Bag for packing liquid, and producing method

A manufacturing method and packaging technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of easy damage, corner point damage, etc., and achieve simple manufacturing process, increase the mood of life, and be easy to place upside down or sideways Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

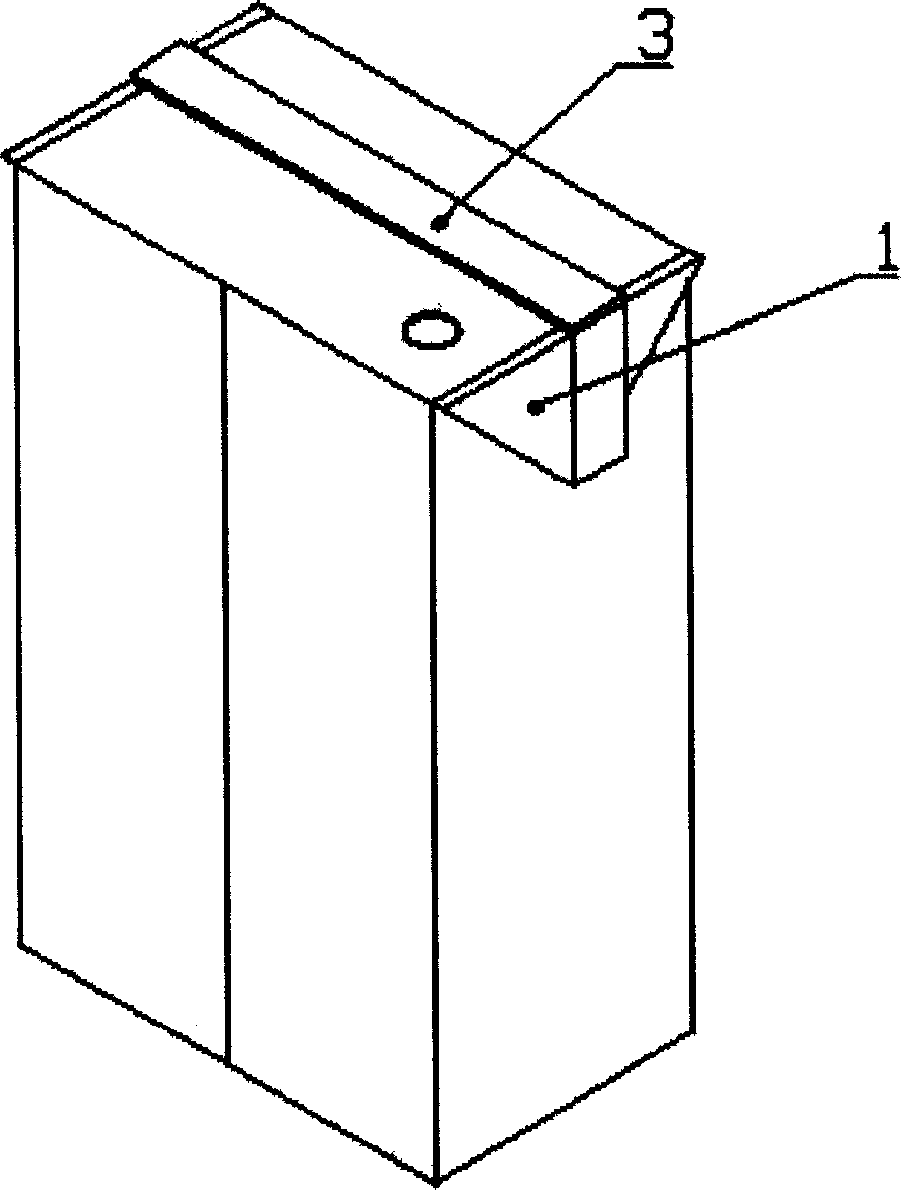

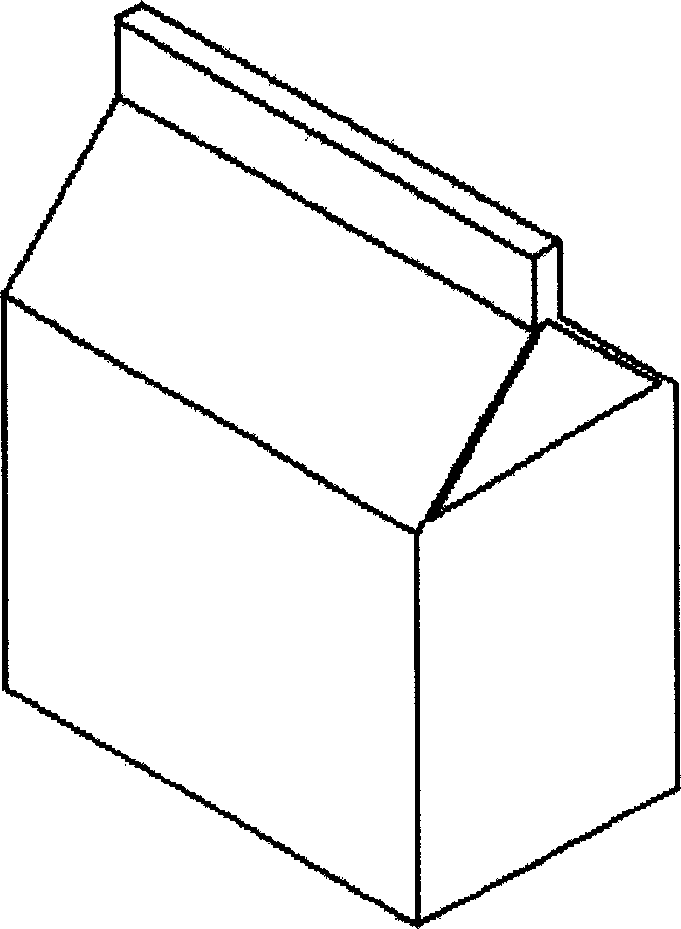

[0031] Such as Figure 6 As shown, before the brick pack forming operation, its structure is similar to a pillow pack, which is formed by the packaging material through tubular forming, vertical sealing, pouring and horizontal sealing, and unit slitting. At this time, the horizontal sealing edge 3*(3) stands up, and the folding