Working oil cooler

A technology of working oil and cooler, which is applied in the direction of fluid pressure actuators, soil movers/excavators, fluid pressure actuator system components, etc., which can solve the problems of high manufacturing cost and design restrictions, and achieve the increase of manufacturing cost , Avoid damage, prevent pulsation and abnormal high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings.

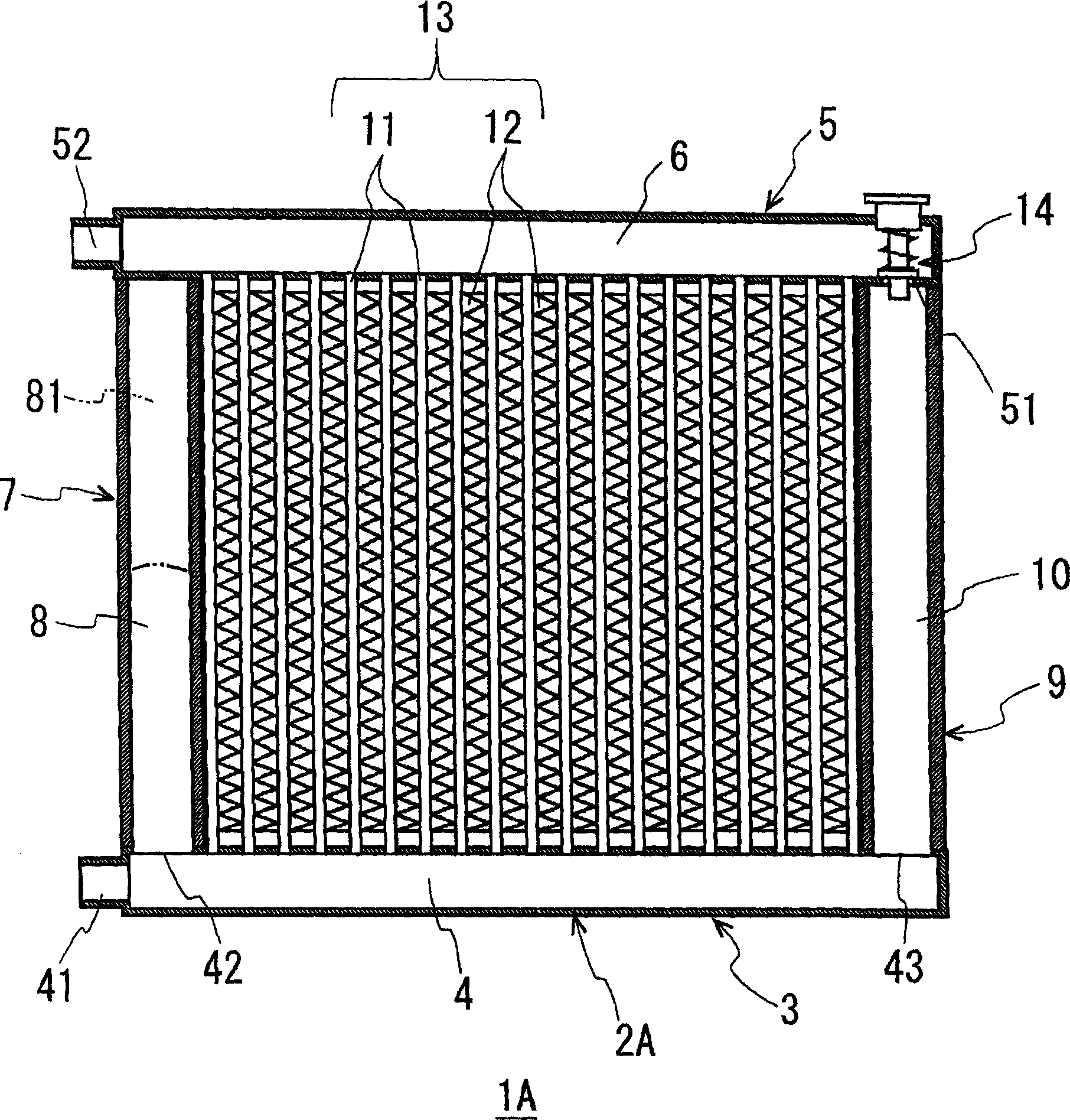

