Ink removing agent for toughened glass and preparation method thereof

A technology of tempered glass and deinking agent, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems affecting the health of printed matter users, solvent odor, physical injury, etc., to achieve strong lasting power, not easy to decompose , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

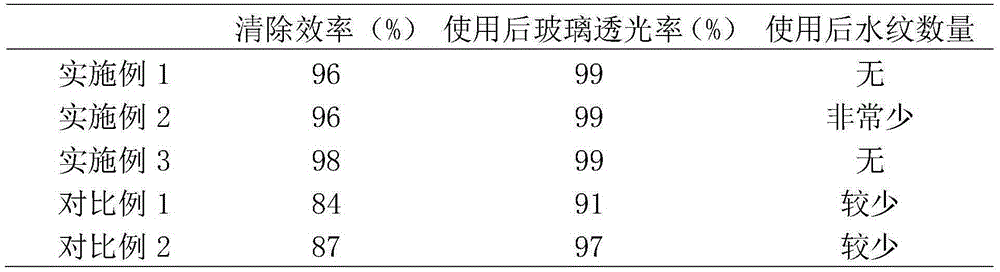

Examples

Embodiment 1

[0022] A preparation method of tempered glass deinking agent, comprising the steps of:

[0023] 1) Raw materials: Prepare the raw materials in the following weight percentages: fatty alcohol polyoxyethylene ether sodium sulfate 5, fatty alcohol polyoxyethylene (9) ether 10, fatty acid alkanolamide 10, vinyl acetate 3, absolute ethanol 35, ortho Dibutyl phthalate 1.5, polyacrylamide 1, essence 2, activator 1, the balance is deionized water;

[0024] 2) Mixing: Add fatty alcohol polyoxyethylene ether sodium sulfate, fatty alcohol polyoxyethylene (9) ether, fatty acid alkanolamide, and vinyl acetate into deionized water, heat to 35°C, stir for 10 minutes, and rotate at 3000r / min, then add dibutyl phthalate, polyacrylamide, essence, and activator, heat to 35°C, stir for 10min, rotate at 3000r / min, add absolute ethanol, stir, and stand for 20min to obtain the finished product;

[0025] The activator described in step 1) is obtained by the following steps:

[0026] ①High-speed di...

Embodiment 2

[0030] A preparation method of tempered glass deinking agent, comprising the steps of:

[0031] 1) Raw materials: Prepare the following raw materials in weight percentage: fatty alcohol polyoxyethylene ether sodium sulfate 8, fatty alcohol polyoxyethylene (9) ether 8, fatty acid alkanolamide 12, vinyl acetate 2, absolute ethanol 45, ortho Dibutyl phthalate 0.5, polyacrylamide 3, essence 1, activator 2, the balance is deionized water;

[0032] 2) Mixing: Add fatty alcohol polyoxyethylene ether sodium sulfate, fatty alcohol polyoxyethylene (9) ether, fatty acid alkanolamide, and vinyl acetate into deionized water, heat to 45°C, stir for 5 minutes, and rotate at 2500r / min, then add dibutyl phthalate, polyacrylamide, essence, and activator, heat to 45°C, stir for 5min, rotate at 2500r / min, add absolute ethanol, stir, and stand for 10min to obtain the finished product;

[0033] The activator described in step 1) is obtained by the following steps:

[0034] ①High-speed dispersion...

Embodiment 3

[0038] 1) Raw materials: prepare the following raw materials in weight percentage: fatty alcohol polyoxyethylene ether sodium sulfate 6, fatty alcohol polyoxyethylene (9) ether 8, fatty acid alkanolamide 10, vinyl acetate 3, absolute ethanol 40, ortho Dibutyl phthalate 1, polyacrylamide 2, essence 1.5, activator 1.5, the balance is deionized water;

[0039] 2) Mixing: Add fatty alcohol polyoxyethylene ether sodium sulfate, fatty alcohol polyoxyethylene (9) ether, fatty acid alkanolamide, and vinyl acetate into deionized water, heat to 40°C, stir for 8 minutes, and rotate at 2000r / min, then add dibutyl phthalate, polyacrylamide, essence, and activator, heat to 40°C, stir for 8 minutes, rotate at 2000r / min, add absolute ethanol, stir, and stand for 15 minutes to obtain the finished product;

[0040] The activator described in step 1) is obtained by the following steps:

[0041] ①High-speed dispersion and emulsification treatment: Break the honeysuckle, add the same weight of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com