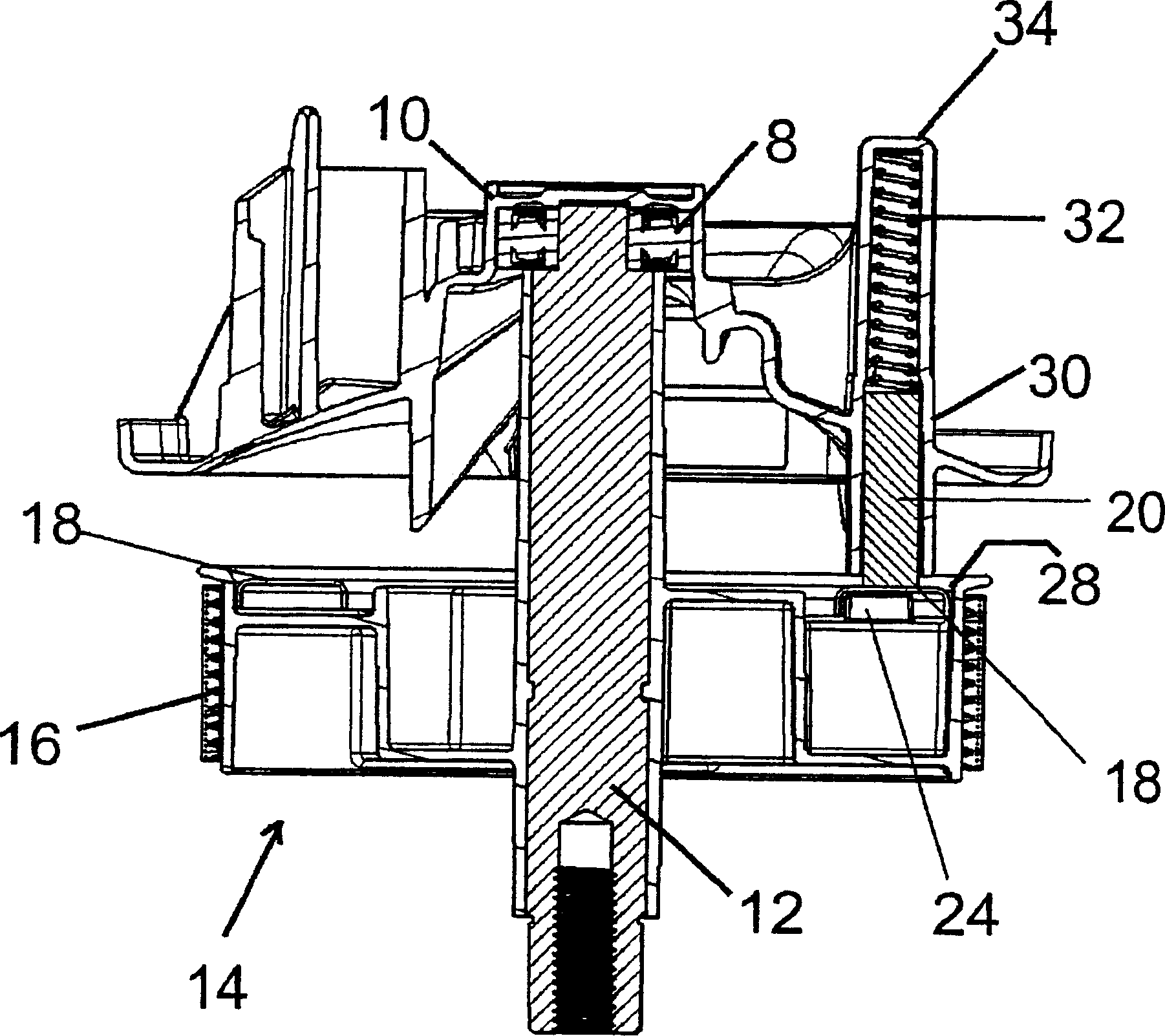

[0022] The spindle 12 is mounted for rotation on bearings 8 . A drum or pulley 14 is mounted on the spindle 12 in non-rotatable relationship. work as figure 2 As shown, the spindle 12 is mounted within the bearing 8 and the drum is held in position adjacent the drive shaft 4 such that a drive belt 16 can be fitted over the drive shaft 4 and the drum 14 to transmit the rotational drive from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com