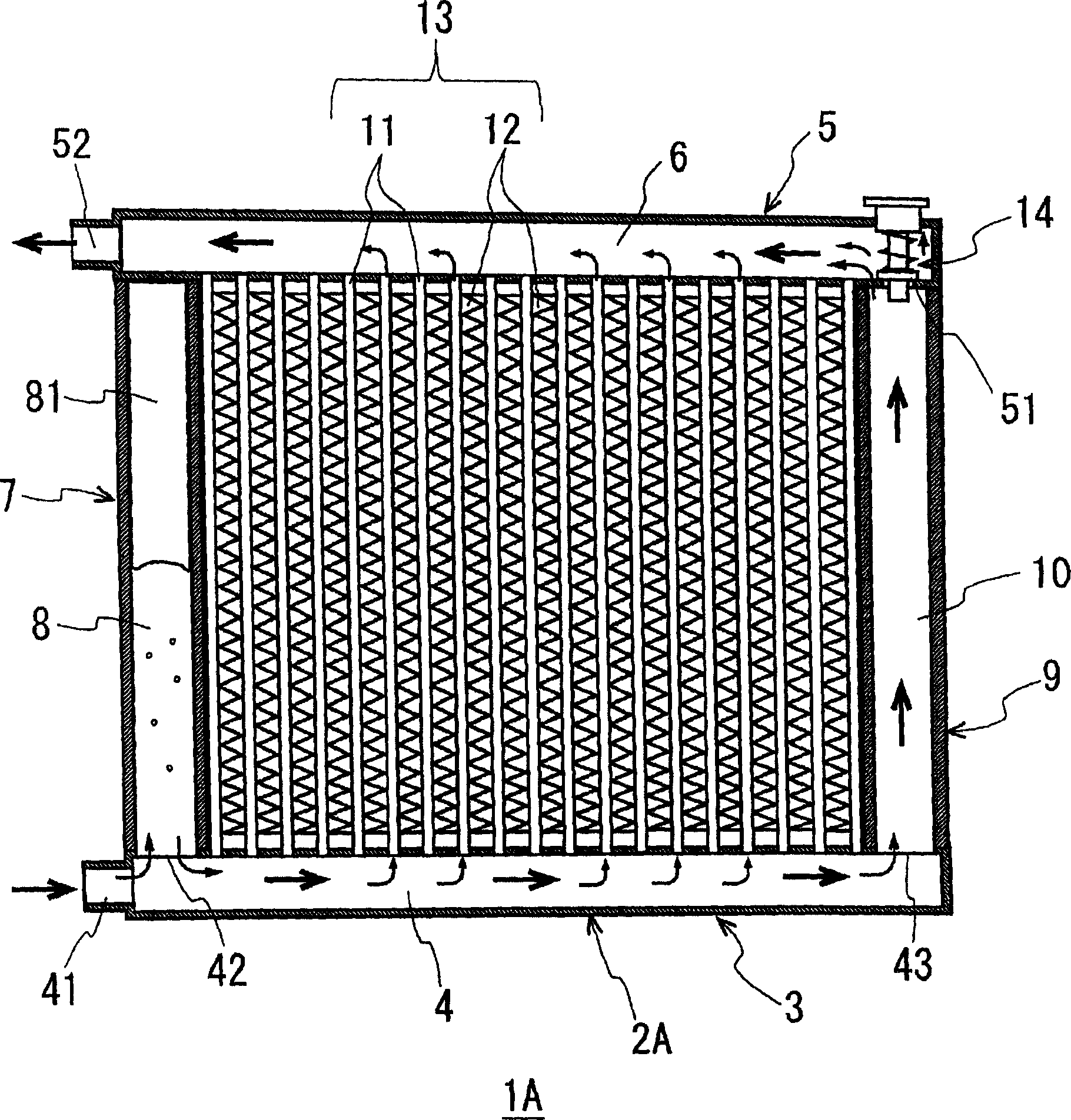

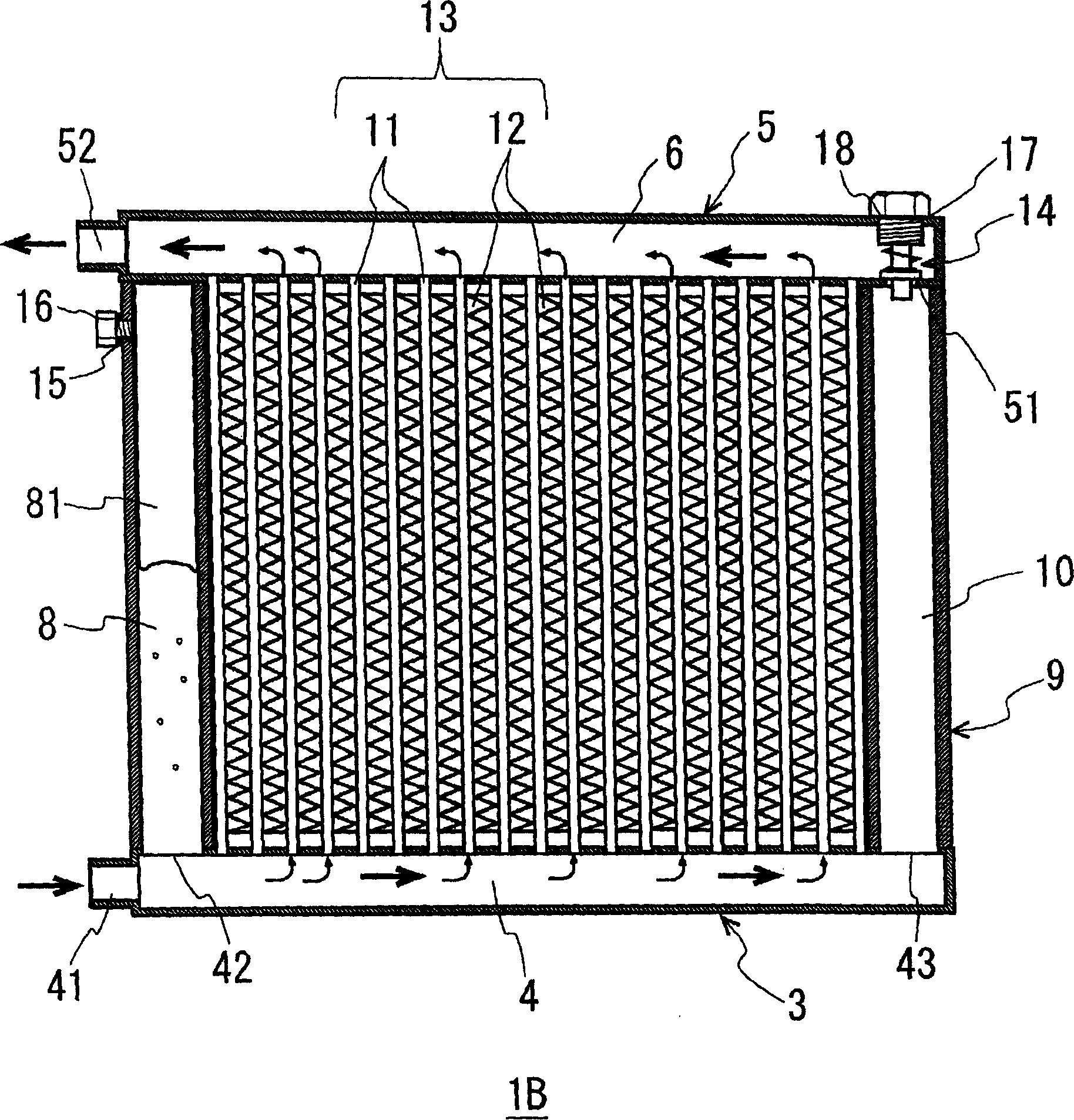

[0027] figure 1 It is an example of an embodiment of the present invention, and is a longitudinal sectional view seen from the front side of hydraulic oil cooler 1A. The hydraulic oil cooler 1A is formed as a solid frame body 2A made of roughly square cast aluminum or the like as a whole, and a horizontally long rectangular inlet chamber 4 and a horizontally long outlet chamber 6 arranged in parallel therewith are respectively arranged in the opposing horizontal frame 3, 5, between these inlet chambers 4 and outlet chambers 6 is connected a heat radiation section 11 that is formed by arranging a plurality of pipes in parallel, and a heat exchange section 13 is arranged between the heat dissipation sections 11, and the heat exchange section 13 is equipped with The heat dissipation member 12 formed by bending a thin metal plate can also be provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com