Forcipated mutual-inductor, forcipated ammeter and verification method of forcipated ammeter

A technology of clamp transformers and clamp ammeters, which is applied in the direction of measuring current/voltage, instruments, and measuring electrical variables, etc., and can solve problems such as power outages, loss of factories, institutions, and casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

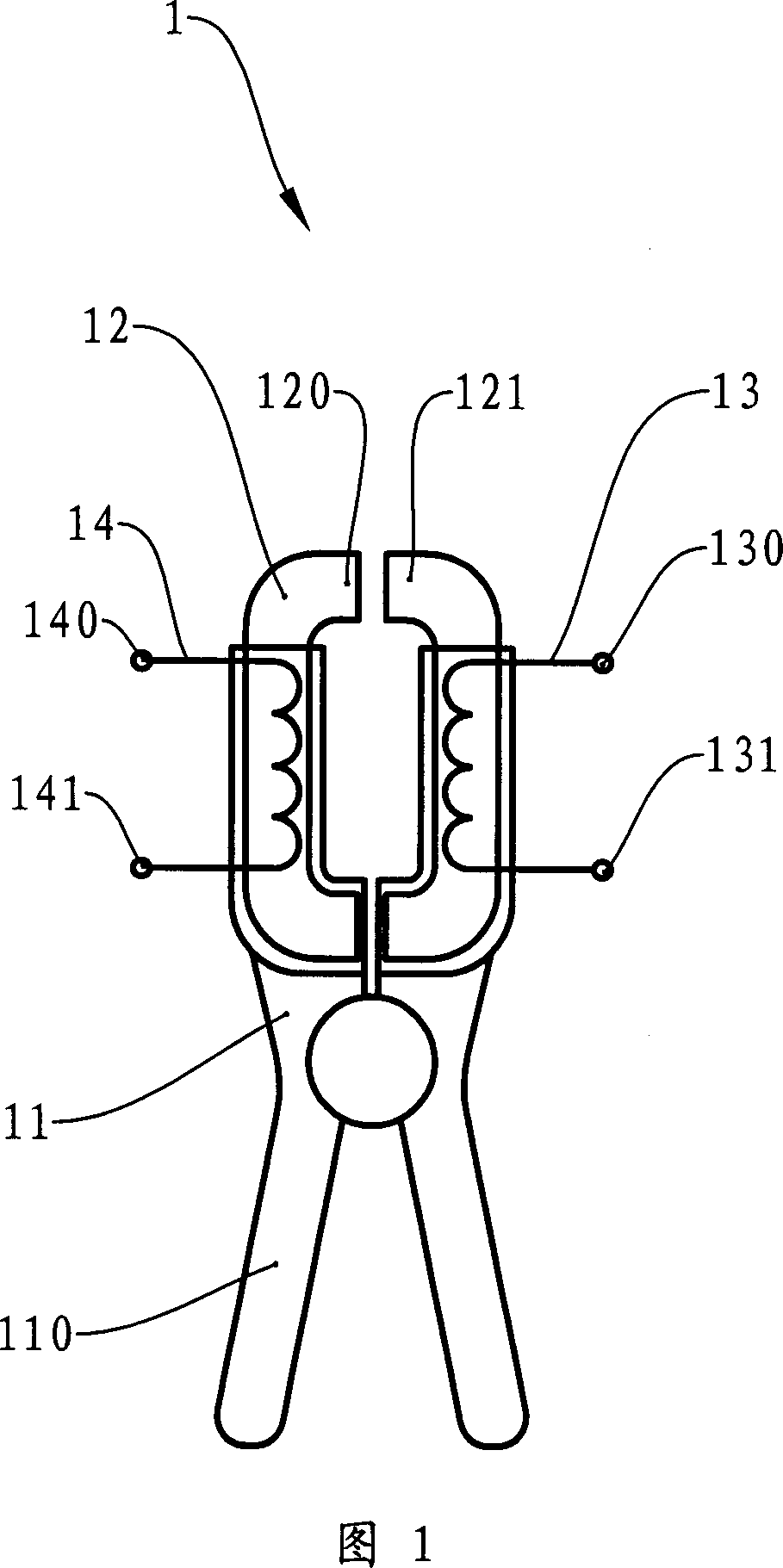

[0018] Referring to FIG. 1 , the clamp transformer 1 of the present invention includes a housing 11 , an iron core 12 housed in the housing 11 , a detection coil 13 and a correction coil 14 arranged on the iron core 12 .

