Regeneration pretreatment machine for silica gel plastic bottle

A preprocessing machine and plastic bottle technology, applied in the direction of plastic recycling, recycling technology, solid waste removal, etc., can solve the problems of affecting the timely smelting and processing of plastic bottles, high labor intensity, low operating efficiency, etc., and achieve the degree of mechanization and automation Improvement, mechanization and automation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

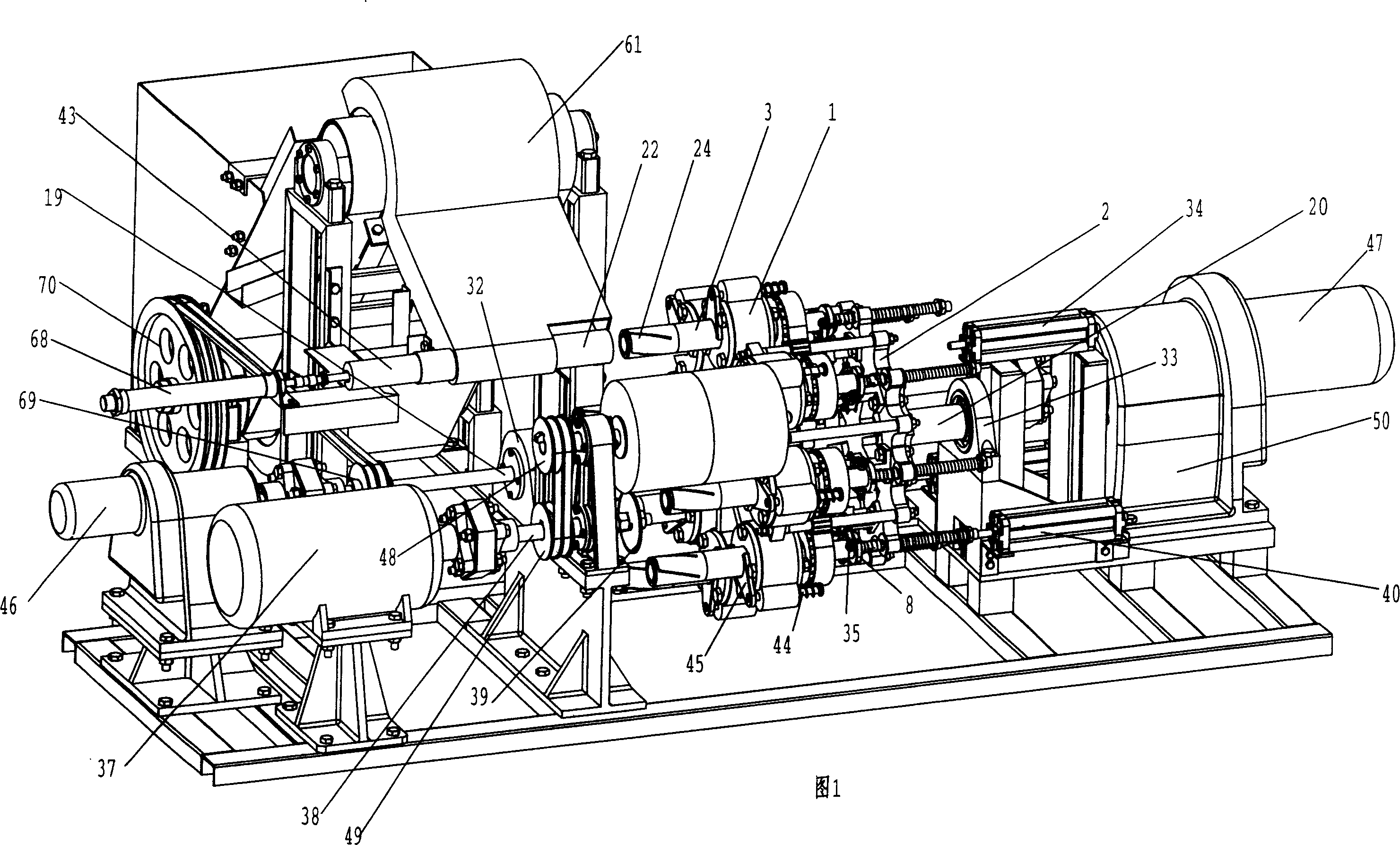

