Stripping solution composition for removing transparent conductive film and photoresist

A technology of transparent conductive film and photoresist, applied in the preparation of detergent composition, non-surface active detergent composition, detergent mixture composition, etc., can solve the problem of inability to remove photoresist, metal Effects and other issues, to achieve good removal effect, excellent removal effect

Active Publication Date: 2007-02-28

DONGJIN SEMICHEM CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, etchant has a fatal effect on metals and cannot remove photoresist, so it is not suitable to be used as a stripper with the above functions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~23 and comparative example 1~5

[0065] According to the composition and content shown in Table 1 below, each component was mixed to prepare a photoresist stripper composition (unit: parts by weight).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

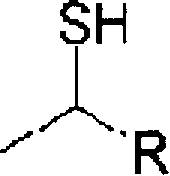

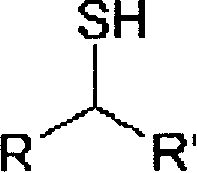

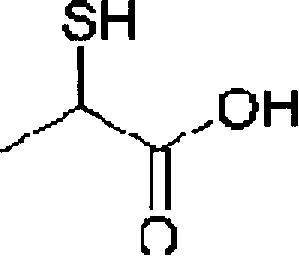

The present invention relates to a stripping solution composition for removing photoresist and transparent conductive film. More concretely, the present invention provides an organic acid transparent conductive film remover capable of removing the transparent conductive film of the semiconductor device and a stripping solution composition containing the remover, wherein the stripping solution composition comprises more than two components and is composed of organic amine and solvent. The composition may further comprise the glycol ether compound serving as segregation resistance agent. The composition of the present invention comprises organic acid transparent conductive film remover, so that transparent conductive film can be removed. And, the transparent conductive film remover comprises sulphur and can be used as antiseptics to prevent the metal wiring of the lower metal film from being corrupted, thus, under the condition of keeping the metal pattern made by the current LCD manufacturing procedure, the present invention is capable of removing the photoresist of the formed pattern and selectively or totally removing the clear electrode of the photoresist coated on the metal wiring and the clear electrode of the metal wiring.

Description

technical field [0001] The present invention relates to a stripping liquid composition used for stripping the photoresist used in the formation of metal wiring, especially a stripping liquid composition containing two or more components of organic amine and solvent, containing It is a transparent conductive film remover used to prevent metal wiring and remove part or all of the transparent conductive film deposited on metal wiring or photoresist (photoresist), and may further include a diol-based protic solvent for anti-segregation A stripper composition for removing transparent conductive films and resists. Background technique [0002] In manufacturing processes of semiconductor devices such as integrated circuits (ICs) and very large-scale integrations (VLSIs), and liquid crystal displays (LCDs), metal wiring is usually formed by applying a photolithography process. Furthermore, representative transparent conductive films ITO and IZO are deposited on the substrate, and g...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03F7/42

CPCG03F7/425G03F7/426G03F7/422C11D3/2068C11D3/3472C11D7/265C11D2111/22

Inventor 金柄郁尹锡壹金玮溶许舜范

Owner DONGJIN SEMICHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com