Method for regaining moisture of cabo and production lines

A production line and tobacco stem technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of insufficient moisture uniformity and quality uniformity, affecting the uniformity of moisture regain of tobacco stems, and differences in moisture content of tobacco stems, etc., achieving good results , easy to implement, and short resurgence cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described below in conjunction with the accompanying drawings.

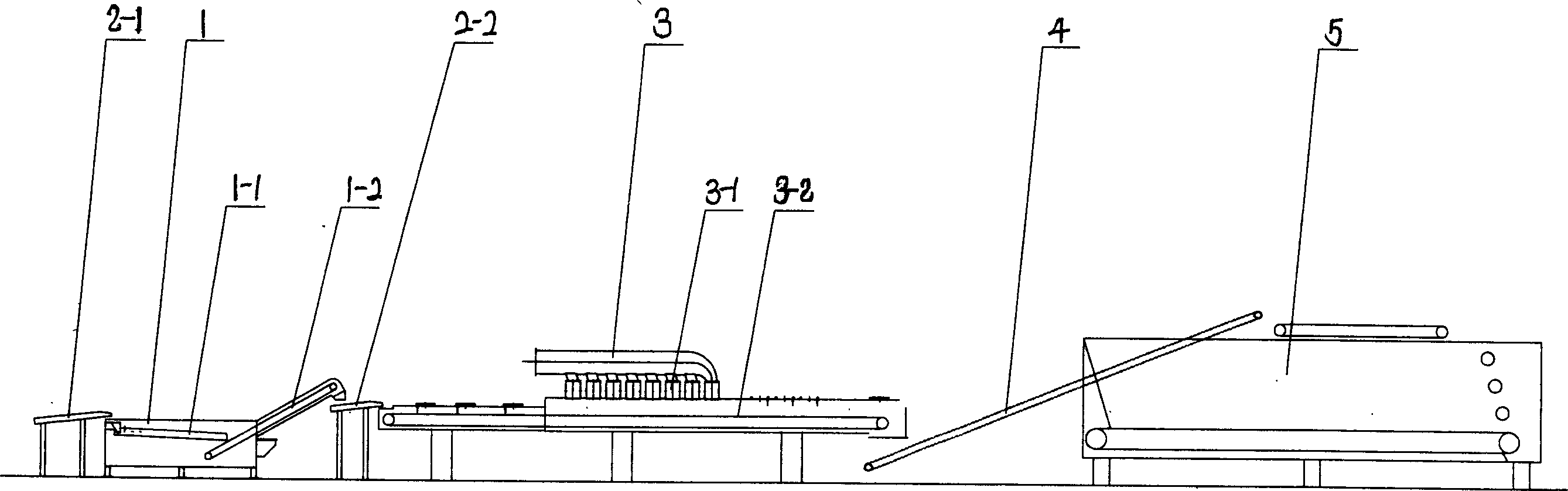

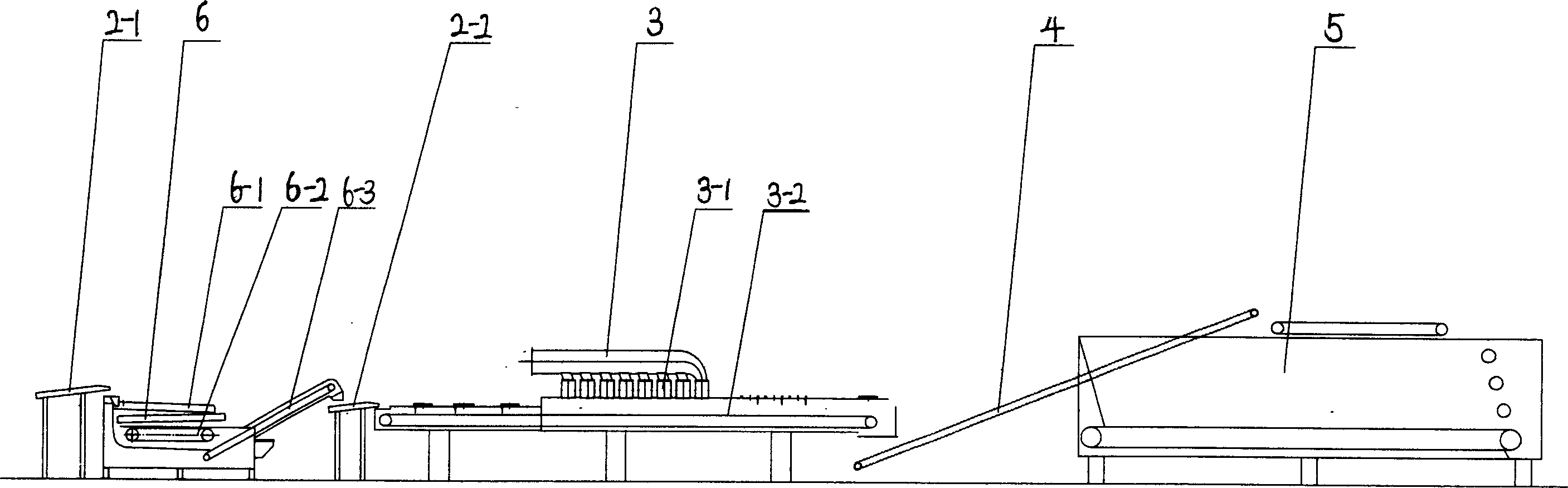

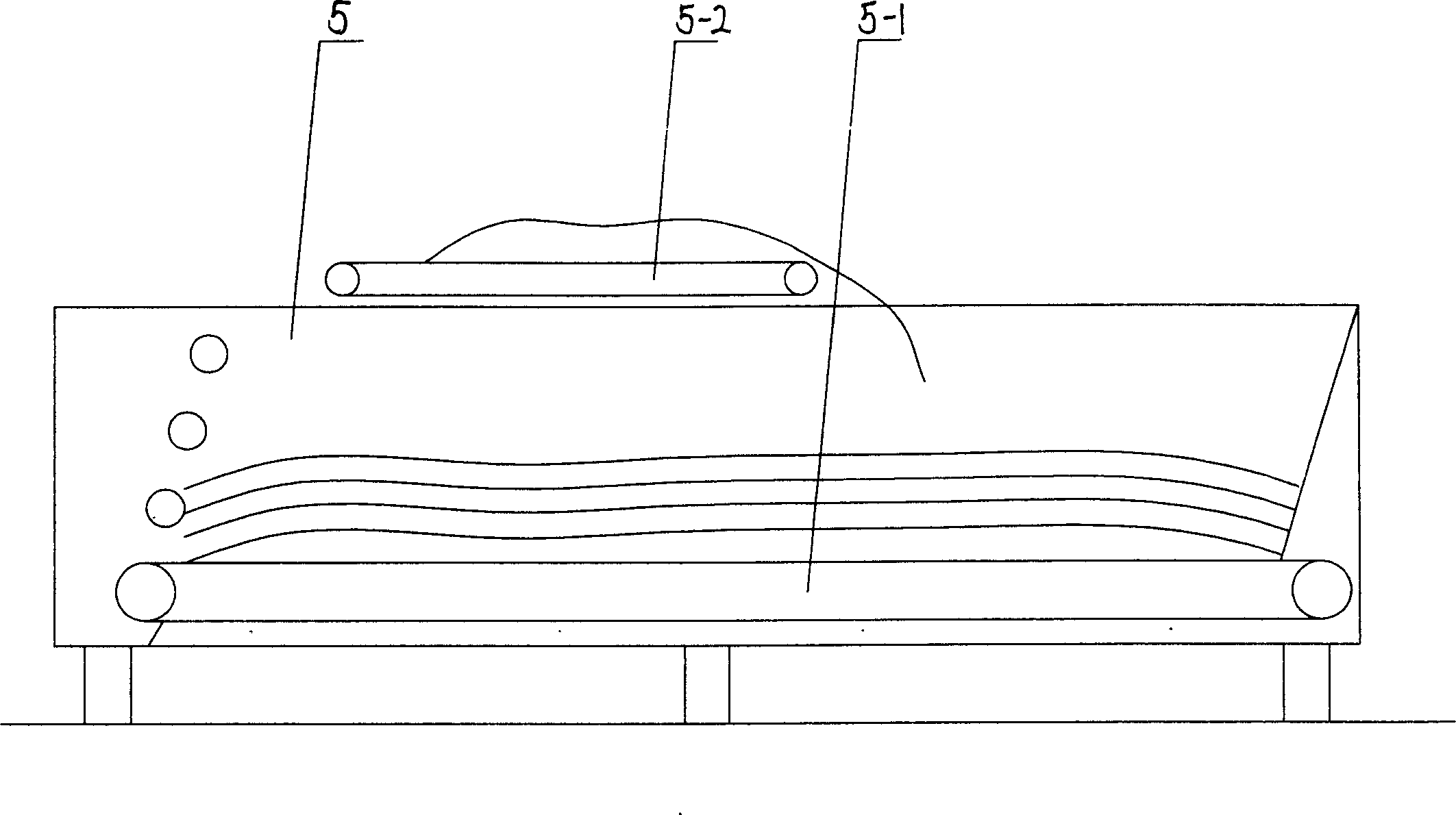

[0018] Such as figure 1 As shown, the production line is mainly composed of vibrating conveying equipment 2-1, stem washing equipment 1, vibrating conveying equipment 2-2, conveyor belt 3-2, microwave heating equipment 3, belt conveying equipment 4, and stem storage cabinet 5 arranged in sequence. Composition, the technological process is: washing the stems—→draining water—→microwave heating—→storing the stems.

[0019] The tobacco stems enter the production line after the unpacking and feeding process is completed, and then form a uniform and stable flow, and are sent to the stem washing or steeping equipment 1 by the vibrating conveying equipment 2-1. In the stem washing equipment 1, the tobacco stems are driven by the water flow, and the washing process is completed in the washing tank 1-1, and the tobacco stems are separated from the water flow by the lifting mesh belt 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com