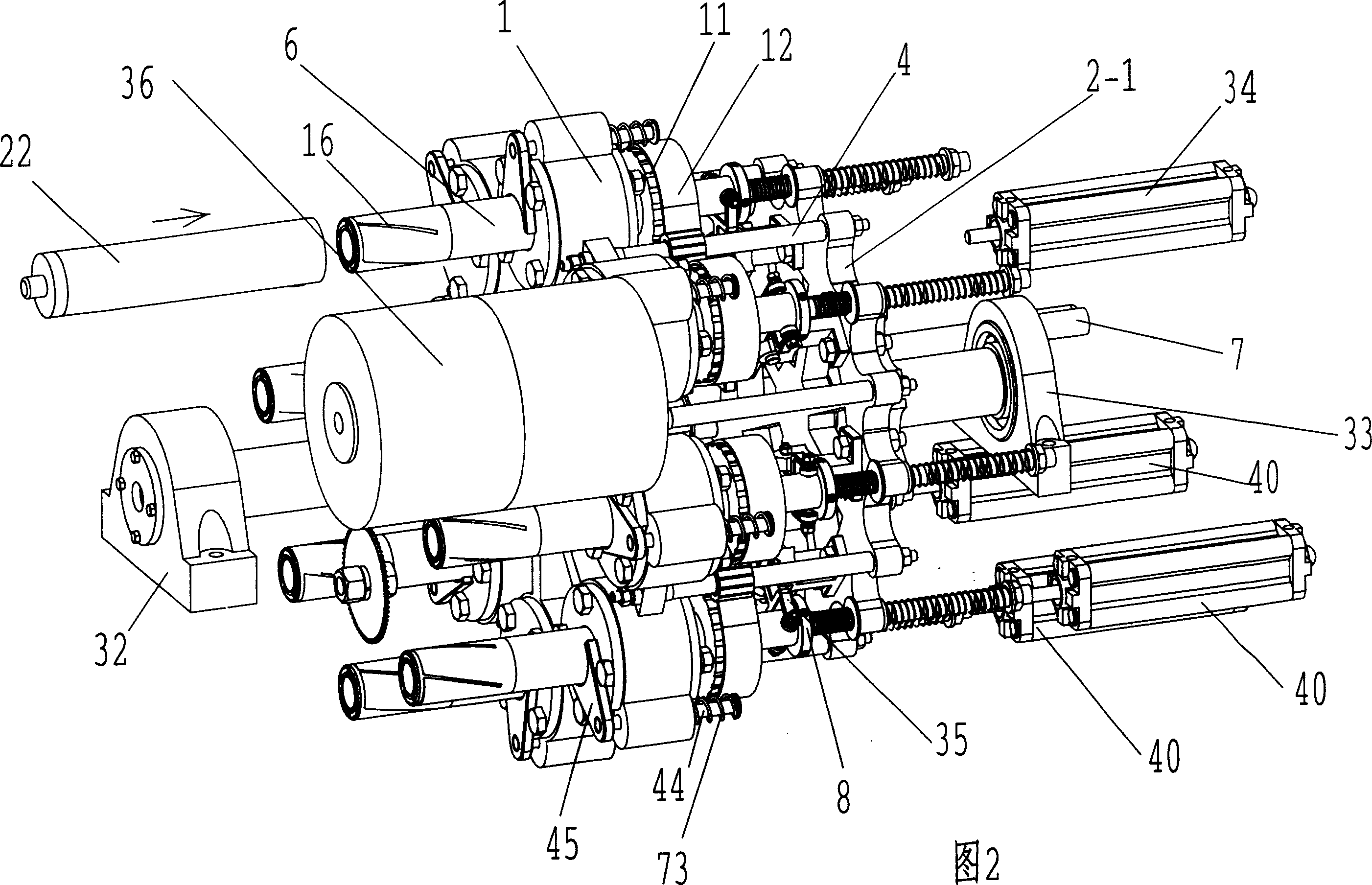

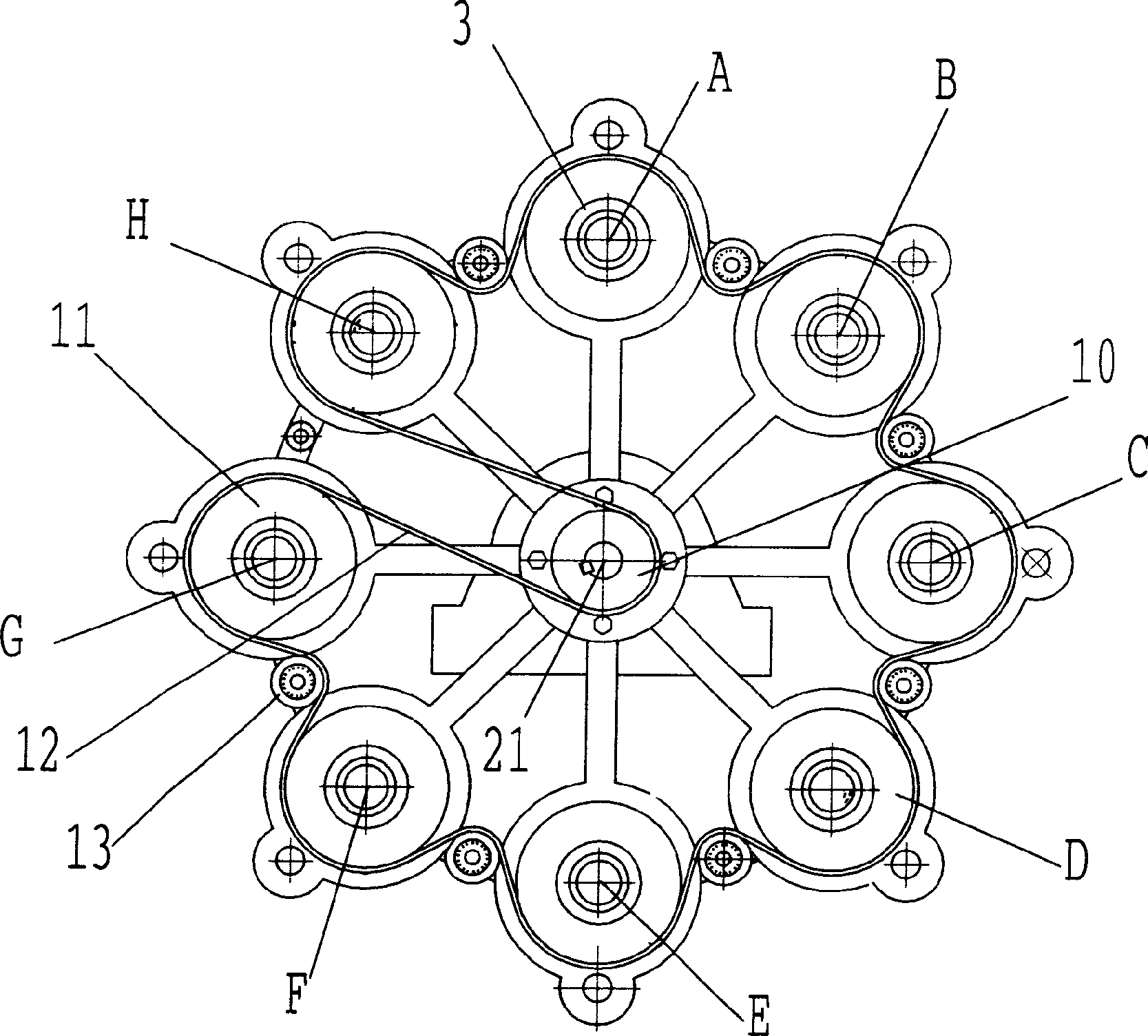

[0046] Refer to accompanying drawing 1,2,3,4,5. In the multi-station circulation device, the turntable 1 is used to place the chuck 3 and accommodate the components of the autorotation mechanism, and the sheave mechanism is used to complete the intermittent cycle movement. The docking disc 2-1 of the double discs in the sheave mechanism is used for coaxial and spaced docking with the turntable 1, and the intermittent mechanism composed of the sheave discs 2-2 and the dial 2-3 is used to complete the intermittent cyclic motion of the docking body. Figure 5 When the middle dial 2-3 rotates clockwise, the dial shaft 2-4 on it enters the radial groove 2-5 on the grooved wheel, and the grooved wheel and the conjoined docking plate and the pull-connected turntable are synchronized Rotate, when the dial shaft 2-4 breaks away from the radial groove, the outer convex arc 2-5 on the dial is screwed into the inner concave arc 2-6 on the grooved wheel, and the grooved wheel is in an inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com