Floating type laser incision system

A laser cutting, floating technology, applied in laser welding equipment, welding/cutting auxiliary equipment, clamping and other directions, can solve the problem of continuous positioning and cutting, etc., to overcome the influence of electronic control devices, reasonable transmission structure design, Fast and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

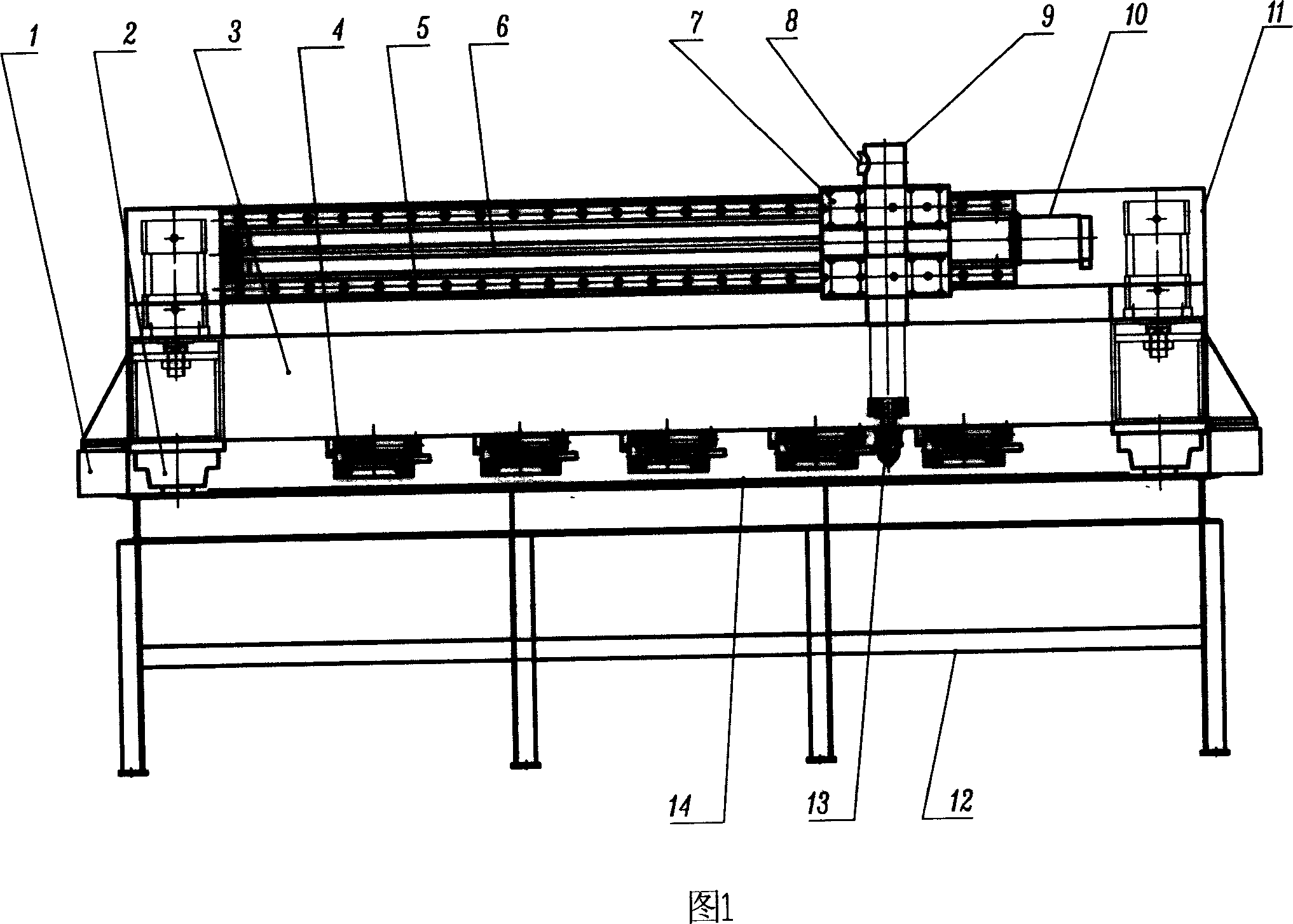

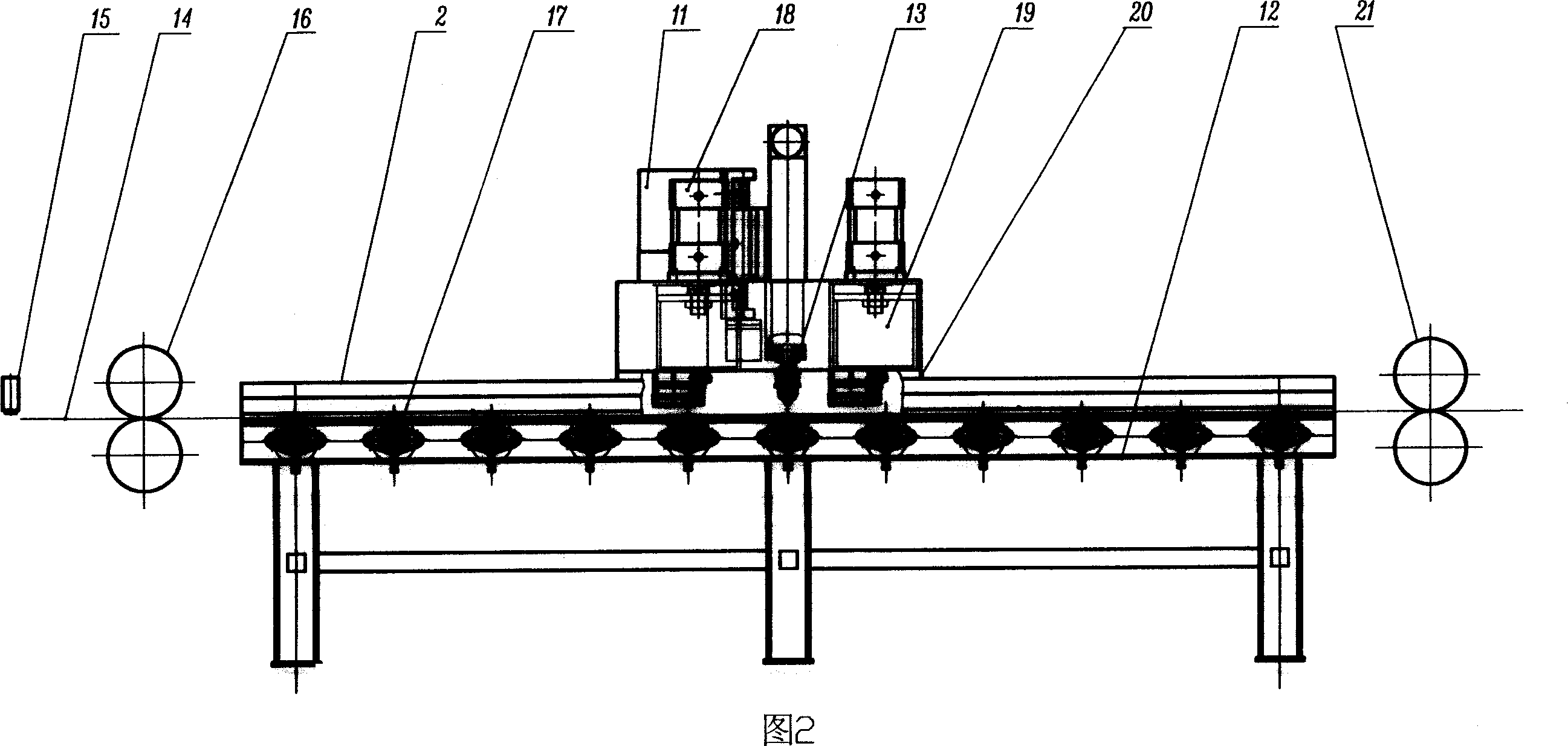

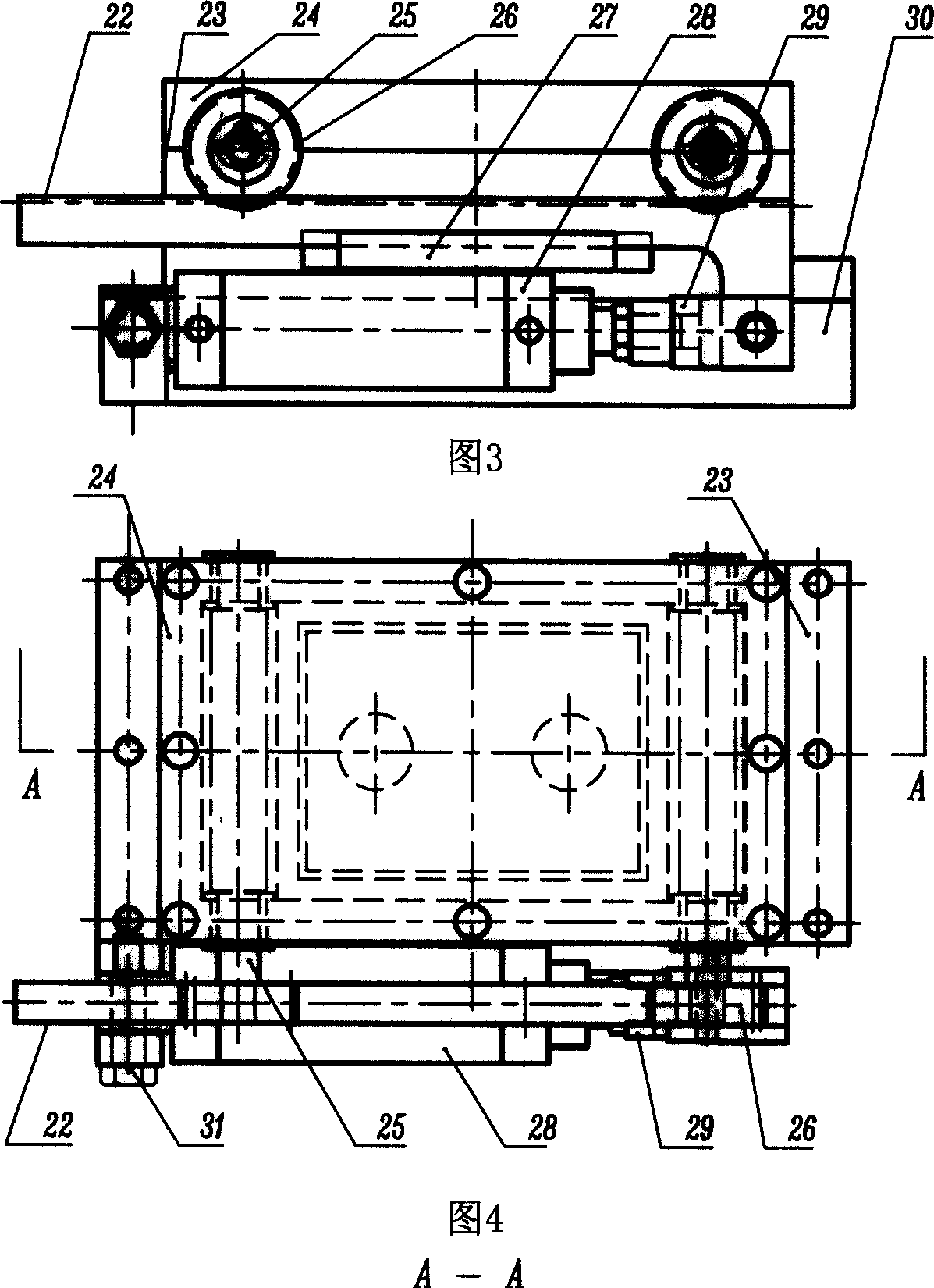

[0018] The specific structure of the present invention will be described in detail according to Figs. 1-5. The device includes a main frame 12 with a plurality of supporting rollers 17 and two longitudinal guide rails 2, a truss and a laser head 13 assembled on the transverse guide rail 5 of the truss, a permanent magnet positioning clamp 4 and the like. Wherein the truss includes an assembled lower beam 3, a support frame 11 and a vertical guide frame at its bottom, a connecting slider 20 that can move along the longitudinal guide rail 2, a vertical guide column 19 fixed on the connecting slider 20, and an air pressure circuit. , optical system and electrical control system, etc. The specification, shape, and size of the main frame 12 and the truss should be determined according to the specification, cutting shape, and size of the steel plate to be cut (that is, the cold-rolled coil after tailor welding) 14 . Rodless cylinders 1 are fixed on both sides of the main frame 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com