[0019] The casing 11 has an "X" shaped handle 110 , and the iron core 12 is divided into a left half 120 and a right half 121 , and operating the handle 110 can separate or close the left half 120 and the right half 121 . When the left half body 120 and the right half body 121 are closed, a complete magnetic circuit is formed in the iron core 12 .

[0020] The detection coil 13 has two connections 130 , 131 and the correction coil 14 has two connections 140 , 141 .

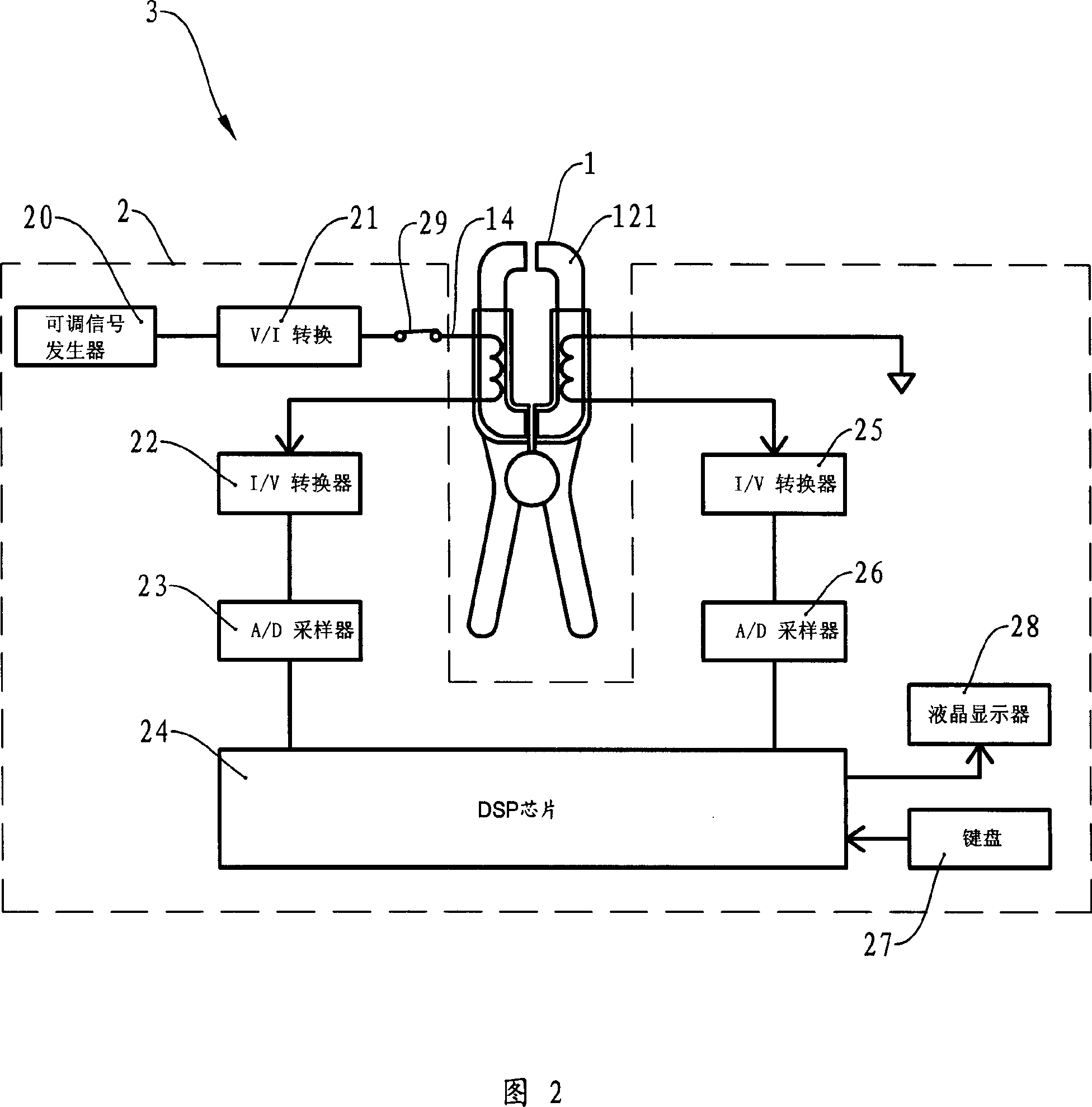

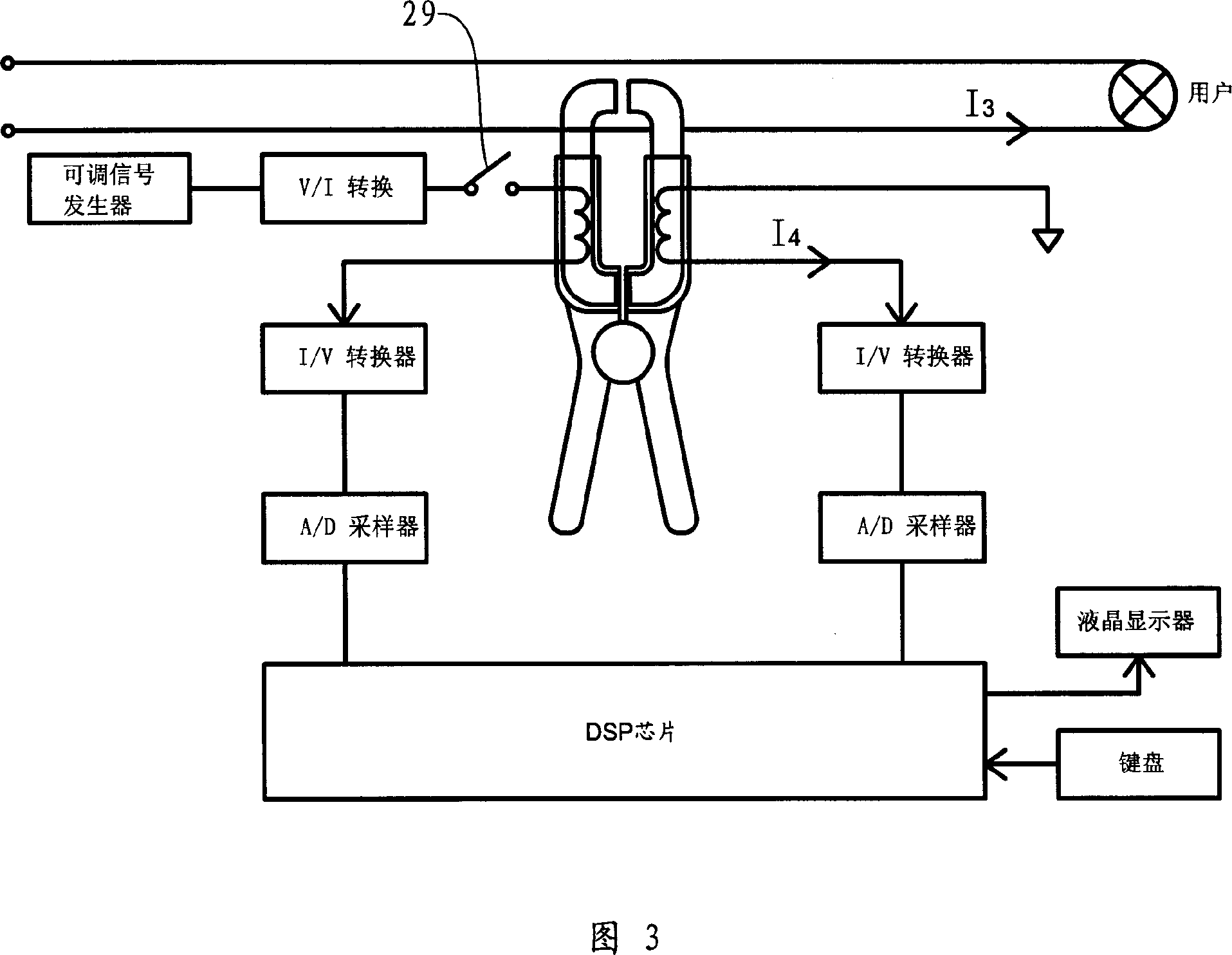

[0021] FIG. 2 is a schematic structural diagram of the clamp ammeter 3 according to the present invention. The clamp ammeter 3 is composed of a clamp transformer 1 and an auxiliary circuit 2 . All circuits within the dotted line box in FIG. 2 can be regarded as auxiliary circuits 2 . The role...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com