New pattern plastic warmhouse booth

A greenhouse and plastic greenhouse technology, which is applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve the problems of unusable films, increased labor, and high erection costs, and achieve economical and practical erection costs, enhanced safety performance, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

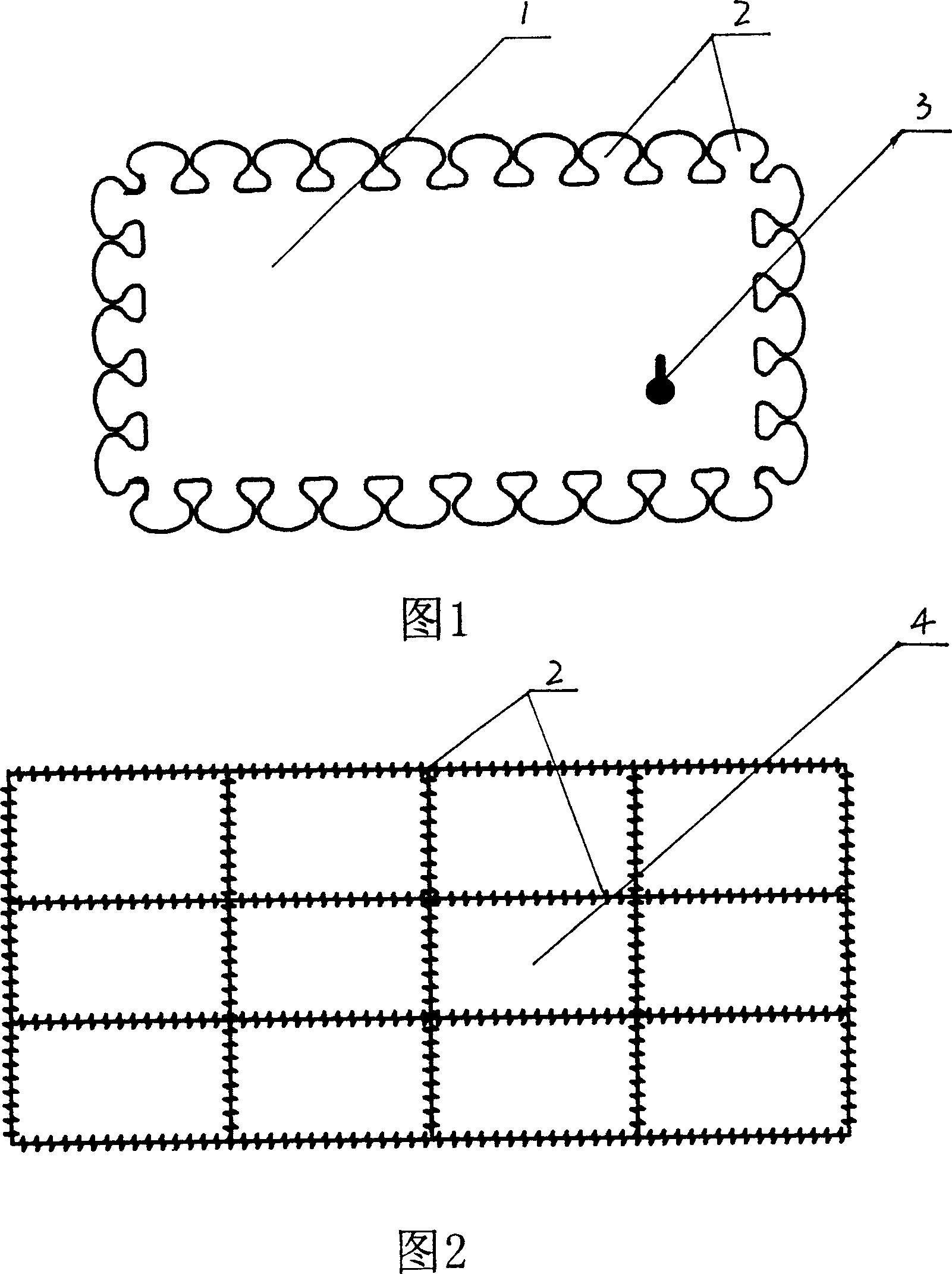

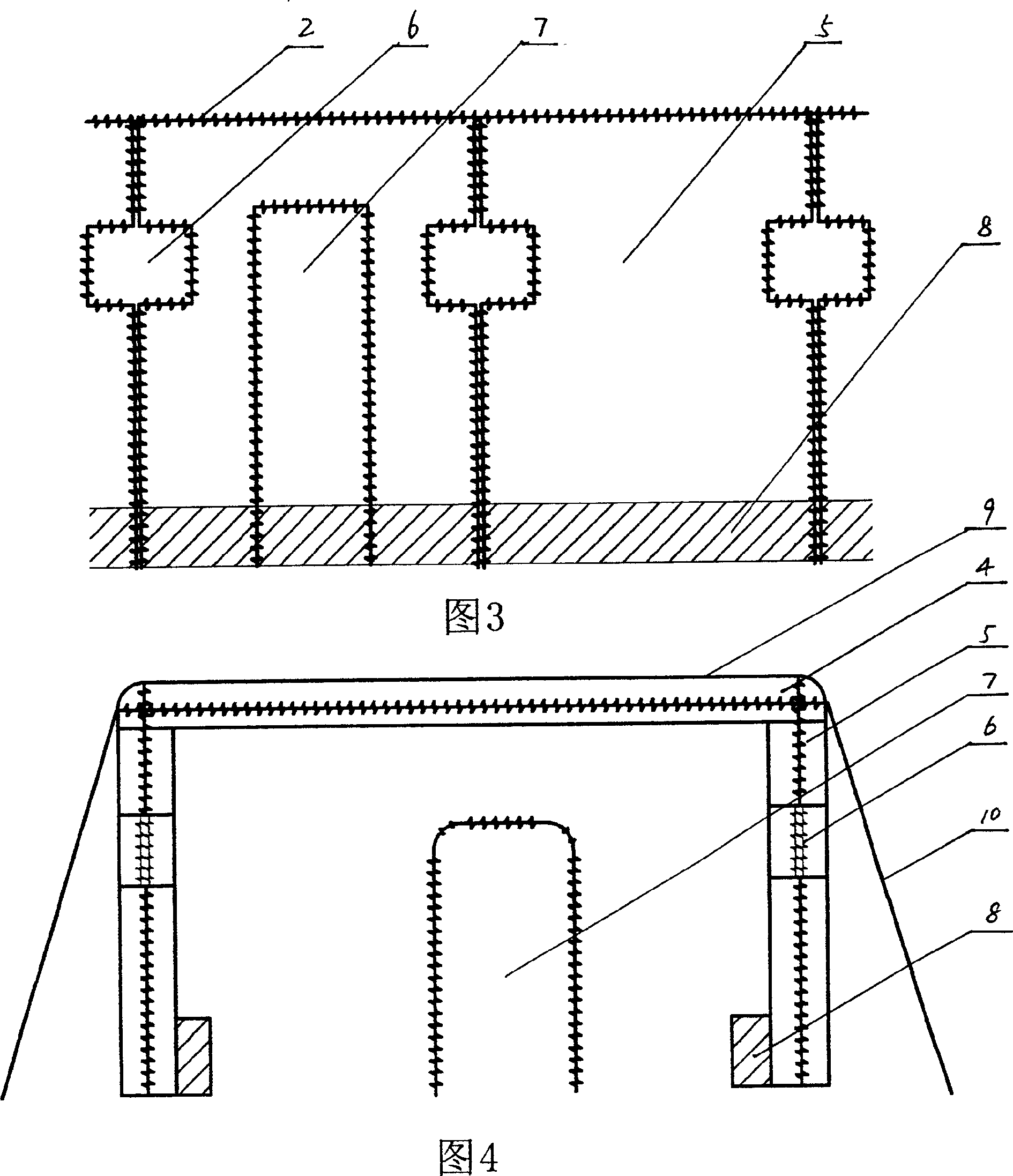

[0026]Under the production technology conditions of the existing plastic film, first according to the different structures and performance characteristics of each part, process and manufacture the double-layer sealed airbag with an inflatable nozzle with corresponding size, structure, shape and strength performance. The edge of the airbag is a bulb-shaped button tooth. When in use, there is no need for any support, just fill the airbag with a certain amount of air and buoyancy gas, and then connect the airbags with a certain air pressure with bulb-shaped buttons to intersect each other, and assemble according to the size of the required greenhouse. For the corresponding size of the ceiling, use the same method to assemble the side wall, ventilation window and door curtain, then connect the ceiling and the side wall to assemble, finally erect the side wall, pour sand and water into the tank inside the side wall Just fix it. In addition, according to the weather conditions, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com