Lithium ion battery pole piece, electricity core and method for making same

A technology of lithium-ion battery and manufacturing method, which is applied in the field of lithium-ion battery pole piece, battery cell and its production, can solve the problems of increasing battery difficulty, affecting battery capacity, time-consuming and labor-intensive, etc., and achieves the improvement of fast and high-current charging and discharging. ability, reduce connection difficulty, and shorten the effect of collecting path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0034] The implementation of a lithium-ion battery pole piece and battery cell of the present invention will be described below by taking the positive pole piece and battery cell of a 26650 cylindrical lithium-ion battery as an example.

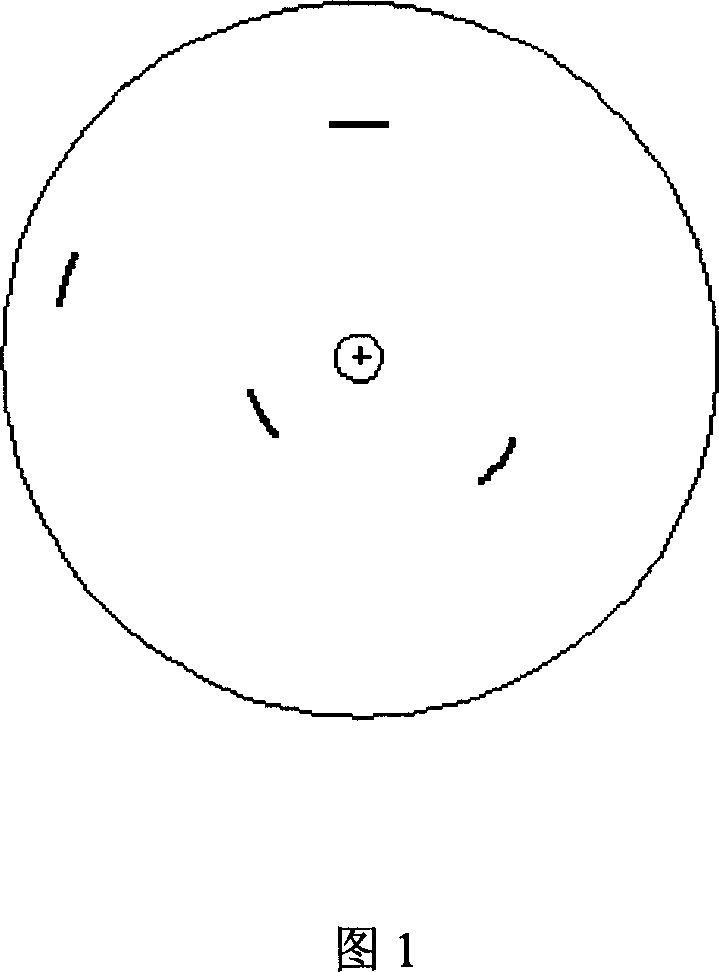

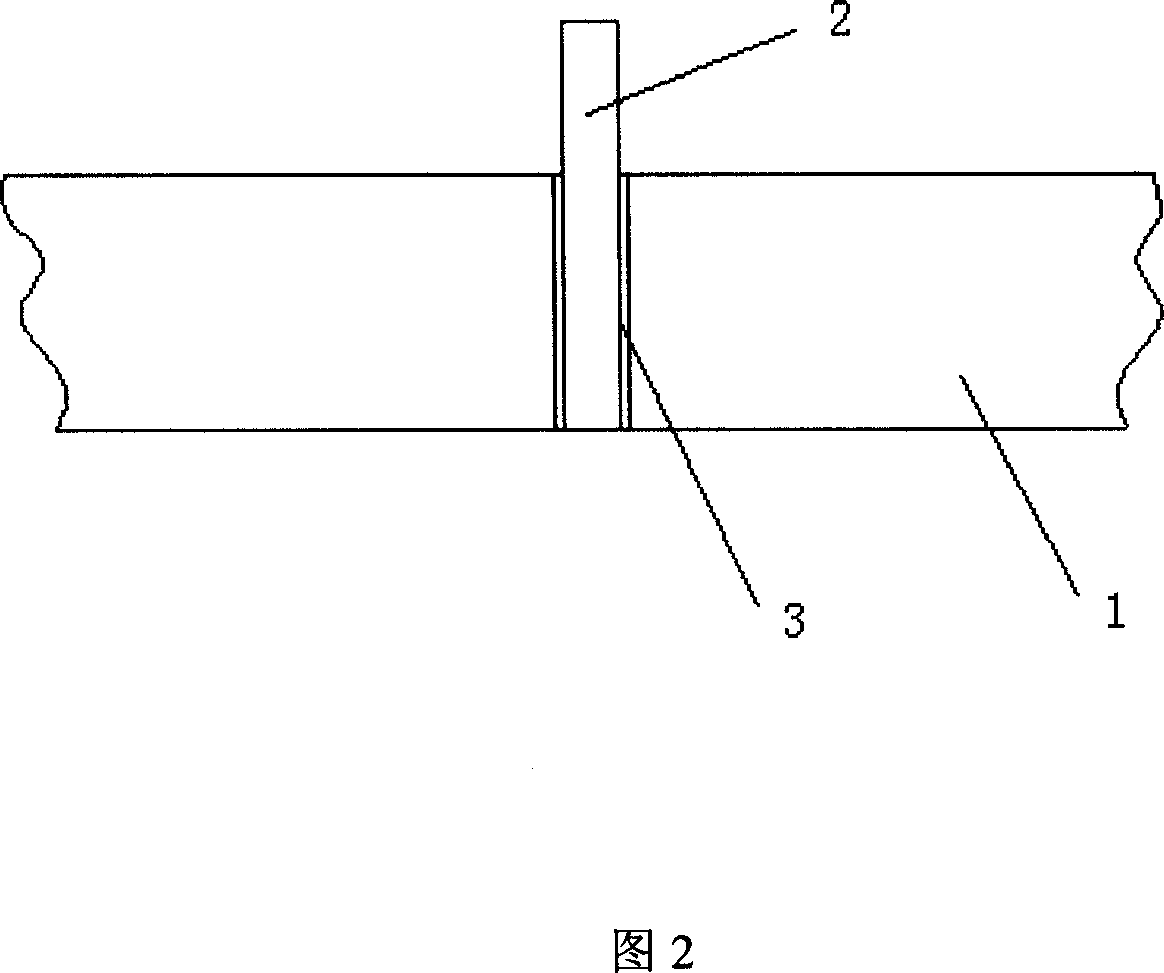

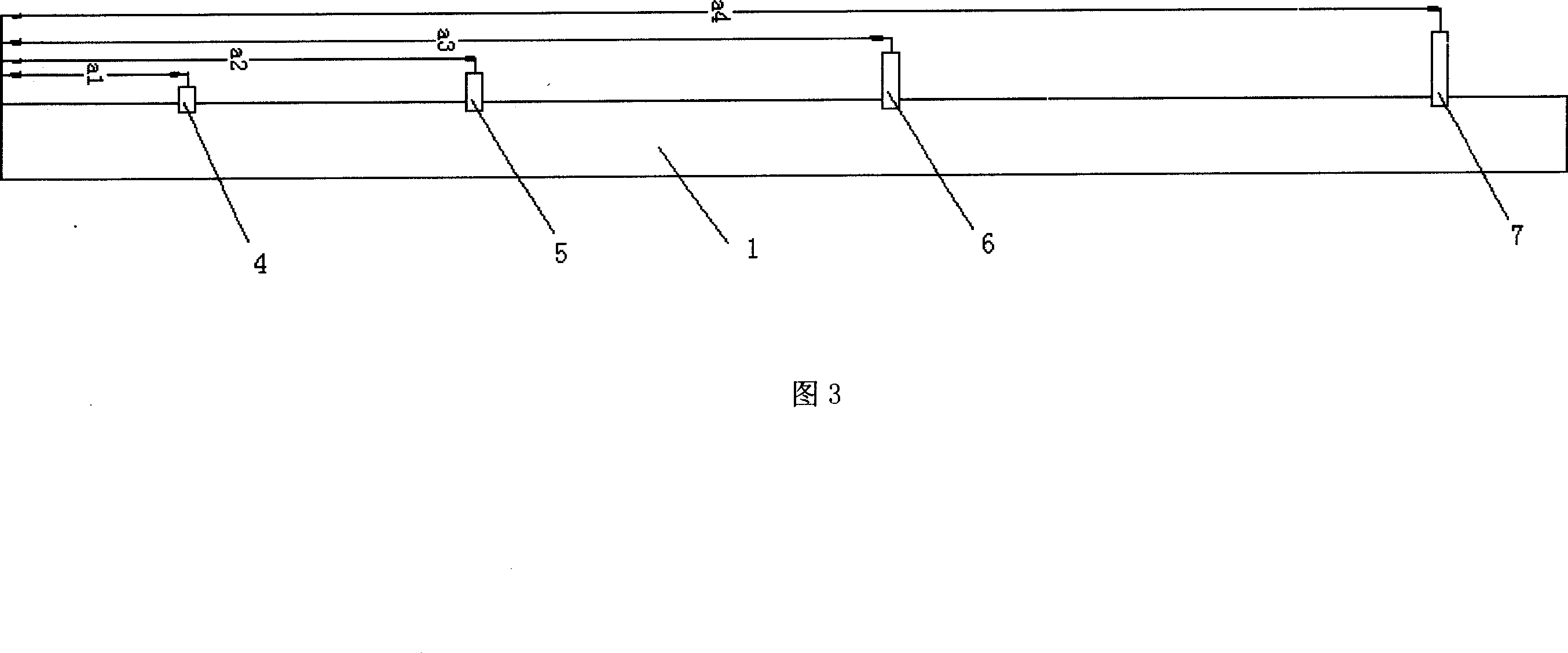

[0035] As shown in FIG. 3 , a positive pole piece 1 of a 26650 cylindrical lithium-ion battery has a total length of 1565 mm. First, all the active material is coated on the pole piece 1; then, the distance from the front end is 172.05mm, a2 is 555.00mm, a3 is 935.95mm, and a4 is 1336.50mm. Remove the active material at these four positions, thereby forming four lug connection regions. The widths of these four lug connection areas are all less than half of the width of the pole piece, as shown in Figure 3 and Figure 5, where 8 is the lug connection area on the pole piece at a distance of 172...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com