wing 1*(1) expands freely into a triangular bag shape. The difference between this structure and the pillow pack is that the capacity holder (or plywood) of the equipment for producing brick packs is trough-shaped, and the sides 6 and 6* of the unit pack after slitting are relatively straight, and the four corners of the four corner wings 1*( 1) It has a triangular package shape. The capacity holder (or splint) of the equipment for manufacturing pillow packs is flat, and the sidewalls of the pack are not squeezed, so the pack has no flat sides.

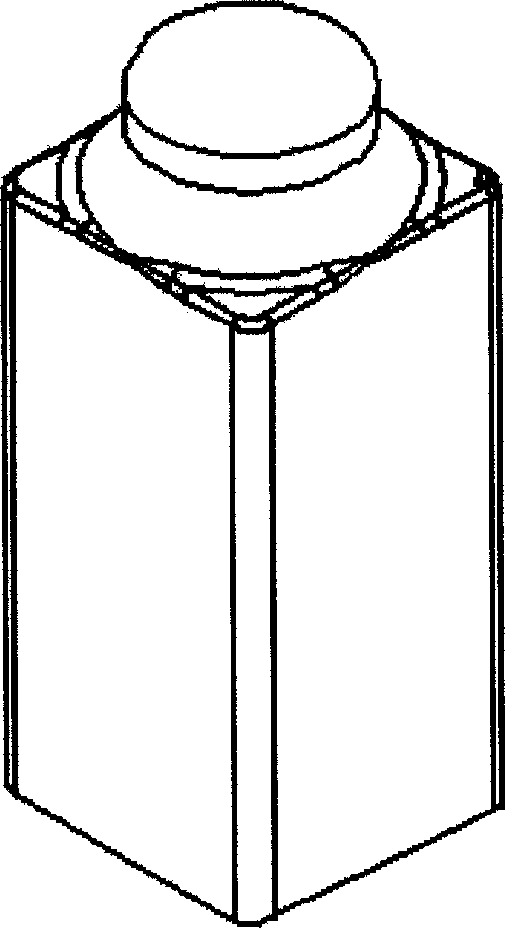

[0032] Figure 7 It is the complete brick package product of the present invention. The angled wings 1 and 1* a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com